|

Recycled HDPE Sandwich Composite Materials for Casting Using FDM 3D Printing https://ift.tt/2ZyEZ2Q In ‘Recycled HDPE reinforced Al2O3 and SiC three dimensional printed patterns for sandwich composite material,’ authors Narinder Singh, Rupinder Singh, Ranvijay Kumar, and IPS Ahuja explore new ways to create sacrificial patterns for investment casting using FDM 3D printing and recycled materials. While recycling is a major concern overall, worldwide, increasing use of thermoplastics raises even more questions in terms of waste disposal. Because of the challenge in separating sub-parts, researchers have been seeking other ways to recycle—expressly, without separation.

Previous research has been performed regarding recycled HDPE for wood composite, and WPC has been studied as well, although the authors inform us that bioplastics are usually cost-prohibitive for use. In most cases, however, polymers do include fillers meant to strengthen thermal and mechanical properties. Investment casting usually requires a mold and ceramic shells to create prototypes, with separation lines and inserts built into the molds. Structures are then finished, assembled, and filled with liquid wax, after which, the contents of the mold are broken out.

New technology has been responsible, however, for better accuracy and strength in final products created through rapid prototyping. In this research, the scientists used feed stock filament wire made of HDPE and reinforced with Al2O3/SiC (of average diameter 50 μm). Patterns were then fabricated on an open-source FDM 3D printer. Traditionally, such production would take up to three months just to make one part, costing up to $500. With FDM 3D printing, the process took only eight hours at the most. With die stone powder, the team was able to create a reliable sandwich composite material, offering shell stability, and temperature resistance up to around 1100 °C. Along with Al, other metals and alloys can be used too, with the end results presenting suitable surface hardness and porosity levels for prototyping.

Composite materials are becoming increasingly popular in the world of 3D printing and additive manufacturing as researchers continue to find new ways to produce better prototypes and parts, whether in using wood composites, continuous carbon fiber, metal polymers, or other polymer composites. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com. [Source / Images: ‘ Recycled HDPE reinforced Al2O3 and SiC three dimensional printed patterns for sandwich composite material’] Please enable JavaScript to view the comments powered by Disqus. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 31, 2019 at 11:42PM

0 Comments

FDM 3D Printing of Rocket Fuel Grains https://ift.tt/2SZcEjR In ‘Small-Scale Static Fire Tests of 3D Printing Hybrid Rocket Fuel Grains Produced from Different Materials,’ authors Mitchell McFarland and Elsa Antunes create a device to evaluate small-scale fuel grains, focusing on material regression rates, as well as comparing them to other hybrid fuels in experiments that are important to the space industry as new rockets and motors are created, using a variety of technologies and new materials. McFarland and Antunes explain that 3D printing has been the ‘most impressive advancement,’ and especially with FDM 3D printing as it offers all the benefits that are attractive to investors and manufacturers, from speed in production to substantial savings on the bottom line.

Typical casting and curing techniques can be more difficult—and despite improvements in such methods—designs are still limited in innovation and must account for post-processing in removing the tooling. Supports are not required for fuel grain fabrication very often, but even if they are, the structures are easily removed due to water-soluble materials. To complete their goal of analyzing regression, the authors performed several small-scale static fire tests with 3D printed materials, including:

Each grain was created 100 mm long and 20 mm in diameter, with a 6 mm diameter combustion port. The team 3D printed a series of ABS grains using a Prusa i3 MK2 FDM 3D printer, with the materials subjected to three-minute burns, tested, and measured.

Small-scale fuel grains, left to right: ABS, PLA, PETG (Polyethylene terephthalate glycol), PP, ASA, Nylon, and AL (PLA with aluminum particles).

Some of the settings were modified to avoid any defects that could affect the performance of the materials. The team noted ‘zits’ on the outer surfaces of some prints—describing them as ‘oozing’ in some cases, or ‘stringing’ across the chamber. For future projects and manufacturing of components, such issues would have to be resolved. For this experiment, the researchers emphasized that they were concerned with material selection over port geometry.

ASA had the highest average regression rate, followed by nylon, and then PEETG.

