|

Interview with Massimo Bricchi on 3D printing biodegradable materials(D) https://ift.tt/2FIpbTB Massimo Bricchi This is an interview with Massimo Bricchi who is Kuraray Europe’s Regional Marketing Manager. Kuraray Europe is involved in the production of Chemicals and resins, fibers and textiles, high-performance material, and medical products. In this interview, the discussion is focused on the 3D printing biodegradable materials that Kuraray has been manufacturing. Take us through your organization and a brief introduction to the service and products you offer? The Kuraray Group is an expanding, stock exchange-listed specialty Chemicals Company headquartered in Tokyo, Japan, with around 8.500 employees and annual sales of over EUR 4 billion. Kuraray Europe GmbH is a wholly-owned subsidiary headquartered in Hattersheim and Main and has around 850 employees. Kuraray is the world’s largest producer of polyvinyl alcohol (PVA) and an international leader in the development and use of innovative high-performance materials for many industries. Besides PVA, we sell PVB resin to produce solvent-soluble filaments for FFF. PVB has similar mechanical properties as PLA, is very transparent and can be polished, after printing by spraying it with alcohol that dissolves the surface of the objects, therefore, giving that shiny look. For the future we are planning to introduce to 3D printing also other Kuraray products like high-temperature PA (Nylon) and elastomers. What is the significant aspect of your 3D printing water-soluble materials and how important are they in 3D printing? The main features that differentiate our material from the competition are:

How compatible are your filaments with the 3D printers in the market, are there specific printers to use on? Our filament can be used on any Fused Deposition Modelling (FDM), or Fused Filament Fabrication (FFF). Do you see 3D printing biodegradable material as another crucial material in 3D printing for the future? 3D printing biodegradable materials will be a crucial material especially if you consider the microplastic issue. The market is also now focused on the pure technical performance of support materials. Mowiflex water soluble filament What is your vision with the Africa 3D printing market? Do you have plans for it? Kuraray does not have a clear vision yet. We have exhibited at various 3D Printing fairs but hardly got visitors from Africa. We have no idea of the potential market in Africa, for our support material but would be glad to learn more about it.

And lastly, how do you see 3D printing in the future? We are now in an early phase of the market where you see many players, from very small family companies to large enterprises continuously offering new products and technologies. But we already see that the market is moving from a hobby-like approach to real industrial use of 3D Printing. You can see it also by looking at big companies like BASF or Henkel investing a lot into 3D printing. We expect a future consolidation of the market where only bigger companies having the capability to develop new and reliable products will survive. Unpolished and Polished PVB Bottle Please enable JavaScript to view the comments powered by Disqus. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 30, 2019 at 05:51PM

0 Comments

https://ift.tt/2FITyZQ

The Nydus One Syringe Extruder (NOSE): Turns Your Prusa i3 Into a Bioprinter https://ift.tt/2Ys7Wxe Researchers from Germany are exploring democratizing bioprinting with their findings outlined in ‘Nydus One Syringe Extruder (NOSE): A Prusa i3 3D printer conversion for bioprinting applications.’ Recognizing the promise of this new technology and all that surrounds it, the authors focus on the potential for eliminating animal testing in the pharmaceutical industry, along with the ability to offer patient-specific treatment in nearly every area of medicine. But, applications could extend far beyond these. In this study, the research team studies the performance of a Prusa i3 converted with a Nydus One Syringe Extruder (NOSE), allowing for hydrogel extrusion and ‘tunable deposition precision’ with a syringe holder. Projects like these are possible because of open-source technology, and here, the team was able to alter their low-cost 3D printing hardware to experiment in bioprinting. The combination of NOSE and the Prusa i3 platform in an open source bioprinting package is a potentially powerful one that could democratize bioprinting worldwide. Building on CMU’s FRESH research that has already lead to tissues being made on low-cost printers this is really a potentially groundbreaking moment in bioprinting. So far bioprinters have been niche and cost 100,000’s or tens of thousands. With FRESH CMU already has demonstrated for three years that low-cost bioprinting for $500 to a $1000 is possible. But, this GPL licensed research combined wit the popular Prusa i3 open source 3D printer could be the thing that makes bioprinting accessible. What this paper does is give you a step by step guide on how to bioprint using a modified Prusa printer and some extra parts. In one fell swoop, hundreds of thousands of Prusa operators could potentially now experiment with bioprinting. No matter what type of hardware, software, or materials are used though, challenges still abound in bioprinting as researchers must work hard to keep cells alive in the lab. Open sourcing allows for smaller labs to forge ahead in bioprinting also as they can bypass the cost of commercial hardware which could cost hundreds of thousands of dollars. Modifications to the Prusa i3 with the NOSE offer many benefits, to include:

