|

3D Printing News Briefs, October 31, 2020: Farsoon, ExOne, Fusion3 & Create it REAL https://ift.tt/2HNDmdZ We’ve got news on materials and software in today’s 3D Printing News Briefs. Farsoon is offering biocompatible polymer powder materials for medical 3D printing, and ExOne will optimize its sand 3D printers for use with ceramic foundry sand. Finally, Fusion3 and Create it REAL have developed a new white label slicing software together. Farsoon Offering Biocompatible Polymer Powder for Medical AM In 2019, China’s Farsoon Technologies unveiled its Flight Technology for the Flight 252P platform, and this summer released two plastic powders for high-temperature 3D printing with the platform, PA12 based FS3201PA-F powder and FS2300PA-F polyamide powder. But the company also uses its plastic laser sintering technology to create parts out of its FS3300PA polyamide powder for medical applications, such as PPE and orthotic devices. The biocompatible material has great mechanical properties, good chemical stability, and received medical-grade evaluation stating that it’s okay to use for intracutaneous reactivity, irritation, and skin sensitization. The medical division of the Huaxiang Group has been using FS3300PA material and the Farsoon 403P 3D printer to print medical applications, like surgical and operational tools for short-term skin or mucosal membrane contact. Additionally, service bureau customers who participated in beta testing with the Flight 403P systems have intensely investigated the new biocompatible material, and have found it to have a good balance of strength and durability. Flight Technology is now entering its commercial operation phase. ExOne Optimizing Sand 3D Printers for Cerabeads The ExOne Company (Nasdaq: XONE) announced an agreement with Japanese ceramic products manufacturer ITOCHU Ceratech Corporation to optimize its sand 3D printing systems to be used with ITOCHU’s premium Naigai Cerabeads, a ceramic foundry sand that’s used to create cores and molds for the metal casting of high-value products, like impellers, cylinder blocks, pumps, and hydraulic valves, in the automotive, construction, mining, and oil and gas industries. Cerabeads are used at over 100 foundries around the world with a variety of metals, including aluminum, iron (gray, ductile), and steels (low-alloy, carbon, stainless), and will be used with sand 3D printing as well. As part of this new agreement, ExOne will develop and optimize the print process settings of its S-Print, S-Max, and S-Max Pro sand printers so they can be used with Naigai Cerabeads. In addition, ExOne will also offer this material together with its 3D printers as part of an optimized package for its North American customers. Quote request Are you looking to buy a 3D printer or 3D scanner? We're here to help. Get free expert advice and quotes from trusted suppliers in your area. Powered by Aniwaa Fusion3 and Create it Real Develop 3D Slicing Software 3D printer manufacturer Fusion3 and Danish company Create it REAL partnered up to develop REACTOR, a new white label 3D slicing software. REACTOR is powered by Create it REAL’s REALvision slicing engine, and is meant to be used with Fusion3’s professional FDM 3D printer line. The software offers customers a commercial software experience with many traditional slicing features, along with several new ones, such as a built-in certified materials list, enhanced print quality, both online and offline activation options, a streamlined interface, and “modifiers,” which make it possible to apply unique settings, like strength and weight, to different sections of a print.

REACTOR software is now available to Fusion3 customers as a bundle when they purchase one its F410 3D printers, or a standalone package through the company’s online Replacement Parts Store. In addition, Fusion3 is also offering a free upgrade of the slicing software to original owners of its F400 and F410 printers, though some limitations do apply. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 31, 2020 at 07:23AM

0 Comments

Model No. 3D Prints Furniture from Agricultural Waste https://ift.tt/2TA4504 3D printing is often viewed as one of the key sustainable technologies, primarily because it can produce complex structures in one single part, facilitates efficient designs, and creates less waste. Even more so, when this technology is combined with resources that are reused instead of being discarded, efficiency skyrockets. Based on this idea, a startup that makes artfully crafted furniture has taken the concept of a circular economy to new levels. By combining sustainably sourced agricultural material waste, California-based Model No. has been creating on-demand custom furnishings using 3D printing technology. Every item is 3D printed from biopolymers and plant-based resins that provide the flexibility of customization without the need for harmful petrochemicals – commonly used during traditional manufacturing and finishing of furniture products. Model No.’s eco-friendly materials are sourced from the remains of food crops which further reduce waste and allow upcycling of unused resources. Because these biopolymers are made from plants that are continually re-planted, the oxygen produced even helps offset any carbon dioxide emissions in the production process.

Model No. uses recycled and bio-resins to print every piece of furniture, as part of its commitment to eco-friendly furniture design. Image courtesy of Model No. With the mission to redefine the future of furniture, co-founders Jillian Northrup, Jeffrey McGrew, and Vani Khosla created a company that is operating at the intersection of design, technology, and sustainability. Each one of the artfully crafted pieces is offered with a selection of pre-customized models created by the Model No. design team, which can be ordered just as they are, or can be fully customized to fit a particular style, budget, and home. 3D printed on large, custom-built 3D printers in Model No.’s facility, every furnishing can be produced in house and delivered in two weeks, eliminating long wait times and wasteful inventory. Each can be customized using the company’s computer numerical control (CNC) tools to create truly unique pieces, adjusting everything from the dimensions and contours to the color and finish materials.

Model No. uses customized 3D printers in-house to create its custom furnishings. Image courtesy of Model No. Having the printing capability right in the manufacturing site also allows the design and manufacturing teams to make small scale models of each idea. Finding the right combination of form and customization options usually requires many iterations of sketches and small scale prototypes. Northrup stated in the Model No. site that making the smaller prototypes is a really good way to quickly and inexpensively make design decisions: “Once we see the small version of the piece in hand, we can do preliminary stress tests and visual proportions analysis, letting us know what changes we need to make for the piece to be truly functional as well as beautiful.”

Model No. design and manufacturing process to create furniture using 3D printing technology and agricultural waste. Image courtesy of Model No. Along with in-depth planning capabilities, the team relies on its six 3D printing machines to create some intricately complex designs that are inherently possible thanks to the technology. As the company continues to grow, it will continue to constantly develop new technology in-house to improve functionality as well as leverage and contribute to other open-source innovations and technologies from around the world. Quote request Are you looking to buy a 3D printer or 3D scanner? We're here to help. Get free expert advice and quotes from trusted suppliers in your area. Powered by Aniwaa Since founding the company in 2018, the team of designers has been working to produce a variety of tables, seating, and décor. With more than 35 product options, ranging from vases to coffee tables, customers have a wide variety of colors, designs, and budgets to choose from, which can result in one-of-a-kind pieces.

Model No. coffee tables are 3D printed using agricultural waste and customizable. Image courtesy of Model No. Traditional furniture manufacturing continues to have a heavy impact on the environment. According to the U.S. Environmental Protection Agency (EPA), the amount of furniture and furnishings that end up in a landfill rose from 7.6 million tons in 2005 to 9.7 million tons in 2015, and the rate of increase is accelerating. Wood was the largest material category in furniture, and ferrous metals were the second-largest category. Plastics, glass, and other materials were also found. Furniture also has a significant carbon footprint, which includes everything from the materials used, to the manufacturing process, to the environmental costs of climate-controlled storage, to shipment. In fact, UK-based My Tool Shed reported in 2019 that the average piece of furniture consumes approximately 47kg of carbon dioxide equivalent, which is the same as 5.3 gallons of consumed gasoline or driving some 30 to 60 miles.

Model No.’s manufacturing team makes large furniture pieces using 3D printing and sustainable materials. Image courtesy of Model No. Instead, Model No. hopes to do things differently. Aside from its biopolymers and plant-based resins, the company uses sustainably harvested wood for some of the larger furniture pieces, like the dining tables and particularly for an ergonomically designed curved chaise lounge – the flagship product of the company. When possible, the designers choose to use local species in all the wood details of its products, which means no deforestation or clear-cutting is involved. Using local recyclable materials made in the U.S. helps avoid the negative environmental impact of importing materials from overseas, and has proven very practical during the 2020 COVID-19 pandemic that has shifted the world and turned global supply chains into a commercial nightmare. Model No.’s reliance on local resources and its proprietary 3D printing technology has proven an ideal solution as the world moves toward better manufacturing structures, systems, and in-house technologies that involve minimizing the amount of inventory held in global supply chains. The results are clear, browsing through the company’s site, the artfully designed pieces evoke clean cuts and minimalist elegance, capable of embellishing any living space, but best of all, they come with the added seal of sustainability and disruptive technology at its core. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 30, 2020 at 08:32AM 3D Printz Partners with Fishy Filaments to Distribute Recycled Nylon 3D Printing Filament10/30/2020 3D Printz Partners with Fishy Filaments to Distribute Recycled Nylon 3D Printing Filament https://ift.tt/35Ks3vq There are plenty of unique, and even strange, materials out there that innovative people have figured out how to 3D print with, from a wide variety of food products like chocolate, meat and fake meat, sugar, salt, pancake batter, and even grapes, to nearly every metal imaginable, such as aluminum, titanium, stainless steel, copper, cobalt chromium, and gold. Obviously, we 3D print with a lot of plastic materials, and plenty of biomaterials, and people are 3D printing materials like ceramics, glass, diamonds, fabric, and even cannabis! Cornwall-based startup Fishy Filaments provides another interesting 3D printing material: it turns recycled nylon fishing nets into engineering-grade filament in an effort to save marine life .

By the time Fishy Filaments receives the nets from its independent third party labs, they’ve been used by Cornish fishers for several months already, but that’s all, since the net surfaces become cloudy and stop catching fish. The nylon from these nets is a little salty, and sometimes even has bits of seaweed clinging to it, but the business says “the underlying high quality polymer is still there.” They aim to keep it that way as well, by not over-processing the material and wrecking its value by adding chemical modifiers. Since officially releasing its recycled fishing net filament onto the market last year, the Cornish startup says that artists, hobbyists, professional product designers, and even heavy industries have put the material to good use.

Another UK company that clearly shares the startup’s values is Telford-based 3D Printz Limited, headquartered in the county of Shropshire, which borders Wales to the west. The two recently signed an eco-friendly distribution deal, which will benefit 3D Printz by helping to grow its 3D printing product range.

3D printing has the potential to be a more sustainable method of manufacturing, and this factor is often discussed in the industry. There’s less energy usage and wasted material, more sustainable material options, and often reduced shipping needs as well. So a partnership between a 3D printing specialist and supplier like 3D Printz and Fishy Filaments, which is centered on sustainability, is pretty advantageous for both. You can purchase Fishy Filaments’ premium Porthcurno blend, on 750 g spools, for £59.99 (including VAT) on the sales portal of the 3D Printz website. Named after a spectacular beach in the UK, according to the startup, Porthcurno is good for use in applications where flexibility and translucency are needed, and its light blue-green color means it will take many off-the-shelf dyes pretty well. 3D Printz offers free delivery on orders over £50. (Source: Shropshire Live / Images: Fishy Filaments) Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 30, 2020 at 08:01AM CogniCAD 4.0 Preps Parts for Both 3D Printing and Traditional Manufacturing https://ift.tt/3kHFHFz ParaMatters, the California-based provider of the CogniCAD generative design and multi-material topology optimizing cloud solution, have announced the release of a software upgrade, CogniCAD 4.0. The new upgrade caters to both additive and traditional manufacturers, and includes faster, more robust solvers for design constraints, including vibrational considerations, an advanced structural support generator, and improved features such as hollowing, slicing, orientation, and latticing capabilities to enable improved material saving and efficiency in 3D printing parts.

