|

https://ift.tt/0kbJtZM

1 Million Part Order Signals Bright Future for Low-Cost 3D Printing Services https://ift.tt/82KwQPJ Utah 3D printing service Merit3D has received an order for 1 million components from Adhesives Technology. The parts are being made—some 40,000 a week—on Photocentric printers using BASF Ultracur EPD 1006. Remarkably, the item is a rather quotidian one—not a space part nor an implant. No, this is a hanger that connects an epoxy tube to its nozzle. Adhesives Technology had some supply chain issues and, with a lead time of two weeks, Merit3D designed a 3D printed a solution for them. The 3D printing is being performed on a Photocentric Magna system and was later improved so that it could be used on many more epoxy tubes. Rather than go overseas, Adhesives Technology ordered a production run of 30,000 3D printed units. At 100,000 parts, the component was redesigned to be more cost-efficient. At 500,000, a further improvement was implemented. The company then went on to make 40,000 a week. At one point, the company obtained a Utah Manufacturers Modernization Grant for robotics and automation to reduce costs even further.

There are a lot of bridge manufacturing examples out there that we don’t often hear about. On cars and the like, some bridge parts have been printed which are in and of themselves cheap, but are attached to something expensive. GM’s example with Multi Jet Fusion is a case in point. In other cases, a 3D printed component could be low cost, but issues with its supply chain could block millions in revenue. Generally, first production runs may be performed with additive, but a company would tend to switch to molding later on. In the case of this project from Merit3D, this is a remarkably low-value part, that is also not attached to a super expensive element, but is instead attached to a relatively low cost item.So this component could push the thinking of people in additive towards new more consumable parts. The unit is also very flat, while the additive manufacturing (AM) industry usually likes its parts more three dimensional and complex. Therefore, such an extensive run is also remarkable and a million parts total is amazing. There must have been a unique confluence of events to make this make sense for everyone. All of this pays into Merit3D’s larger goal of reshoring jobs and production to its native Utah, where it is situated in the heart of coal country. Merit3D, or something very much like it, is the future. We will still have service bureaus for high-value parts and prototypes, but a new series of companies will emerge that will be able to make low-cost parts at high volume. We’ve written about this in 2021 and again more recently. Alongside Merti3D is Slant3D, which is using desktop 3D printers for manufacturing, which you can hear more about from CEO Gabe Bentz in the 3DPOD episode below.

While Gantri is using desktop machines to make lamps and other home decor, which you can learn more about from founder Ian Yang in the 3DPOD episode here:

These firms will be followed by many more, but there is more scope for completion. Using Formlabs machines, it would be possible to print custom hearing aids in a small store close to customers. With cheaper Phrozen machines, one could make molds for jewelry or other components. And machines such as those from Photocentric can clearly perform much bigger production runs still. It’s no surprise then that Formlabs has released automation tools for its machines or that Mosaic, in Canada, has developed a print farm solution. However, I really think we need more automation and QA tools, as well as software, to further assist these firm in making low-cost production with 3D printing a reality. I can’t wait to see more cases like this emerge! The post 1 Million Part Order Signals Bright Future for Low-Cost 3D Printing Services appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 23, 2023 at 08:40AM

0 Comments

https://ift.tt/XKroSh0

US and Australia Form Clean Energy Pact as WTO Head Calls for “Reglobalized” Supply Chains https://ift.tt/vm4z5YQ Amidst the G7 summit in Hiroshima last weekend, CNBC interviewed the Director-General of the World Trade Organization (WTO), Ngozi Okonjo-Iweala, concerning her general outlook on the current state of international trade. Okonjo-Iweala acknowledged the significance of supply chain resilience to CNBC’s Martin Soong, and, notably, called for the world to “reglobalize”: At the same time, the Nigerian economist also argued that “the multilateral trading system has been largely resilient during all these crises.” Okonjo-Iweala — the first woman and first African to lead the WTO — pointed out that as disruptive as the crises of the last couple of years have been to the global economy, all the fixes that have emerged have also been the product of that same economy’s core system of multilateral trade agreements. Thus, although the WTO and G7 are separate organizations, it does seem like they generally see eye-to-eye on this particular issue. Rather than a winding down of globalization, we are, in fact, in the earliest phases of globalization 2.0:

As if to drive home precisely those points, the US and Australia announced on Saturday that the two nations had signed a bilateral cooperation agreement to make climate change and clean energy “a central pillar” of their alliance. The compact entails a broad framework of shared long-term goals and plans for binational economic cooperation. Perhaps most lucratively for everyone involved, this includes plans to “coordinate policies and investments to support the expansion and diversification of responsible clean energy and critical minerals supply chains” and “accelerate the development of markets for established and emerging technologies.” This is more or less identical to the clean energy portion of an overall much more broad-sweeping agreement between the US and Canada announced in March, 2023. We are now seeing the emergence of the world’s newest economic bloc, and, rather unsurprisingly, it is being built around the Five Eyes nations. Along those same lines, uncertainty in the future of the trade relationship between the US and China is still the most critical fact in the global economy, and that becomes truer the more directly related a given topic is to the semiconductor industry. As such, in a business context, 3D printing will continue to be among the industries most affected by uncertainty surrounding US-China trade.

Developments such as these help alleviate some of that uncertainty, if only because more is now known about what the stakes are. “De-risking,” as opposed to decoupling, does seem to be a good term to sum up all the changes that the US and China are currently making to their respective economies. While these topics may be anxiety-inducing, then, it does at least seem like world leaders are not acting completely irrationally. It is unlikely that we are going to wake up one morning to find out that all trade between the US and China has been banned. What is likely, on the other hand, is that all of the 160+ nations in the WTO are increasingly going to move in the direction of redesigning their economies around the idea of “what if we had to make this here.” This has more to do with the need to decarbonize the economy than it does with animosity between the US and China. In that case, it can only be a good thing for companies in all the advanced manufacturing industries — so long as they, too, remember to diversify their supply chains. The post US and Australia Form Clean Energy Pact as WTO Head Calls for “Reglobalized” Supply Chains appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 23, 2023 at 08:40AM

https://ift.tt/bMYXiGz

UltiMaker CEO Weighs in on the Release of the Method XL 3D Printer https://ift.tt/CGEfk82 Today, UltiMaker announced the release of the Method XL 3D printer. The XL features a 100°C heated chamber and heated build plate optimized for ABS and carbon fiber (CF) -ABS. With a build volume of 305 mm x 305 mm x 320 mm, the new system positioned as an entry level printer for industrial components. We’ve seen dental specific machines, but this is one specifically meant to make big ABS and ABS-CF parts. To learn ore about the Method XL and UltiMaker´s recent progress, we interviewed UltiMaker CEO Nadav Goshen. The Method XL 3D PrinterThe team has taken care to reduce warpage and increase dimensional accuracy of components, while also featuring both an activated carbon and HEPA filter. You can use UltiMaker´s RapidRinse tap water soluble ABS support if you wish, or use your own materials by relying on the LABS Experimental Extruder. Some previously tested materials on the LABS extruder are Jabil SEBS, a 95A shore elastomeric filament, Polymaker PolyMax PC and LEHVOSS PAHT 9891, a high-temp CF-PA material. The XL works with CloudPrint and is intended to be a very application-specific printer. Goshen opined that the recently released UltiMaker S7 is a versatile professional 3D printer, especially if the user wants to experiment. He thinks of it as the machine used in the design department and for prototypes. Meanwhile, the XL is for more specialized departments and companies, as the machine is designed for engineering- and production-focused applications. According to Nadav, this is due to the popularity of ABS and how close the XL can get to injection molding properties, making the machine appeal to this specific subset of users. ABS is the focus of the XL given its prevalence, strength and durability. One big advantage of the Method XL has to do with UltiMaker’s considerable IP related to the isolated build chamber, the heated build chamber, and other IP acquired from Stratasys, Ultimaker, and Makerbot. The XL´s accuracy and part dimensional accuracy is key to obtaining the performance it has.

