|

http://img.youtube.com/vi/Z36rb4D993w/0.jpg

3D Printing News Unpeeled: Microwave Kilns, Bike Holders and Fiber Optics https://ift.tt/cjvqe2f An international team of Korean, British, German and Australian researchers have managed to make a nano printed camera that fits onto the tip of a fiber optic cable. That may improve noninvasive medical imaging and procedures as well as sensors. The Virtual Foundry’s materials are being used by a maker in microwave kilns. Jankcomponents showcases us a bicycle holder business.

The post 3D Printing News Unpeeled: Microwave Kilns, Bike Holders and Fiber Optics appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/t3QgHY6 October 31, 2022 at 11:28AM

0 Comments

U.S. Postal Service Board of Governors to Meet Nov. 10 https://ift.tt/9YCGyoT WASHINGTON, DC — The U.S. Postal Service Board of Governors will meet Nov. 10, 2022, in open session at Postal Service headquarters, 475 L’Enfant Plaza, SW, Washington, DC. The public is welcome to observe the meeting beginning at 8:30 a.m. ET in the Benjamin Franklin Room on the 11th floor. The Board is expected to discuss the following items: Printing via USPS News https://ift.tt/S0KGFOx October 31, 2022 at 11:21AM Imaginarium 3D Printing Service Becomes First Member of HP Digital Manufacturing Network in India10/31/2022

https://ift.tt/QADt8N9

Imaginarium 3D Printing Service Becomes First Member of HP Digital Manufacturing Network in India https://ift.tt/pRCrBqL Imaginarium, a rapid manufacturing and prototyping company in Mumbai, announced that the company has become the first member of HP’s Digital Manufacturing Network (DMN) in India. In the press release announcing the expansion of the DMN into what is expected to soon become the world’s most populous nation, representatives of both companies cited a longstanding working relationship as the primary reason behind Imaginarium’s selection as India’s first DMN partner. Relatedly, Imaginarium also recently acquired the HP Jet Fusion 5200, designed for mid-volume industrial use with a variety of different thermoplastics. Imaginarium works with a number of Western companies, including the Dutch original equipment manufacturer (OEM) Ultimaker, which announced a partnership with Imaginarium earlier this year. In addition to 3D printing, the company also utilizes a range of other advanced manufacturing techniques, and provides software services and training.

HP, for its part, has been doing business in the nation since 1964, and at the end of 2021 announced its plans to produce in India the desktops, laptops, and monitors that the company sells there, at its production facilities in Chennai. Those plans are in line with the Make in India initiative that has been a part of Prime Minister Modi’s administration since its inception, and which was updated with a National Strategy on Additive Manufacturing (AM) at the beginning of 2022. India’s AM progress has quickly and consistently grown this year, not just in terms of partnerships with Western companies like Phillips, but also concerning homegrown projects like its military’s use of concrete printing. As I always mention in posts about the nation, the buildup of India’s manufacturing base has taken on new meaning since the formalization of an Indo-American Basic Exchange and Cooperation Agreement, during the lame duck part of the Trump administration.

Thus, the expanding presence of Western tech OEMs in India has to be viewed in the context of growing tensions between the US and China over Taiwan, among a variety of other issues. The military alliance between the US and India is an insurance policy against the US’s potentially someday getting shut out of the South China Sea. Beyond that, HP simply sells a substantial amount of hardware in India. HP’s eventual production of everything in India that it sells in India would constitute/require an enormous shift in supply chains. On the AM side, the company’s entry into the Indian market likely won’t end with Imaginarium, in which case HP could hypothetically start using the Indian market as a test case for mass printing of components of its own tech products (as it does 3D print parts of its MJF printers). In any event, the supply chain chaos like the drought-glut supply cycle the world has experienced over the last couple of years — most recently concerning chips — makes on-demand production close to the point of sale the only realistic long-term strategy for global conglomerates hoping to ensure supply-chain security. The post Imaginarium 3D Printing Service Becomes First Member of HP Digital Manufacturing Network in India appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/t3QgHY6 October 31, 2022 at 09:09AM

https://ift.tt/WgI0aVf

Meet the CEOs of AM Investment Strategies 2022 https://ift.tt/GogamTX On November 10, 2022, a week ahead of Formnext, 3DPrint.com, SmarTech Analysis, and Stifel’s Global Technology Investment Banking Group will be hosting a free online event that will give attendees unprecedent insight into the financial landscape of the 3D printing industry. Over the course of two panels and three hours, attendees will have a chance to listen to 3D printing CEOs, analysts, investment bankers, and a venture capital director discuss the financial state of the industry. To prepare attendees for the event, we are profiling the panelists involved. In a previous article, we discussed the AM financiers participating in AM Investment Strategies. Here, we’ll take a brief look at the executives that will be spread out across the two panels of the event. Panel 1FormlabsA manufacturer of low-cost, professional 3D printers, double unicorn Formlabs is a uniquely successful startup in the additive manufacturing (AM) sector and its CEO, Max Lobovsky, will be participating on Panel 1, from 9:00am to 10:30am. During last year’s AM Investment Strategies, Lobovsky had strong opinions on such topics as whether or not his firm would go public. He may have since been vindicated, due to the faltering climate for SPAC companies. Velo3DOne of the most exciting startups in the AM industry today, Velo3D represents a sort of benchmark for the status of the sector. The company’s tightly controlled metal laser powder bed fusion (PBF) technology has been used by numerous manufacturers to produce unique parts for high-performance sectors ranging from space to oil and gas. CEO Benny Buller will be able to discuss his firm’s SPAC journey and the state of the industry now as it compared to when he first entered the market. 3D SystemsAs the inventor of 3D printing, 3D Systems is in a novel position in our first panel, as it has continuously transformed alongside the industry as a whole. CEO Jeff Graves has taken the 3D printing stalwart in a new direction more recently, expanding its focus from industrial products to regenerative medicine, all while streamlining the company’s entire operation. How has this approach worked out for 3D Systems so far? Markforged