The software solution automates the development of production-ready generative design and optimized topologies, with built-in finite element analysis, and provides a cloud or Windows desktop-based CAD-agnostic solution for engineers and designers across key industries. The new upgrade now means the software serves a broad range of additive manufacturing, and traditional manufacturing methods, including 3-axis, 5-axis CNC-milling, investment and die casting. What’s more, all designs generated by the CogniCAD platform are directly usable for additive systems and transferrable to traditional manufacturing processes, allowing for easy and flexible integration into existing manufacturing and supply chains. Notably, the software accepts all inputs from a broader and more varied potential user base for industrial production, and can then generate ready-for-production STL or STEP designs, in minutes or hours as opposed to weeks and months. The platform’s services are offered as a pay-per-design or on-going subscription service and are cloud and desktop accessible now. In 2019, the company launched CogniCAD 3.0 at Formnext, with advanced topology optimization features and metal AM simulation capabilities. Now with CogniCAD 4.0, the upgrade has improved on 3.0 and expanded its capabilities to include other manufacturing methods besides AM. The software platform is known for its proprietary functions including its unique mesostructural generative design feature that mimics natural structures to create optimal porous structures and load-optimized designs. The company, with Co-founder and Board Member Avi Reichental, is backed by venture-firm XponentialWorks. In 2018, soon after the software platform was launched at CES 2018, CTO and Co-Founder Michael Bogomolny outlined the effectiveness of one its features in a Linkedin article – showing how its multi-material topology optimization feature could be used to create a significantly lighter, topology optimized titanium-aluminum composed part compared to an aluminum-only part. Such autonomous and user-friendly features with automated CAD-to-production-ready files provides powerful, cloud-based solutions to engineers and designers particularly in automotive, aerospace, motorvehicle and medical industries. Earlier this year, another generative design solution provider Additive Flow, introduced its additive awareness feature, with AM-specific intelligence in part design. In July this year, MSC Software, a subsidiary of Hexagon known for their AM simulation software, released a generative design tool that can be used on laptops to create production-ready optimized designs for 3D printing. And indicating the fast-growing potential in additively-intelligent design software in digital manufacturing workflows, nTopology closed a round of funding, led by New York-based Insight Partners, raising its total to $40 million in funding to date. This further points towards the acceleration being made in AM-specific software over the last three years, as observed by SmarTech in its look into the additive manufacturing software landscape 2020. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 30, 2020 at 07:31AM HP Announces New 3D Printing Software Powered by Dyndrite, New TPA Powder with Evonik https://ift.tt/2HNzZE6 This summer, Seattle-based additive manufacturing hardware and software solutions provider Dyndrite and HP decided to join forces to license Dyndrite’s geometric kernel technology in order to power next-generation cloud and edge-based digital manufacturing solutions. The goal was for HP, the founding member of the Dyndrite Developer Council, to create a software platform that could power AM factories of the future. This week, the two companies announced the first commercial application built on Dyndrite’s core Accelerated Geometry Engine: HP’s Universal Build Manager Powered by Dyndrite, an advanced AM software solution.

As a solution for delivering CAD-to-print workflows for additive, the new Universal Build Manager Powered by Dyndrite will work to bring automation, improved performance, and scalability to the AM industry. It includes strong build preparation tools, such as support generation, slicing, patterning, nesting, labeling, and CAD import. According to a Dyndrite press release, it’s an OEM- and process-agnostic tool, as well as the first GPU-accelerated AM Build Prep and Management solution in the industry. Dyndrite’s plug-in architecture helps to protect important IP, and HP’s Universal Build Manager Powered by Dyndrite offers a process- or machine-specific plugin infrastructure, so 3rd party software and hardware developers don’t miss out.

This solution supports several different production-grade AM technologies: Binder Jetting, Selective Laser Melting (SLM), Powder Bed Fusion/DMLS, Selective Heat Sintering (SHS), Electron Beam Melting (EBM), Selective Laser Sintering (SLS), Fused deposition Modeling (FDM), Stereolithography (SLA), Digital Light Projection (DLP), Laminated Object manufacturing (LOM), Composite-Based Additive Manufacturing (CBAM), and, of course, HP’s Multi Jet Fusion. Because it’s powered by Dyndrite, the software leverages its Engine for integrated Python scripting APIs for automation and workflow integration, and also uses NVIDIA Enterprise GPUs for computation acceleration. This will, according to HP, allow for personalization and end-to-end control.

To learn more, check out Dyndrite’s case study, or log on to its Dyndrite Day event at 11 am EST, October 29th, for a sneak peek at the new HP Universal Build Manager Powered By Dyndrite. HP has even more news to share—together with its long-time partner, chemical company Evonik, it has developed a new co-branded elastomer, which has been optimized for HP’s Multi Jet Fusion (MJF) technology and will be sold exclusively through HP. This new specialty powder is a flexible, high-performance 3D printing material based on a thermoplastic amide grade (TPA), and will be presented virtually at formnext connect, November 10-12th.

The newly released thermoplastic elastomer is a lightweight-construction material with a Shore A hardness of 91 and a very low density of 1.01 g/cm³. According to Evonik, TPA has high fatigue resistance and durability, and is well-suited for prototypes, and even functional end-use products, that require high energy return and extensibility, like automobile components, sporting equipment, end-of-arm tooling, and ducting and bellows. Additionally, it’s a perfect match for efficiently creating high-quality parts on HP’s Jet Fusion 4200 3D printers.

Evonik’s TPA ready-to-use material is excellently suited for production of functional high-tech 3D plastic parts—prototypes as well as series products—that call for high extensibility and energy return, such as sports equipment or automobile components.

Several Evonik customers, such as GoProto, a rapid manufacturing company that specializes in quick-turn, on-demand, custom manufacturing, have already put Evonik and HP’s new TPA to the test.

“The combination of production quality material properties like high wear resistance, energy return, longevity and light weight continues to impress at every application,” says Jesse Lea, President & CEO at GoProto. (Image: GoProto) Enabled by the new elastomeric TPA, GoProto has just introduced 3DElastoPrint, a 3D printing parts service that makes rubber-like parts for customers that traditional manufacturing methods would not be able to achieve.

(Images courtesy of HP unless otherwise noted) Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 30, 2020 at 07:02AM Markforged Gets New CEO as Founder Gregory Mark Becomes Chairman https://ift.tt/34GPWo7 3D printer manufacturer Markforged will have a new CEO, as Shai Terem takes over, replacing company founder Gregory Mark, who transitions to the role of Chairman. The company said the change in leadership is the result of a planned succession, designed to position the company for continued success in its next phase of growth. Particularly as the additive manufacturing (AM) industry experiences rapid adoption amid supply chain disruptions and ongoing evolution. Terem, who previously served as President and Chief Operating Officer (COO), will now take on the development and execution of short- and long-term strategies and day-to-day operations. His main goal is to continue delivering value to key stakeholders as the company continues to scale. In his previous capability, Terem had reorganized the go-to-market strategy to have a channel-first approach and built a strong infrastructure for rapid, efficient, and scalable growth. Joining Markforged in December 2019, Terem already had significant operational and leadership experience in the industrial 3D printing sector, having served as President of the Americas region at Kornit Digital, a worldwide market leader in 2D digital printing for textiles. Before that, Terem spent four years with Stratasys, where he had roles in increasing leadership in product marketing, channel enablement, finance, and operations. The Israeli-born executive served for 11 years in the Israeli Navy (IDF) before going on to lead several teams in banking institutions and founding companies, and describes himself as a “proven team builder” who “always finds a way to get things done.”

In his new role as chairman, Mark will focus on evangelizing the adoption of AM platforms among engineers, designers, and manufacturing professionals. As Markforged’s leader for the past seven years, Mark, an MIT alum at the Department of Aeronautics and Astronautics, has helped democratize metal and carbon fiber 3D printing. He also considered that before he founded the company, access to strong 3D printed parts was limited only to those who could afford million-dollar machines. Today, however, there are thousands of parts in just about every industry: “We have parts flying in space, and on commercial and military jets; we have hundreds of thousands of parts used by frontline workers to fight COVID.” All of them are printed on a platform that is robust enough for end-use aerospace, but even affordable to high schools and colleges. Quote request Are you looking to buy a 3D printer or 3D scanner? We're here to help. Get free expert advice and quotes from trusted suppliers in your area. Powered by Aniwaa

The Metal X 3Dprinter enables job shops to deliver parts to customers faster and at lower cost by quickly tooling up a production line. Image courtesy of Markforged Since its foundation, Markforged has transformed manufacturing with 3D metal and carbon fiber printers, capable of producing parts tough enough for the factory floor. Created in 2013 and based in Watertown, Massachusetts, Markforged now has about 300 employees globally, with $137 million in both strategic and venture capital. The company’s range of end-to-end processing systems has steadily become the go-to platforms for many users that want to improve the production of parts, like the US Department of Energy (DoE)’s national science laboratory Sandia National Labs, Škoda Motor, and the Dubai Electricity & Water Authority (DEWA), just to name the most recent ones. According to the company, AM is approaching a tipping point. While 3D printing technologies have been available since the late 1980s, considerable advancements in technology and unprecedented supply chain disruption driven by the ongoing global pandemic are supporting mainstream adoption. A 2020 Wohlers Report projects the AM industry will grow eleven times over the next decade to become a $640 billion industry, offering a wider market for Markforged.

The X7 by Markforged is the turnkey industrial 3Dprinter for every type of functional part. Image courtesy of Markforged

With one of the largest connected install base and fastest growth in its category worldwide, Markforged continues to build a leadership team to position the company, its customers, and partners to take full advantage of the innovations supporting the latest significant wave of manufacturing disruption. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 30, 2020 at 06:32AM