Once parameters are set, the researchers promise an algorithm delivering a ‘collision-free path.’ They must be set carefully and correctly, however, and the team suggests that users practice first by fabricating and experimenting with basic samples. If desired, the printer mainframe can also be replaced with a RebelliX frame. The research paper also includes information regarding:

A selection of the most commonly used bioprinting techniques: a) Inkjet bioprinting describes the deposition of biomaterials (and cells) in a low viscosity range by production and depositioning of drops in the 1-100 pL range. b) Extrusion Bioprinting: a continuous thread of biomaterial containing cells is extruded through a needle and deposited on a print surface. A broad range of viscosities is possible. c) Laser-induced forward transfer: the biomaterial is deposited on a gel ribbon. Laser impulses then initialize the release of small drops onto a receiver plate. The choice of the printing technique depends on the desired resolution, the type of biomaterials and the cell-type and -density. Costs for converting the Prusa i3 into a comprehensive bioprinter are minimal, and the FRESH method means that users can print complex geometries, using concentrated hydrogels for bioprinting purposes. The researchers did note, however, that the NOSE system was lacking in some areas:

The NOSE bioprinting setup exhibited an 81 percent survival rate of HEK293 cells during experimentation and promising 85 percent rate for embryonic stem cells (mESC). Again, however, some major issues did arise as the FRESH microgel proved to be ‘non-ideal’ for cells exposed over 30 minutes.

The NOSE modification consists of four 3D-printed parts: (1) the mounting part of the y-carriage and adapter for the modular syringe holder (“main adapter”), (2) a syringe holder with a diameter suitable for common 10 mL disposable syringes (“syringe holder”), (3) part to mount a NEMA17 servo engine (“servo mounter”), (4) the press part to move the syringe-piston (“mechanical press”). All parts have been printed using 0,01 mm layer height using support structures. Any support structure leftovers or unfitting hinges were gently polished using fine sandpaper.

Bioprinting may be much more common in research labs around the world today, from microfluidic platforms to scaffolds for bone regeneration and more, but for most scientists, the ultimate goal is that of 3D printing human organs. Impressive strides have already been made, however, with cellularized hearts, human brain tissue, animal brains, and many other spectacular models. Given that the Prusa i3 is an inexpensive 3D printer capable of high-quality 3D prints this development could potentially democratize bioprinting. If the NOSE nozzle works well then this could make the i3 an affordable bioprinting platform, for some bioprinting applications, for use in the lab and classroom. The Prusa i3 is the predominant FDM system architecture and hundreds of thousands of Prusa and Prusa clones are scattered across the earth. With the NOSE nozzle and the i3 bioprinting could now become affordable for many people worldwide. Sometimes a moment changes everything, sometimes that moment is this one.

A selection of the most commonly used bioprinting techniques: a) Inkjet bioprinting describes the deposition of biomaterials (and cells) in a low viscosity range by production and depositioning of drops in the 1-100 pL range. b) Extrusion Bioprinting: a continuous thread of biomaterial containing cells is extruded through a needle and deposited on a print surface. A broad range of viscosities is possible. c) Laser-induced forward transfer: the biomaterial is deposited on a gel ribbon. Laser impulses then initialize the release of small drops onto a receiver plate. The choice of the printing technique depends on the desired resolution, the type of biomaterials and the cell-type and -density. [Source / Images: ‘ Nydus One Syringe Extruder (NOSE): A Prusa i3 3D printer conversion for bioprinting applications’] Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 29, 2019 at 05:36PM

https://ift.tt/2xuexvf

French Researchers Develop Algorithm to Generate Interior Ribbed Support Vaults for 3D Printed Hollow Objects https://ift.tt/2X5ufHq

Hollowed Bunny printed with our method, using only 2.2% of material inside (compared to a filled model). The supports use 316 mm of filament over a total of 1,622 mm for the print). In 3D printing, every layer of material must be supported by the layer below it in order to form a solid object; when it comes to FFF 3D printing, material can only be deposited at points that are already receiving support from below. French researchers Thibault Tricard, Frédéric Claux, and Sylvain Lefebvre, from the Université de Limoges (UNILIM) and the Université de Lorraine, wanted to look at 3D printing hollow objects, and proposed a new method for hollowing in their paper “Ribbed support vaults for 3D printing of hollowed objects.”