The Progress of UltiMakerIt was in May 2022 that Ultimaker and MakerBot shocked the world by announcing a merger of the two competitors. Since then, the resulting company has had a subtle change of brand and released a new Ultimaker-style machine, the UltiMaker S7 mentioned above. Goshen was able to speak to the progress the firm has made since the merger took place.

As well as the workflow specific-products Nadav sees many improvements coming to Cura, with his company on the path to developing very robust solutions for more relevant products in a growing market. The application specific-strategy seems to be a good idea. Companies are now slow to adopt additive and balk at the strange materials and new equipment. Application-specific, well-dialed-in solutions could be key in letting firms adopt 3D printing more quickly. UltiMaker is strong in software; it has an extensive materials library and materials knowledge compared to competitors. Application-specific, workflow-based strategies play to the firm’s established and recognized strengths. If the company can then effectively market directly, with its channel and by itself, then the tactic could be a winning one. The risk is that, if not sufficiently differentiated, these application-specific offerings will confuse new clients and make the brand more diffuse. UltiMaker will also have to thin out product development efforts, focusing them on various workflows rather than the core product. Tactical sense could, therefore, lead to an overall weaker offering in due time. Think of the beautiful differentiation done by Nokia before its fall. That firm had a phone for every single group of people and use, but the market didn’t understand this, leading to a confusing brand and shopping experience. Along came a man with a pair of New Balance shoes and a turtleneck pointing to one phone to rule them all and Nokia was wiped out. UltiMaker still has a strong installed base and a lead on those gunning for it. They have time to execute well on this strategy, make mistakes, and still pull out ahead, but the firm will have to keep innovating in its flagship printers to keep its lead. The post UltiMaker CEO Weighs in on the Release of the Method XL 3D Printer appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 23, 2023 at 08:40AM Postmaster General Louis DeJoy Extols Significant Organizational Progress In 2023 National Postal Forum Keynote Address https://ift.tt/GgQ7pSZ CHARLOTTE, NC — Today, Postmaster General and CEO Louis DeJoy welcomed 3,500 attendees to the 2023 National Postal Forum in Charlotte. In his keynote address to the annual convention of the mailing and shipping industry, DeJoy extoled the progress the Postal Service is making under its 10-year Delivering for America plan and how the agency’s immediate priorities will better position the Postal Service and its customers for success in the future. Printing via USPS News https://ift.tt/mwcRQAW May 22, 2023 at 06:02PM

https://ift.tt/Vvs6tW1

BMW Plant 3D Prints Massive Engine Cylinder Sand Cores Automatically https://ift.tt/2r4il8U Thanks to a partnership with Loramendi and voxeljet, BMW’s Landshut plant now has the ability to automatically 3D print large-scale sand cores for casting cylinder heads for high-efficiency engines. The new process is both a significant milestone for voxeljet as it expands its work with the world’s largest automakers and for BMW, which is increasingly automating its additive manufacturing (AM) operations. In May 2022, BMW announced the completion of the Industrialization and Digitalization of Additive Manufacturing (IDAM) project, which enabled the automated printing, finishing, and conveyancing of parts made with metal laser powder bed fusion (LPBF). This latest Industrialization of Core Printing (ICP) project applies a similar approach to sand core 3D printing, used for casting cylinders for the BMW B48 engine.

3D printed sand cores made using voxeljet technology. AM was the fabrication method of choice for the automaker, due to the ability to optimize cylinder head design, improve engine efficiency, and reduce consumption. However, 3D printing sand cores requires various labor-intensive steps, including raw material preparation and recycling before printing and drying, removal and cleaning of the printed parts after the job is complete. To streamline the process, the partners developed an automated production line, featuring voxeljet’s VX1300-X printer and Loramendi’s Microwave-Curing.

A rendering of BMW’s sand core production line. Loramendi and voxeljet began developing the ICP setup in 2019, along with ASK Chemicals, which developed a binder that would limit post-processing of sand cores. The line consists of robotic arms that automatically remove 3D printed sand cores from the voxeljet machine and transfer them to curing units, which is then moved to Loramendi’s microwave-curing machines for finishing. With the new setup, the BMW Landshut plant is able to produce thousands of 3D printed cores per week. While this represents another step in automation for BMW’s production of metal parts with 3D printing, it also builds on voxeljet’s continued success in the automotive space. The German company’s U.S. customer, Tooling & Equipment International, is 3D printing sand cores for the series production of large-format, weight-saving structural components for Cadillac’s CELESTIQ vehicle, a limited series luxury car estimated to cost $300,000. The post BMW Plant 3D Prints Massive Engine Cylinder Sand Cores Automatically appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/cGtnDEB May 22, 2023 at 09:12AM

https://ift.tt/9cJMWTB

Killer 3D Printing Applications: Variable Density Cushioning https://ift.tt/OaTE36D One of the biggest opportunities for 3D printing applications out there is variable density cushioning. This is a widely misunderstood area that could unlock multi-billion revenues for additive manufacturing (AM). One of the reasons for this is that, apart from an excellent effort at Ultimaker years ago, there is currently no meaningful cross-industry application development going on in material extrusion. Another reason is that there is so much shoe disinformation in the world that the true value is lost. Both these issues are clouding the significant opportunity that is variable density cushioning. Application Development SuccessWhile the options for material extrusion in variable cushioning is being forgotten, HP, Carbon, and EOS are doing an excellent job of gathering up cross-disciplinary skills and experiences to develop new applications with their partners. Working with materials companies and manufacturers as far afield as climbing shoes, outdoor outfitters, bike seats and basketball makers, these original equipment manufacturers (OEMs) are developing end-use applications that are centered around their technologies. These three firms have realized that, in order to really move the needle for additive, they have to marshal a portion of the value chain to collectively develop breakthrough applications that give their technology 1., true volume replete with 2., margins and 3., marketing impact. That holy trinity could get these firms new streams of significant revenue tied to their platforms, as well as marketing, and knock on business development success. If they turn one sporting goods firm, the whole industry could pivot to additive for some components. If the 3D printing revolution isn’t as popular as first imagined, we should man the barricades. Or, perhaps in this metaphor, it would be more apt to consider the trio as being the only ones constructively working on tearing down the barricades to additive via breakthrough applications. Cushioning ExplainedOne key area where 3D printing can play a difference is in cushioning for a wide variety of items, including the following:

If we see cushioning surfaces as a single application, then it could eventually be one of the most high-volume and profitable 3D printing applications worldwide. There is a potential balance there between volume and margin protection, with firms becoming much like Gore. The $4.5 billion textile business is known for Goretex, which is expensive, highly functional, and the gold standard of breathable weather protection. It will be a hard slog getting there, but the potential for 3D printing will be much larger than that. There are two particular areas where AM can outperform other processes: surfaces and cushioning. We will look at grip, wicking, and optimal performance of 3D printed surfaces in another post. Here we will only look at cushioning. Shoe InterferenceGenerally, the 3D printing shoe opportunity is looked down upon, due to the huge gulf between cost levels of manufacturing shoes and those of additive footwear and insoles. I wholly agree. Most of the 3D printed shoe stuff going on is marketing fluff. It’s a great example of using a 3D print to anchor a cost-effective marketing campaign. However, I do believe that there are some real opportunities in shoes within the current economic paradigm as it relates to slippers, institutional shoes, specialized footwear and as a differentiator for certain low-volume, low-fashion-risk models. Eventually, when material costs are reduced significantly and truly automated 3D printing production is established, it will be possible to reduce costs in line with shoe manufacturers’ expectations. Conversely, someone could disrupt the existing shoe market by reducing their fashion risk and having better niche designs that are more timely, in line with the havoc that Zara´s Inditex has wrought on the fashion market. Now, these are all Hail Mary types of developments that could occur if the stars align. But, the gulf between the wishful thinking in footwear is confusing the future potential of the category. LatticesNow, under the partial clouds of shoe disinformation, we can see the emergence of a peculiar element: the lattice. Lattices are extremely useful if you want to save weight on a non structural component somewhere. And we’re going to be surrounded by lattices in AM for—like—ever. They are the most obvious way to obtain cushioning while saving on material cost and print time in vat photopolymerization and powder bed fusion. Their super cool, distinctly 3D printed look means that designers, C-level types, and marketeers love them. There are plenty of amazing things that lattices can do, but they are very problematic and overused in a lot of applications. The most positive thing I can say about lattices is that they’re the Prius of polymer additive in consumer applications so far. By now, you can see what is happening: the people tied to making lattices are making the lattices that marketeers love because their processes are in part tied to and identified with these structures. You will not believe just how lattice-centric the sketch of the future department is at the moment. It is difficult to predict the performance of a lattice under stress and repeated forces. After many and variable cycles of load, powder bed fusion and vat polymerization part performance degrades. Doubtlessly these issues will be ameliorated over time, but there is a better way. No One in the Cell´s CornerMaterial extrusion is a very cost effective 3D printing process, but since no one is really trying to develop the technology or performing any breakthrough application development in any significant way, no one is fighting for material extrusion in cushioning. Lattices abound, but cell shapes are ignored. There have been few totally breakthrough moments in additive for me, but one such moment was when I saw the post from Steve Wood (aka “Gyrobot”) on variable density insoles in 2014. To me then, the shoe case could make sense if the right conditions could be met. With variable density insoles the squishiness, rebound and softness of a sole could be change at many individual points through varying the infill. With material extrusion you can print TPU, silicone or PP and then vary the thickness and pattern of infill to conform to a particular walking style, therapeutic need, back issue or tread. Through this innovation you can 3D print a unique at every point insole that can conform to your walking style or mend it. You can then get an insole that is uniquely comfortable that cannot be made with conventional manufacturing techniques. Now, it will be a bit ugly, but you can use Dye Mansion or AMT technology to make it look better through vapor smoothing. You’d have to automate a 3D print farm of desktop machines to print these soles as well. It will, however, eventually be significantly less expensive than a 3D printed component made with other processes. Well in line with what could be profitable for high-end applications and insoles. You could ensure that soldiers experience less fatigue, that FedEx staff smile more easily towards the end of a long day, or that the employees at McDonalds perform their jobs more comfortably. In short, you could optimize walking performance in a way not shown yet. You could make it tougher at the part where your toe meets the sole, squishier in another area, and demonstrate less lateral motion in other parts, while being firmer towards the back, and having more cross motion in another part. In effect, you could make a completely unique sole to make the wearer more comfortable. If we look at all the firms that failed in shoe 3D printing none of them deployed this and many were tied to far too expensive components that did nothing for the user. Variable density insoles could change all that. But..wait it gets betterBut, we can do so much more. We can encapsulate air in each pocket. We can make the shape, amount and pressure of that air different. We can therefore go far beyond the performance and comfort advantages in air inside shoes seen so far. We can also customize air cushions just for you. We can also customize the infill pattern, the infill wall thickness, the infill fill, the geometry of the infill inside the infill pattern and we can do this at every millimeter. We can add different materials as infill and different for infill walls also. So we can create a unique material that goes far beyond what can be done with conventional manufacturing. And this could change the calculus of shoes and insoles. Now, we’d all have to get scanned and spend like a half an hour doing exercises on pads and cameras. That change in consumer behavior will be difficult. But, if you turn this into an event or desirable thing then it could move the needle for a certain segment in the shoe market. But, I think that selling to the police force, factories and other institutions would be much easier since you can sell them on lower fatigue and better performance. Other CushionsIt would probably be far easier to look to other examples outside of footwear however. Now in some cases lattices, if their long term performance can be guaranteed could be better than cells. Lattices could let air pass through which is why applications such as bike seats and backpack cushions could be a win for them over material extrusion. Famously in helmets, we can design structures that can absorb fast impacts and slow heavy ones optimally through 3D Printing. Some of this may also be a win to powder bed of vat photopolymerization’s ability make these structures well. But for others the wider material selection and lower cost will probably make them a win for material extrusion. If humans are not lying down, they’re walking or standing and if they’re not doing that they’re sitting. In all of these cases we can improve the contact of the human with the world or with one thing in particular. In aircraft seats or prosthetics, we can change industries by designing unique materials that could give optimal long term comfort. Mattresses, office seats, wheelchair seats and others could be mass customized. Or they could be radically redesigned and updated. In some cases radical form factor changes could impact industries by making another two rows of airline seats possible or by making cars roomier while keeping their volume. In other cases long term comfort will make the difference. Software tools could be used to radically redesign all the cushioning surfaces we can come in contact with. We can make much compact travel pillows that fold in on themselves and are more comfortable. We can make better industrial gloves, bike gloves and military gloves as well. We can make your sleep, walk to the office, car journey, sit down meeting better too. Wherever you are in long term or uncomfortable contact with the world we can make it better for you. And one of the best methods for that is to 3D print differing infill patterns, infill materials and structures, infill wall thicknesses at every point according to the optimal at that one point using Material Extrusion. The post Killer 3D Printing Applications: Variable Density Cushioning appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/cGtnDEB May 22, 2023 at 09:12AM

https://ift.tt/JflBUKy

Jabil Introduces First PLA for Powder Bed 3D Printing https://ift.tt/8GaE5FQ When we last caught up with Luke Rodgers, senior director of R&D at Jabil (NYSE: JBL), the manufacturing solutions provider was in the process of releasing a new material for powder bed fusion (PBF) that was derived from sequestered carbon monoxide. At RPAID + TCT 2023, the materials scientist was back with a new carbon-capturing polymer for PBF—this time, PLA. The First PLA for PBFSpeaking to Rodgers at the tradeshow, we learned how this polymer, ubiquitous in material extrusion, introduces new benefits to the world of PBF. Developed in collaboration with NatureWorks, the world’s largest maker of PLA, Jabil’s PLA 3110P combines the printability of this typically corn-starch-based plastic with the high throughput and complexity enabled with PBF. Because Jabil is vertically integrated, it has everything from compounding to cryogenic grinding, allowing partners like NatureWorks to access all of these capabilities from a single supplier.

