|

https://ift.tt/aXN5eMq

3D Printing Webinar & Event Roundup: April 30, 2023 https://ift.tt/ZLyOcQC We’re starting with the obvious in today’s roundup—RAPID+TCT 2023 returns to Chicago this week! But there are still plenty of other offerings as well, including the Ceramics Expo, SIMULIA Americas Users Conference, and webinars on topics including FEA simulation, bioprinting for drug discovery, and more. Read on for all the details! 3D Printing News UnpeeledOur Executive Editor Joris Peels, who’s also the Vice President of Consulting at SmarTech Analysis, offers a news livestream one to two times a week called 3D Printing News Unpeeled at 9:30 am EST. For each episode, Peels gets on LinkedIn Live and tells us, in 20 minutes or less, what he considers to be the top news stories from the 3D printing industry that week, and why they’re important. Some of the stories in his roundup are ones we’ve covered at 3DPrint.com, and some are not, but they are all equally interesting and impactful. May 1 – 4: Offshore Technology ConferenceFirst things first, the Offshore Technology Conference (OTC) 2023 will be in Houston, Texas this week, from May 1-4. Comprising 45 technical sessions, over 300 technical presentations, more than 1,000 exhibitors, and networking opportunities, it’s sure to have everything you need to learn about “Delivering the Future of Offshore Energy.” This is the 50th year for OTC’s flagship conference, which is sponsored by 13 industry organizations and societies that work together to develop the technical program. Several AM industry companies will be exhibiting at OTC 2023, including Roboze, 3D Systems, 3DXTECH, and more.

You can register for the event here. May 2 – 3: Ceramics ExpoThe doors open for the Ceramics Expo in Novi, Michigan on Tuesday, May 2nd, and the event ends on the 3rd. Co-located with the Thermal Management Expo, Ceramics Expo is organized in association with founding event partner The American Ceramic Society (ACerS). Attendees come from a wide range of industries, including energy, automotive, electronics, aerospace and defense, medical, chemicals, semiconductors, and more. The main focus will be on the latest advancements and innovations in materials and technology, and over 30 experts will lead discussions on technical ceramics, while more than 250 exhibitors are ready to show you their latest solutions.

You can register for the free expo here. May 2 – 3: Design-2-Part Show OrlandoAlso from May 2-3, the Design-2-Part trade show comes to Orlando, Florida. It’s the region’s largest design and contract manufacturing show, and will feature over 140 American suppliers that can help your business mitigate risk, shorten the supply chain, and get parts manufactured on time. Over 300 service categories will be represented, including forming, plastics, castings, rubber, machining, and of course, 3D printing.

You can register for the free trade show here. May 2 – 4: RAPID + TCT 2023Returning to the Windy City, RAPID + TCT 2023 will be held in McCormick Place from May 2-4. 250 experts will take the various stages at North America’s largest and most influential additive manufacturing event, covering a variety of subjects from vertical tracks in aerospace, defense, automotive, and healthcare and focus sessions on the necessary parts of the AM ecosystem, like R&D, DfAM, supply chains, metrology, and more. With nearly 400 exhibiting companies, there will be plenty to look at, and you won’t want to miss the AM Industry Celebration on the first night.

You can register for RAPID here. Keep an eye out for the 3DPrint.com on the floor, and, for the first time, at Booth #2157! May 2: Mastering CAM Integration for SOLIDWORKSOn Tuesday, May 2nd, HCL CAMWorks is holding a webinar on “Mastering CAM Integration for SOLIDWORKS” at 11 am EST. Join the webinar if you’re looking to increase productivity, or just want a new integrated CAD/CAM solution, and learn about the benefits of integrated CAD/CAM for SOLIDWORKS with SOLIDWORKS CAM and CAMWorks. Attendees will learn tips and tricks to make the transition to a new system easier, see the integrated solution that automates CNC programming, and more.

You can register for the webinar here. May 2: FEA Simulation with 3DEXPERIENCEAlso on May 2nd, Dassault Systèmes will explain “Doing FEA with 3DEXPERIENCE Works roles: Who, What, When?” Join the webinar at 1 pm EST to learn a more holistic view of the different solutions available to analysts, engineers, and designers on the 3DEXPERIENCE platform for Structural Finite Element Analysis (FEA), fluid flow and thermal using Computational Fluid Dynamics (CFD), and more. Attendees will also learn more about the Structural FEA roles and how they can benefit from the SIMULIA- and ABAQUS-powered 3DEXPERIENCE Works Structural portfolio.

You can register for the webinar here. May 3 – 4: Space Tech ExpoThe 11th edition of the Space Tech Expo will be held in Long Beach, California from May 3-4. From exhibitors and presentations to B2B matchmaking, approximately 3,300 visitors will arrive to learn about all things related to the innovative space technology sector. Multiple AM industry companies will be exhibiting at the event, including Equispheres, Additive Industries, DMG Mori USA, and more.