Figure 2: A Stanford bunny model is hollowed using a standard offsetting approach. The resulting cavity (R) will not print properly due to local minima (red) and overhanging areas (orange). While most people think of 3D printing supports as external ones that support overhanging parts of an object, the interior of an object may also need support structures.

Inner supports should occupy a small amount of space with the print cavity, and the impact on overall print time should be slight. Other researchers have contributed a variety of ideas in terms of support structures with 3D printed hollowed objects, including:

The researchers explained how to support a 3D object by “sweeping through its slices from top to bottom” and searching for any unsupported parts, then adding necessary material below them in the next slice; this material doesn’t need to cover the entire unsupported area, and can take any shape.

The team then explained their algorithm for ribbed support vault structures. The idea is to use three main operations to produce supports: propagating and reducing supports from the above slice, detecting areas that appear to be unsupported in the current slice, and adding the supports needed for it.

The team 3D printed a variety of PLA models with the same perimeters on different systems. Orange models were fabricated on an Ultimaker 3, while the yellow Moai was printed on an Ultimaker 2 and the octopus on a CR-10. A Prima P120 was used to make white models, the blue Buddha was printed on an eMotion Tech MicroDelta Rework, and a dual-color fawn was made on a Flashforge Creator Pro. The quality of these prints matches models with a dense infill, thanks to the full support property offered, and the algorithm generates multiple small segments that require individual printing, which led to many “retract/prime operations surrounding travels.”

The team also evaluated how much material their method needed, and compared this with materials used for iterative carving and support-free hollowing methods. They also noted how layer thickness impacted support size, and recorded processing times.

Comparison with Support-Free Hollowing and Iterative Carving. The input volume represents the volume (in mm3) and height (in mm) of the model.

The researchers concluded that their algorithm ensures complete support of deposited material, which can be helpful for extruding viscous or heavy materials like concrete and clay. They believe that their method for 3D printing hollowed objects through generating ribbed internal support structures could one day lead to novel external support structures as well. Discuss this and other 3D printing topics at 3DPrintBoard.com or share your thoughts below. Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 29, 2019 at 02:06AM New Balance and Formlabs Launch TripleCell 3D Printing Platform and Rebound Resin for Athletic Shoes6/28/2019

https://ift.tt/2NiXwPf

New Balance and Formlabs Launch TripleCell 3D Printing Platform and Rebound Resin for Athletic Shoes https://ift.tt/329GUgi While I’m not much for recreational jogging these days, I’ll always remember my first real running shoes – a pair of dark gray Sauconys, which I got to pick out from the store when I made the track team in seventh grade; a short-lived activity, as I was neither fast enough for sprinting nor strong enough for shot put. Shoes have changed dramatically since then in their looks and features. Manufacturing processes have only recently begun to change with new weaving techniques, more use of polymers, and 3D printing. With the way things are going these days, it may not be long before everyone’s favorite pair of athletic shoes is of the 3D printed variety, no matter which manufacturer they come from. Back in 2015, Boston-based athletic leader New Balance announced that it was teaming up with 3D Systems to create the first 3D printed running shoe. The company released its Zante Generate shoe a year later, and while it wasn’t the first 3D printed shoe ever created, it was the first to be made commercially available.

New Balance realized it would need a specific material that didn’t yet exist in the industry. The new TripleCell platform can deliver components that are pretty close to traditional performance cushioning, thanks to the proprietary photopolymer Rebound Resin that was developed as a result of the partnership. Rebound Resin was designed in order to make resilient, springy lattice structures with, according to a Formlabs press release, “the durability, reliability, and longevity expected from an injection molded thermoplastic.”

Using the new TripleCell platform for both prototyping and manufacturing allows the creation of shoes with a high cushion zone, which transitions to an area of high stability, within a single design, using a single material. It also helps decrease the time to market.

The $175 FuelCell Echo shoe will come in September, and the first full-length high performance running product will launch in 2020.

Discuss this story and other 3D printing topics at 3DPrintBoard.com or share your thoughts below. [Source/Images: Formlabs] Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 28, 2019 at 04:51PM

https://ift.tt/2J4NnQE

What Are Follow Up Emails and How to Use Them Effectively https://ift.tt/2IUasH5 Follow up emails are a great source of valuable information. If you plan them carefully, you might expect high engagement rates (e.g., open and click-through rate). This article is aimed at helping you apply follow ups strategically and increase the value of your email marketing.