https://ift.tt/31WgbW5

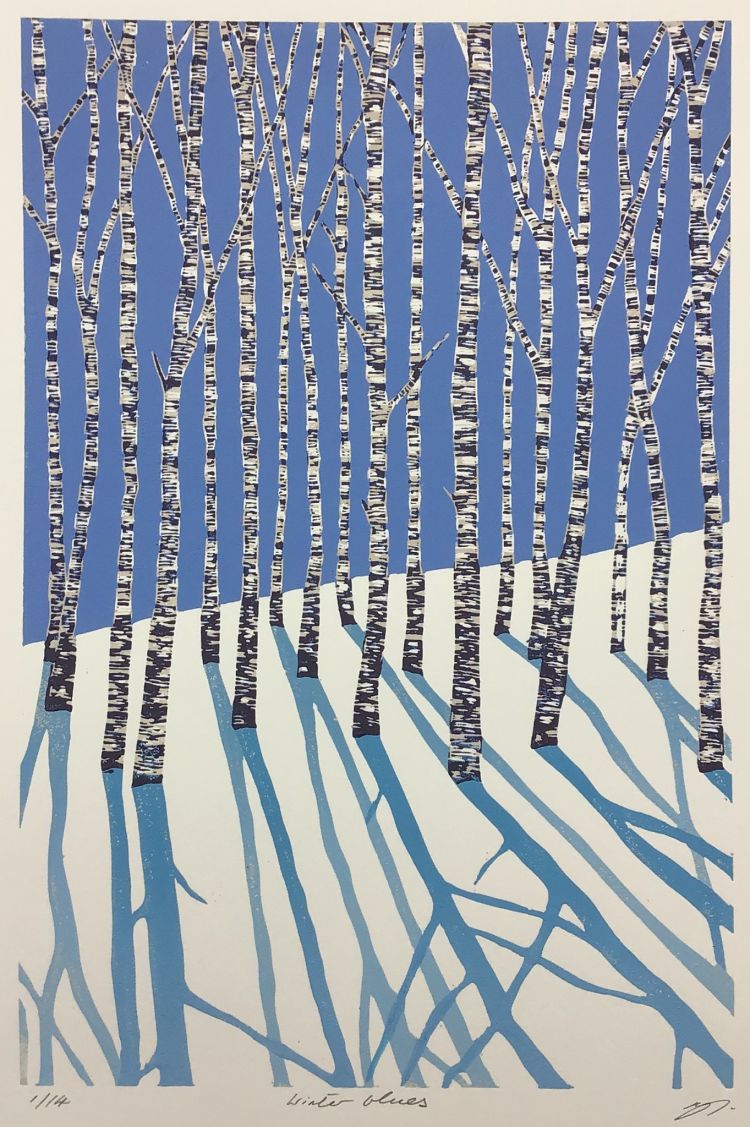

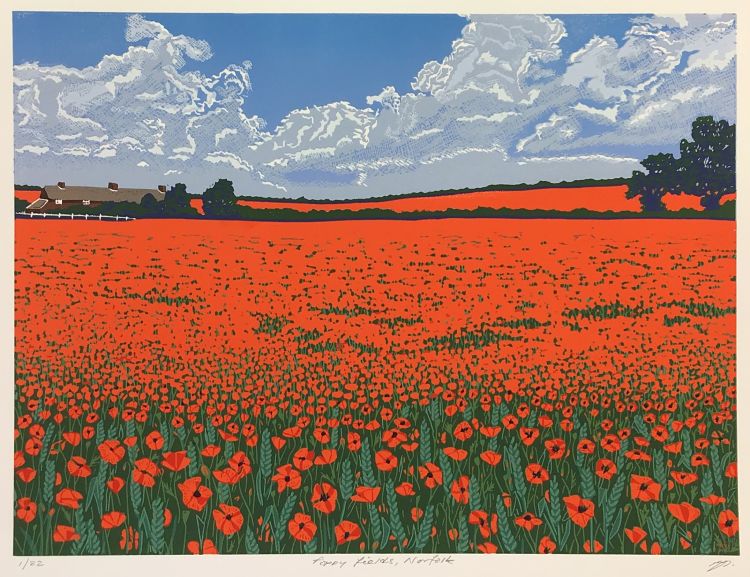

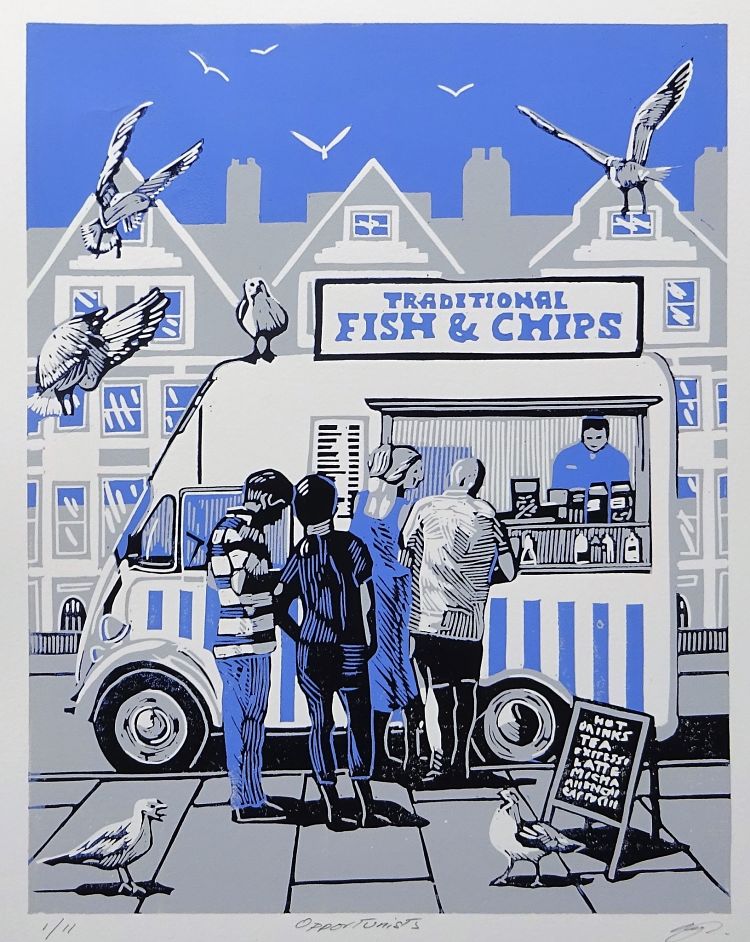

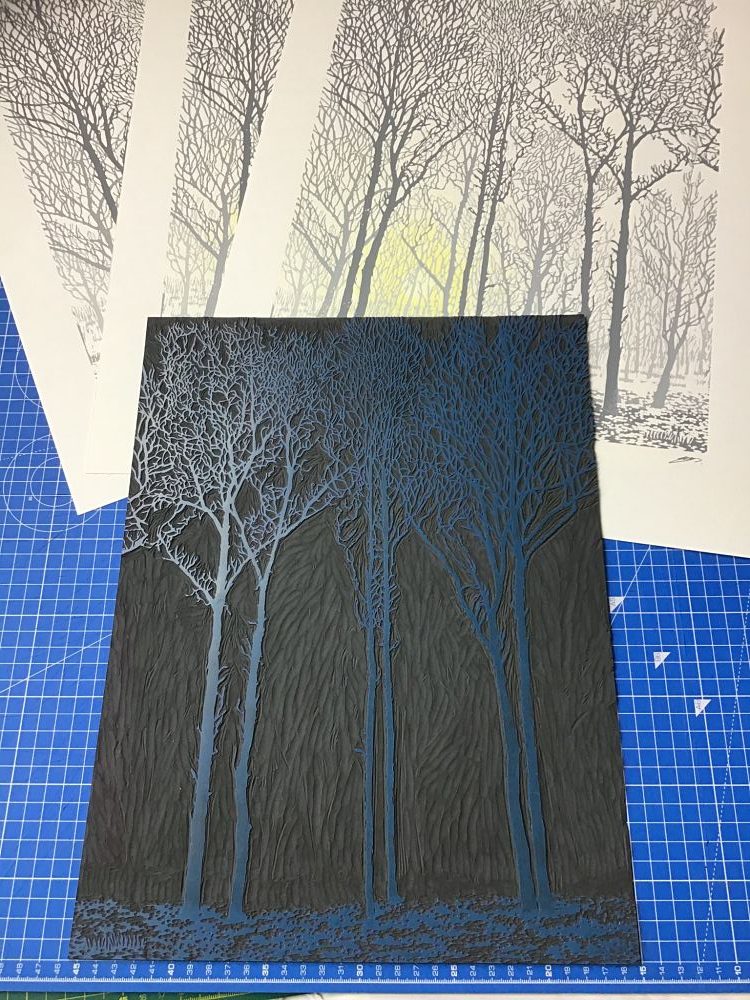

Margaret Mallows https://ift.tt/3kHjVlx Following early success as a teenager exhibiting oil paintings at the prestigious Mall Galleries in London, Margaret Mallows found her aspirations to pursue art thwarted by a busy work and family life. Four years ago, after deciding to retire early from work, she found the time to once again create art.

You can apply to join our printmaking community at www.members.peopleofprint.com. Printing via People of Print https://ift.tt/2DhgcW7 October 30, 2020 at 04:49AM U.S. Postal Service Continues to Deliver a Record Number of Ballots https://ift.tt/31UbXy2 Oct. 29, 2020 U.S. Postal Service Continues to Deliver a Record Number of Ballots122 Million Ballots Processed and Delivered Amid Historic Political and Election Mail Volume; Extraordinary Measures Underway to Deliver Ballots Currently in Mail System WASHINGTON, DC — With less than one week until the November election, new U.S. Postal Service data show an exceedingly high-volume of mail moving through the system and a focus on delivery of ballots. “With increased volume in both mail and packages and external challenges, mail is moving,” said Kristin Seaver, Chief Retail and Delivery Officer of the Postal Service. “The Postal Service continues to implement extraordinary measures to advance and expedite the delivery of the nation’s ballots. These efforts include extra pick-ups, extra deliveries, and delivery units running regular collections on Sunday. From today through Sunday, local carriers will be stopping at and checking every residential mailbox for outbound mail, including ballots.” Key Facts

Due to an increase in overall mail volume of all types, COVID-19 impacts, the Oct. 12 federal holiday and ongoing efforts to prioritize and advance the nation’s ballots, First-Class Mail service performance was 80.85 percent for the week of Oct. 17 through Oct. 23. “While our ongoing commitment is to maintain the highest level of service performance for all mail, we acknowledge that our full focus and prioritization on election ballots is having a near-term impact on the overall on-time performance of other products throughout the network,” continued Seaver. “Additionally, we are actively engaging with our management teams and union leadership to ensure we have the right level of staffing and oversight given the increased impacts of COVID-19, and our unwavering commitment to keeping employees and customers safe.” “In the final push through the election, our entire team remains laser focused on advancing ballots to local boards and election officials as quickly as possible,” said Seaver. 1Election ballot counts are measured by use of Intelligent Mail Barcode with Ballot identifier. If a ballot was entered without these identifiers it is not measured in the count. This information is provided for illustrative purposes to provide sense of scale of Election Mail volume the Postal Service has and continues to process and deliver this election season. Outbound ballots are defined as blank ballots delivered from election officials to voters and inbound ballots are defined as completed ballots delivered from voters to election officials. ### Printing via USPS News https://ift.tt/2hH9aDC October 29, 2020 at 03:15PM

https://ift.tt/3mERm93

50 Letterpress Printers, Studios, and Artists You Should All Know About https://ift.tt/3myqAPl People of Print are excited to present a list of our top 50 letterpress printers, studios and artists. Including typographic studios, bespoke stationery printers, and some of our very own Official POP Members, we’ve compiled some of our favourite letterpress artists who are bringing and maintaining the heritage craft of letterpress printing into the modern age. 1: Type Tom 2: No Plan Press 3: La Tipografa Toscana 4: Thomas Mayo & Co 5: The Garage Press 6: Fresh Lemon Print 7: Letterpress de Paris 8: Neu Haus Press 9: M. C. Pressure 10: One Strong Arm 11: Letterpress Play 12: Rodrigo Cuberas 13: TypographHer 14: Bruno Press 15: Vahalla Studios 16: Wood Words 17: IS Projects 18: Letterpress Design / Lyme Bay Press 19: p98a 20: Swell Press 21: Starshaped Press 22: InPressed 23: Dafi Kuhne 24: Fireater 25: Typoretum 26: Coxswain Press 27: The Liquorice Press 28: De Kijm & zonen 29: Three Cheers Press 30: Reflex Letterpress 31: The New Typography Workshop 32: Ane Thon Knutsen 33: Mayday Press 34: The Alphabet Press 35: Archivio Tipografico 36: Karakter Prints 37: Prelo Prints 38: Ben Blount 39: David Wolske 40: Prickly Pear Paper 41: Blackbird Letterpress 42: Kennedy Prints 43: Tipo Móvil 44: Artcadia 45: Matt Holmes 46: Gingerly Press 47: The Letterpress Collective 48: D&D Letterpress 49: Drayson & Stock 50: Paper Jam Press Printing via People of Print https://ift.tt/2DhgcW7 October 29, 2020 at 10:17AM

https://ift.tt/2HMmioo

What Audience Development Is (And 4 Steps to Build Your Clique) https://ift.tt/2HNOlnn Your audience keeps your brand relevant. You may know this already but without them, your brand is as good as dead. That’s why audience development is critical for every business. It focuses on a key element of your business — your customer base. It also helps you stay aware of their needs and maintain a lifetime connection with them so they keep coming back. So what does ‘audience development’ mean?Remember how you feel when someone gets you a very expensive gift… Happy, right? Now imagine someone goes out of their way to get you a box of your favorite brand of chocolate and a bottle of your favorite wine? It’ll make you feel special and loved. It’s the same with your audience — they feel special and important when they see content that’s tailor-made for them. Or when you send them a short email wishing them a happy birthday. It’s the little things you do consistently that help you build your audience and lead to a boost in revenue, and an increase in your customer base and repeat customers. This is what audience development is all about: building and nurturing a crowd of loyal people and customers around your brand who constantly engage with you and keep coming back for more. It’s about getting to know your customer base to understand the kind of content they like to see. This way, you can anticipate their needs and create content and campaigns that resonate with them. It’s more effective than aggressive and mindless marketing. Because the more you connect with your audience, the better you can create content that’s carefully personalized for them; research even shows that 63% of consumers prefer personalized content. Your audience development plan in 4 steps:As a business owner, you need to prioritize audience development. But this isn’t an easy feat especially if you’re a new business owner without any experience with it. So how do you build an audience of raving fans? Strategic content marketing, that’s how. Because content marketing focuses on creating and sharing valuable content to attract your target audience. And in this blog post, you’ll be learning how to build your audience from scratch with a 4-step strategy: Step 1. Build a compelling brand storyYour brand story is simply the story of the values, ideas, and experiences that shape your brand. For example, HEY.com’s brand story is completely ingenious — a perfect example of a compelling brand story. The company was born after the co-founders, Jason and David, wanted to change and improve how people use email. So they built HEY.com. Their brand story, featured on their homepage (as shown in the screenshot above), is a written representation of what they’re really about, why they exist, and what sets them apart from their competitors — and yours should too. A compelling brand story is the foundation for creating relevant content to attract your audience without trying too hard. So how do you build a compelling brand story?