While the world of 3D design and 3D printing is full of wonders that are wide-ranging—and from around the world—the study of materials continues to grow more fascinating. 3D printing and additive manufacturing processes with metal are involving impressively, along with polymers, and many other alternative forms such as concrete, wood, and more. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com. [Source / Images: ‘ Small-Scale Static Fire Tests of 3D Printing Hybrid Rocket Fuel Grains Produced from Different Materials’] Please enable JavaScript to view the comments powered by Disqus. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 31, 2019 at 11:12PM Poietis: Bioprinting With Their Innovative Laser-Assisted Technology https://ift.tt/2OtaOcs

In 2013, the European Union passed legislation that instituted a ban on the sale of animal-tested products in the continent, followed by other countries like India, Israel, Norway, Taiwan, and New Zealand, while the practice is being contested in the US and other markets where it is still legal. Companies like Poietis are using 3D bioprinting technology to develop a more cost-effective, versatile, and ethical way for companies to go about testing. But that’s just one of their advantages, along with the development of the multimodal bioprinting platform Next Generation Bioprinting (NGB); the creation of Poieskin, commercial bioprinted human tissue; and the NGB-C system for clinical applications. In 2012 and after 20 years of professional experience in the biotech MedTech sector, the co-founder of Poietis, Bruno Brisson, met Fabien Guillemot (the other co-founder of the company and CEO).

Regulatory pressure everywhere to ban animal testing and concerns about animal experiments to model human health, along with the animal experiment ban for the cosmetics industry in Europe, has resulted in an evergrowing demand for in vitro alternatives. This is one of the reasons why Poeitis founders decided to first focus on in vitro applications for the skin tissue market. To do so, they hired an interdisciplinary team of physicists, software developers, biologists, and pharmacists to bring their expertise to the areas of laser and optics, microfluidics, machine learning, cell biology, and tissue engineering as well as cell therapy manufacturing. Their bioprinted in vitro models are used in dermo-cosmetics, but also in pharmaceutical research, for example, to evaluate the mechanism of actions for validating new drug candidates in the case of disease models. The company, headquartered in Pessac, France, soon developed partnerships with other firms. In 2015, chemical giant BASF signed an agreement with Poietis to 3D print skin for cosmetic testing purposes, using the 3D laser-assisted bioprinting technology to further develop its Mimeskin tissue, which is one of the closest equivalents to the original physiological equivalents of real human skin. After their success, they moved towards improving the skin models by increasing structure complexity and adding new cell types. Almost around the same time, Poietis became associated with the L’Oréal group and began researching how to bioprint hair as a viable solution for people suffering from alopecia.

A 16 layer 3D structure designed with Poietis CAD software and created with the NGB-R’s extrusion process At Poietis, the core of their expertise is the high-resolution laser-assisted bioprinting, after which they have based and developed their Next-Generation Bioprinting (NGB) platform, which they claim gives tissue engineers and researchers greater freedom in the choice of biomaterials and hydrogels, and greater versatility in their research and development. The two bioprinters currently marketed are the NGB-R Bioprinter (commercialized for research applications) and the NGB-C Bioprinter (a clinical-grade, GMP-compliant system dedicated to clinical applications and challenges of industrial manufacturing of implantable tissues).

At Poietis, they talk about the process as a form of 4D printing, claiming that “the approach consists in programming self-organized tissue (cells and extracellular matrix) that evolve in a controlled way until specific biological functions emerge”. So that by analyzing tissue evolution during maturation, they are able to optimize the initial tissue architecture defined by a CAD tool in order to improve the functionality of the printed tissues and guarantee that they are manufactured in the most reliable way. The company is developing dedicated software to program tissue self-organization, which means that they will anticipate the evolution of the bioprinted construct with time. And time plays a big role in 4D bioprinting, something which makes their system quite unique. We have talked about 4D printing before, which means creating 3D objects that change their shape over time in response to stimuli such as heat, moisture or light, making structures that easily adapt to their environment. On the hardware side, Poietis applies its laser-assisted bioprinting technique using laser pulses programmed to be sent every nanosecond, used to deposit microscopic droplets of cell-laden ink on a cartridge (composed of an ink film spread on a glass plate). Via the software, they can control the physical conditions of the ejection (like energy and viscosity), as well as the droplet volume to near picolitre accuracy. According to the company, the process can achieve 20 µm resolution at speeds of 10,000 droplets a second, resulting in cell concentrations of 100 million cells/mL and 100 percent cell viability. VIDEO The process led Poietis to develop Poieskin, a bioprinted skin made up of a human full-thickness skin model that is entirely produced by 3D bioprinting.