What is a follow up emailA follow up email is an email you send after any significant point in the customer journey with a goal to collect a piece of information. You might send follow up emails to people who download your content asking them if they found it valuable. You can send a follow up email to people who are in the middle of a free trial of your service, with questions regarding their experience. You can follow up after an event in order to touch base.

You can schedule your follow ups as autoresponders to create tailor-made programs that will perfectly match your subscribers’ needs and interests.

When should I send follow up emailsI recommend following a simple principle – send a follow up email whenever there is an information need that justifies sending one. Obviously, you should always consider your target audience preferences and use common sense. Those information needs vary from company to company and depend on whether you operate in a B2B or B2C environment. Here are a few common examples:

B2C follow up emails

A fragment of a welcome email from Fellow. The email promotes the awarded product, a blog with interesting content, incentivizes purchase with a discount code, and informs about the brand’s social media channels.

You can use the email welcome series to onboard new customers. Here’s a blog explaining how to do it right: How to Onboard New Customers with Welcome Emails

An email from care/of with customized product based on survey results.

An email from IKEA with the Net Promoter Score (NPS), sent after visiting their shopping center.

B2B follow up emailsThe customer journey in B2B environment might be longer and more complex. Here are a few practical tips form the expert, Beata Patfield, Senior Business Development Executive at GetResponse:

If you like the idea of automated emails – using autoresponders and marketing automation workflows to send emails in specific time intervals or in response to your customer’s actions, here’s a perfect article for you: 30+ Automated Emails You Should Be Sending Today

Follow up email vs follow up email cyclesSome time ago we did a podcast with Dr Dave Chaffey, CEO and co-founder of digital marketing advice site Smart Insights, where he gives the following advice:

So, think about the customer journey, and decide if one email or rather a series of emails will bring the best results. Here’s a comparison between a single email and an email cycle.

How to write a follow up emailHere are a few tips that will help you write an effective follow up email.

Tips for writing a great follow up email

1. Think of the information you would like to getWhat exactly do you need to know? Think carefully about the purpose of the follow up email. It will help you set up a goal for the email (determine CTA) and create a compelling email. This step determines whether it’s a good idea to send this message at all.

2. Use a subject line and a preheader to provide a clear messageThe subject line and preheader are the elements that your contacts see before opening the email. Make good use of the inbox space and increase enagagement.

3. Keep it shortFocus on the goal of the message. Whether you want to ask for a favor or pose a question, get straight to the point:

When do you send follow up emails?Ready to create your own follow ups? Sign up for a free trial and make the most of your email marketing program.

Feel free to share your fresh thoughts and best practices in the comment box below. We’d love to learn more on follow ups from you.

The post What Are Follow Up Emails and How to Use Them Effectively appeared first on GetResponse Blog - Online Marketing Tips. Printing via GetResponse Blog – Online Marketing Tips https://ift.tt/2Xap2TD June 28, 2019 at 06:23AM

https://ift.tt/2NiHWmB

Interview with Kunal Mehta of Blueprint 3D Printing Consulting and Strategy https://ift.tt/2FDYSxD Just recently Stratasys launched Blueprint. Stratasys has had a consulting arm for a number of years now. The firm wanted to present and establish the Blueprint as independent-minded however. Application development and getting customers from standstill to up to speed in 3D printing is a hugely challenging task. It is rare that people can bridge both the technical side of things and business enough to translate needs into appropriate strategies. Industrializing processes and new materials is also very challenging and each new market or material has its unique challenges. Blueprint will have to also maintain its independence and independent thought while still being a part of one of the largest 3D printer OEMs in the field. Will the team succeed? This responsibility is on the shoulders of the very bright Kunal Mehta, whom we interviewed.

What is Blueprint?

So, I pay you and then you tell me to get a Stratasys Printer?

What kind of engagements have you done?

For what kinds of customers would you like to work with?

What kind of experience do you bring to the table?

So, what advice would you give me if I’m a firm looking to use 3D printing?

And if I want to use 3D printing for production?

On what technologies do you advise customers?

How does a typical engagement work?

What stumbling blocks do companies entering 3D printing often encounter?

Why is it difficult to design for additive?

From an organizational perspective, why do 3D printing implementations go wrong?

What materials are you looking forward to seeing?