Step 2. Choose your audience development channel(s)To build your audience, choose content marketing channels to help you engage and connect with your customer base. There are different channels you can use for effective audience development. You can create a blog on your website and engage with your audience there. You can also use social media outreach platforms like Pinterest, LinkedIn, Facebook, Instagram, YouTube, and Twitter. Lastly, you can build an email list and engage your customer base through email. And research by Databox reveals that 44% of marketers say that email and social media marketing were effective for reaching their target audience. But remember to stick to actively using 1-3 channels to begin with so you don’t get overwhelmed. Ideally, there are two key channels that need to be part of your audience building strategy:

Let’s take them one after the other: Key channel A: Social media interactions — while being focused on your audience’s needsSocial media helps you make your brand more accessible to your audience. So when coming up with a social media strategy, be aware of these two things:

This infographic from Accion highlights the features of various social media platforms to help you choose the best one for your business: Key channel B: Email marketing with a personal touchEmail marketing is a digital marketing strategy that lets you connect with your audience through email. And when you’re creating email campaigns and newsletters, remember this:

Step 3. Create meaningful, hyper-relevant contentOnce you’ve selected your favorite channels to build an audience on, you need to prioritize sharing only relevant content. Relevant content will always resonate with your audience. So make sure you’re creating content that they find relevant (useful), not just creating content to fill up your page or tick a checklist in your marketing strategy. When your content inspires your audience to take actions that better their lives, they’ll keep coming back. Besides that, relevant content gives them something to share with their followers and connections that will attract new customers. Tools for creating contentTo create content that will wow your audience, there are several tools you can leverage to help with your design, research, writing, and editing process. Here’s a list of some great tools (based on their function) that will help you create well-structured, accurate, and visually appealing content: How to create hyper-relevant contentThe only way to create content that resonates with your audience is to first carry out audience research and come up with topics that will attract them. Then come up with an attractive headline optimized for search engines. Your content should be well researched, accurate, thought-provoking, and informative for your audience. Mom and Dad Money is a great example of a business that’s creating content to attract their audience. They’re a financial service company that helps new parents make financial decisions that will keep them financially secure. The company has a great blog with good financial advice for parents in every area of life from health insurance and investments, to budgeting and saving for college. This content hooks their audience because they learn from these blog posts and apply them in real life. Take a look at the amount of traffic their website got this month: And while 17k visitors may not look like much to you, it’s a pretty good number for a niche website that has content specifically targeted at an audience. Step 4. Promote content that will reach your audienceWith the huge amount of content created on a daily basis, you need to promote your content so your audience actually sees it. Promoting your content helps you make the most of it, so instead of creating multiple pieces of content every day, you can focus on developing one good piece of content and then repurpose it through promotion. Remember to use the best promotion tactics for the audience development channel you’ve chosen. Here are different ways you can promote your content to reach your target audience: I. Hold online contestsHolding online contests where customers can win freebies is another way to get people talking about your brand and grow your audience. An example of a brand doing this is The Souled Store. They held a giveaway with some of their products on Instagram. To enter, users had to like the picture, follow their Instagram page, and tag their friends who remind them of iron man. This is a free content promotion tactic for them as they got lots of engagement on that post with over 5000 likes, and over 600 comments. II. Network on social mediaYou can comment on posts and network with prospective clients using your preferred audience development channels. Connecting with your target audience will get you noticed and will drive traffic to your page and website. No wonder 73% of marketers believe in the power of social media. You can also use paid promotion channels; each social platform has options for sponsored ads, sponsored posts, and targeted or customized ads. III. Offer existing customers freebies when they refer your business to others.When you offer loyal clients freebies for referrals, it makes them a lot more motivated to tell others about you because they know there’s something in it for them. For example, Scribe Writing, a book publishing company, offers their published authors $2,000 dollars for referring other authors to them. They get the money in cash when the new author signs up to get published with them. IV. Google and Facebook adsFacebook and Google have great ad campaigns your business can take advantage of. There are various Facebook ads, but creating a custom audience and targeting lookalike audiences is best for audience development. You can upload your email list to Facebook and target them or target lookalike audiences that have the same interests or are of the same age bracket as your customer base. Erika Volk, a fitness expert, created a Facebook ad advertising her free email course. Her goal was to build her email list, so clicking on the ad took leads to a landing page to register for the email course. The results were amazing — they got 1,892 email subscribers and 11,850 visitors in one month. V. Create lead magnets to build your email listWhen you promote content and get the attention of your target audience, you need to offer them lead magnets to build your list. You can create lead magnets like webinars, ebooks, toolkits, YouTube videos, and more to attract new customers to join your email list. A lead magnet is an incentive or value proposition you offer prospective customers in exchange for their email addresses. It’s a win-win situation because your prospective customer gets value while you get to build your customer base. For example, MuleSoft — a Salesforce company — offers prospective customers an ebook to help improve their apps. With this, they’re able to get more potential clients to their email list. ConclusionNow that you know all about audience development, you can start building your own clique. Having a brand community will help you build your business, so pay attention and stay connected to them. A large customer base means more profit for you and return customers who stay loyal to your brand and refer you to their network. Remember, you can only be remembered when you keep reaching out. Printing via GetResponse Blog https://ift.tt/2Xap2TD October 29, 2020 at 10:04AM |

Categories

All

Archives

April 2023

|

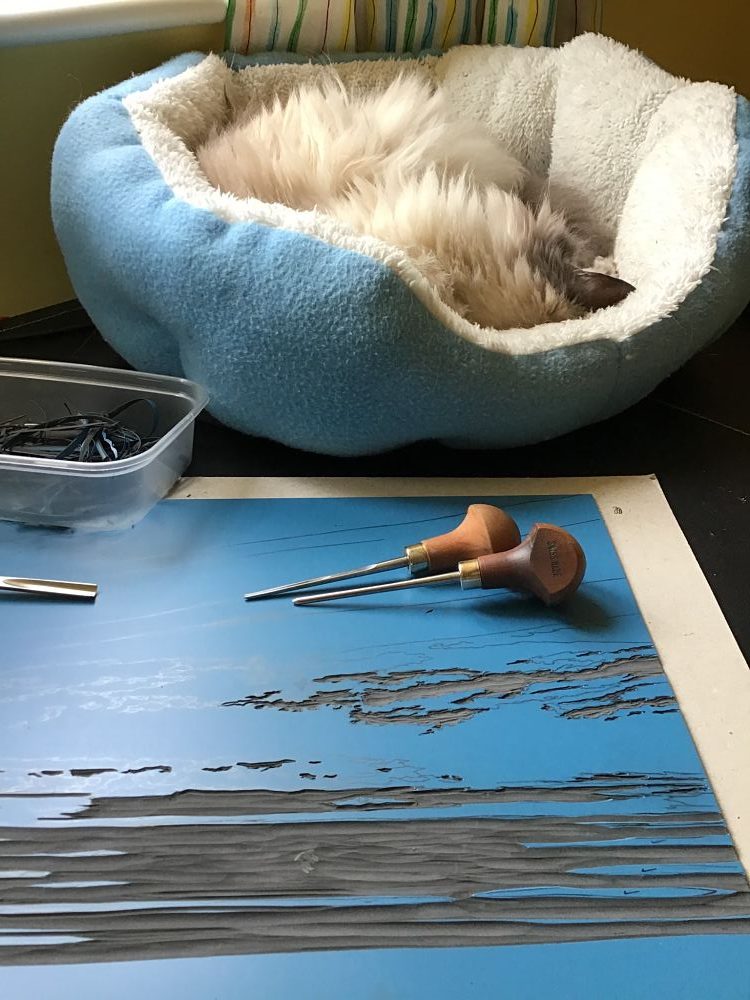

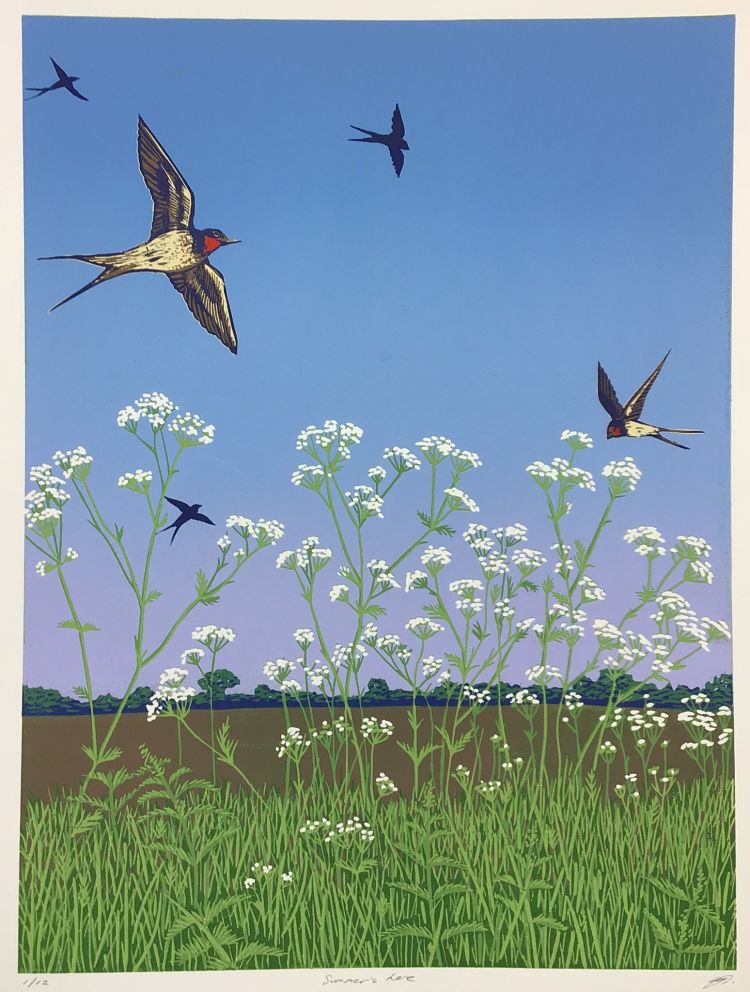

Having always had a love of all types of print and a growing collection bought over the years, Margaret decided to teach herself lino printing; armed with a book and basic kit, her very first attempt had her hooked. Despite no training in the printing method, within a few months her confidence in her work had grown and she began exhibiting locally and selling online. Margaret’s work has again been exhibited at The Mall galleries as well as local exhibitions, won competitions and awards, and can be found in 21 countries worldwide.