Jabil PLA 3110P, based on NatureWorks’ Ingeo

At the jump, Jabil has several applications in mind for the material, including vacuum and thermoforming, casting, and as a more sustainable substitute for fossil fuel-based polymers. As for thermoforming, in which a material is heated and shaped around a mold, the material has the compression strength and temperature resistance ideal for manipulating materials like polycarbonate, PETG, and polypropylene.

Captured at RAPID + TCT, this image shows a thermoformed dental aligner with 3D printed PLA mold alongside an educational model, also made from Jabil’s new material. For metal casting, the PLA is able to melt without expanding or leaving very little residue. When printed with PBF, it also has the surface finish necessary for casting. There have been numerous stories in which desktop 3D printing users 3D print PLA models, wrapping them in a ceramic mold and burning out the models with molten metal. Unlike desktop material extrusion machines, PBF doesn’t suffer from obvious layer lines, thus resulting in smoother metal components. Perhaps more importantly, PLA 3110P is also much more sustainable, with a carbon footprint that is 89 percent smaller than PA 12, according to NatureWorks. At the same time, it is comparatively inexpensive. This means that, when it comes to thermoforming, casting, or even printing models, prototypes, jigs, and fixtures, users now have a renewable alternative to petrochemicals. As companies seek to reduce their emissions, they can substitute their legacy materials with PLA.

New Materials PartnershipsIn addition to the new PLA, Jabil also announced a collaboration with Nexa3D in which its PK5000 material, the aforementioned polyketone (PK) derived from sequestered carbon monoxide, was made available for Nexa3D’s QLS 236 and QLS 820 SLS printers. Along with that collaboration, Jabil was also involved in the development of a material that protects against electrostatic discharge (ESD). Created with Mechnano, the powder combines Jabil’s polyketone (PK) with Mechnano’s carbon nanotubes for use in PBF 3D printing. This allows for parts that can withstand functional testing and use in areas where ESD is an issue, such as in electronics manufacturing.

Line trimmer gas tank printed in Jabil’s PK 5000, an eco-friendly, powder-based additive material engineered to deliver improved strength, chemical resistance and resilience in comparison to general-purpose nylon materials, such as PA 12. Image courtesy of Jabil. The manufacturing solutions provider is planning to continue its formulation of more sustainable polymers. Jesse Sumstad, Senior Product Manager at Jabil, put it this way during our interview:

The post Jabil Introduces First PLA for Powder Bed 3D Printing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/lq7KsOw May 22, 2023 at 07:51AM

https://ift.tt/qH4V6el

Glidewell & LuxCreo Partner for Chairside Dental 3D Printer Package https://ift.tt/wBJxWPD Glidewell, a large American dental lab, has partnered with LuxCreo a dental 3D printer, software, and materials company, to offer a solution for in-office 3D printing. Ostensibly, LuxCreo is an exponent of the chair-side dental revolution, giving dentists a chance to 3D print partials, intermediates and aligners in their offices. Meanwhile, Glidewell is a service that operates over 400 3D printers in its facilities to send parts to dentists and labs. In this case, the companies have launched fastprint.io, a bundle made up of a 3D printer, wash and cure station, and softwarefor in-office use. Clients can rely on resins developed by Glidewell for night guards and models, while using LuxCreo resins for crowns, retainers, and same-day clear aligners. These can all be printed on the cobranded 3D printer and software solution, which starts at $16,990 but can also be augmented with mills and 3D scanners. The companies also tout reduced post-processing when compared to other machines.

The dental additive manufacturing (AM) market is a fascinating one, with SmarTech Analysis’s recent dental report estimating the segment to be worth $4 billion. We’re seeing a rapid adoption of 3D printing throughout the industry, from lab to dentist. A large number of end-to-end solutions are being created that make 3D printing easy and convenient. Competition is increasingly fierce, as materials companies produce printers, firms are selling hardware-as-a-service, and dentists are performing work that would have previously been done by labs. To me the dental 3D printing industry is an exciting portend of what is to come in 3D printing in general, as the technology becomes embedded in many more industries. In the case of Glidewell and LuxCreo, it’s kind of as if Snap On wants to sell you a forge so you could make your own hand tools. In any other industry, they would be unlikely bedfellows, but, the movement that is 3D printing in dentistry is reshuffling the value chain so radically that such a partnership makes sense. Both firms can complement each other and strengthen their joint offering while still competing. The proposition sounds like an attractive one. Dentists are now spoiled for choice with regards to 3D printing solutions. Due to the increased competition in the market, the partnership seems like a wise one for both Glidewell and LuxCreo. Glidewell is a big player in the U.S. dental AM market and LuxCreo is an emerging player with exciting technology. Both could do well on their own, but they are mere minnows when compared to firms such as Swiss giant Straumann and U.S.-based Dentsply Sirona, which has between $2.2 and $3 billion in revenue. Retailers and distributors such as Henry Schein have a lot of market power, as well, with close to $10 billion in revenue alone. It is nice to be a swift and spry firm, but being small surrounded by giants makes you wonder about their intentions and capabilities as their long shadows constantly interrupt your thoughts. Together, both companies have access to a lot of Glidewell customers and can head off competition in chair-side dental. Lower cost 3D printers from China will enter the market and more integrated solutions will emerge, as well. If this is a solid partnership, it could really expand the markets of both businesses considerably and strengthen their offerings. The post Glidewell & LuxCreo Partner for Chairside Dental 3D Printer Package appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/lq7KsOw May 22, 2023 at 07:51AM

https://ift.tt/t7KBYgd

POP Member Showcase | 9 Pattern Projects https://ift.tt/rRTbkYZ This month we’re stoked to showcase a selection of projects from our community that celebrate or feature the art of pattern. From innovative methods of screen printing, to hand-carved block prints created for repeat patterned fabric, check out the projects below! Sofya Volfkovich: Overlapping Circles Study Anna Sutherland: Screen Printed Fabric Richard Peacock: Hidden Door Niloufar Lovegrove: Papery Peace Lewamakes: Knitting Mermaid Magdalena Krupska: Aztec Pattern Sophie Amelia: Authentic Expression Alchemic Print: Patterns Pamela Haining: Colourful Block Print Floral Pattern

Check out more incredible work from our community at www.members.peopleofprint.com. Want to join our leading community of printmakers and benefit from a heap of perks? APPLY HERE. Printing via People of Print https://ift.tt/jQKGazh May 22, 2023 at 05:42AM

https://ift.tt/87Xse0O

3D Printing Webinar & Event Roundup: May 21, 2023 https://ift.tt/TAqcndi There are several conferences and trade shows to tell you about in this week’s roundup, along with a few webinars as well. Materialise will discuss what’s new in Magics, 3D Systems will introduce you to the MJP 2500W Plus printer, America Makes will hold a town hall for members, Velo3D’s roadshow continues in Europe, and more. Read on for all the details! 3D Printing News UnpeeledOur Executive Editor Joris Peels, who’s also the Vice President of Consulting at SmarTech Analysis, offers a news livestream one to two times a week called 3D Printing News Unpeeled at 9:30 am EST. For each episode, Peels gets on LinkedIn Live and tells us, in 20 minutes or less, what he considers to be the top news stories from the 3D printing industry that week, and why they’re important. Some of the stories in his roundup are ones we’ve covered at 3DPrint.com, and some are not, but they are all equally interesting and impactful. May 22 – 23: ISG TechXchange – Smart ManufacturingFirst up, from May 22-23, ISG (Information Services Group) is holding TechXchange: Smart Manufacturing in Chicago. With a focus on improving efficiency and productivity, the event welcomes industry leaders and ISG subject matter experts, who will share their best-practice insights to help attendees navigate the necessary processes, technologies, and culture to refocus their business strategy and achieve successful outcomes. Four main themes will be explored: technology security, the industrial metaverse, connected value chain, and sustainable manufacturing.