On the heels of a SPAC IPO, Markforged remains one of the sector’s most promising firms with its broad range of specialty 3D printing technologies. Most recently, the business entered the metal binder jet space with the acquisition of Digital Metal, instantly shifting the competition of this burgeoning sector. President & CEO Shai Terem’s insight into the road toward mass production of 3D printed metal parts will be invaluable in this regard. Panel 2Desktop MetalRepresenting one of the most exciting companies in AM, Desktop Metal CEO Ric Fulop will be present on our second panel of the day. Kicking off the SPAC IPO trend, Desktop Metal has been shaking up the industry altogether, making some interesting and potentially controversial acquisitions. Is it on track to become the AM behemoth it seeks to be? With the largest market share in metal binder jetting, there is a distinct possibility. StratasysAlongside Panel 1’s 3D Systems, Stratasys is the most established 3D printer OEM in the market. Not only does it have the largest market share in 3D printing, but its acquisition of several firms along with internal developments has given it a broad range of five AM technologies. CEO Yoav Zeif will be on board to discuss if he is able to successfully integrate these new businesses amid a turbulent economy. Fathom Manufacturing

Fathom Manufacturing is a unique player in the 3D printing services space, as it was essentially created by investment firm CORE Industrial Partners. CEO Ryan Martin has guided the business as it has made numerous acquisitions in an attempt to build one of North America’s leading 3D printing service bureaus. How has it’s SPAC IPO impacted its fortunes? ASTRO AmericaASTRO America is a standout among this crowd. Not a 3D printing company, but a non-profit 3D printing think tank, the organization is made up of AM and U.S. military veterans. This is particularly true of President & Co-Founder Neal Orringer, who has worked in a number of roles in the U.S. government and with 3D Systems. The group is closely affiliated with the Biden administration’s AM Forward program and Orringer will likely have keen insight into how this initiative can present opportunities for AM investment from our panelists and beyond. Morf3DMorf3D is specialty AM service bureau acquired recently by Nikon. With everything it takes to manufacture high-performance items for high-performance sectors, including space and aerospace, the company represents a new generation of service bureaus that are capable of producing the highest standards of parts for industrial giants. CEO Ivan Madera is in a novel position to discuss how to successfully scale a business, secure investments, and thrive within a rapidly growing and competitive space. Representing just a handful of the panelists participating in in the two roundtables of the day, these three experts are wealth of knowledge unto themselves. To register for the event, visit the AM Investment Strategies 2022 page. The post Meet the CEOs of AM Investment Strategies 2022 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/t3QgHY6 October 31, 2022 at 09:09AM Leading Saudi Construction Firm Breaks Ground on First Two-Story 3D Printed Home in Middle East10/31/2022

https://ift.tt/gIwrP0W

Leading Saudi Construction Firm Breaks Ground on First Two-Story 3D Printed Home in Middle East https://ift.tt/65vtoX0 Dar Al Arkan, the largest property developer in the Kingdom of Saudi Arabia (KSA), announced that the company has broken ground on the Middle East’s first two-story home built with additive construction (AC) methods. Dar Al Arkan announced its first residential 3D printed construction project in the summer of 2021.

Concurrently with the first project’s launch, Dar Al Arkan also announced that the company had partnered with the leading firm in the AC market segment, Denmark’s COBOD. Relevantly, COBOD’s signature machine, the BOD2 concrete printer, is also in-use on the recently announced project in Houston, Texas to construct the US’s first two-story printed residence.