Where will Blueprint be in five years? Please enable JavaScript to view the comments powered by Disqus. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 28, 2019 at 05:42AM

https://ift.tt/2Lq3hIj

Purdue University: 3D Printing Nanoantenna Arrays for Metasurfaces https://ift.tt/2XBXNAL Jithin Prabha of Purdue University explores AM processes using 2 photon polymerization, useful for a variety of applications such as optics, along with metamaterials and surfaces, microfluidics, tissue engineering and bioprinting, and further exploration of innovative ways to deliver drugs. Prabha outlines his work in ‘3D Printing of Nanoantenna Arrays for Optical Metasurfaces,’ discussing how nanostructures can be fabricated in what could be referred to as ‘true 3D printing.’

An 800nm femtosecond laser was used to create the nanoantenna arrays, which were consequently studied using a scanning electron microscope and a Fourier Transform Infrared Spectrometer (FTIR).

(a) linear excitation vs two photon excitation (b) Spatial intensity profiles in the center of the beam axis for the two cases. The profile of excited molecules integrated in the transverse direction is shown at the left of each 3D plot [1]. In using this method, the antennas were designed in Autodesk Inventorand then sliced into layers using slic3r. The array of antennas was printed at 40×40 µm or 50×50 µm on a coverglass substrate, coated with gold of 55nm in thickness by e-beam evaporation. Varied optimization parameters included:

(a) simulation model for diabolo antenna showing gold structure of thickness T on glass, other dimensions as shown and electric field polarization direction, (b) Magnetic field enhancement (G = T = 50 nm, D = 310 nm, λ = 1940 nm) excited result showing central hotspot with peak magnetic field enhancement of 220 normalized with the magnetic field without the gold structure [12].

3D printing is applicable in nearly every industry today but is extremely useful to researchers and scientists endeavoring to create complex geometries and structures, and often on the nano- or micro-scale from fabricating metal structures to making high-resolution parts, and devices for more streamlined microfabrication. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

(a) Sections of microvalves for microfluidics[8] (b) Micro-caged device for drug

(a) The top view of the cad model of the diabolo antenna with dimensions, (b) the [Source / Images: ‘ 3D Printing of Nanoantenna Arrays for Optical Metasurfaces’] Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 28, 2019 at 02:42AM

https://ift.tt/2ZSFxk4

Carbon and Arkema’s Sartomer Subsidiary Partner to Increase Materials Performance & Digital Manufacturing Adoption https://ift.tt/2XzIRTO

Using its innovative Digital Light Synthesis (DLS) technology, which is enabled by its proprietary CLIP process, Carbon is working to reinvent how we design, engineer, and manufacture polymer products, such as automotive and mobile protection solutions, parts for medical devices, shoes, and even blender nozzles. Since it was founded, the company has shared a similar goal with Sartomer – to drive innovation in order to scale resin manufacturing and process technology, so that DLS 3D printed parts can be more cost-competitive and reliable.

As additive manufacturing continues to advance and mature, we will keep seeing the way that products are designed and fabricated change across industries…and partnerships like this one between Arkema and Carbon are at the forefront of these changes. Already, their collaboration has been responsible for creating some, according to a press release issued about the partnership, “holistic solutions” that are changing things up in the consumer goods, dental, and sporting markets. Earlier this week, Carbon announced that it had received $260 million in additional investments after a round of growth funding; one of the participants in this round was Arkema, which invested $20 million in Carbon’s Growth Funding Round. This funding will help Carbon support its next generation of integrated digital manufacturing platforms, solutions, and materials. As the two companies have a similar vision for the AM industry, their growing partnership is a great way for them to use advanced materials technology to grow their collective pipelines of production applications. What do you think? Discuss this story and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below. Please enable JavaScript to view the comments powered by Disqus.Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 27, 2019 at 07:11PM Interview with Mark Wrigley of Elektric-Works https://ift.tt/2XAcC6Q Inspired by the Apollo moon landings, Mark Wrigley embarked on a career in physics in the early 1970s. Initially specialising in optics and infra-red pyrometery his social skills soon took his career into program management, sales, marketing and product management. He is a great communicator and can transcend boundaries with his ability to explain technically complex issues to a wide audience. Operating at the forefront of disruptive technological change, he participated in the explosive growth of the mobile digital communication industry. In 2011 he set up his own company; Elektric-Works which explores the way disruptive technology and making can empower individuals and startups. Give us some background and how it has influenced your career.

What benefits do you see in terms of being creative in the artistic sense and tech sense?

Talk about some of your outreach work you do?

What are your thoughts on the Maker Movement?

Pikon Device made by Mark How important is passion to the work you do?