You can register for the event here. May 22 – 25: Automate ConferenceIn Detroit, from May 22-25, Automate, the largest and most inspiring showcase of automation in North America, will be held. With 200 expert speakers and over 750 exhibitors on the show floor—including HP, Triton Robotics, Creaform, igus, Lumafield, and more—attendees will have the opportunity to discover powerful automation solutions, from robotics and AI to machining and 3D printing. There will be keynote presentations, small workshops, training opportunities, live demonstrations, a startup competition, and plenty of time for networking. Plus, the event will also feature a Workforce Development Day for students over the age of 12, to help them start building a strong foundation for success.

You can register for the event here. May 23 – 25: MedtecLIVE with T4MIf you’re interested in learning more about connecting the medical technology supply chain, come to MedtecLIVE with T4M, the leading platform for the European medtech industry, in Nürnberg, Germany from May 23-25. The exhibition topics will be design and R&D; materials and components; processes, mechanical engineering, manufacturing, and automation; IT in medical technology; measurement, testing, and validation; and services in biomedical engineering. There will be a special startup area and a startup contest, as well as guided tours of the exhibition floor, and for the opportunity to discuss important medtech topics, develop new ideas, and network with other professionals, check out the Medical World Café.

You can purchase a ticket for the event here. May 23 – 25: SPS Italia – Automation & Digital for IndustryAlso from May 23-25, the 11th annual SPS Italia for smart, digital, and sustainable industry and industrial automation returns to Fiere de Parma in Italy. In the exhibition hall, the best automation technologies and digital solutions to help transform Industry 4.0 will be on display, and the special District 4.0 exhibition is dedicated to four fundamental areas of the industrial sector: Digital & Software, Robotics & Mechatronics, the new Sustainable Innovation, and Additive Manufacturing.

You can get a ticket for the event here. May 23: What’s New in Materialise MagicsAt 10 am EST on Tuesday, May 23rd, Materialise will discuss “What’s New in Magics” in a live webinar focused on the latest features of the powerful software. Attendees will learn how to automate repetitive tasks and optimize processes, how to improve control, connectivity, and traceability in production, and more from Materialise software experts Egwin Bovyn, Product Line Manager of Magics 3D Print Suite; Lieve Boeykens, Sales and Pre-Sales Enablement Manager; Laurens Schulte, EMEA Presales Manager; and Tem Bertels, CO-AM Product Line Manager.

You can register for the webinar here. May 23: 3D Systems’ New MJP 2500W Plus PrinterAlso on the 23rd, 3D Systems will discuss its “New MJP 2500W Plus: Reduce gold loss with better surface finish and achieve up to 25% faster print speed” in a webinar at 2 pm EST. This new 3D printer for wax 3D printed jewelry patterns offers faster print speeds in XHD printing mode, and its new high resolution ZHD mode makes it possible to print extremely smooth casting patterns. Additionally, the printer can deliver very high-quality surface finishes, so there’s less need for manual polishing at the end. Save time and waste less precious metals, while also improving quality, with this new system from 3D Systems.

You can register for the webinar here. May 24 – 25: Space Operations SummitFrom May 24-25, the Space Operations Summit by Defence IQ will be held in Kensington, London. It’s the only conference to look at space as not only an independent operational domain, but also an enabler for joint all-domain operations, and welcomes space commands, government officials, industry leaders, and academia to share the challenges they face, and the solutions they’ve found. Over 100 organizations will be involved in the conference, and as a major challenge within the sector is how space commands can better leverage commercial capabilities, outside opinions from industry, policy makers, military, and others should be especially helpful in addressing the issue.

You can register for the conference here. May 24 – 25: Advanced Engineering 2023 at Antwerp ExpoAlso from May 24-25, the Advanced Engineering conference at Antwerp Expo will take place in Belgium, which covers every stage of the product development process for all sectors of the Benelux manufacturing industry. There will be several high-tech demo zones on the show floor, including an AI Hub and a VR/AR Zone, as well as presentations, a startup event, a teacher program, and plenty of exhibitors, including 3D Infinity, Flam3D, Metal Technics 3D, and more.

You can register for the conference here. May 24: Velo3D Continues Roadshow in NorwayVelo3D continues its 2023 “The Proof is in the Printing” global roadshow this week with a stop in Stavanger, Norway, on Wednesday, May 24th. From 9:30 am – 4:30 pm CET, a Metal AM Workshop will be presented at Forum Jæren. The tour, which will make stops in other cities across Europe, the U.S., and the Asia/Pacific region, will show attendees how Velo3D’s fully integrated solution can help achieve lower costs, better part performance, supply chain flexibility, and repeatability. There will also be real-world examples of customer-printed parts, and attendees can ask questions, and get answers from, technical experts.

You can register for the Stavanger stop here. May 24: America Makes Member Town HallFinally, on the 24th, America Makes will hold a Member Town Hall – Ecosystem at 1 pm EST. Kimberly Gibson, the America Makes Ecosystem Director, will provide an update on the Ecosystem program. The other speaker will be America Makes Membership Coordinator Laurie Wittkugle.

You can register for this members-only town hall here. The post 3D Printing Webinar & Event Roundup: May 21, 2023 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/lq7KsOw May 21, 2023 at 08:46AM |

Categories

All

Archives

April 2023

|

PLA-based powder, offers 89% smaller carbon footprint compared to PA 12 when used in powder-bed fusion technologies. Image courtesy of Jabil.

PLA-based powder, offers 89% smaller carbon footprint compared to PA 12 when used in powder-bed fusion technologies. Image courtesy of Jabil.