Vision 2030 is an all-encompassing economic and infrastructural overhaul that the KSA announced in 2016, a little over a year before King Salman deposed his nephew, Muhammad bin Nayef, as Crown Prince, replacing the latter with Mohammed bin Salman (MBS), who is King Salman’s son. Given that MBS was the one who, as deputy Crown Prince, announced the Vision 2030 plan, the decade-plus megaproject is often viewed as interchangeable with his leadership. In particular, it is seen as an effort to deflect away from some of KSA’s more flagrant human rights abuses. Along with a general plan to wean the Kingdom’s economy off of its dependence on fossil fuel profits, the centerpiece of Vision 2030 is the project called NEOM, the name for the wildly ambitious, futuristic, idiosyncratically narrow smart city that KSA has been hyping for years. That project is drastically behind schedule: initially announced in 2017, NEOM was intended to be partially finished by 2020, and expanded by 2025. Delays related to the exodus of Western businesses from KSA owing to the assassination of journalist Jamal Khashoggi, followed by the pandemic, now make those deadlines seem impossible. On the other hand, Dar Al Arkan, for one, seems to be pushing along on the Shams Ar Riyadh project, a “city-within-a-city” in KSA’s capital, which is also the largest city on the Arabian peninsula. Both of Dar Al Arkan’s printed villa projects are a part of Shams Ar Riyadh, which has already sold out of all its units. Additionally, MBS announced another project last week, worth $10 billion, called the Global Supply Chain Resilience Initiative. Considering the growing inextricability between additive manufacturing (AM) technologies and the idea of supply chain resilience, KSA is almost certainly in the process of ramping up its incorporation of AM — including the AC market segment. Along those lines, does it matter if NEOM is never, in fact, built? Given KSA’s progress on admittedly less ambitious, less broad-sweeping projects, NEOM could end up proving just as valuable as a sandbox for new tech as it ever would be as a real place where people actually live. Moreover, the growing bonds between KSA and China suggests a realistic rationale behind the possibility that the Kingdom could be having to go to evermore extreme lengths to hide its hand on the global stage. NEOM may never be completed, but if KSA’s economy is transformed in the process of its development, that might be easily forgiven. Images courtesy of Dar Al Arkan The post Leading Saudi Construction Firm Breaks Ground on First Two-Story 3D Printed Home in Middle East appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/t3QgHY6 October 31, 2022 at 09:09AM 3DPOD Episode 126: Mass 3D Printing with Joe Allison, Evolve Additive CEO https://ift.tt/UVGvTM9 CEO of Evolve Additive Joe Allison got started with 3D printing in 1987. After working for 3D Systems, he started Solid Concepts, which would grow to become one of the world’s largest additive manufacturing service bureaus before its ultimate purchase by Stratasys. In turn, Joe served as the CEO of Stratasys Direct Manufacturing. What’s more, it would pioneer parts on commercial aircraft, drones, and in all sorts of applications. Joe tells us of his pioneering role in the industry and what he is doing now at Evolve Additive, where he was appointed CEO this past summer. Really exciting episode that covers a lot of things that you may not know. The post 3DPOD Episode 126: Mass 3D Printing with Joe Allison, Evolve Additive CEO appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/t3QgHY6 October 31, 2022 at 09:09AM

https://ift.tt/lWtmaZ6

This Is Halloween: Spooky 3D Printed Ghosts & Ghouls & Pumpkins https://ift.tt/QTjZFqh There’s nothing scarier than not having decorations for your Halloween party. So we’ve compiled a short list of some of our favorite spooky 3D printed models from Thingiverse, MyMiniFactory, Pinshape, and Cults3D. Check them out below! Jumpy GhostyThis first one, by Thingiverse user Tomo_designs, is so cute and bouncy I can’t handle it! The little ghost can work as a decoration, but also as a toy, because he can jump up in the air. It’s a two-part print that doesn’t require any supports, and the legs on the bottom that give him a bounce in his step snap right on. Skeleton Candy BowlNothing says Halloween quite like candy, and this spooky candy bowl by MyMiniFactory user Merlwynd certainly does the trick! It was printed out of PLA, on a Prusa i3 MK3, and looks like it would hold several delicious mini candy bars. Halloween skull lampsSpeaking of skeletons, this fantastic skull lamp by Pinshape user mingshiuan was remixed from a Skull Playset design on Thingiverse and will certainly light up the room at your Halloween party! Meshmixer was used to design the lamp, while Makeware was the slicing tool, and it was printed on a Flashforge Creator out of PLA with 0% infill, two shells, 0.2 mm layer height, and 60 mm per second extrusion speed. Cute ghost earringsIf you want to be the best-dressed ghoul at the party, you’ll definitely need these adorable 3D printed ghost earrings, by Cults 3D user twothingies, which could also be worn as pendants. They’re an easy print, with 0.15 mm layer height and a 0.4 mm nozzle, and even with a color change at the 7th layer, the whole print took less than ten minutes!

MX5 Light-Up TeethYou’ll feel like you’re in Stephen King’s novel Christine with these 3D printed light-up fangs for your car by Thingiverse user timmyisasleep! You’ll need both black and white PLA filament, and a strip of LED lights, wiring, two M8 hex head bolts, two M8 nuts, two large M8 penny washers, and red paint for the blood on the bottom. In addition to a 3D printer (this user printed the teeth on a Creality Ender 3), you’ll also need a soldering iron and solder, hot glue gun and glue, and a small paint brush. The fangs print without supports or rafts, at 0.3 resolution and a 30% infill, and the assembly instructions have been listed.

Flexi Print-In-Place Skeleton HandI love these flexible skeleton hands by MyMiniFactory user peterlanoie so much because they’re so versatile. You could use them almost anywhere—just sitting next to the food at your party, hanging on to the edge of the candy bowl during Trick or Treat, gripping the banister with the aid of some double-sided tape, etc. If you have a shirt with long enough sleeves, you could even hold one so it’s part of your Halloween costume! These were 3D printed out of beige PLA on a Creality CR-6 SE system. Halloween: Spider-web ring dishIf you’re rolling cookie dough or meatballs for a party, or you decide to go with my idea of using the skeleton hands in your costume, you may need a place to store any rings you might be wearing, and where better than this little 3D printed ring dish in the shape of a spider web? Pinshape user lu_yu described it as a “unique little accessory item for your Halloween themed party,” and that’s the perfect description. If you don’t want to put rings in the dish, you could also maybe use it to hold your car keys, or just set it out as a fun decoration. Brain texture roller cookie cutterJust like the description by Cults 3D user 3Demon says, this set of cookie cutters and cookie stamp roller is “perfect for when you’re having zombies over!” One part of the cookie cutter stamps the brain pattern, while the other cuts out the shape, so you don’t have worry if you’ve rolled out your dough too thin. These models print without supports, and the recommended settings are a 15% infill and 0.15 mm layer height. Mmm, brains…

