|

https://ift.tt/vK6nEsm

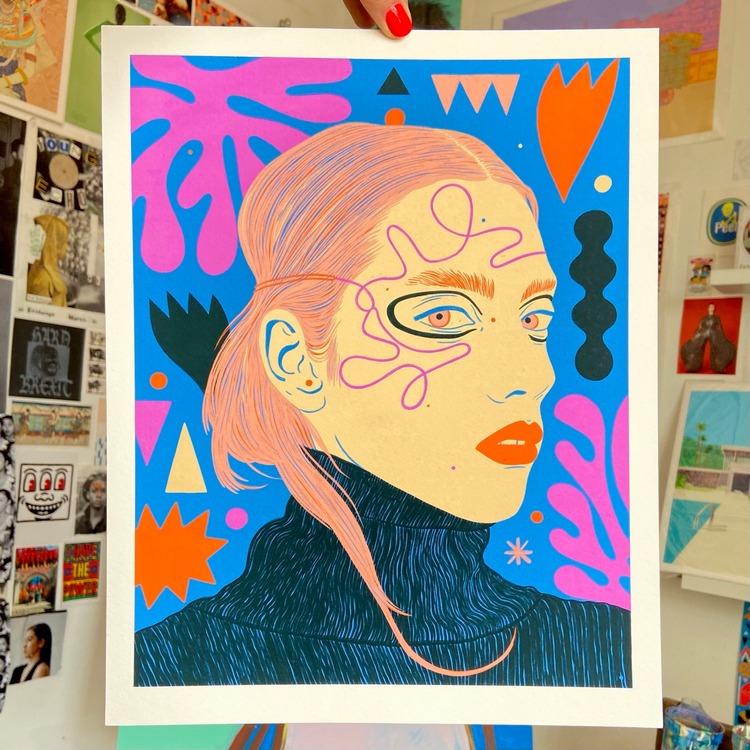

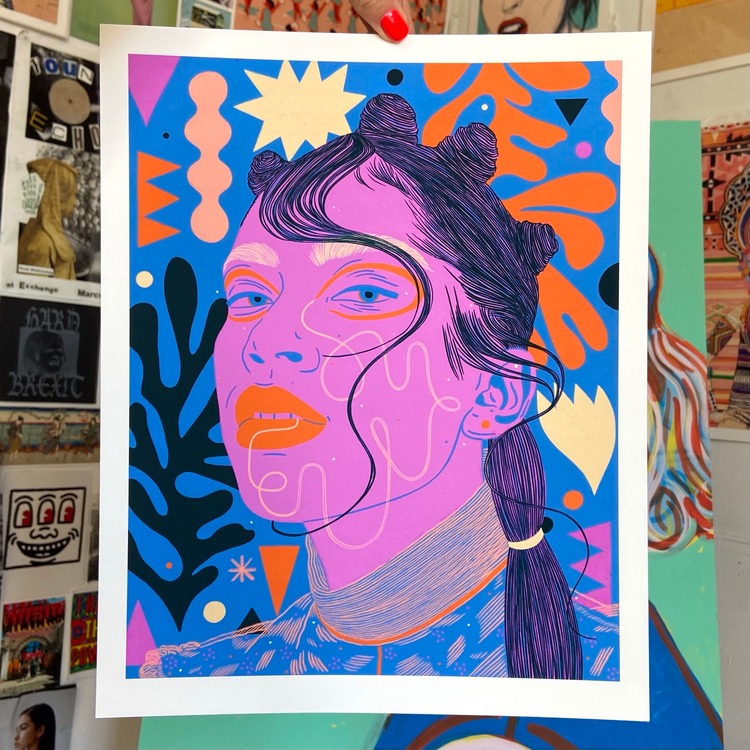

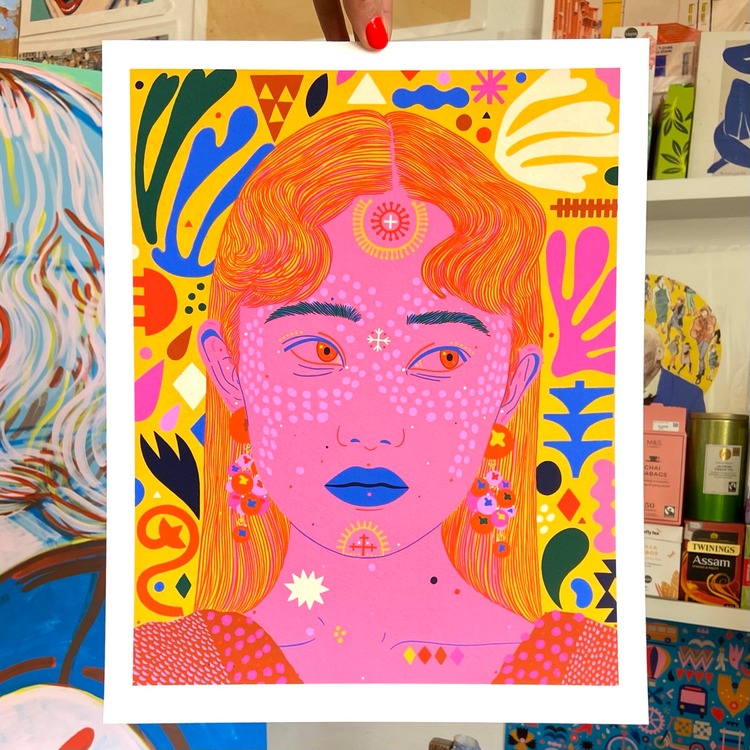

Anna Higgie | Hybrid https://ift.tt/Ew1NBDb Australian-born and Bristol-based illustrator Anna Higgie has released a new series of works that combine the flat, abstract forms that she typically uses in her mural work, with human faces and portraiture.

www.annahiggie.co.uk Printing via People of Print https://ift.tt/ekt0Fwl July 29, 2022 at 05:48AM

0 Comments

Mail and Package Delivery Averages 2.5 Days Across The Nation https://ift.tt/vXHgOq6 WASHINGTON — The United States Postal Service reported new delivery performance metrics for the first three weeks of the fiscal fourth quarter. During the reporting period, the average time for the Postal Service to deliver a mailpiece or package across the nation was just 2.5 days. Printing via USPS News https://ift.tt/1v6qfN3 July 28, 2022 at 02:32PM

https://ift.tt/dAVFDKZ

Hofer https://ift.tt/WI30i2u Davina Schluttenhofer is a graphic designer, illustrator, and letterpress printer based in Kent. The Hofer studio was established in the Autumn of 2018. Founded by Davina, Hofer translates from German as ‘farm house’, and Schlutte ‘the valley’ – handy given that Davina and her family are nestled at the edge of one, albeit in the Garden of England.

The comp room had been an escape whilst studying at St Martin’s, and Davina then attended letterpress workshops with Alan Kitching whilst studying at the RCA. It was a visit to the Alan Kitching show at Somerset House in 2016 that reignited her love of the process, and was the driving force behind purchasing a cylinder proofing press.

Printing via People of Print https://ift.tt/ekt0Fwl July 28, 2022 at 05:59AM

https://ift.tt/9T8vIVS

3D Printing Facility Opened at Bengaluru Airport City https://ift.tt/16Xtgr8 Peekay Group, a South Indian industrial outfit, has partnered with Bengaluru Airport City Limited (BACL), to open an additive manufacturing (AM) center at Bengaluru Airport City. The latter is a retail district currently under development near Kempegowda International Airport Bengaluru (BLR). BLR, one of the world’s fastest growing airports, is already the third-busiest in India, after those in Delhi in and Mumbai. Similarly, India’s AM sector is one of the fastest growing in the world: over the past year, the nation’s government has unveiled project after project revolving around the technology, across a wide range of applications and sectors.