With a tissue engineering market worth an estimated 15 billion dollars, and growing, the bioprinting industry is getting a lot of attention, and companies all over the world are taking notice. Poietis has three patents covering its bioprinting technology, and a recent financing round of five million euros to accelerate technological developments that could lead to the first implantation of a bioprinted tissue into patients starting in 2021, and is well is on its way to becoming one of the innovative European startups to look for during the coming years.

The bioprinting technology available at Poietis is the result of innovative research, and over a ten-year time lapse at Inserm and the University of Bordeaux, resulting in wins at the iLab competition in 2014, the World Innovation Challenge Phase II in 2017, and most recently the EY Disruptive Strategy Award. But Poietis is lucky to be among a forward-looking bioprinting environment. The groundbreaking technology has seen some challenges over the last few years, and not every country has made efforts to help with its development.

In many ways, Poietis has begun to change the future of regenerative medicine and the manufacture of living tissue. With uses in cosmetics and drug testing that are quickly becoming an alternative to animal testing everywhere, the company is fast to becoming a household name in France, pushing the advances of their innovation into clinical labs and giving researchers more tools to efficiently surpass the limits of bioprinting. We’ll have to wait until 2021 before the first implantation of bioprinted tissue into patients become a reality. Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 31, 2019 at 08:24AM Scientists Use 3D Printed Models to Further Congenital Heart Disease Studies https://ift.tt/2YzD6lt In the recently published ‘Accurate Congenital Heart Disease Model Generation for 3D Printing,’ researchers explore 3D printing for diagnosis, treatment, and planning in congenital heart disease (CHD) patients. CHD usually presents itself at birth and can be difficult to analyze, even with 3D medical images—and despite many different studies by scientists around the world. The researchers note that 3D printing has been ‘widely adopted’ in clinical settings lately, offering for improvements in the following:

(Top) Examples of large structure variations in CHD. In normal heart anatomy (a), PA is connected to RV. However, in pulmonary atresia (b), PA is rather small and connected to descending Ao. In common arterial trunk (c), Ao is connected to both RV and LV, and PA is connected to Ao. (Bottom) Pulmonary atresia and common arterial trunk examples in our dataset, with large variations from normal heart anatomy. In the dataset for this research, combining deep learning and graph matching for whole heart and great vessel segmentation in CHD, patients ranged in age from one month to 21 years old—while most were from one month to two years old. Out of 16 cases, the study covers 14 types of CHD to include the most common 8, which are atrial septal defect (ASD), atrio-ventricular septal defect (AVSD), patent ductus arteriosus (PDA), pulmonary stenosis (PS), ventricular septal defect (VSD), co-arctation (CA), Tetrology of Fallot (ToF), and transposition of great arteries (TGA).

Overview of the proposed framework combining deep learning and graph matching for whole heart and great vessel segmentation in CHD. The researchers explain that there has already been a prolific amount of research using the multi-modality whole heart segmentation method, with ‘state-of-the-art performance’ found in combining 3D U-net for segmentation and a simple convolutional neural network for label position prediction. Another technique involves using the basic simple convolutional neural network for label position prediction, while another handles blood pool and myocardium in blood pool segmentation.

Motivated instead by the promise of graph matching, they used deep learning and graph matching, collecting 68 CT images overall, with an 11.9 percent higher Dice score. The framework consisted of:

Segmentation results were printed on a Sailner J501Pro for evaluation—a process that took the researchers about three to four hours. The researchers assessed the 3D printed model as correct, and with clear shape and connections, with minor refinements necessary such as thin coronary vessels.

3D printed models have proven to be more than just helpful in many different areas of the medical realm, especially as they are able to offer so much in terms of education not only for students but also for patients and their families, as well as helping in the preoperative stages—and during the actual operation too with surgical planning models.