Happy Halloween from everyone here at 3DPrint.com! The post This Is Halloween: Spooky 3D Printed Ghosts & Ghouls & Pumpkins appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/Sb7B4RA October 31, 2022 at 07:35AM

https://ift.tt/CdXEUsM

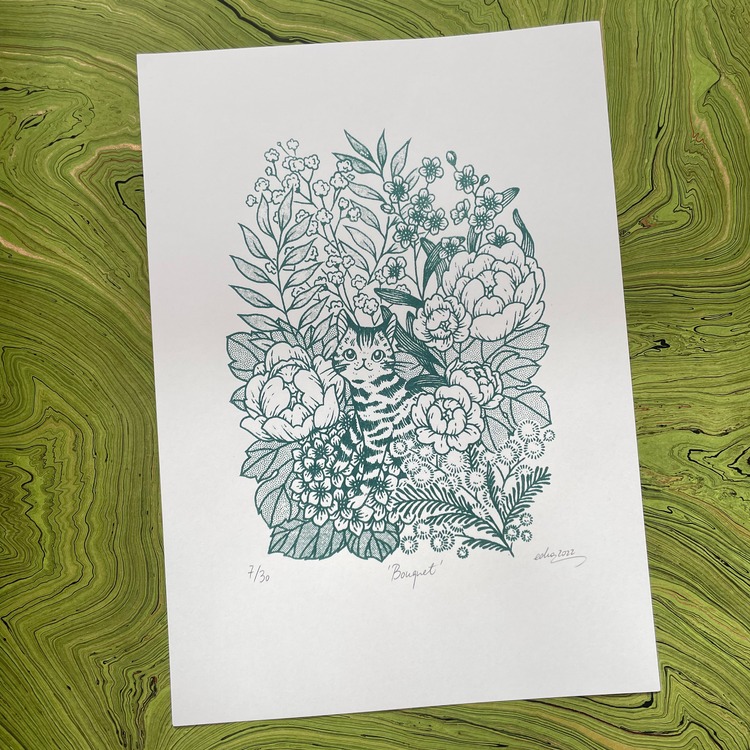

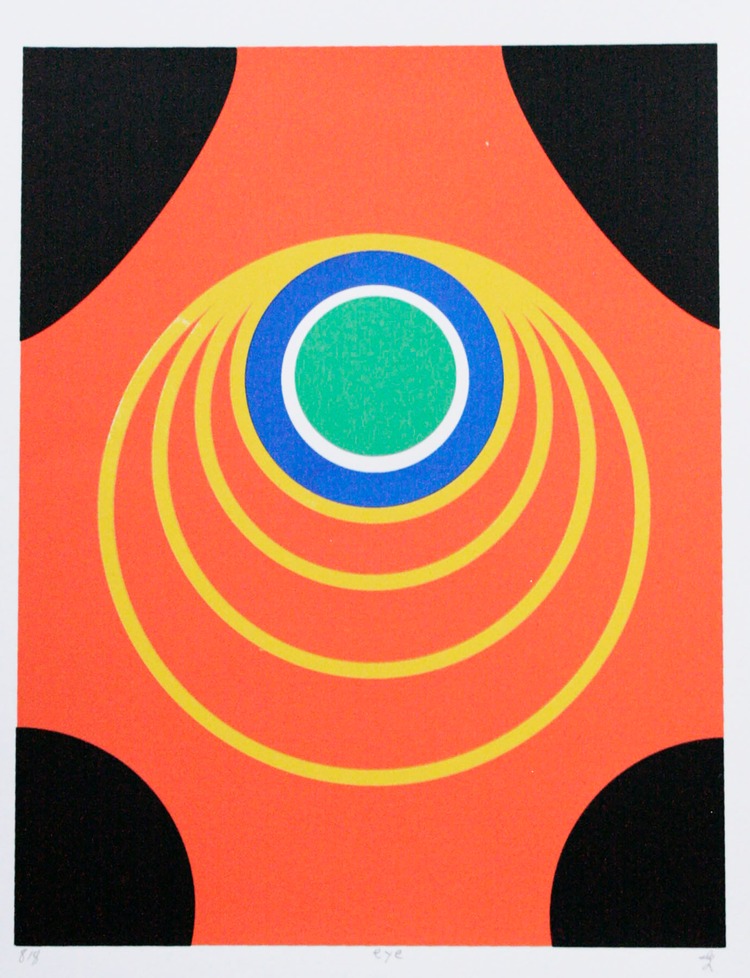

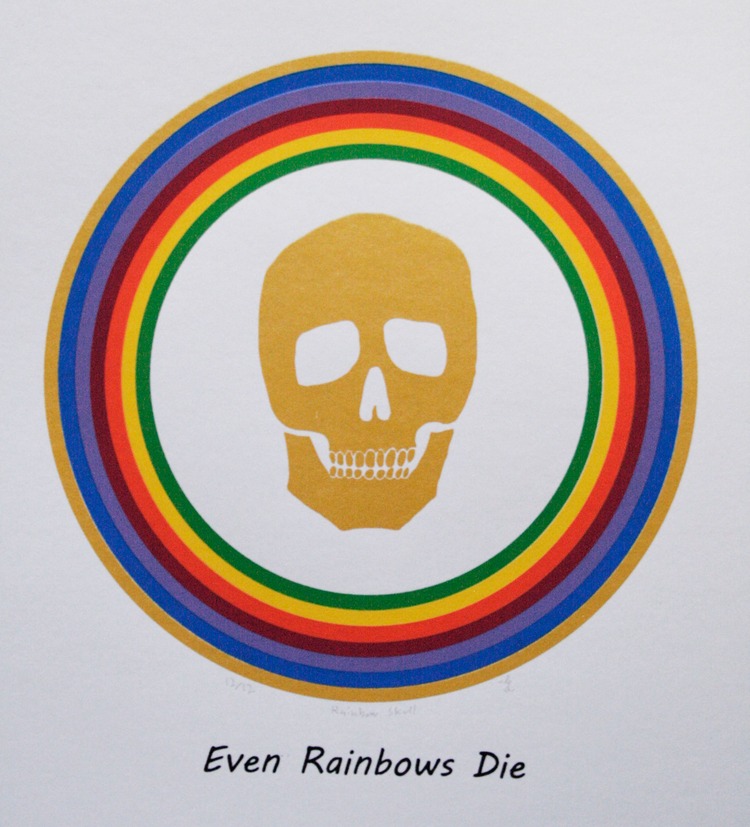

POP Member Showcase | 7 Screenprints https://ift.tt/j3wF8tu We’re proud to once again be showcasing a selection of awesome projects by the talanted members of our community! This month we are presenting an array of screen print projects, from patterned jumpers, to multi-layered prints. Check out the work below: Sunnu Rebecca Choi: Secrets Exposed Redbellyboy: Women Of The World Take Over – Gold Edition Aalok Trivedi: Composition Series Isabelle Lin: Bouquet Abi Prints: Tiger Lopez&SonPGH: 2022 Dungarees & Squeegees: Jazzy Shapes Autumnal Sweatshirt

Browse more incredible work from our community at www.members.peopleofprint.com. Want to join our community and benefit from a heap of perks? APPLY HERE. Printing via People of Print https://ift.tt/3dX9xjU October 31, 2022 at 05:12AM

https://ift.tt/wPB3psC

3D Printing Webinar and Event Roundup: October 30, 2022 https://ift.tt/pqdCALu We’re ramping up again in this week’s roundup, with several events taking place, including ICAM 2022, DEVELOP3D Live, ASME’s AM Medical Summit, and more. In terms of webinars, Stratasys and 3D Systems each have two this week, Nexa3D will talk about developing its XiP printer, 3DHEALS welcomes panelists to discuss point-of-care 3D printing, and more. October 31 – November 4: ASTM ICAM 2022The 7th annual ASTM International Conference on Additive Manufacturing (ICAM 2022), sponsored by ASTM’s Additive Manufacturing Center of Excellence (AM CoE), will be held in-person from October 31st to November 4th in Orlando, Florida. Related to certification, standardization, and qualification, with an emphasis on industry-specific requirements that address the full AM process chain, ICAM will welcome experts from around the world for keynote speeches, panel discussions, technical presentations, sponsored exhibits, networking receptions, and more. Additionally, the Student Presentation Competition, Young Professional in AM awards, and ASTM International Additive Manufacturing Awards of Excellence in Education, Research, and Standardization will take place. 3DPrint.com was at ICAM last year, and we’re back again for 2022!