As the joint managing director of Peekay Group notes, the facility’s purpose is not just output, but education, as well. In this sense, it joins multiple other, similar AM centers that have sprung up across India over the past year or so. Moreover, Peekay Group’s intentions to forge ties with large research institutions obviously has a lengthy precedence in the industry as a whole, and particularly, in the EU countries with the most active AM sectors. India has successfully leveraged this dynamic as well, especially in additive construction (AC) and metal AM. The deployment of that tested formula for success, at the center of a major regional commercial development project, has the potential to make a big impact in consolidating all of the progress India’s AM sector has made thus far. As I’ve mentioned in posts prior to this one, India’s National Strategy on Additive Manufacturing (NSAM) is probably one of the starkest implied challenges to Chinese industrial supremacy from any government that’s not the US. And that is of course not accidental, considering that the US and India are now officially military allies. In this same vein, it is notable that the venture capital arm of Siemens, Siemens Project Ventures, owns a 20 percent stake in BLR airport. The more that the Sino-American cold war intensifies, the clearer it is that western powers consider South India to be indispensable, as the linchpin in creating a potential global supply route that bypasses Belt-and-Road. Thus, beyond its tangible value in creating things and jobs, and even beyond its educational value, this sort of project — in a planned, futuristic, “airport city” — has an intangible, symbolic value. That value lies in the image of India that the Indian government, and western powers, want to broadcast to the rest of the world. The post 3D Printing Facility Opened at Bengaluru Airport City appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/OXlrpez July 27, 2022 at 10:16AM

https://ift.tt/s6YgxRV

$43M to Drive Tiny 3D Printing Tech for Boston Micro Fabrication https://ift.tt/Iw2MJc4 Boston Micro Fabrication (BMF) has closed a Series C round of funding totaling $43 million, led by Shenzhen Capital Group Co., Ltd. (SCGC). This large infusion of capital will allow the startup to continue expanding its micro 3D printing technology. Micro 3D PrintingFounded in 2016, BMF focused on building 3D printers that rely on Projection Micro Stereolithography (PµSL) for millimeter-scale parts with micron-level tolerances. With systems of varying levels of resolution, ranging from 25 all the way down to 2 microns, the Boston startup’s microArch 3D printers are already used in a variety of sectors, including medical device and electronics manufacturing. In the past year alone, BMF doubled its install base and now has machines installed at over 200 customer locations globally. It also expanded its operations in Greater Boston; Shenzhen and Chongqing, China; and Tokyo, Japan. With the new funding, the startup will drive its product development, sales and marketing, and customer support.

3D printed glaucoma stents, meant to be inserted into a patient’s eye to treat glaucoma. Image courtesy of BMF. BMF’s Micro 3D Printing CompetitionThe world of 3D printing tiny things is growing in size. In addition to BMF, there are such firms as Cubicure, UpNano, SwissLitho AG, Microlight3D, Nano Dimension’s Fabrica, and Nanoscribe. This last company was acquired by bioprinting firm BICO. UpNano and Nanoscribe are currently competing to scale these processes in order to mass produce tiny, 3D printed parts. The technologies offered by these firms could potentially revolutionize the fields in which they’re used. They could lead to much smaller surgical devices, such as new drug delivery mechanisms or uniquely shaped laparoscopic instruments, or new types of lab testing equipment via microfluidics. In the realm of electronics, there’s the possibility of photonic computing and more densely packed, geometrically optimized circuit boards, an application that Nano Dimension is specifically focused. Obviously, SCGC believes in the technology, which is a substantial endorsement, given the company’s 490 investments and 85 exits. Established by the Shenzen government, this venture capital firm previously put money into Formlabs and Desktop Metal. Interestingly, all three startups are based in the area. Could Shenzen be making a play for the New England 3D printing scene? The post $43M to Drive Tiny 3D Printing Tech for Boston Micro Fabrication appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jda3tAW July 27, 2022 at 08:18AM