Having always had a love of all types of print and a growing collection bought over the years, Margaret decided to teach herself lino printing; armed with a book and basic kit, her very first attempt had her hooked. Despite no training in the printing method, within a few months her confidence in her work had grown and she began exhibiting locally and selling online. Margaret’s work has again been exhibited at The Mall galleries as well as local exhibitions, won competitions and awards, and can be found in 21 countries worldwide.

Inspiration is often found from her surroundings in the Fens in East Anglia, and her garden and home. She also often brings a twist of humour to her prints. Most of her works are multi-colour reduction prints; just one sheet of lino is used for an entire print, with more cutting away of the lino after each colour is printed. By the time the print is finished, there may be very little of the lino sheet left. This type of printmaking leaves no room for error; if at any stage a mistake is made, it will ruin the entire edition. “Adrenaline runs high throughout the whole process! It’s a slow, methodical process of building the print one layer at a time” describes Margaret.

Inspiration is often found from her surroundings in the Fens in East Anglia, and her garden and home. She also often brings a twist of humour to her prints. Most of her works are multi-colour reduction prints; just one sheet of lino is used for an entire print, with more cutting away of the lino after each colour is printed. By the time the print is finished, there may be very little of the lino sheet left. This type of printmaking leaves no room for error; if at any stage a mistake is made, it will ruin the entire edition. “Adrenaline runs high throughout the whole process! It’s a slow, methodical process of building the print one layer at a time” describes Margaret.

Her favoured materials are Japanese vinyl, Pfeil cutting tools, Somerset satin paper and Schmincke inks. Margaret doesn’t have a studio, instead working from home; her study being the place to sit and draw and carve lino, often accompanied by her ‘supervisor’, a Ragdoll cat called Phoebe, who has a bed on the desk. Also in the study is an indoor drying line for hanging prints, with pegs with holes drilled through the tops and threaded through the line to maximise space. Her kitchen/diner serves well as a place to ink and print, and the dining table holds a large table top press.

Her favoured materials are Japanese vinyl, Pfeil cutting tools, Somerset satin paper and Schmincke inks. Margaret doesn’t have a studio, instead working from home; her study being the place to sit and draw and carve lino, often accompanied by her ‘supervisor’, a Ragdoll cat called Phoebe, who has a bed on the desk. Also in the study is an indoor drying line for hanging prints, with pegs with holes drilled through the tops and threaded through the line to maximise space. Her kitchen/diner serves well as a place to ink and print, and the dining table holds a large table top press.

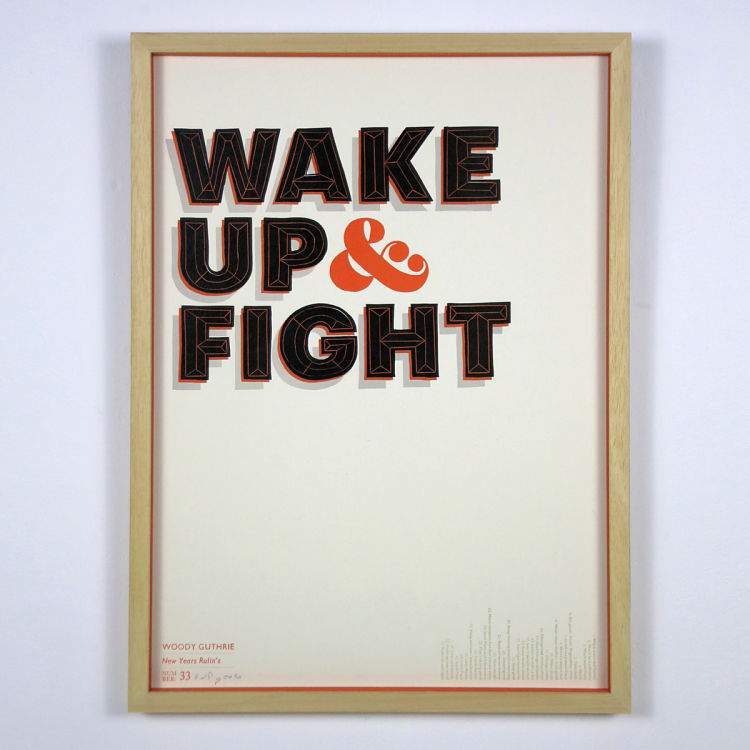

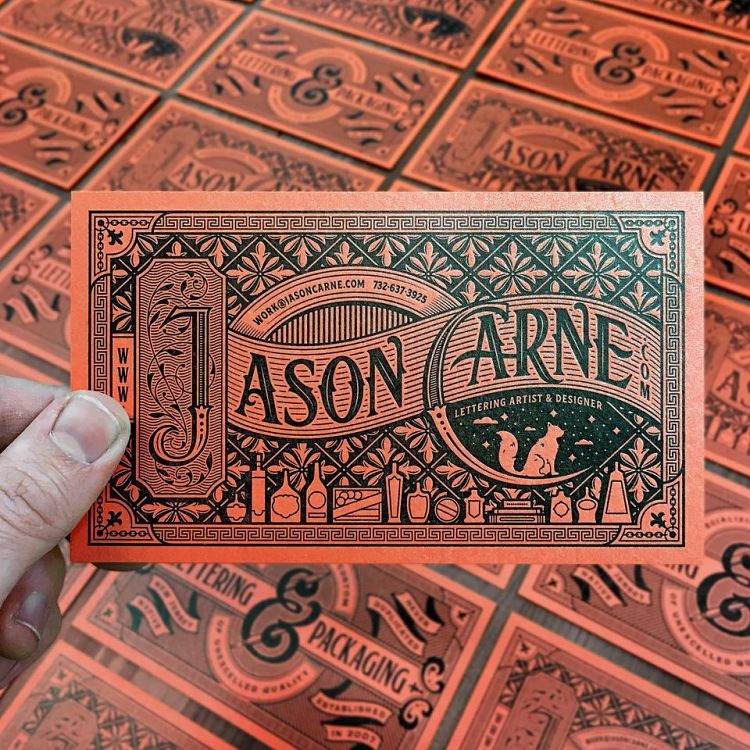

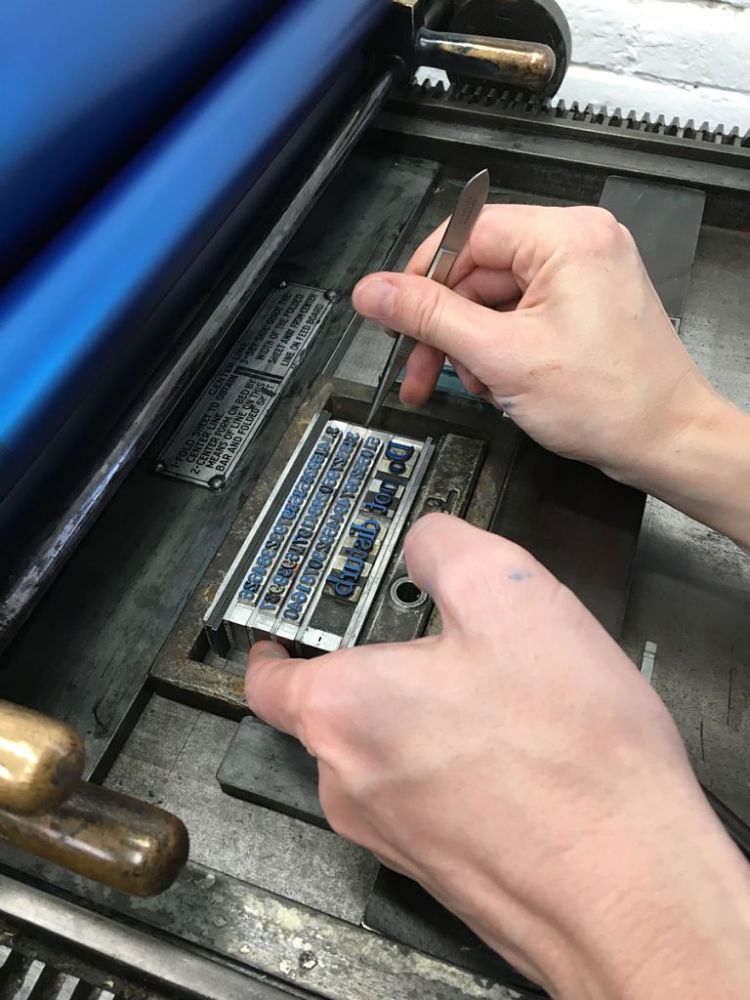

With over 10 years worth of experience in Letterpress printing and type design, Type Tom aka Tom Boulton has created work for both trade and personal clients, including organisations such as Tate Modern, Southbank Centre, V&A, Fortnum & Mason, and Design Museum. Tom operates his printmaking studio with an ethical ethos, aiming to reduce, reuse and recycle as much as possible, as well as fixing up and repairing old machinery. After completing his degree in Typographic Design at the London College of Printing, Tom has since moved to live and work by the sea in Bognor Regis, where he is growing his type and printing press collection.

With over 10 years worth of experience in Letterpress printing and type design, Type Tom aka Tom Boulton has created work for both trade and personal clients, including organisations such as Tate Modern, Southbank Centre, V&A, Fortnum & Mason, and Design Museum. Tom operates his printmaking studio with an ethical ethos, aiming to reduce, reuse and recycle as much as possible, as well as fixing up and repairing old machinery. After completing his degree in Typographic Design at the London College of Printing, Tom has since moved to live and work by the sea in Bognor Regis, where he is growing his type and printing press collection. Letterpress Studio No Plan Press is driven by the idea that having no plan is sometimes the best plan. The studio was founded and is run by Jesse Kirsch. Knowing his best work happens without a blueprint, Jesse finds new ways to use geometry, colour, and bold typography in order to explore the everyday from a different perspective. No Plan prints are modern, fun and guaranteed to make you think.

Letterpress Studio No Plan Press is driven by the idea that having no plan is sometimes the best plan. The studio was founded and is run by Jesse Kirsch. Knowing his best work happens without a blueprint, Jesse finds new ways to use geometry, colour, and bold typography in order to explore the everyday from a different perspective. No Plan prints are modern, fun and guaranteed to make you think. Based in Tuscany, Italy, La Tipografa Toscana have an online shop where they sell beautiful letterpress prints, as well as offering custom letterpress printing and workshops from their studio. Owner, Martina Vincenti set up the studio in order to preserve the ancient printing technique, and cultivate and spread the culture of artisan typography, all whilst furthering her talents as a typographer, graphic designer and craftswoman.

Based in Tuscany, Italy, La Tipografa Toscana have an online shop where they sell beautiful letterpress prints, as well as offering custom letterpress printing and workshops from their studio. Owner, Martina Vincenti set up the studio in order to preserve the ancient printing technique, and cultivate and spread the culture of artisan typography, all whilst furthering her talents as a typographer, graphic designer and craftswoman. Based in a small village in the Cotswolds UK, Thomas Mayo & Co produce letterpress and foil blocked prints, business cards and other ephemera using a variety of vintage presses and time-honoured techniques. Laser-cut and CNC manufacturing is often used within his work, combining newfangled processes with these old methods. Working with many designers in different fields (hence the “& Co”) Thomas Mayo produces a wide range of products from bespoke prints, movable wooden printing type and blocks, to large-scale installations.