You can register for ICAM 2022 here. October 31 – November 4: 3D Printing News UnpeeledOur Executive Editor Joris Peels, who’s also the Vice President of Consulting at SmarTech Analysis, launched a daily news livestream called 3D Printing News Unpeeled. Each weekday at 9:30 am EST, Peels gets on LinkedIn Live and tells us, in 20 minutes or less, what he considers to be the top news stories from the 3D printing industry that day, and why they’re important. Some of the stories in his roundup are ones we’ve covered at 3DPrint.com, and some are not, but they are all equally interesting and impactful. The next 3D Printing News Unpeeled livestream will be this Monday, October 31st, at 9:30 am EST, and will continue the rest of the week at the same time. You don’t want to miss it! November 1 – 3: ASME’s AM Medical SummitThe AM Medical Summit, powered by ASME, returns to Minnesota November 1-3 to address the AM industry’s biggest medical challenges through collaboration and case study technical sessions. The summit is co-located at the Minneapolis Convention Center with the Medical Design & Manufacturing (MD&M) Minneapolis and VisualizeMED events, and its themes will include medical devices, orthopedics, medical modeling, point-of-care manufacturing, and more. Plus, attendees have the option to tour the Mayo Clinic and the University of Minnesota.

You can register for the summit here. November 1: DEVELOP3D LiveOn Tuesday, November 1st, DEVELOP3D, a publication with its own voice dedicated to product development, design, and CAD, will host its DEVELOP3D Live event in the UK. The event itself will be held at the University of Sheffield, and all of the main stage presentations will be streamed live for audiences around the world, covering topics related to the future of design and manufacturing, from audio products and robots to sports cars and more.