https://ift.tt/6e4bMjd

Can 3D Printing Make Your Organization Innovative? https://ift.tt/otbjn0r No, 3D Printing Alone Cannot Make an Organization InnovativeCan additive manufacturing (AM) simply make an organization innovative by throwing a few 3D printers at it? Is it able to transform a company through mere exposure to the technology alone? The obvious answer here is: of course not. Many companies have bought 3D printers in a flawed desire to become more innovative. It’s as if they’re hoping that the simple addition of a system to an office will serve as a kind of shrine to innovation. Once installed, the 3D printer’s magical innovation aura will waft over the team and make them innovative. A Box is a BoxPerhaps it’s the universal applicability of the television that confuses people. You can put someone in front of a TV and they’ll drift into a flickering, colorful stupor as multicolored rays light up their face and life. Uninitiated, we can go from active to passive just by introducing a TV to a room. Maybe this has led some to think that a 3D printer will be as usable. And, perhaps, we in the AM industry are to blame here in part. After all, we sold these things as easy to use. A box is just a box. However, a 3D printer can become a tool if it’s in the right hands. A 3D printer won’t magically make a person innovate. It won’t even make them more likely to do so. For that to happen, they have to know how to use it. 3D Printer TrainingWithout taking the 2,000 hours or so to learn CAD, a user can’t make the specific solutions necessary to really get the most out of the printer. What’s more, they would need additional training to understand 3D printing technology itself, at least at a high enough level to produce designs that matter. Then, they’d have to learn to deal with the actual machine: maintaining it, calibrating it properly, etc. However, even once all of this is done, they won’t magically become innovative. Culture over BoxesTo make a company more innovative, team members might consider organizational design and culture. This might include: empowering employees, allowing everyone to speak at meetings, listening to them all, cross-functional teams, and a generally more open culture. and much more. If an employee feels as though they have to make what their boss wants or that no one will listen to them, they’re not going to be the one to make a breakthrough solution. If workers operate under “management by fear,” then innovation, learning and expression aren’t being fostered. Neither are diversity of thought or opinion. If everyone is trying to impress the boss during a brainstorm, rather than solve a problem, then the group might as well not be brainstorming at all. Those institutional behaviors that would turbo charge a 3D printing implementation are those that would drive innovation internally anyhow. If a company is currently not innovative, it will need to find its own path to innovation through the difficult, but potentially cathartic process of organizational change towards a more open culture where all voices are heard.

From the “Collecting Innovation Today” interview with innovator Carroll Shelby on August 19, 2008 at Carroll Shelby Licensing, part of The Henry Ford’s “OnInnovation” project that celebrates the contributions of today’s innovators. Photo from the collections of The Henry Ford, Dearborn, Michigan, USA. Photographer, Michelle Andonian. There’s a “Me” in TeamEven if an organization does evolve to exhibit an open culture, it doesn’t mean that a given manager will be capable of fostering innovation correctly. If a manager is too fond of listening to themselves think and speak, they may drown out the voices around them. If they micromanage, they’ll transform the 10 voices surrounding them into their own and stifle any truly independent thought. So even with the right culture and tools, a team could still have the innovation wrung out of them with the wrong manager. Teams of rivals may super charge a company’s sales department, but collaboration and using the unique skills present in all members will probably get a business further in innovation scenarios. The “I” in FailEven then if all of the other preconditions are met, a given manager may be the wrong person for the job. An organization needs a problem solver who understands the company’s culture and is knowledgeable about the business challenges. An unconventional thinker will do well, but they will do even better if paired with a conventional thinker. If a manager is motivated to show off cool ideas, then they may hardly ever develop solutions. If they’re paid to solve problems, then they may gravitate to the problems that leaders have, not necessarily those that the entire team has. If their career depends on this, they may be too cautious. If they have a sandbox, they’ll just play and probably won’t build. A lot of success in innovation derives from alignment and motivation on a very personal level. The right teams, and the right manager, and the right incentives will have much more impact on success in innovation within an organization than any magical box will. You may give me a wand but I’ll not be a wizard just yet. The InCompetence Center