Based in a small village in the Cotswolds UK, Thomas Mayo & Co produce letterpress and foil blocked prints, business cards and other ephemera using a variety of vintage presses and time-honoured techniques. Laser-cut and CNC manufacturing is often used within his work, combining newfangled processes with these old methods. Working with many designers in different fields (hence the “& Co”) Thomas Mayo produces a wide range of products from bespoke prints, movable wooden printing type and blocks, to large-scale installations. The Garage Press was founded in a South London garage in 2018 by Simon Trewin, who has spent the last twenty-five years working with internationally renowned musicians, authors and brands on furthering their literary and publishing ambition. Simon designs and prints onto paper and card using found vintage images and fonts from a variety of sources including his own library of vintage wood and metal type, and antique blocks. As well as creating his own range of cards, prints and bookmarks, Simon also undertakes commissions for a selection of clients. You can also check out their shop on

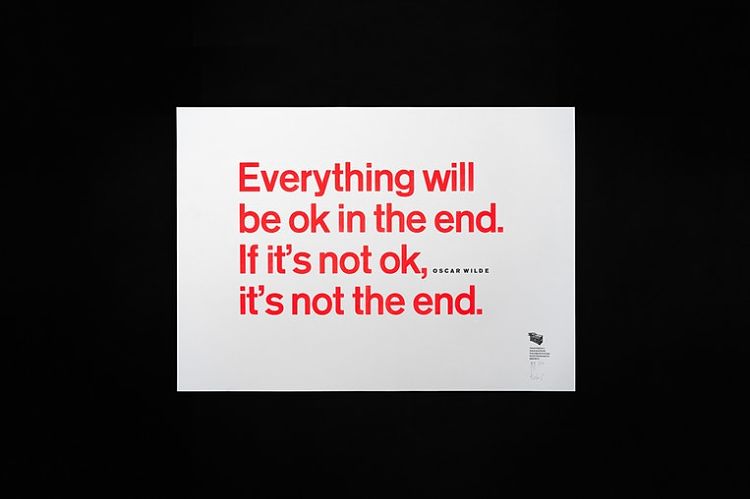

The Garage Press was founded in a South London garage in 2018 by Simon Trewin, who has spent the last twenty-five years working with internationally renowned musicians, authors and brands on furthering their literary and publishing ambition. Simon designs and prints onto paper and card using found vintage images and fonts from a variety of sources including his own library of vintage wood and metal type, and antique blocks. As well as creating his own range of cards, prints and bookmarks, Simon also undertakes commissions for a selection of clients. You can also check out their shop on  Fresh Lemon Print is a typographic and letterpress studio creating funky limited edition posters using traditional printing techniques. Created by Phil Gambrill, who by day, is an award-winning graphic designer and by night, turns back the clock and enters his letterpress studio to set wood block type and create unique letterpress posters. Phil enjoys nothing more than lifting a fresh print from the press and marvelling at the wonderful imperfections caused by the ageing wood type, whilst cursing in frustration as to why certain letters, just won’t print!

Fresh Lemon Print is a typographic and letterpress studio creating funky limited edition posters using traditional printing techniques. Created by Phil Gambrill, who by day, is an award-winning graphic designer and by night, turns back the clock and enters his letterpress studio to set wood block type and create unique letterpress posters. Phil enjoys nothing more than lifting a fresh print from the press and marvelling at the wonderful imperfections caused by the ageing wood type, whilst cursing in frustration as to why certain letters, just won’t print! Situated in the heart of Paris is the small print shop, Letterpress de Paris, who specialise in letterpress printing and hot foil stamping. Alongside working together with artists and designers on custom pieces, the team have also created a stationery line, including greeting cards and note books. Their goal is to build bridges between the art scene and old-school printing techniques, whilst having fun and creating cool things.

Situated in the heart of Paris is the small print shop, Letterpress de Paris, who specialise in letterpress printing and hot foil stamping. Alongside working together with artists and designers on custom pieces, the team have also created a stationery line, including greeting cards and note books. Their goal is to build bridges between the art scene and old-school printing techniques, whilst having fun and creating cool things. Neu Haus Press is a print shop located in Portland, OR, focusing on creating and printing letterpress art. The studio was founded in 1996 by Chris Chandler when he acquired his first Vandercook Press in Venice Beach, CA. Through the years his love, talent, knowledge and collection of this vintage craft has grown. From 30 years working as a tour manager and sound engineer for bands he has had the privilege of sharing his passion of letterpress with musicians in collaborations with their art work.

Neu Haus Press is a print shop located in Portland, OR, focusing on creating and printing letterpress art. The studio was founded in 1996 by Chris Chandler when he acquired his first Vandercook Press in Venice Beach, CA. Through the years his love, talent, knowledge and collection of this vintage craft has grown. From 30 years working as a tour manager and sound engineer for bands he has had the privilege of sharing his passion of letterpress with musicians in collaborations with their art work. M. C. Pressure offer a range of letterpress and hot foil stamping services. For the team, printmaking is special in that it offers a handmade touch. The company is continually growing by acquiring new presses and new collaborations with an exciting and broad range of clients. From their Florida studio the team work on commissions and collaborations, and also create their own range of letterpress printed stationery and accessories.

M. C. Pressure offer a range of letterpress and hot foil stamping services. For the team, printmaking is special in that it offers a handmade touch. The company is continually growing by acquiring new presses and new collaborations with an exciting and broad range of clients. From their Florida studio the team work on commissions and collaborations, and also create their own range of letterpress printed stationery and accessories. Located in the heart of Dublin city, One Strong Arm is a letterpress print studio creating contemporary typography-led work using traditional methods. The studio’s output usually involves their ever-growing collection of antique wood and metal type, but on occasion, it will also include some more modern techniques and processes. While much of their work comes in the form of self-initiated projects, they also work closely with designers, artists, agencies, writers, musicians, illustrators, collaborators, experimenters and co-conspirators to create thoughtfully produced work of all kinds.

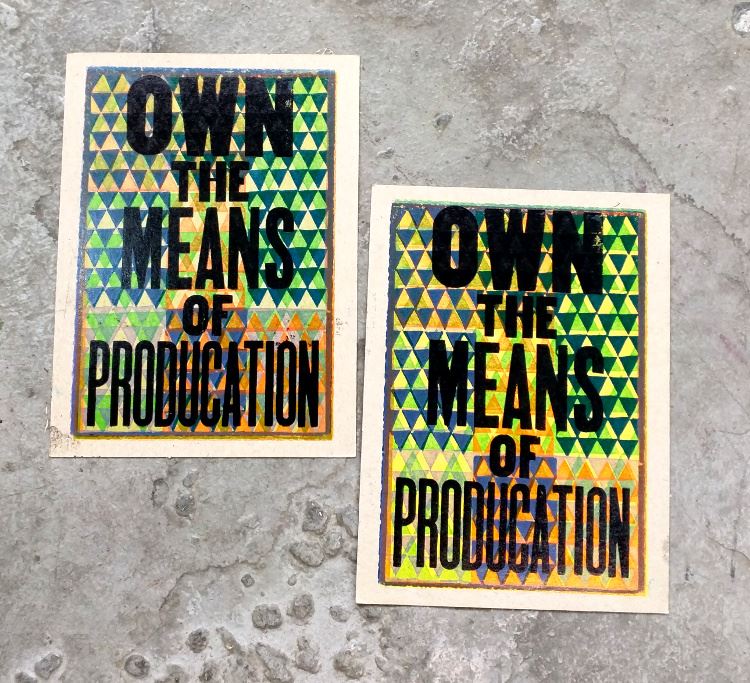

Located in the heart of Dublin city, One Strong Arm is a letterpress print studio creating contemporary typography-led work using traditional methods. The studio’s output usually involves their ever-growing collection of antique wood and metal type, but on occasion, it will also include some more modern techniques and processes. While much of their work comes in the form of self-initiated projects, they also work closely with designers, artists, agencies, writers, musicians, illustrators, collaborators, experimenters and co-conspirators to create thoughtfully produced work of all kinds. Founded by Kyle Hawley, and printed in Austin, Texas, Letterpress PLAY strive for sustainability in their practices, supporting community and fostering play for all. Their collection of zero-waste paper toys, cards, posters, washable paper hats, hankies, and garments aim to inspire curiosity and wonder. A portion of their proceeds also go to their favourite children’s charities. Letterpress PLAY’s range of paper products employ a full range of printing methods using lead or wooden type, blocks, or polymer plates. All items are printed by hand or with machines dating back to the Industrial Revolution, and are 100% biodegradable.

Founded by Kyle Hawley, and printed in Austin, Texas, Letterpress PLAY strive for sustainability in their practices, supporting community and fostering play for all. Their collection of zero-waste paper toys, cards, posters, washable paper hats, hankies, and garments aim to inspire curiosity and wonder. A portion of their proceeds also go to their favourite children’s charities. Letterpress PLAY’s range of paper products employ a full range of printing methods using lead or wooden type, blocks, or polymer plates. All items are printed by hand or with machines dating back to the Industrial Revolution, and are 100% biodegradable. Since 2011, Rodrigo Cuberas has had his own workshop and printmaking studio in Buenos Aires, from which he produces both small and medium format abstract letterpress prints, as well as business cards for select clients. His interest in letterpress began in his student days when he bought woodtypes rescued from presses that had closed. Without any press, he printed manually and by hand, thanks to the frottage technique. With the passage of time and experience, he has now acquired a collection of presses and elements of work that have improved his process and prints. However, his work remains faithful to experimental exploration, looking for alternatives beyond the technique.

Since 2011, Rodrigo Cuberas has had his own workshop and printmaking studio in Buenos Aires, from which he produces both small and medium format abstract letterpress prints, as well as business cards for select clients. His interest in letterpress began in his student days when he bought woodtypes rescued from presses that had closed. Without any press, he printed manually and by hand, thanks to the frottage technique. With the passage of time and experience, he has now acquired a collection of presses and elements of work that have improved his process and prints. However, his work remains faithful to experimental exploration, looking for alternatives beyond the technique. TypographHer, aka Nicole Arnett Phillips, is a letterpress printer with over 20 years experience in design. From her studio in New Zealand she creates prints, artist books and ephemera about design, politics, and the environment. Her studio is well equipped with machines including a 1872: Albion Press, a Kingsley hot stamp foiler, and a 1960’s Farley N025CWL, alongside a plethora of other equipment used for bookbinding, pressing, and relief printmaking.