You can register for the in-person event here and the livestream version here. November 2 – 3: TriMech’s Global Technology EventTriMech is holding a free Global Technology Event and SOLIDWORKS 2023 Launch on November 2nd and 3rd, offering the latest in 3D design, cloud collaboration, and manufacturing. There will be over 25 virtual expert-led sessions, and attendees can get their questions answered by the experts and exhibitors, explore the event to win prizes, interact with the global SOLIDWORKS community, and more. Sessions will run from 9 am to 1 pm EST, and then again from 1 to 5 pm EST.

You can register for the event here. November 2 – 3: Advanced Engineering 2022Also from November 2nd to the 3rd, Advanced Engineering 2022, the UK’s leading gathering of OEMs and engineering supply chain professionals, will be held in Birmingham. The event celebrates collaboration, innovation, and sustainability within the engineering and manufacturing industries, and is free to attend. Show zones include composites engineering, advanced metals, space and satellite, testing and quality control, and more.

You can register for the event here. November 2: Copper Additive ManufacturingFeaturing technical experts from 3D Systems, NASA, and Elementum 3D, Deep-Tech Showcase is holding a webinar on “Pushing the Limits of Copper in Additive Manufacturing” on Wednesday, November 2nd at 11 am EST. Presentations by these specialists will focus on the potential copper offers when designed and produced in an additive manufacturing environment, and attendees will hear valuable real-world insights about the material’s growing capabilities in the AM market, as well as its impact on thermal management and rocket propulsion applications, and have the chance to ask questions as well.

You can register for the webinar here. November 2: Stratasys Offers FDM Product UpdateStratasys is hosting an online “FDM Product Update for Parts Providers” at 12 pm EST on the 2nd. The speakers will be Allen Kreemer, Senior Strategic Applications Engineer, and Perry Hubbing, Senior Project Engineer, both from Stratasys.

You can register for the webinar here. November 2: Discussion on EV Design & Manufacturing AdvancementsAlso on November 2nd at 12 pm EST, 3D Systems is co-sponsoring a roundtable discussion, along with Sandvik Coromant, about “Advancements in the design and manufacturing of electric vehicles.” Scott Cost, Segment Manager – Transportation & Motorsports, will be speaking on behalf of 3D Systems.

You can register for the webinar here. November 2: End-Use Parts Production with Stratasys & MaterialiseThe final 12 pm EST webinar on Wednesday the 2nd will be focused on “Unlocking AM: The Future of End-Use Part Production,” a joint panel by Materialise and its CO-AM partner Stratasys. Panelists from Materialise and Stratasys, as well as Sikorsky, General Atomics, and ABI Research, will discuss digital manufacturing and how it enables end-use part production.

You can register for the webinar here. November 2: Developing Nexa3D’s XiPNexa3D engineers and Xometry experts will discuss the development of the XiP, a desktop 3D printer with industrial-level speed, and how it happened in just 18 months, in “From Sketch to SKU: Developing XiP, the World’s First Ultrafast Desktop 3D Printer,” this Wednesday at 2 pm EST. Attendees will learn about the product development and prototyping of the XiP, how the companies collaborated to reduce and offset the carbon footprint of their manufacturing efforts, and more.

You can register for the webinar here. November 2: DfAM Event by HP & AltairThe last November 2nd webinar, held at 2 pm EST, will be a joint HP 3D Printing and Altair event all about design for additive manufacturing, or DfAM. The in-person event will be held at Automation Alley in Troy, Michigan, and will include discussions from Altair, HP, and Gonzalez Group experts, as well as a tour of the Gonzalez facilities to see how the company is using additive to consolidate parts, reduce weight, and shift some tooling on their manufacturing lines from metal to polymer.

You can register for the webinar here. November 3rd: Becoming an SLS Open Parameters ProSinterit will discuss “How to become an SLS open parameters PRO” in a webinar at 11 am EST on Thursday, November 3rd. Attendees will hear from Sinterit experts Jakub Malec and Dominik Stasiak about how to become an SLS pro user and print vast numbers of printouts and moveable parts with high quality, the top parameters you need to know to become more flexible, and more.

You can register for the webinar here. November 3: Point-of-Care 3D Printing PanelFinally, also at 11 am EST on the 3rd, 3DHEALS wraps the week up with a virtual panel on “Point of Care 3D Printing.” At the end of 2021, the FDA published a discussion paper on the subject of POC 3D printing, and invited the public to submit comments in order to create more clarifying regulatory guidance. So for this panel, 3DHEALS invited several experts with both industrial and clinical experiences in POC 3D printing to discuss the exciting topic.