From the “Collecting Innovation Today” interview with innovator Steve Wozniak on August 18, 2008 at the Computer History Museum, part of The Henry Ford’s “Oninnovation” project that celebrates the contributions of today’s innovators. Companies will often have an innovation department. This always puzzles me because it indicates that only the people in this department can innovate. Or, worse still, it could indicate that no one else is allowed to innovate. Just like HR is the only team dedicated to employee policies, this small table is only for the employees who are innovating. Competence centers are meant to spread knowledge and ability, but are often fortresses behind which innovation is curtailed. The focus on only boasting senior members, engineers, or other employees with very specific roles bothers the hell out of me. It’s the people on the shop floor that can contribute the most meaningful innovations, problems, and insights. The person in the factory, delivering the product to small shops, or ensuring the product looks good in a tiny kiosk somewhere is the right employee to inform a manager about the biggest unseen issues. Extrapolating correctly on their findings will often also have the biggest impact. A lot of people turn to cosmetology in innovation whereby a new green tea flavor, website, video, or silly gimmick will take attention away from truly innovative packaging or new products that could result in completely fundamental innovation. Also, by restricting innovation to the “innovation people” alone, a business doesn’t obtain the insights from across the organization. Armed with an ¨innovation mindset,” they also take a clinical buzz word driven approach to innovation and forget that as parents, children, partners, friends, and neighbors, employees can introduce widely shared problems to the team solving. The ivory-tower-innovation-industrial-complex is a self-perpetuating, self-mythologizing series of expensive brainstorms and exercises that delude businesses into a false sense of security. ExceptionsTherefore, culture, incentives, and capturing the broadest possible opinions are much more important than any box. Now, there is an exception that we’ve seen happen across the 3D printing industry. In some top-down businesses that are very process-driven and regulated, 3D printers can introduce innovation by empowering shop floor employees to design problem-solving parts by themselves. In these bottom-up innovation paths, we can see that the right employee can arm themselves with a printer (if they have CAD skill) and then bring to management a part they’ve already 3D printed to solve a problem. Here, we can see that this employee has a printed, concrete example that can show off the solution immediately. This has worked many times across many companies in 3D printing. General availability of free CAD and 3D printing classes that anyone can follow would be very valuable to any company. General availability of spare, unconstrained 3D printing capacity will also foster teams to maker their own solutions. As a tool for innovation, a 3D printer will not work. However, if we make the courses and the capacity available company wide to all employees, then eventually some innovation should follow from it. Not in a guided, predictable or department-driven manner. Not via any one manager, but through the eventuality of one employee becoming so annoyed or inspired by something that they solve it themselves. If you just put a few 3D printers somewhere and expect them to spit out innovation by themselves—even in the hands of a small elite team—it will not work. I could wear a tutu but it wouldn’t mean that I can dance. Nor, if I wore it long enough, would I become a ballerina. Feature image courtesy of Ultimaker. The post Can 3D Printing Make Your Organization Innovative? appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jda3tAW July 27, 2022 at 08:18AM

https://ift.tt/OYXoPd9

3D Printing News Briefs, July 27, 2022: Standards, Software, & Research https://ift.tt/6WbqaBp In today’s 3D Printing News Briefs, a proposed standard from ASTM International would define filament properties. Mango 3D announced a major update for its Lychee slicer. Finally, on to research, first focused on 3D printing technology that could advance biofilm science, and then on bioprinting stem cells for cardiovascular regeneration. ASTM Developing Standard for 3D Printing Filament PropertiesA new standard is being developed by ASTM International that would be used for testing the tensile properties of filaments. The proposed standard is being written by the organization’s additive manufacturing technologies F42 committee, and will be used to determine the basic performance information on, and define properties for, the raw materials used in the most common material extrusion 3D printers on the market. ASTM International member Haibin Ning is leading the development effort for this proposed standard, and said that it “can help users from labs to industries, especially aviation, aerospace, automotive, and defense, to select the filament that meets their requirements. It can also facilitate quality control and optimization of filament production for the manufacturers.” These efforts are specifically related to Sustainable Development Goals #9 and #12 on innovation and responsible consumption and production laid down by the United Nations. Lychee Slicer Releases New Features & User InterfaceMango 3D offers a customizable operating system to manage 3D printing hardware, and announced that its 3D model preparation software, Lychee Slicer, has released an updated user interface for future projects, as well as some major new features and a more dynamic logo. The user interface has a cleaner look, and is also more intuitive, in order to make print preparation quick and easy, and the new features were created to help reduce print errors related to model size and facilitate the transition from virtual to real. Users can see the exact size of their future completed print using the new Physical Size Mode, and another new feature is Support Painting, which speeds up the creation of manual supports.