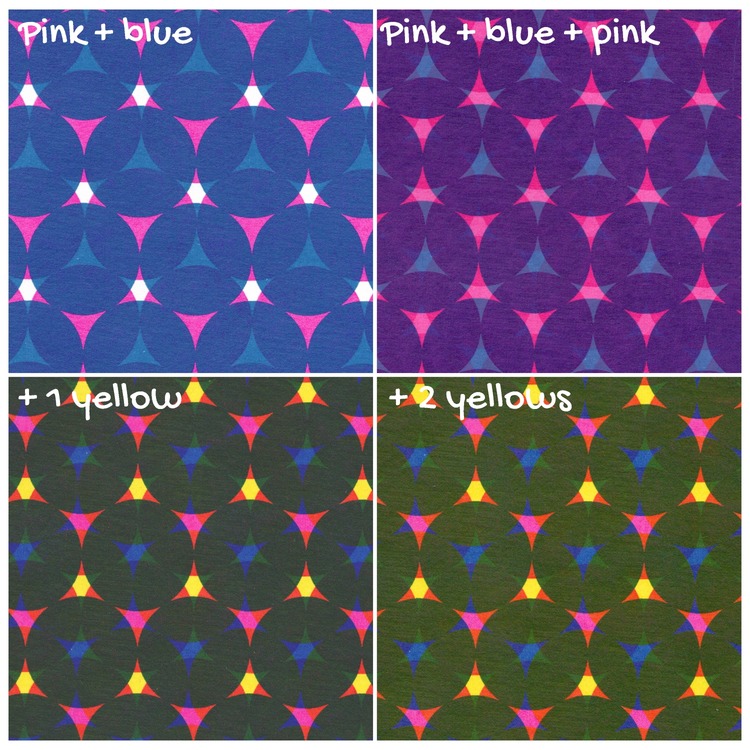

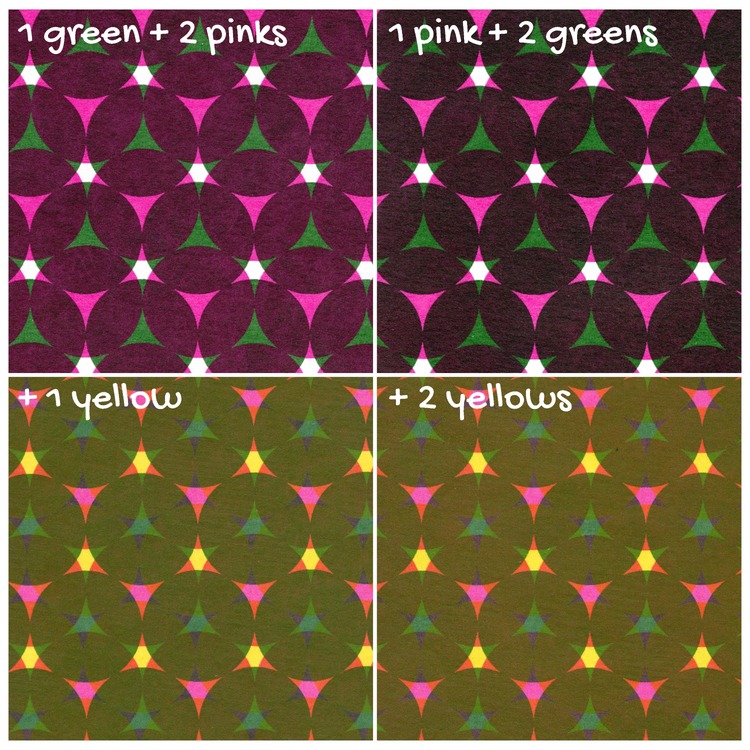

This series of 19 screen prints dedicated to colour and ink behaviour by Sofya Volfkovich uses an overlapping circles grid created with one screen in two or three layers. By playing with the order of colours printed and the amount of strokes she made with each colour, Sofya achieved slight differences that change the overall look and feel of the final print. While doing this, she also discovered that drops of water on the screen can provide some very interesting effects – controlling these will probably be the subject of her next study.

This series of 19 screen prints dedicated to colour and ink behaviour by Sofya Volfkovich uses an overlapping circles grid created with one screen in two or three layers. By playing with the order of colours printed and the amount of strokes she made with each colour, Sofya achieved slight differences that change the overall look and feel of the final print. While doing this, she also discovered that drops of water on the screen can provide some very interesting effects – controlling these will probably be the subject of her next study.

Anna Sutherland’s work is all about pattern; as a passionate screen printer Anna designs and prints colourful, intricate patterned lengths of screen printed fabric. Many of her patterns are inspired by nature and the flowers around her. All of her designs are initially hand drawn before being transformed into multi-colour repeats. Anna screen prints these patterns of 1, 2 and 3 colour designs up to 5m in length at a time. While she prints on oatmeal linen for her homewares range, Annas favourite part of screen printing a length on a coloured base cloth is when the final screen is lifted.

Anna Sutherland’s work is all about pattern; as a passionate screen printer Anna designs and prints colourful, intricate patterned lengths of screen printed fabric. Many of her patterns are inspired by nature and the flowers around her. All of her designs are initially hand drawn before being transformed into multi-colour repeats. Anna screen prints these patterns of 1, 2 and 3 colour designs up to 5m in length at a time. While she prints on oatmeal linen for her homewares range, Annas favourite part of screen printing a length on a coloured base cloth is when the final screen is lifted.