(Top) Visualized comparison between the state-of-the-art method Seg-CNN [12] and our method. The differences from the ground truth are highlighted by the red circles. (Bottom) Examples of 3D printing models using our method with some minor manual refinement. [Source / Images: ‘ Accurate Congenital Heart Disease Model Generation for 3D Printing’] Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 31, 2019 at 07:54AM Experiments with 3D Design and 3D Printing of Mesh Fabrics with FDM and PLA https://ift.tt/2Kf6Uyx 3D printing and materials are an intertwined science, and one that many researchers, engineers, and manufacturers put a lot of research and development into today—all working toward the goal of perfecting production. In ‘Design for Material Extrusion on Mesh Fabrics,’ UK researchers delve more specifically into the use of ‘off-the-shelf’ PLA for mesh fabrics created via FDM 3D printing. Their study was created for the purpose of helping designers understand more about the complexities of progressive fabrication techniques and specifically, issues in adhesion. Additive manufacturing and 3D printing offer huge opportunities for fashion designers to innovate, and produce an infinite array of patterns and textures, along with complex geometries as desired. The researchers categorize 3D printed textiles as either fully 3D printed and flexible or 3D printed polymers that have been placed on textile fabrics as an addition afterward. Because fashion design is such an artistic endeavor, 3D design and printing are an enormous technological complement, allowing for innovation that may not have been possible before. The researchers explain that 3D printing offers new applications for the following:

Advanced studies are needed, however, to address and conquer numerous challenges that other users are continually battling such as diminishment of mechanical properties, adhesion issues, finishing processes, and more. Here, samples were created with Prusa PLA, using a Prusa i3 MK3 printer. The researchers experienced challenges as the first sample was found to be extremely poor in terms of adhesion and stability, but the second one was much more positive.

The fabric set up secured using clips. It is recommended to cut the fabric to the size of the build platform (25cmx23cm) so that it can be stretched flat on the build platform, preventing the nozzle to be caught on the fabric.

The specimen set up on a Universal Testing Machine for T-Peel Test. The specimen was clamped firmly on the grips of the testing machine without slippage throughout the test. The research also uncovered data regarding porosity, showing that larger pores resulted in a better intermolecular bond between layers, with PLA-F1 and PLA-F3 offering larger pore sizes. The team also found that in 3D printing on mesh, many adhesion issues can be prevented as they present ‘opening gaps’ for firm adhesion measures; however, lower ‘stretch-ability’ allows better adhesion consistency too. Ultimately, the study showed that laminating fabric in between two polymer layers is the secret to creating a bond, with form-locking connections, working well with the following:

Surface properties are important, along with chemical properties and the makeup of the substrate. Previous research has also shown that polymers have better adherence success on:

3D printing has been an enormous boon for designers around the world, as well as users interested in using materials and textiles for manufacturing purposes. In fashion, we have seen 3D meld into the next dimension with the 4D Kinematics dress, to entire collections including jewelry and shoes, and a variety of new materials and inks. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com. [Source / Images: ‘ Design for Material Extrusion on Mesh Fabrics’] Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 31, 2019 at 06:15AM Open Source DIY Telescope Prime Features Raspberry Pi and 3D Printed Parts https://ift.tt/31fbQKT While the majority of us are not astronauts, there is a tool that can be used in your home to make you feel like you’re just a little bit closer to the stars – the telescope. Five years ago, a group of UK researchers from the University of Sheffield, including physicist Mark Wrigley, were inspired by NASA’s Juno spacecraft to create their own DIY telescope, the PiKon, using 3D printing and a Raspberry Pi. Now, a pair of Polish scientists have followed in their footsteps with their own parametric, open source, DIY telescope with 3D printed parts. Aleksy Chwedczuk and Jakub Bochiński wanted to help popularize astronomy by making their own semi-professional, yet affordable, telescope model for at-home use, for which people can then download the files and create on their own. Chwedczuk and Bochiński call their creation the Telescope Prime, and created the first prototype in just eight hours. The initial prototype was then used to take pictures of the moon, and the final version was finished in less than three months. Polish 3D printing company Sygnis New Technologies offered to help the scientists create their DIY telescope by sharing their equipment.

The telescope model, which all together costs less than $400 to put together, is made of three main parts: the 20 cm diameter parabolic mirror (with a recommended focal length of 1 m), a Raspberry Pi microcomputer with a camera and touch display, and 3D printed parts that are used to fix the camera and the mirror. To help keep costs down, “readily available materials,” like wood, screws, and a paper tube, are used to build the Telescope Prime. In a further effort to keep the telescope fabrication as inexpensive as possible, it does not have lenses. Light is focused in a single spot, and stops on the mirror. A boarding tube makes up the body of the device, and plywood parts are then added. The telescope can use its build-in camera to take images of the night sky, and transmit them online in real-time using the touchscreen of a computer, projector, or tablet. Additionally, you can easily increase and reduce the size of the telescope – just enter the mirror’s size into the program, and all of its dimensions will be automatically converted.