MSU Researchers Advancing Biofilm Science with 3D Printing

MSU microbiology doctoral student Kathryn Zimlich, left, and Isaak Thornton, doctorate student in mechanical engineering, with a 3D printing device they have used to deposit microbes and create biofilms. Credit: MSU Photo by Adrian Sanchez-Gonzalez Biofilms—the slimy mats created when bacteria and various other microbes stick to surfaces—form complex communities that usually aren’t affected by normal disinfectants. But scientists in Montana State University’s Center for Biofilm Engineering are designing a 3D printing system for replicating these communities so they can be studied, and new treatments found. MSU doctoral students Isaak Thornton, mechanical engineering, and Kathryn Zimlich, microbiology, have been testing their system, which can lay out a precise grid of individual bacteria in hydrogel and then solidify the material using laser light, creating what’s described as a “rudimentary” biofilm. The 3D printer will allow them to do multiple passes with different strains and species of bacteria, which then enables the creation of more complex, layered biofilms. Fluorescent dye added to the bacteria makes it easy for researchers to see the microbes inside using special microscopes, so they can better study cell interactions and develop treatments in a controlled setting.

Thornton and Zimlich presented their work during the recent Montana Biofilm Meeting, which invites global researchers and industry partners to discuss biofilm science. Bioprinting & Tissue Engineering For Cardiovascular Tissue RegenerationFinally, researchers from Stanford University, Graver Technologies in New Jersey, and the Center for Tissue Regeneration, Veterans Affairs Palo Alto Health Care System published a review article titled “Advances in three-dimensional bioprinted stem cell-based tissue engineering for cardiovascular regeneration.” 3D bioprinting produces tissues that mimic the function and structure of real tissues, such as cardiovascular ones. Because bioprinted tissues can, as the team explained, “better recapitulate in vivo physiology,” they can be used in many applications, such as disease modeling, drug testing and screening, in vitro cellular studies, regenerative medicine, and biocompatibility analysis. But, the matrix molecules in bioprinted tissues can’t quite recreate the complexity of cellular morphologies and the extracellular matrix; however, it helps to include a vascular network, as well as patterned 3D bioprinted tissues. The researchers go more in depth into recent 3D bioprinting advances, applications, challenges, and perspectives in their article.

The post 3D Printing News Briefs, July 27, 2022: Standards, Software, & Research appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jda3tAW July 27, 2022 at 08:18AM