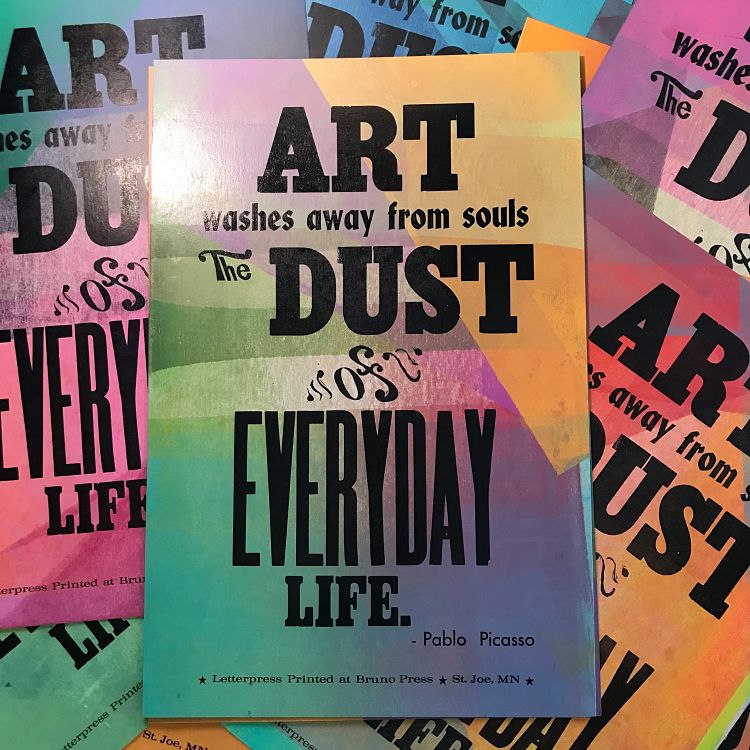

TypographHer, aka Nicole Arnett Phillips, is a letterpress printer with over 20 years experience in design. From her studio in New Zealand she creates prints, artist books and ephemera about design, politics, and the environment. Her studio is well equipped with machines including a 1872: Albion Press, a Kingsley hot stamp foiler, and a 1960’s Farley N025CWL, alongside a plethora of other equipment used for bookbinding, pressing, and relief printmaking. Bruno Press was founded by Mary C. Bruno, who learned her love of printing from her design professor father Don Bruno. Since his passing in 2003 she has taken over his small letterpress print shop in St. Joseph, Minnesota and expanded, both physically and figuratively. Mary has an irreverent line of greeting cards and more that is sold nationwide, and also teaches the old school tradition of letterpress printing the way her father taught her. She organises international travelling art exhibitions with printers all over the world. She hand-sets wood and lead type to produces items including posters and broadsides, and loves to collaborate with other printers, poets, musicians, kids, and designers.

Bruno Press was founded by Mary C. Bruno, who learned her love of printing from her design professor father Don Bruno. Since his passing in 2003 she has taken over his small letterpress print shop in St. Joseph, Minnesota and expanded, both physically and figuratively. Mary has an irreverent line of greeting cards and more that is sold nationwide, and also teaches the old school tradition of letterpress printing the way her father taught her. She organises international travelling art exhibitions with printers all over the world. She hand-sets wood and lead type to produces items including posters and broadsides, and loves to collaborate with other printers, poets, musicians, kids, and designers. Vahalla Studios is a full service letterpress studio located in North Kansas City, Missouri. The team have been printing for clients both large and small since 2006, creating works for such clients including Myspace, Ralph-Lauren and Warner Bros. Music. They love working with artists, designers, illustrators, and creatives of all experience levels. Their letterpress studio has the facility to allow for them to score, die cut, print, perforate, and foil stamp.

Vahalla Studios is a full service letterpress studio located in North Kansas City, Missouri. The team have been printing for clients both large and small since 2006, creating works for such clients including Myspace, Ralph-Lauren and Warner Bros. Music. They love working with artists, designers, illustrators, and creatives of all experience levels. Their letterpress studio has the facility to allow for them to score, die cut, print, perforate, and foil stamp. Wood Words is the letterpress printmaking studio of Julia Humfress. It’s a space for the visual exploration of typography through tangible, movable wood letters. Some of her work takes a traditional approach and explores typography and meaning through the printed word. Her more abstract pieces explore printed letterforms and the spaces that surround them, giving vintage alphabets a contemporary language and new life without the distraction of meaning.

Wood Words is the letterpress printmaking studio of Julia Humfress. It’s a space for the visual exploration of typography through tangible, movable wood letters. Some of her work takes a traditional approach and explores typography and meaning through the printed word. Her more abstract pieces explore printed letterforms and the spaces that surround them, giving vintage alphabets a contemporary language and new life without the distraction of meaning. IS Projects is a public access printmaking and book arts studio located in Fort Lauderdale, Florida. In addition to a fine art gallery, the studio houses letterpress, fine art printmaking and book arts equipment, and offers workshops, hourly studio rental, internships, book binding services, edition printing and commercial printing. Their mission is to promote innovations and developments to print and book media by providing knowledge, training, and a supportive work space for artists.

IS Projects is a public access printmaking and book arts studio located in Fort Lauderdale, Florida. In addition to a fine art gallery, the studio houses letterpress, fine art printmaking and book arts equipment, and offers workshops, hourly studio rental, internships, book binding services, edition printing and commercial printing. Their mission is to promote innovations and developments to print and book media by providing knowledge, training, and a supportive work space for artists. Letterpress Design is run by Lisa Paice and Ross Jones from the beautiful Isle of Wight. With over 25 years of letterpress print experience, Lisa started Letterpress Design in 2008. As well as supplying letterpress print for international clients, together with her partner Ross she also runs Lyme Bay Press, providing photopolymer printing plates, inks and other letterpress print supplies for the small and large printer. You can browse their print collection on

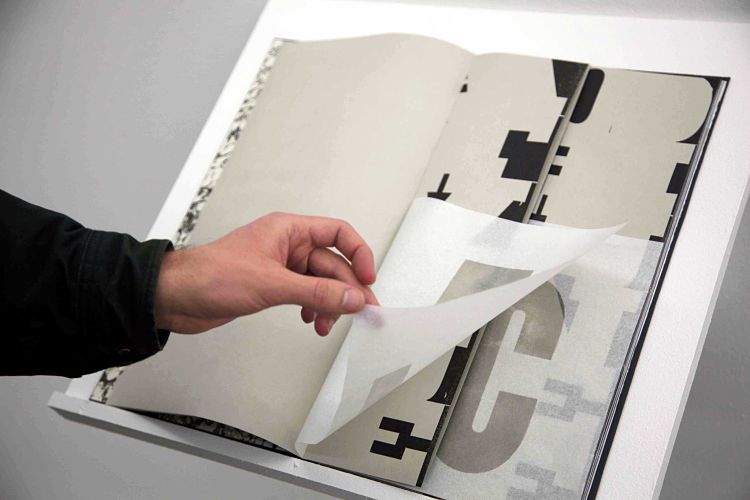

Letterpress Design is run by Lisa Paice and Ross Jones from the beautiful Isle of Wight. With over 25 years of letterpress print experience, Lisa started Letterpress Design in 2008. As well as supplying letterpress print for international clients, together with her partner Ross she also runs Lyme Bay Press, providing photopolymer printing plates, inks and other letterpress print supplies for the small and large printer. You can browse their print collection on  Located in Berlin, and founded by Erik Spiekermann and Susanna Dulkinys, p98a is an experimental letterpress workshop dedicated to letters, printing and paper. They are a group of multi-disciplined designers, exploring how letterpress can be redefined in the 21st century through research, printing, collecting, publishing and making things. p98a work with hot metal and wood-type, several proof presses, a Heidelberg Windmill platen, and other traditional analogue equipment which they combine with digital technologies.

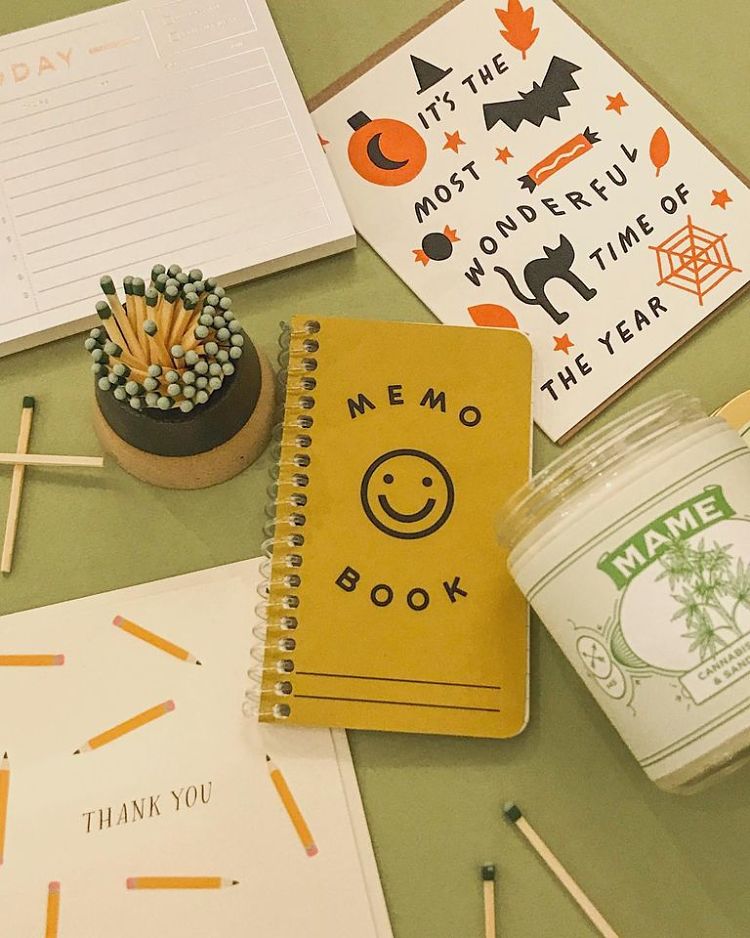

Located in Berlin, and founded by Erik Spiekermann and Susanna Dulkinys, p98a is an experimental letterpress workshop dedicated to letters, printing and paper. They are a group of multi-disciplined designers, exploring how letterpress can be redefined in the 21st century through research, printing, collecting, publishing and making things. p98a work with hot metal and wood-type, several proof presses, a Heidelberg Windmill platen, and other traditional analogue equipment which they combine with digital technologies. Founded by Britt Rohr in 2014, Swell Press is a design and letterpress company based in Los Angeles, inspired by the salt water, sunsets, and palm trees of coastal California. From one-of-a-kind wedding and event invitation suites, to sleek and sophisticated stationery and branded collateral, Swell Press create beautiful and unique printed ephemera. The studio have their own online store selling printed goods, as well as offering bespoke work for clients and brand collaborations.

Founded by Britt Rohr in 2014, Swell Press is a design and letterpress company based in Los Angeles, inspired by the salt water, sunsets, and palm trees of coastal California. From one-of-a-kind wedding and event invitation suites, to sleek and sophisticated stationery and branded collateral, Swell Press create beautiful and unique printed ephemera. The studio have their own online store selling printed goods, as well as offering bespoke work for clients and brand collaborations. Established in 1999, Starshaped Press stay true to the original craft of letterpress, celebrating antique metal and wood type by showcasing the beauty and relevance of well-designed, historic type. Starshaped Press focus on reusing existing materials (some over 150 years old) for all projects, meaning no plastic is ever used in production. The studio offer a range of workshops, custom projects, and also have their own online store selling a diverse collection of prints and stationery.