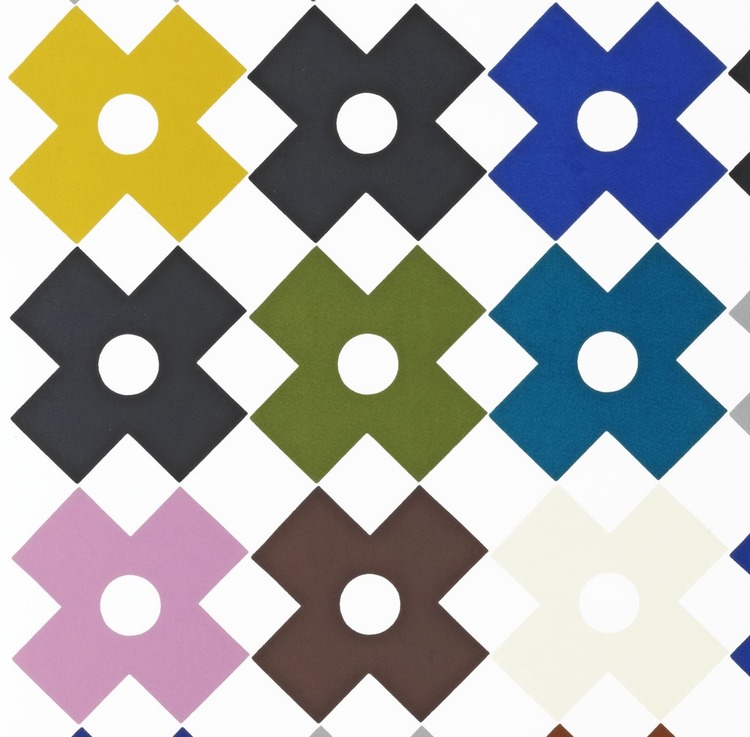

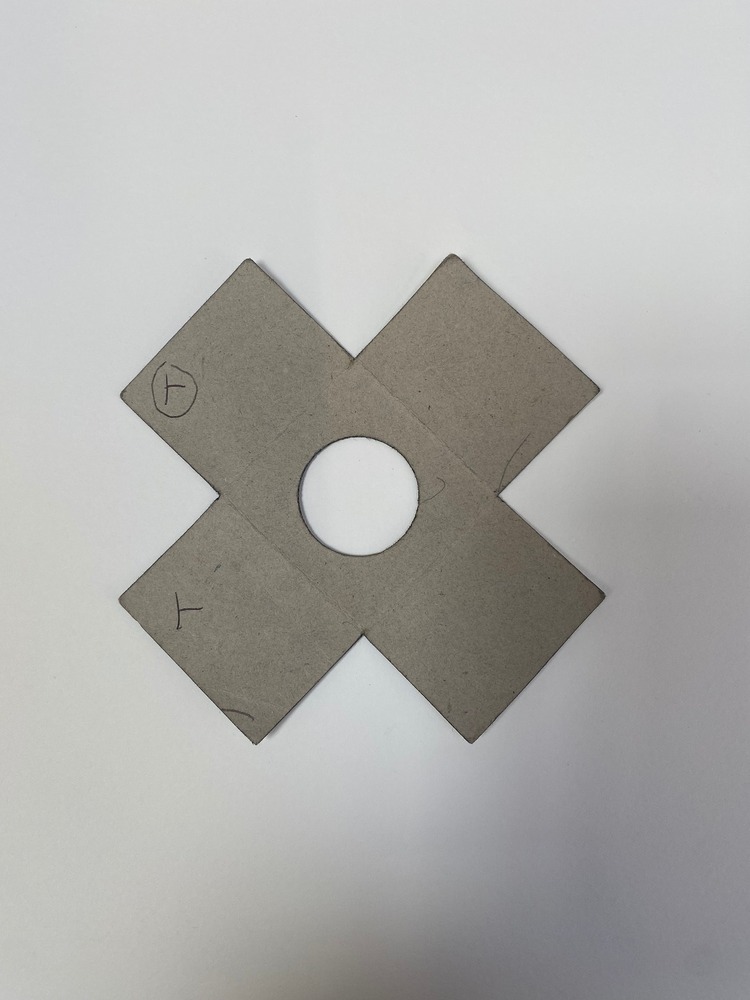

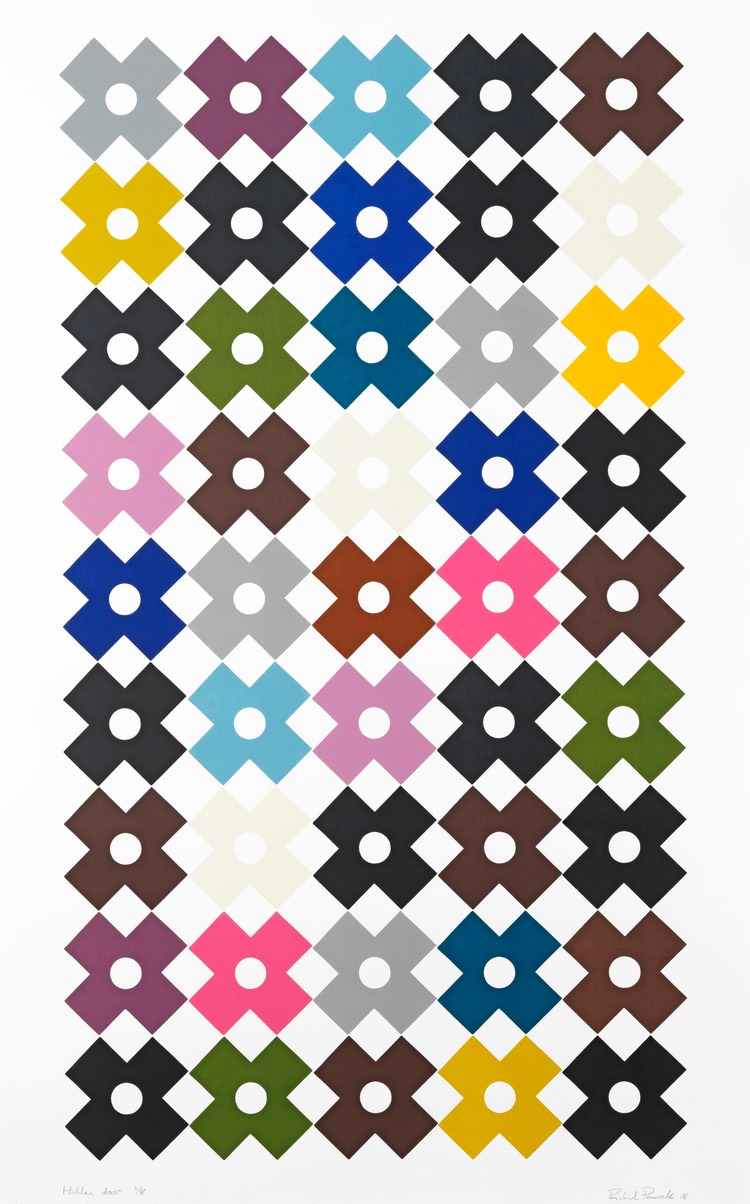

Richard Peacock works with pattern in many of his screen prints. Hidden Door is a strong example of this; a simple repeated shape shot through with colour. The stencil is from a simple piece of carboard packaging – taken from a light bulb and exposed on the screen. “I like repeating shapes like this – they are often slightly irregular (as if the manufacturer can’t be bothered to make them perfect), which introduces odd gaps and misalignments into the composition,” says the printmaker. The print is 112 cm x 69 cm and is a portrait composition, so quite a small Hidden Door, but quite a big screen print.

Richard Peacock works with pattern in many of his screen prints. Hidden Door is a strong example of this; a simple repeated shape shot through with colour. The stencil is from a simple piece of carboard packaging – taken from a light bulb and exposed on the screen. “I like repeating shapes like this – they are often slightly irregular (as if the manufacturer can’t be bothered to make them perfect), which introduces odd gaps and misalignments into the composition,” says the printmaker. The print is 112 cm x 69 cm and is a portrait composition, so quite a small Hidden Door, but quite a big screen print.

Papery Peace celebrates the ancient history of Persia through the choice of attire style, and elements in pattern in contrast to the current mandatory dress code for women. “It symbolises a free land where people can exchange ideas, creativity, and elements of imagination peacefully,” states printmaker Niloufar Lovegrove. The linocut is printed on both sides of Hosho paper roll, cut and folded like a dress. It measures approx 80 x 105 x 6 cm, and was a finalist in an exhibition during covid.

Papery Peace celebrates the ancient history of Persia through the choice of attire style, and elements in pattern in contrast to the current mandatory dress code for women. “It symbolises a free land where people can exchange ideas, creativity, and elements of imagination peacefully,” states printmaker Niloufar Lovegrove. The linocut is printed on both sides of Hosho paper roll, cut and folded like a dress. It measures approx 80 x 105 x 6 cm, and was a finalist in an exhibition during covid.

The Knitting Mermaid is a 45 x 64 cm lino print (image size DIN A2), handcarved and printed with black Caligo Safe wash ink by Lewamakes. The printmaker tells us; “This young mermaid was bored with her normal fishtail and took it upon herself to update her tail pattern with some creativity! It is her first knitting project so there might be some mistakes or irregularities but she is doing her best and every creative started at some point with some imperfect art. I think we can all relate to it. Nevertheless, she will definitely stand out amongst the sea folk and she is excited to show off her new piece.”

The Knitting Mermaid is a 45 x 64 cm lino print (image size DIN A2), handcarved and printed with black Caligo Safe wash ink by Lewamakes. The printmaker tells us; “This young mermaid was bored with her normal fishtail and took it upon herself to update her tail pattern with some creativity! It is her first knitting project so there might be some mistakes or irregularities but she is doing her best and every creative started at some point with some imperfect art. I think we can all relate to it. Nevertheless, she will definitely stand out amongst the sea folk and she is excited to show off her new piece.”

These patterned linocuts by Portugal-based printmaker Magadalena Krupska are inspired by ritual dance, body movement, and expression. “Everything happens in the sand, surrounded by waves. Feel the sun and move your body,” states the artist.

These patterned linocuts by Portugal-based printmaker Magadalena Krupska are inspired by ritual dance, body movement, and expression. “Everything happens in the sand, surrounded by waves. Feel the sun and move your body,” states the artist.