You can register for the discussion here. Do you have news to share about any future webinars or virtual and live events? Please let us know! The post 3D Printing Webinar and Event Roundup: October 30, 2022 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/Sb7B4RA October 30, 2022 at 09:15AM

https://ift.tt/7Z2ImuY

3D Printing News Briefs, October 29, 2022: Software Release, Smooth Parts, & More https://ift.tt/27NMmPy We’re starting with product launches and updates in today’s 3D Printing News Briefs. Artec 3D launched its Metrology Kit, and VoxelDance released the latest version of its All-in-One build prep software. Chromatic announced a new Smooth-Mode technology. Moving on, a CSEM project is focused on 3D printing pipes with embedded sensors. Finally, these drones are able to 3D print structures in flight. Artec 3D Launches Metrology Kit for More Accurate 3D ScanningArtec 3D has announced the release of its new Metrology Kit, which allows for deformation analysis and greater accuracy in measuring objects and areas in all sizes. The 3D optical coordinate measuring system is available in both an Entry and a Professional version, and offers a versatile, easy to use photogrammetry solution for high-precision inspection in the aerospace and defense, automotive, and oil & gas industries. The kit is compatible with inspection software solutions like PolyWorks and Geomagic Control X, and includes the Metrology Kit plugin, scale bars, adapters, measurement targets, and a camera with a resolution of up to 30.3 megapixels and a 28 mm wide angle lens. Both DaaKS- and VDI-certified, the Artec Metrology Kit is completely portable, so it can operate as a standalone optical measurement solution, as well as a referencing tool for better 3D scanning performance over distance. It offers precise measurements in less than 15 minutes, can capture objects in motion, and provides point-based accuracy (RMS) up to 0.002 mm + 0.005 mm/m and length measurement accuracy up to 0.015 mm + 0.015 mm/m. VoxelDance Releases Latest Version of All-in-One AM Build Prep SoftwareThis month, AM software provider VoxelDance released Voxeldance Additive 4.0, which is the latest version of its All-in-One AM build preparation software. This release, with over 30 new features and optimizations, will enable users to boost industrial 3D printing productivity. Some highlights of the VDA 4.0 release are a new shrink wrap feature, which can accurately calculate and wrap a layer around the part while ignoring the inner details; border reinforcement for stronger support restraint; web support and tree support; a mesh smooth feature that removes sharp details to ensure a more appealing geometry, and more.

Chromatic Develops Smooth-Mode Technology for Rubber Parts

Chromatic’s RX-AM 3D printing technology provider Chromatic 3D Materials recently introduced its new Smooth-Mode technology in order to 3D print durable rubber parts with ultra-smooth surfaces at commercial volumes. The company’s team of AM experts fine-tuned the viscosity and surface tension of Chromatic’s 3D printable thermoset polyurethane materials, and Smooth-Mode actually uses chemistry to create smooth, ultra-bonded parts. Industrial manufacturers can now use Smooth-Mode with Chromatic’s RX-AM materials to print smooth, high-quality polyurethane parts, like gaskets, seals, and grommets, that have superior aesthetics, finer dimensional accuracy, and no necessary post-processing or surface finishing.

CSEM 3D Printing Pipes with Embedded SensorsCentre Suisse d’ Electronique et de Microtechnique (CSEM) is coordinating the EU-funded Advanced Heat Exchange Devices (AHEAD) project, which means to improve the performance of thermal control systems by 3D printing pipes with embedded sensors. These systems are critical components in many high-performance devices, such as space rockets and satellites, but most current thermal control systems are bulky and need many connection cables. The goal of the AHEAD project, which is expected to last two years, is to use AM to develop systems that are wireless, compact, and less expensive in order to improve efficiency and enable real-time data collection. The AHEAD consortium partners are currently targeting space modules and the new particle detectors at the European Organization for Nuclear Research (CERN) as applications, though they hope to bring the technology to the pre-industrial stage so it can be used for a variety of applications, including machine tooling, irrigation mechanisms, industrial heating and cooling systems, automotive parts, and more.

UK Researchers Develop Drone Swarm for Aerial 3D Printing

Credit: University College London, Department of Computer Science/Dr. Vijay M. Pawar & Robert Stuart-Smith, Autonomous Manufacturing Lab Finally, a research team from Imperial College London, the University of Bath, and University College London took inspiration from bee swarms engineering their hives to create a fleet of drones that can autonomously 3D print structures while flying in the air. The drones act independently, but work as a team, and the researchers hope the platform, called Aerial-AM, could one day be used to rapidly build bridges, shelters, or even houses, in areas that are difficult to access in order to help during weather emergencies like wildfires and hurricanes. In several proof of concept tests, which are outlined in a research paper, the self-organizing drone swarm was able to print structures with minimal human supervision using materials like foam and a cementitious mix. The team developed a software framework for their swarm that was able to tap into natural precedents and previous engineering ideas to get each drone to work in tandem with the others while extruding material, but not flying into each other. Aerial-AM combines AI and physics to create two types of flying robot platforms: the BuilDrone, which autonomously deposits material based on its program, and the ScanDrone, which uses computer vision to scan ongoing construction for quality control purposes, and then provides feedback with each deposited layer. The only part human supervisors are part of is running a simulation before printing to generate a virtual job using three or more drones, in order to determine the best way to print a material. The post 3D Printing News Briefs, October 29, 2022: Software Release, Smooth Parts, & More appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/sGkwqaN October 29, 2022 at 08:13AM |

Categories

All

Archives

April 2023

|

Secrets Exposed is a series of 7 illustrations, screen printed and packaged in a ‘secret’ box by Sunnu Rebecca Choi. The printmaker tells us; “The inspiration for the series came from the differences between the person and the image of the person, the tension between being and seeming”. Each work is set in a particular time and public space throughout the day, revealing a person’s emotional states and inner thoughts.