https://ift.tt/J7Izq6T

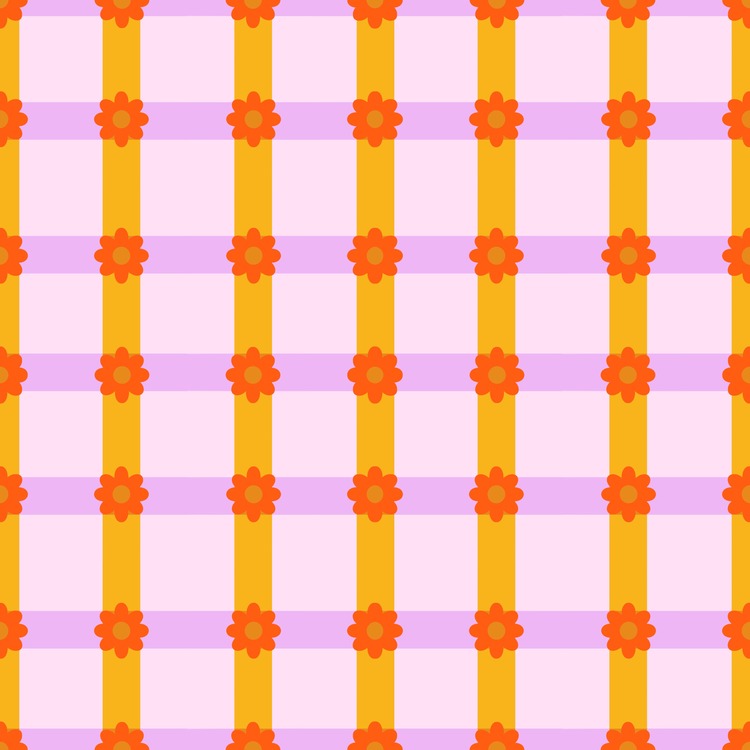

Alice Needham Illustration https://ift.tt/fB6Tamr Alice Needham is a queer British illustrator currently based in Leeds, UK. Working freelance from her home studio as an illustrator and designer, Alice specialises in digital illustration, pattern design, and mural work. She has a wide range of experience, from creating work for largescale print, to working with fashion brands to create in-house illustration styles. “I really enjoy the broad range of projects I get to work on, each one has been completely different and interesting to work on,” says the illustrator. She is also passionate about raising awareness around social issues and movements such as intersectional feminism, LGBTQ+ rights, and more.

Each of her designs starts off with the gathering of references and any briefs from clients. Alice then creates rough sketches which will then get turned into initial drafts. From there, she usually chats to the client about the designs and either finalises them or adds any changes that are needed. Alice works digitally, so everything is created on her iPad Pro, either drawn in Procreate or the Adobe Suite.

Printing via People of Print https://ift.tt/dYRp6th July 27, 2022 at 05:57AM U.S. Postal Service Board of Governors to Meet Aug. 9 https://ift.tt/GXDszKi WASHINGTON, DC — The U.S. Postal Service Board of Governors will meet Aug. 9, 2022, in open session at Postal Service headquarters, 475 L’Enfant Plaza, SW, Washington, DC. The public is welcome to observe the meeting beginning at 4:00 p.m. ET in the Benjamin Franklin Room on the 11th floor. The Board is expected to discuss the following items: Printing via USPS News https://ift.tt/H9asexg July 26, 2022 at 01:45PM USPS Celebrates James Webb Space Telescope https://ift.tt/rZUKRfs The James Webb Space Telescope, the largest and most sensitive ever launched, can peer to the limits of the known universe. Printing via USPS News https://ift.tt/H9asexg July 26, 2022 at 10:06AM |

Categories

All

Archives

April 2023

|

Typically, Anna uses a combination of traditional and digital techniques to create her illustrations, and paints large scale murals by hand. Through her Hybrid series Anna merges these two different strands of her practice, combining the portrait aspect of her the illustration work, with the colourful and abstract shapes she uses in her big scale murals. The process was very playful, using fashion inspired imagery, dancing forms, and a palette of joyful bright flat colours.

Typically, Anna uses a combination of traditional and digital techniques to create her illustrations, and paints large scale murals by hand. Through her Hybrid series Anna merges these two different strands of her practice, combining the portrait aspect of her the illustration work, with the colourful and abstract shapes she uses in her big scale murals. The process was very playful, using fashion inspired imagery, dancing forms, and a palette of joyful bright flat colours.

Anna has worked with many clients in the UK and abroad including Vanity Fair Paris, Laurence King Publishing, the Guardian, the Financial Times, Penguin Books, Planet Mu Records, GQ, Green Man Festival, the National Institute of Fashion Italy and is a regular contributor to British Vogue.

Anna has worked with many clients in the UK and abroad including Vanity Fair Paris, Laurence King Publishing, the Guardian, the Financial Times, Penguin Books, Planet Mu Records, GQ, Green Man Festival, the National Institute of Fashion Italy and is a regular contributor to British Vogue.