The open source models for the telescope parts, which are available for download on the Telescope Prime website, were prepared in advance for 3D printing, so they didn’t need any corrections later. These elements were 3D printed on FlashForge 3D printers out of Orbi-Tech PLA material, and it took a total of 156 hours of printing to create the 17 telescope parts. Kamiński told 3DPrint.com that the two scientists are currently “promoting the project on Polish universities, schools and science institutes.” This makes sense, as the Telescope Prime website explains that the project was “initiated and fully carried out” on the grounds of the Akademeia High School in Warsaw. Discuss this story and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below. [Source/Images: Sygnis New Technologies] Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 31, 2019 at 02:27AM Board of Governors Temporary Emergency Committee to meet Aug. 9 https://ift.tt/2ZjKsul WASHINGTON — The Temporary Emergency Committee (TEC) of the Board of Governors of the U.S. Postal Service will meet Aug. 9, 2019, in open session at Postal Service headquarters, 475 L’Enfant Plaza, SW, Washington, D.C. The public is welcome to observe the meeting beginning at 9:00 a.m. ET in the Benjamin Franklin Room on the 11th floor. The TEC is expected to discuss the following items: Printing via USPS News https://ift.tt/2hH9aDC July 30, 2019 at 01:21PM Upcoming 2019 stamp dedications https://ift.tt/2K9uVHi New Stamp Revealed Printing via USPS News https://ift.tt/2hH9aDC July 30, 2019 at 10:50AM Additive Manufacturing Materials Talent Insight https://ift.tt/2ZlfLoF Recently, at AMPM2019 Conference in Phoenix, Additive Manufacturing industry experts identified materials as one of the main challenges of the 3D printing industry and its growth. Developing more materials in Additive Manufacturing means a higher demand for materials specialised professionals in the AM industry. i-AMdigital has researched the talent landscape within AM materials, to identify where this talent can be found, and what the top employers, universities and technologies used are. Who are the materials specialists, working with 3D Printing?

According to LinkedIn data analysis from June 2019, the three educational backgrounds that dominate the profiles of the AM material specialists are Material Sciences, Materials Engineering and Mechanical Engineering, with respectively 28%, 25% and 20%. Mechanical and material engineering often go hand in hand, and the design of any machine cannot be separated from the materials used to make it, or the materials it will use itself. Moreover, materials must be developed and tested to achieve certain mechanical properties required by certain applications, verticals, markets and certification. This is the reason for the large percentage of mechanical engineering backgrounds. We are likely to see an increase in this combination of mechanical and materials engineering. Whilst the metallurgical engineering background still holds a rather small percentage (3%), we are likely to see an increase in this, as the metal AM business is booming, and experienced metallurgists are increasingly highly sought-after. Top 3D Printing technologies, used by AM materials specialists

i-AMdigital found that an impressive 38% of AM materials specialists primarily work with the Metal Powder Bed Fusion technology. This large percentage can be explained by the impressive boom in the metal AM market; according to the Wohlers’ Report 2019, the industry revenue from metals grew by 41.9% during 2018. This reflects the shift in the AM industry towards developing solutions better suited for serial production rather than rapid prototyping. With 38% of material specialists working in metal AM, a 42% growth of the Metal AM market, and only 3% of material specialists coming from a metallurgy background, we can see a significant skills gap; the industry needs more materials specialists with metal background. Who are their employers?

i-AMdigital investigated the companies employing the highest amount of AM material specialists, and found that they spread across several sectors of the industry; from end-users to 3D Printing Original Equipment Manufacturers. The large employment of material specialists in end-user companies can be explained by the increase in the adoption of 3D Printing. According to Scupteo’s 2018 The State of 3D Printing report, there was an increase of 21% in the adoption of 3D Printing in production environments between 2017 and 2018. End-users, like Boeing and Rolls Royce, are increasingly adopting AM for producing more complex parts with more intricate design, as well as for tooling and prototyping. Employing material specialists is crucial for these end-users to adopt the technology efficiently and to help understand the capabilities of the machines and materials at hand. The AM OEM’s work hand in hand with end-users in order to (together) develop new applications, materials and software – and for that, they need material talent. 3D printing giants HP and Stratasys are natural appearances on this list of largest employers; their continuous development of new machines and applications require them to have a strong team of materials specialists to help drive their R&D departments. Moreover, the new markets and applications that are being explored by the AM OEM’s require new materials, which requires more AM material scientists and specialists. Where are the AM material specialists located, geographically?