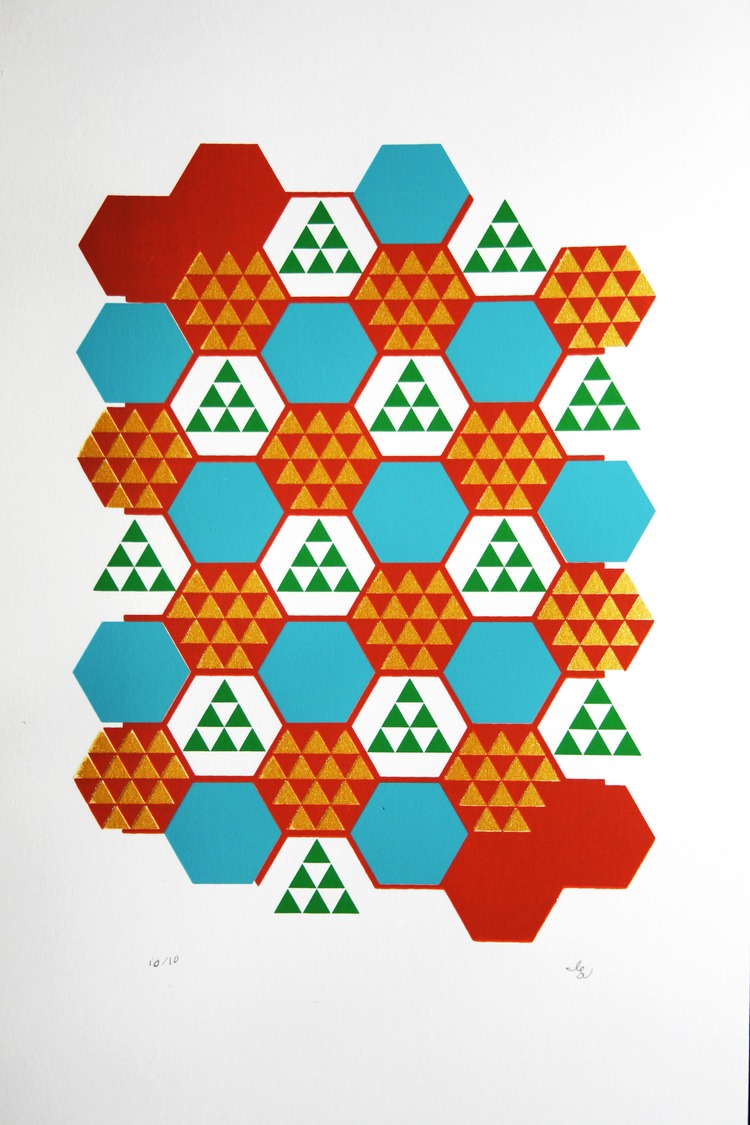

Authentic Expression is Sophie Amelia’s most recent collection of screen printed textiles. This abstract collection takes inspiration from her work with Neurodivergent women and femme aligned people sharing their experiences of life. It includes a variety of print structures, from placement prints to block and half drop repeats, and a range of finishes including foil, flocks, and metallic inks. This gives the collection an elevated sensory approach whilst retaining the adult focused aesthetic.

Authentic Expression is Sophie Amelia’s most recent collection of screen printed textiles. This abstract collection takes inspiration from her work with Neurodivergent women and femme aligned people sharing their experiences of life. It includes a variety of print structures, from placement prints to block and half drop repeats, and a range of finishes including foil, flocks, and metallic inks. This gives the collection an elevated sensory approach whilst retaining the adult focused aesthetic.

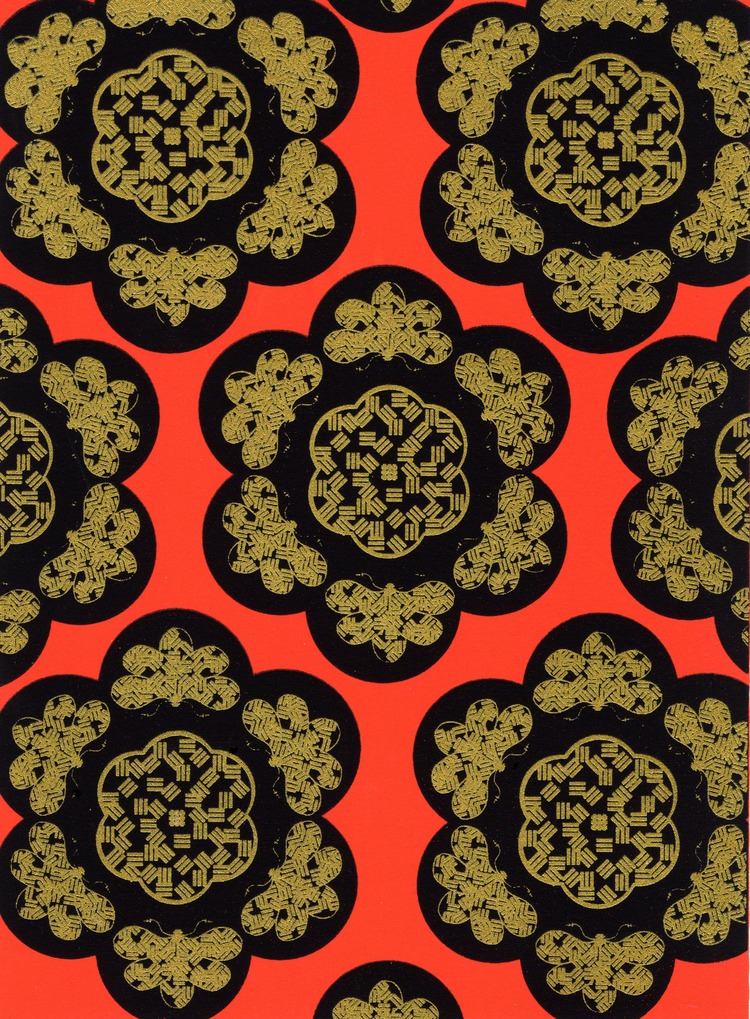

From Japanese to Mexican designs, Alchemic Prints love making patterned prints. They tell us; “Seeing the weaving of images into a hypnotic composition is wonderful. This reason is why I love making it, I want people to feel something unique when seeing my patterns, something crazy, beautiful, or soothing.”

From Japanese to Mexican designs, Alchemic Prints love making patterned prints. They tell us; “Seeing the weaving of images into a hypnotic composition is wonderful. This reason is why I love making it, I want people to feel something unique when seeing my patterns, something crazy, beautiful, or soothing.”

This modern, colourful, floral block printed pattern was created by Pamela Haining using traditional linocut techniques combined with digital methods. This abstract floral design was hand drawn and carved before being printed onto paper first to retain that wabi-sabi, hand printed effect, full of raw texture. The finished print was then recoloured multiple ways and worked into a half-drop repeating pattern. Combining traditional and modern printmaking techniques allows Pamela to create block printed patterns, suitable for printing onto a wide range of fabrics and soft furnishings.

This modern, colourful, floral block printed pattern was created by Pamela Haining using traditional linocut techniques combined with digital methods. This abstract floral design was hand drawn and carved before being printed onto paper first to retain that wabi-sabi, hand printed effect, full of raw texture. The finished print was then recoloured multiple ways and worked into a half-drop repeating pattern. Combining traditional and modern printmaking techniques allows Pamela to create block printed patterns, suitable for printing onto a wide range of fabrics and soft furnishings.

RSS Feed

RSS Feed