Secrets Exposed is a series of 7 illustrations, screen printed and packaged in a ‘secret’ box by Sunnu Rebecca Choi. The printmaker tells us; “The inspiration for the series came from the differences between the person and the image of the person, the tension between being and seeming”. Each work is set in a particular time and public space throughout the day, revealing a person’s emotional states and inner thoughts.

The original edition of Women Of The World Take Over was selected by Grayson Perry as part of The RA Summer Exhibition 2022. It sold out in under a week! This is the 2nd edition, and is hand finished with 24 carat gold leaf. The text is taken from the Scottish poet Ivor Cutler’s song Women Of The World Take Over. Redbellyboy comments; “However, I thought simply ‘taking over’ was too easy for these times and that they would have to do it by force, so I added ‘RISE UP’. But don’t worry, if women do take over the future is bright. That’s why she’s wearing sunglasses.”

The original edition of Women Of The World Take Over was selected by Grayson Perry as part of The RA Summer Exhibition 2022. It sold out in under a week! This is the 2nd edition, and is hand finished with 24 carat gold leaf. The text is taken from the Scottish poet Ivor Cutler’s song Women Of The World Take Over. Redbellyboy comments; “However, I thought simply ‘taking over’ was too easy for these times and that they would have to do it by force, so I added ‘RISE UP’. But don’t worry, if women do take over the future is bright. That’s why she’s wearing sunglasses.”

This series of four abstract screen prints explores the relationship between rigid structure and organic chaos. Much of Aalok’s work centres around mental health and inner dialogues we have as we deal with conflict. With each print, he strives to balance the thought of wanting control with letting in the unexpected, natural elements of life. The series also showcases the varied textures and patterns you can achieve with screen printing. All four limited edition, original prints are available in his shop.

This series of four abstract screen prints explores the relationship between rigid structure and organic chaos. Much of Aalok’s work centres around mental health and inner dialogues we have as we deal with conflict. With each print, he strives to balance the thought of wanting control with letting in the unexpected, natural elements of life. The series also showcases the varied textures and patterns you can achieve with screen printing. All four limited edition, original prints are available in his shop.

After a long period of focusing on linocut and drypoint, printmaker Isabelle Lin wanted to return to screen printing, thus created this small ink drawing to turn into a silkcreen stencil. “I was worried that the finer details would not expose properly if I drew to size, so I chose to draw at a smaller format and enlarge a high resolution scan to reduce the risk,” says the artist. It is printed with Speedball shimmering screenprinting inks on 220g Munken paper.

After a long period of focusing on linocut and drypoint, printmaker Isabelle Lin wanted to return to screen printing, thus created this small ink drawing to turn into a silkcreen stencil. “I was worried that the finer details would not expose properly if I drew to size, so I chose to draw at a smaller format and enlarge a high resolution scan to reduce the risk,” says the artist. It is printed with Speedball shimmering screenprinting inks on 220g Munken paper.

For this year’s 20:20 Print Exchange by Hot Bed Press, Abi created a three layer Screen Print called Tiger. Abi felt inspired to create a piece based on abstract forms, using slightly transparent inks to build up the depth within the print. Printed onto 100% recycled cotton rag paper, the quality and the textures are beautiful, adding to the metallic and neon paints used.

For this year’s 20:20 Print Exchange by Hot Bed Press, Abi created a three layer Screen Print called Tiger. Abi felt inspired to create a piece based on abstract forms, using slightly transparent inks to build up the depth within the print. Printed onto 100% recycled cotton rag paper, the quality and the textures are beautiful, adding to the metallic and neon paints used.

This year, Lopez & Son moved to making more complex designs by pushing their limits with colour and shape. “We wanted to make prints that draws everyone’s eyes to them, making a focal point for any room or gallery,” state the duo. These designs are inspired by the Buddhist art of Mandalas, colourful imagery used for meditation. By doing this they hope to make their pieces more than decor, but a form of contemplation for the individual.

This year, Lopez & Son moved to making more complex designs by pushing their limits with colour and shape. “We wanted to make prints that draws everyone’s eyes to them, making a focal point for any room or gallery,” state the duo. These designs are inspired by the Buddhist art of Mandalas, colourful imagery used for meditation. By doing this they hope to make their pieces more than decor, but a form of contemplation for the individual.

This jazzy jumper is super thick luxuriousness, and also vegan approved. Five colour screen print using waterbased inks on organic cotton, printed by hand in Dungarees & Squeegees’ studio in Shropshire. This sweatshirt works for all seasons, but looks especially awesome when the leaves fall. “Made with our brand shapes so all the cool kids will know you’re repping Dungarees + Squeegees!”

This jazzy jumper is super thick luxuriousness, and also vegan approved. Five colour screen print using waterbased inks on organic cotton, printed by hand in Dungarees & Squeegees’ studio in Shropshire. This sweatshirt works for all seasons, but looks especially awesome when the leaves fall. “Made with our brand shapes so all the cool kids will know you’re repping Dungarees + Squeegees!”

materials and technology platform is shown here 3D printing smooth polyurethane grommets with Smooth-Mode.

materials and technology platform is shown here 3D printing smooth polyurethane grommets with Smooth-Mode.

RSS Feed

RSS Feed