Which educational institutions house the talent? www.i-AMdigital.com is a free platform dedicated to upskilling talent in the 3D Printing industry, in the pursuit of providing the industry and employers with a continuously growing talent pool. Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com July 30, 2019 at 10:24AM

https://ift.tt/2KaJqKU

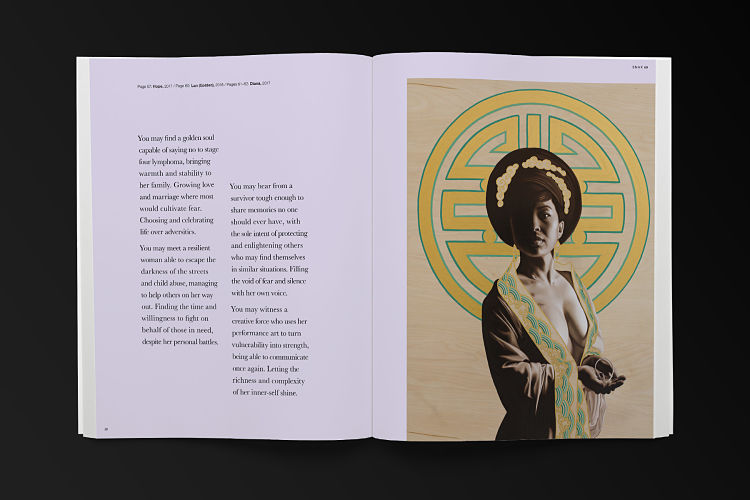

Snax Magazine https://ift.tt/331yKHe Snax Magazine is a carefully curated print experience that promotes independent visual artists. Now available on Department Store, their mission is to create engaging and tangible artistic experiences that directly connect independent artists to the community. At Snax Magazine, the team believe that in an exceedingly digital world, print is still one of our society’s purest and most intimate forms of communication.

Proudly printed in Brooklyn, NY on FSC certified papers with non-toxic, vegetable-based inks, grab your limited edition copy below. www.snaxmagazine.com