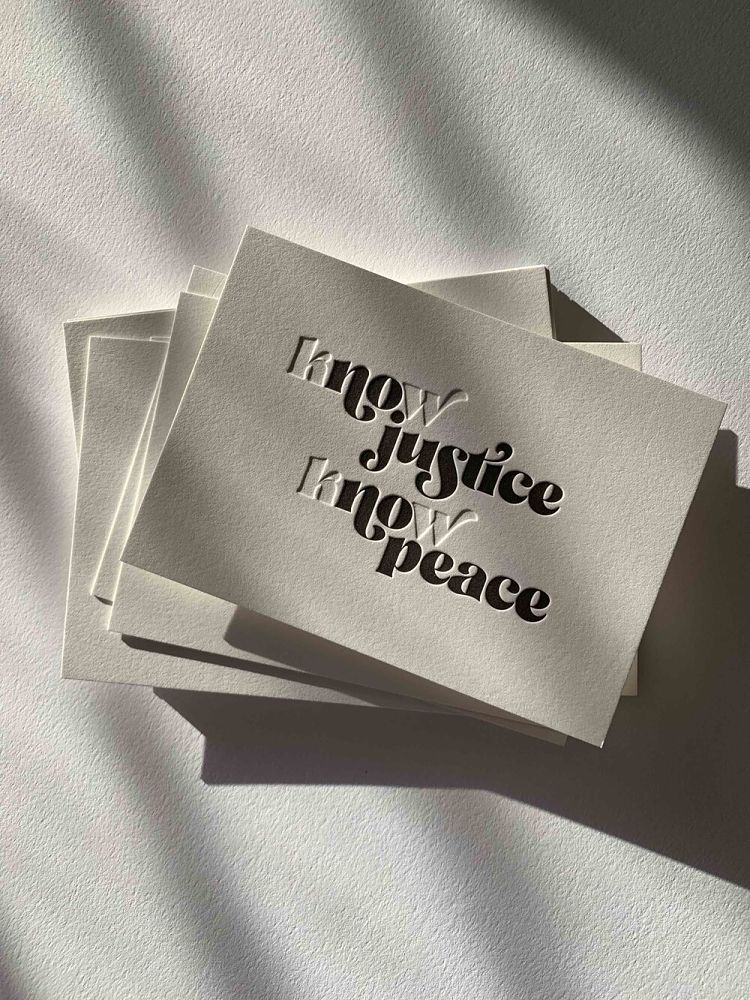

Established in 1999, Starshaped Press stay true to the original craft of letterpress, celebrating antique metal and wood type by showcasing the beauty and relevance of well-designed, historic type. Starshaped Press focus on reusing existing materials (some over 150 years old) for all projects, meaning no plastic is ever used in production. The studio offer a range of workshops, custom projects, and also have their own online store selling a diverse collection of prints and stationery. InPressed is a creative design and letterpress studio that blends traditional printing, fine papers and an aesthetic sense aiming to engage and connect people in a timeless manner. The studio started out in 2015 with its founders Tiago and Simone installing a vintage platten press in a small corner of a garage. With a big passion and curiosity for the traditional printing process, the studio grew little by little and press by press, gaining collaborations with designers and companies along the way. Today their services include; letterpress, hot-stamping and embossing to name but a few.

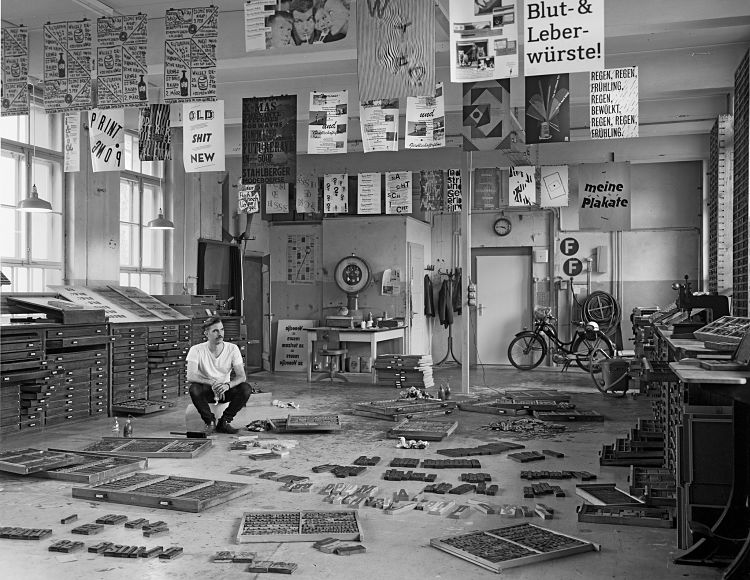

InPressed is a creative design and letterpress studio that blends traditional printing, fine papers and an aesthetic sense aiming to engage and connect people in a timeless manner. The studio started out in 2015 with its founders Tiago and Simone installing a vintage platten press in a small corner of a garage. With a big passion and curiosity for the traditional printing process, the studio grew little by little and press by press, gaining collaborations with designers and companies along the way. Today their services include; letterpress, hot-stamping and embossing to name but a few. Dafi Kühne is a graphic designer and letterpress print maker from Zürich+Glarus, Switzerland. Since 2009 his studio, babyinktwice, has been designing and printing posters, invitation cards and brochures for music, art, architecture, theatre and film projects. In 2011, Dafi also began teaching everything from short workshops to full semesters in various universities in Europe and the United States. His practice combines contemporary graphic design with old style printing technology.

Dafi Kühne is a graphic designer and letterpress print maker from Zürich+Glarus, Switzerland. Since 2009 his studio, babyinktwice, has been designing and printing posters, invitation cards and brochures for music, art, architecture, theatre and film projects. In 2011, Dafi also began teaching everything from short workshops to full semesters in various universities in Europe and the United States. His practice combines contemporary graphic design with old style printing technology. Fireater is a small, independent letterpress workshop that specialises in custom prints, woodtype specimens and custom stationery. Based in the rural Leicstershire countryside, Fireater offer day courses in letterpress printing with the usage of their small Farley and large Korrex printing presses. They offer the ability to cater for most paper sizes and projects. Matt Leach, who founded the studio, studied typography at the London College of Printing, and went on to work at Typoretum whilst amassing his woodtype collection.

Fireater is a small, independent letterpress workshop that specialises in custom prints, woodtype specimens and custom stationery. Based in the rural Leicstershire countryside, Fireater offer day courses in letterpress printing with the usage of their small Farley and large Korrex printing presses. They offer the ability to cater for most paper sizes and projects. Matt Leach, who founded the studio, studied typography at the London College of Printing, and went on to work at Typoretum whilst amassing his woodtype collection. Utilising traditional craft skills, and their collection of antique and vintage printing presses, Typoretum provide a comprehensive letterpress printing and design service. With an extensive library of metal and wooden letterpress type at their disposal, the team can also work from supplied digital artwork, and will etch metal relief plates for letterpress printing, foil stamping or embossing. Based in Colchester, UK, Typoretum is a busy, family run, contemporary letterpress design and printing studio, also offering short courses and internship opportunities.

Utilising traditional craft skills, and their collection of antique and vintage printing presses, Typoretum provide a comprehensive letterpress printing and design service. With an extensive library of metal and wooden letterpress type at their disposal, the team can also work from supplied digital artwork, and will etch metal relief plates for letterpress printing, foil stamping or embossing. Based in Colchester, UK, Typoretum is a busy, family run, contemporary letterpress design and printing studio, also offering short courses and internship opportunities. Coxswain Press is a small letterpress printing and book arts studio located in Tacoma, WA. With a focus on limited edition art prints, greeting cards, hand printed textiles, women’s rights, and artist books, each item is thoughtfully crafted by hand. Taylor, founder of the studio, puts emphasis on not only expertly crafting her work, but educating the public on how it is created and the rich history of the craft.

Coxswain Press is a small letterpress printing and book arts studio located in Tacoma, WA. With a focus on limited edition art prints, greeting cards, hand printed textiles, women’s rights, and artist books, each item is thoughtfully crafted by hand. Taylor, founder of the studio, puts emphasis on not only expertly crafting her work, but educating the public on how it is created and the rich history of the craft. Based in Basingstoke, UK, The Liquorice Press’ love affair with print pushes them beyond the boundaries. They embrace both traditional and cutting-edge techniques to produce exceptional printed pieces for their clients, turning great ideas into beautiful reality. The team offer a letterpress printing service for business or personal stationery, creating works with extra impact, a luxurious feel and a touch of the modern age with traditional values.

Based in Basingstoke, UK, The Liquorice Press’ love affair with print pushes them beyond the boundaries. They embrace both traditional and cutting-edge techniques to produce exceptional printed pieces for their clients, turning great ideas into beautiful reality. The team offer a letterpress printing service for business or personal stationery, creating works with extra impact, a luxurious feel and a touch of the modern age with traditional values. De Kijm & zonen is the printing company of designer Thomas Klaui and graphic artist Donzige Deef. They are an environmentally friendly printing studio based in The Hague, The Netherlands. In their studio they have a beautiful Heidelberg Windmill letterpress platen from 1971, which they use to print with ink and foil, as well as die-cutting, embossing, and blind printing.

De Kijm & zonen is the printing company of designer Thomas Klaui and graphic artist Donzige Deef. They are an environmentally friendly printing studio based in The Hague, The Netherlands. In their studio they have a beautiful Heidelberg Windmill letterpress platen from 1971, which they use to print with ink and foil, as well as die-cutting, embossing, and blind printing. Run by Cory Wasnewsky, Three Cheers Press is a small letterpress print shop based in Nashville, TN . Specialising in letterpress printed goods ranging from business cards, wedding invites, and letterheads, to post cards, greeting cards, and posters, the shop uses a variety of presses to complete any job. In addition to designing and printing products for sale in their shop, Cory can also print your design, or do the designing for you.

Run by Cory Wasnewsky, Three Cheers Press is a small letterpress print shop based in Nashville, TN . Specialising in letterpress printed goods ranging from business cards, wedding invites, and letterheads, to post cards, greeting cards, and posters, the shop uses a variety of presses to complete any job. In addition to designing and printing products for sale in their shop, Cory can also print your design, or do the designing for you. Reflex Letterpress is a print shop located in the Charlestown neighborhood of Boston, and is the studio of artist Ted Ollier. Ted has an online store offering letterpress printed good including stationery and calendars, and also offers classes, wedding and portfolio printing, and studio rentals.

Reflex Letterpress is a print shop located in the Charlestown neighborhood of Boston, and is the studio of artist Ted Ollier. Ted has an online store offering letterpress printed good including stationery and calendars, and also offers classes, wedding and portfolio printing, and studio rentals. Conceived and directed by leading typographic practitioner Kelvyn Smith and letterpress maestro Alan Kitching, The New Typography Workshop is a school of design and typography with letterpress at its core. It offers art directors, artists, designers, printmakers and students the opportunity to study typography and work closely with wood and metal type, letterpress materials and printing equipment. The duo also offer a series of typographic prints to purchase online as part of their print shop.

Conceived and directed by leading typographic practitioner Kelvyn Smith and letterpress maestro Alan Kitching, The New Typography Workshop is a school of design and typography with letterpress at its core. It offers art directors, artists, designers, printmakers and students the opportunity to study typography and work closely with wood and metal type, letterpress materials and printing equipment. The duo also offer a series of typographic prints to purchase online as part of their print shop. Ane Thon Knutsen is a Graphic Designer and Artist working in Oslo. She owns a private letterpress studio where she explores the possibilities of experimental printing with moveable type. Her hybrid approach to her practice has led her to conduct extensive research in combining traditional print with laser cutters and CNC mills. Ane also teaches at The Oslo National Academy of The Arts, works as a freelance lecturer, and hosts printing workshops. She has a particular interest in women in print, private presses and conceptual letterpress.

Ane Thon Knutsen is a Graphic Designer and Artist working in Oslo. She owns a private letterpress studio where she explores the possibilities of experimental printing with moveable type. Her hybrid approach to her practice has led her to conduct extensive research in combining traditional print with laser cutters and CNC mills. Ane also teaches at The Oslo National Academy of The Arts, works as a freelance lecturer, and hosts printing workshops. She has a particular interest in women in print, private presses and conceptual letterpress. Born from an unquenchable love of design, ink, paper and possibility, Mayday Press create hand-printed, letterpress goods through combining modern methodologies with vintage equipment. Nestled in the rolling hills of southwest Wisconsin, Mayday Press is where its founder, May, brings together her love of graphic design, letterpress and stationery supplies.

Born from an unquenchable love of design, ink, paper and possibility, Mayday Press create hand-printed, letterpress goods through combining modern methodologies with vintage equipment. Nestled in the rolling hills of southwest Wisconsin, Mayday Press is where its founder, May, brings together her love of graphic design, letterpress and stationery supplies. The Alphabet Press is a bespoke letterpress stationery brand based in Malaysia. They create wedding stationery, business cards, event invitations, corporate stationery, postcards and art prints using the centuries-old printing technique of letterpress. All of their products are made with the finest materials, craftsmanship, and a sense of understated elegance.