Her working process involves drawings, mostly in a sketchbook, which are then rationalised in Illustrator to simplify and create plates ready for the press. Plates are then mounted on a heavy base to raise to type height for printing. Hofer also work with movable type, but image making has been their main focus. The studio is home to a Swiss-made FAG cylinder proofing-press, providing the opportunity to print with vibrant precision, coupled with the quirks and beauty that only letterpress printing offers. Plate making is currently the only process completed outside of the Hofer studio and print shop. Everything else is generated from the house of Hofer, reducing their environmental impact. Their inks are 90% salvaged, stock FSC-certified, and all packaging is compostable.

Her working process involves drawings, mostly in a sketchbook, which are then rationalised in Illustrator to simplify and create plates ready for the press. Plates are then mounted on a heavy base to raise to type height for printing. Hofer also work with movable type, but image making has been their main focus. The studio is home to a Swiss-made FAG cylinder proofing-press, providing the opportunity to print with vibrant precision, coupled with the quirks and beauty that only letterpress printing offers. Plate making is currently the only process completed outside of the Hofer studio and print shop. Everything else is generated from the house of Hofer, reducing their environmental impact. Their inks are 90% salvaged, stock FSC-certified, and all packaging is compostable.

Hofer take commissions, create greetings cards, prints, and ephemera. The main drive of the studio thus far been greetings cards, but they are shifting their focus to work on larger scale print making on the press. Sometimes the proofing press is just not big enough so they also offer a super-size Giclee process, and screen printing when budget allows. Their work is largely inspired by nature and the natural world, plants, and flora and fauna, and they are influenced daily by the shape, form, and colour found in nature and how this translates into the way we see the natural world.

Hofer take commissions, create greetings cards, prints, and ephemera. The main drive of the studio thus far been greetings cards, but they are shifting their focus to work on larger scale print making on the press. Sometimes the proofing press is just not big enough so they also offer a super-size Giclee process, and screen printing when budget allows. Their work is largely inspired by nature and the natural world, plants, and flora and fauna, and they are influenced daily by the shape, form, and colour found in nature and how this translates into the way we see the natural world.

From monstera to mangetout, cherries to carrots, Hofer nurture their love of nature through print.

From monstera to mangetout, cherries to carrots, Hofer nurture their love of nature through print.

Having always been interested in art, Alice studied a BTEC with a specialism in Fine Art at college, then went on to University to study Fine Art BA Hons. She started creating illustrations in her final year of uni as a way to make a bit of extra cash, and her career snowballed from there as she scored some exciting freelance jobs.

Having always been interested in art, Alice studied a BTEC with a specialism in Fine Art at college, then went on to University to study Fine Art BA Hons. She started creating illustrations in her final year of uni as a way to make a bit of extra cash, and her career snowballed from there as she scored some exciting freelance jobs.

Alice’s work focuses on bold colours and design styles, taking inspiration across a broad spectrum of artistic influences. Her work evokes a retro feel, implementing warm tones that are drawn from inspirations from the 60s/70s. Her studies in Fine Art also influence her work, and Alice often uses the Arts & Crafts and the Pre-Raphalite movements as a starting point for inspiration when doing work for herself.

Alice’s work focuses on bold colours and design styles, taking inspiration across a broad spectrum of artistic influences. Her work evokes a retro feel, implementing warm tones that are drawn from inspirations from the 60s/70s. Her studies in Fine Art also influence her work, and Alice often uses the Arts & Crafts and the Pre-Raphalite movements as a starting point for inspiration when doing work for herself.

“I have been working as a freelance illustrator for just over four years now, I feel I have found my illustrative style now but I am always striving to improve and find new techniques. I just hope I can continue to do my dream job and work on exciting projects, I would love to be able to do some more surface pattern design work and create a range of fabrics or homewares with these.”

“I have been working as a freelance illustrator for just over four years now, I feel I have found my illustrative style now but I am always striving to improve and find new techniques. I just hope I can continue to do my dream job and work on exciting projects, I would love to be able to do some more surface pattern design work and create a range of fabrics or homewares with these.”

RSS Feed

RSS Feed