Printing via People of Print https://ift.tt/2DhgcW7 July 30, 2019 at 03:57AM |

Categories

All

Archives

April 2023

|

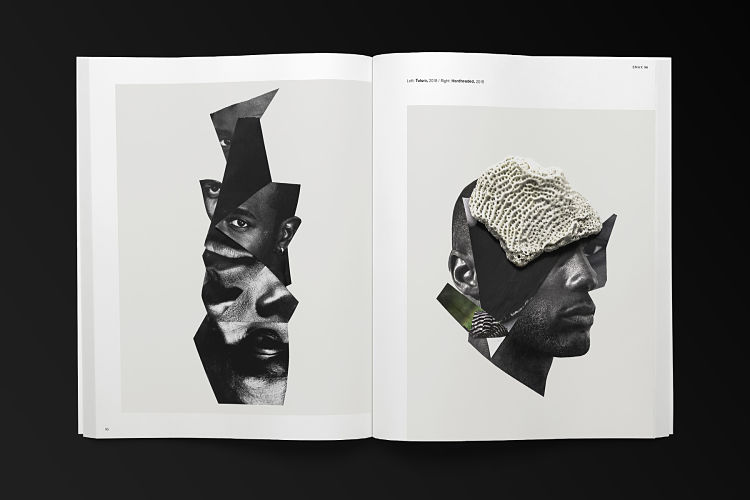

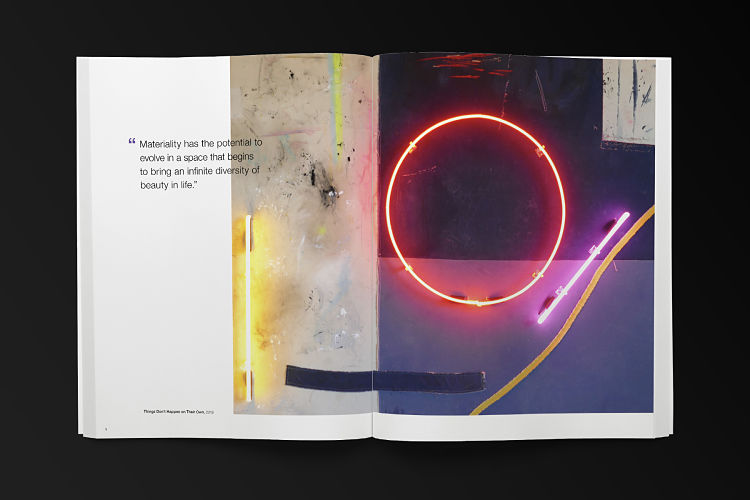

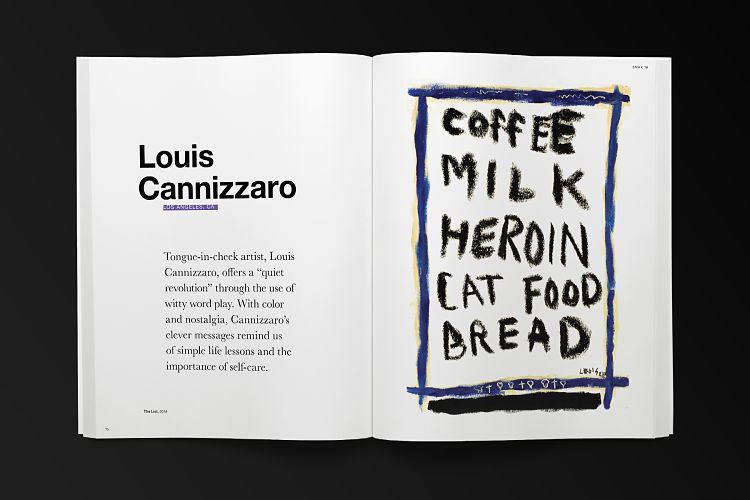

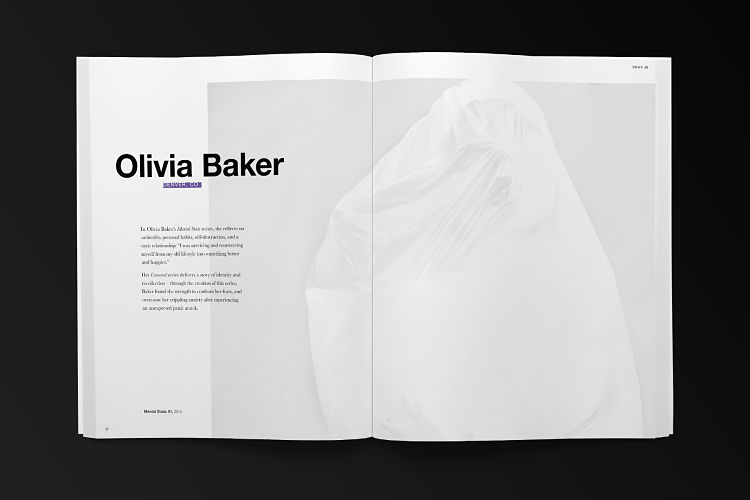

In Issue 6, The Phoenix Issue, talented artists from around the world are brought together to share stories of suffering, endurance, and light. From intimacy and self-awareness, to mental health and landscapes, the theme is reflected in many ways. The latest issue is a gallery of dynamic and powerful artwork that represent the theme of survival and resurrection.

In Issue 6, The Phoenix Issue, talented artists from around the world are brought together to share stories of suffering, endurance, and light. From intimacy and self-awareness, to mental health and landscapes, the theme is reflected in many ways. The latest issue is a gallery of dynamic and powerful artwork that represent the theme of survival and resurrection.

Featured artists include Ajidagba Goodwin, arwalker, Cavier Coleman, Constance McBride, Danni Morris, Em North, Eric Papa, Harlan Hue, Ian Shepard, Jodie Herrera, Jose Romero Jr., Kestin Cornwall, Louis Cannizzaro, Marta de la Parra Prieto, Norm Yip, Ntangou Badila, Oli Berg, Olivia Baker, Shawn Theodore (xST), Terry Urban, Tristan Lindo and Vincent Chung.

Featured artists include Ajidagba Goodwin, arwalker, Cavier Coleman, Constance McBride, Danni Morris, Em North, Eric Papa, Harlan Hue, Ian Shepard, Jodie Herrera, Jose Romero Jr., Kestin Cornwall, Louis Cannizzaro, Marta de la Parra Prieto, Norm Yip, Ntangou Badila, Oli Berg, Olivia Baker, Shawn Theodore (xST), Terry Urban, Tristan Lindo and Vincent Chung.

RSS Feed

RSS Feed