Moon Photo Taken by Mark What are some things that you want all makers to know?

How did your science career fuel your sense of exploration? Please enable JavaScript to view the comments powered by Disqus. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com June 27, 2019 at 08:36AM

https://ift.tt/2ZSvqfa

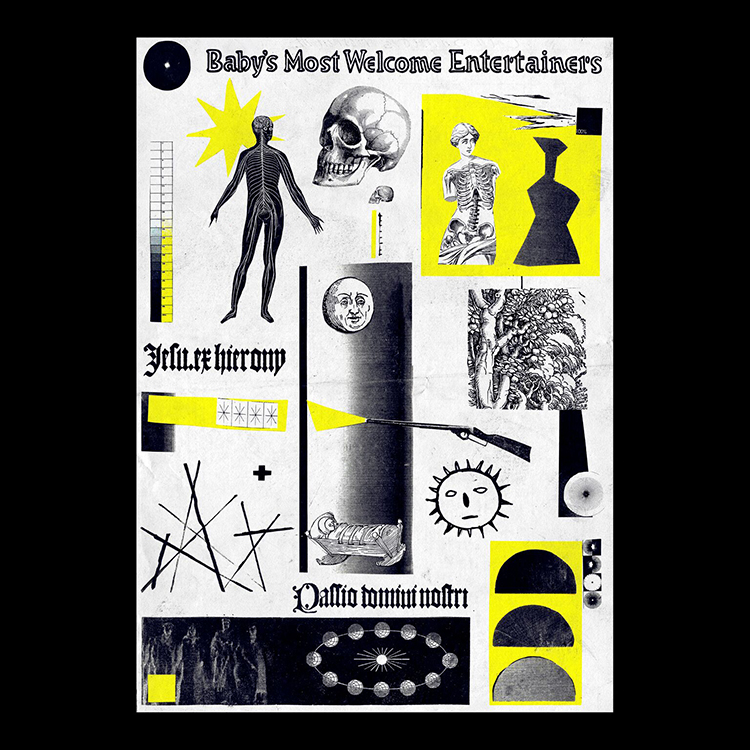

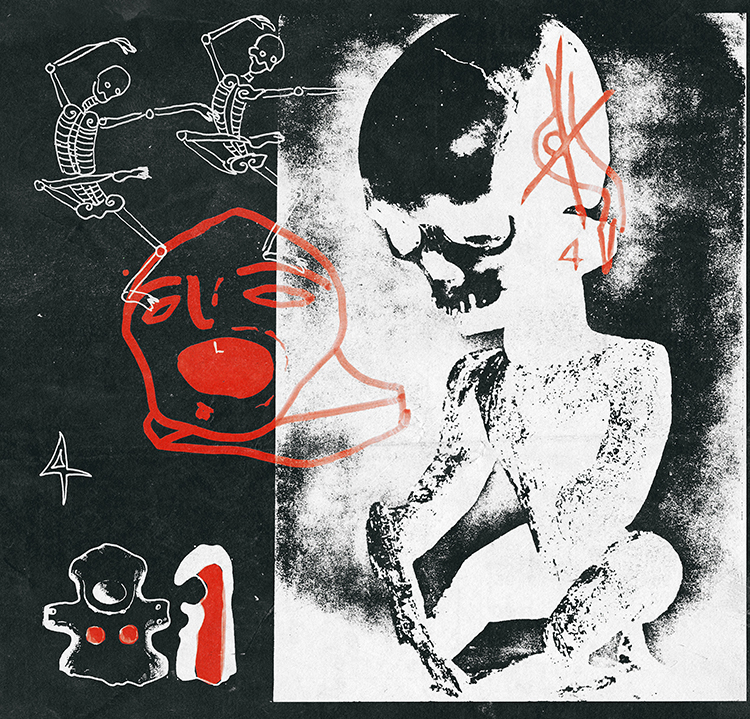

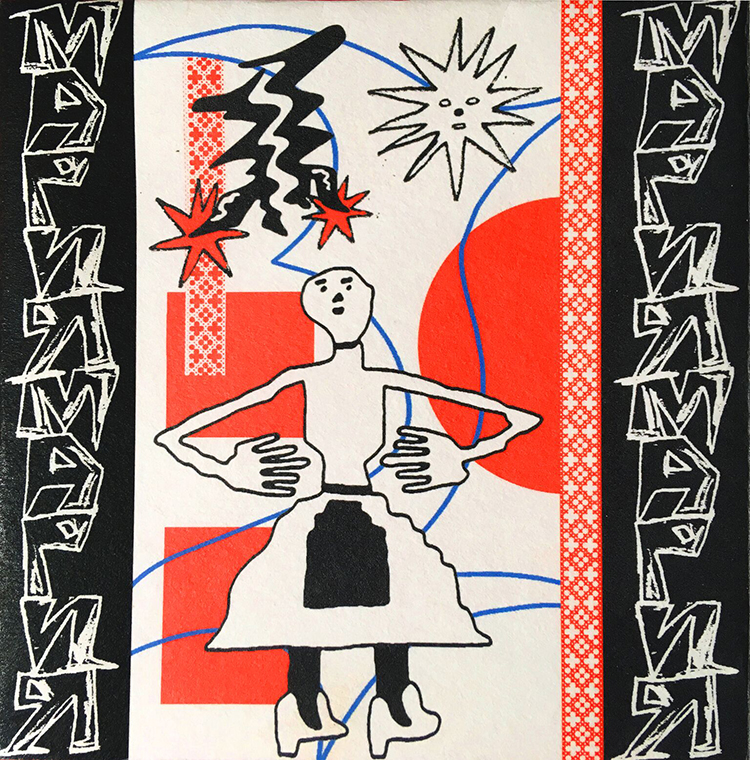

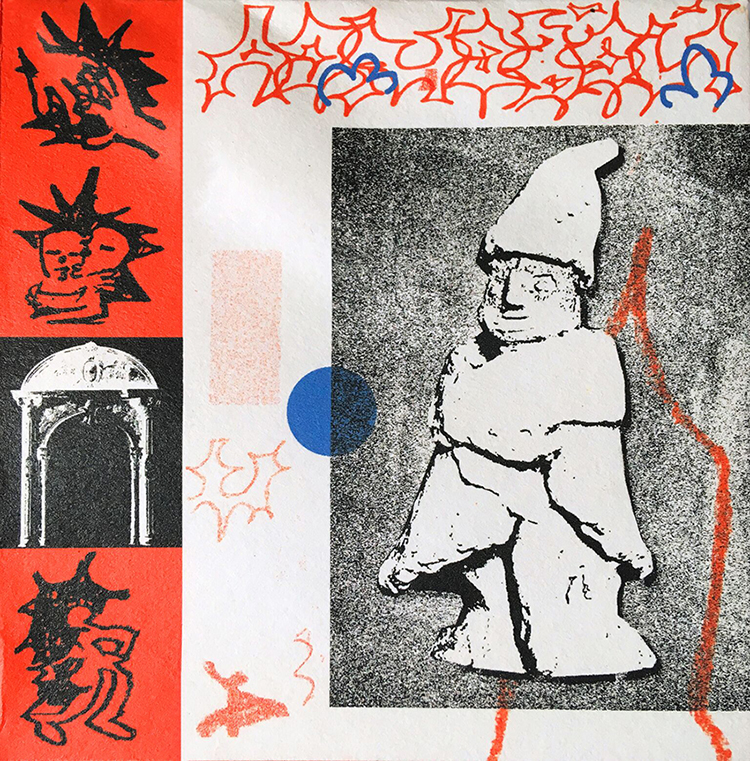

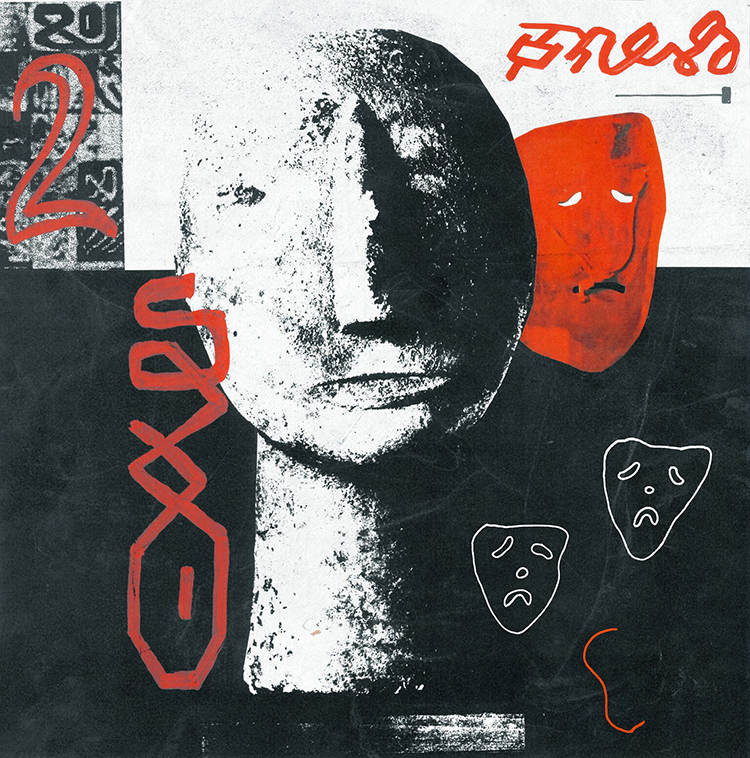

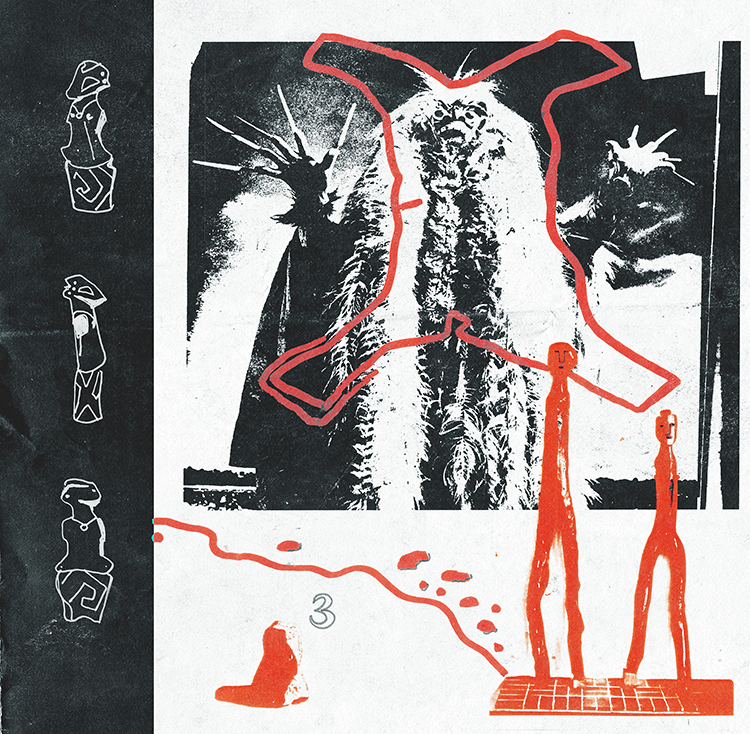

Maria Vorobjova https://ift.tt/2FBxFM6 Recently graduated from Brighton University is illustrator Maria Vorobjova. Taking a multidisciplinary approach to her work, Maria works with interactive processes enjoying the fastpaced and sporadic momentum of running with ideas, generating visual content through a variety of mediums before piecing them together into unconventional collages. Her compositions are rich with symbolism and metaphors, capturing the essence of the subject matter through playfulness and experimentation. Taking inspiration from her Russian cultural heritage, she uses a stark black and white palette with accents of primary colours which allows to both emphasise and give unity to the juxtaposition of the visual elements; such as graphic photos combined with block shapes and drawings.

Printing via People of Print https://ift.tt/2DhgcW7 June 27, 2019 at 08:29AM |

Categories

All

Archives

April 2023

|

Each composition focuses on building a world in which all those different visual elements interact with each other cohesively, leading the eye around the image. “I love to use personification and anthropomorphism, playing with what makes objects and abstract shapes appear human,” says Maria, “I often try to push an object’s form, through abstraction, to detach it from what would be traditionally recognised as a human figure whilst still retaining a ‘human nature”. Employing elements of craft and tactility through her process and having recently exhibited a woven blanket with a graphic and intricate print exploring mental comfort, symbolic of mapping and the materials, its physical tactility adds an extra layer of interaction.

Each composition focuses on building a world in which all those different visual elements interact with each other cohesively, leading the eye around the image. “I love to use personification and anthropomorphism, playing with what makes objects and abstract shapes appear human,” says Maria, “I often try to push an object’s form, through abstraction, to detach it from what would be traditionally recognised as a human figure whilst still retaining a ‘human nature”. Employing elements of craft and tactility through her process and having recently exhibited a woven blanket with a graphic and intricate print exploring mental comfort, symbolic of mapping and the materials, its physical tactility adds an extra layer of interaction.

RSS Feed

RSS Feed