Register for free here. May 3 – 4: SIMULIA Americas Users ConferenceAnother event happening in Novi, Michigan this week is the SIMULIA Americas Users Conference from May 3-4, which will combine all parts of Dassault’s Regional User Meetings (Great Lakes, Houston, and Santa Clara) into one Americas-wide event. There will be multiple keynote and technical presentations, along with partner sessions, so attendees can learn about the various offerings, like structures, electromagnetics, multibody dynamics, and more.

You can register for the conference here. May 3: Velo3D Continues Roadshow in AugsburgVelo3D continues its 2023 “The Proof is in the Printing” global roadshow this week with its first European stop, coming to the Augsburg Aerospace Academy in Germany on Wednesday, May 3rd. The tour, which will make stops in other cities across Europe, the U.S., and the Asia/Pacific region, will show attendees how Velo3D’s fully integrated solution can help achieve better part performance, supply chain flexibility, and repeatability. There will also be real-world examples of customer-printed parts.

You can register for the Augsburg stop here. May 3: Markforged’s Digital Forge SubscriptionsMarkforged has reimagined how it packages software, Success Plans, training offerings: by putting it all together in simple, cost-effective bundles, or subscriptions. You can learn how to “Maximize Success with Digital Forge Subscriptions” in a webinar at 10 am EST on the 3rd. Attendees will learn what Digital Forge Subscriptions are, how they can streamline costs and increase productivity, and what is changing with this move to a subscription offering.

You can register for the webinar here. May 4: Bioprinting for Drug Discovery & DevelopmentOn Thursday, May 4th, 3DHEALS will hold a webinar on “3D Bioprinting for Drug Discovery and Development” at 11 am EST. A newer technology, 3D bioprinting has the potential to revolutionize drug discovery and development in a variety of ways, from realistic in vitro models and personalized medicine to high-throughput screening and drug target identification. Several critical stakeholders in the sector will tell attendees where we are with the technologies and their commercialization.

You can register for the webinar here. May 4: Formlabs on Cloud-Based Collaborative 3D ModelingAlso at 11 am EST on the 4th, Formlabs will hold a webinar that teaches you how to “Design Like a Pro: A Deep Dive into Cloud-Based Collaborative 3D Modeling with Onshape.” Attendees will learn how these tools seamlessly integrate to support your design process and make it more efficient by enabling easier collaboration between team members. Attendees will learn tips for using Formlabs and Onshape to optimize the workflow, see a live demonstration of streamlining the design-to-print process, and have their questions answered.

You can register for the webinar here. May 18: Material Properties of 3D Printed Plastic PartsHere’s your official save-the-date for an exclusive, free webinar by 3DPrint.com and 3DXTECH! At 2 pm EST on May 18th, we’ll discuss “How Chamber Temperature Can Affect the Material Properties of 3D Printed Plastic Parts.” Our Editor-in-Chief Michael Molitch-Hou, will moderate the presentation and discussion with 3DXTECH CEO Matt Howlett.

You can register for this exclusive webinar here. Do you have news to share about any future webinars or virtual and live events? Please let us know! The post 3D Printing Webinar & Event Roundup: April 30, 2023 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/mBLPnVo April 30, 2023 at 08:07AM

0 Comments

3D Printing News Briefs April 29 2023: Rocket Engine Post-Processing for NXG XII 600 & More4/29/2023

https://ift.tt/x7s3gAz

3D Printing News Briefs, April 29, 2023: Rocket Engine, Post-Processing for NXG XII 600, & More https://ift.tt/KZp029F We’re starting 3D Printing News Briefs today with an announcement that a 3D printed rocket motor by Skyroot Aerospace had a successful test-fire. Continuing with aerospace news, Burloak Technologies received approval from Boeing to inspect 3D printed aluminum alloy components. Moving on to business, 3DQue has introduced an order management system that streamlines the process, and AML3D signed a value-added reseller agreement with Phillips Corporation. Solukon delivered a perfect-fit post-processing system for SLM Solutions’ NXG XII 600. Finally, a teenager in Colorado accused of planning school and church shootings had a manifesto, which included instructions on making 3D printed guns. Skyroot Aerospace Test-Fires New 3D Printed Rocket EngineIndian space tech startup Skyroot Aerospace announced that it has successfully test-fired the Dhawan II, its latest 3D printed cryogenic rocket engine. In comparison to common rocket engine technologies, the Dhawan II uses a blend of green-burning propellants—liquid natural gas (LNG) and liquid oxygen (LoX)—that are considered environmentally friendly. According to the startup, fully cryogenic engines are preferred for a rocket’s upper stages due to their enhanced thrust, which leads to better payload capacities. As such, the Dhawan II engine will be used in the upper stage of the company’s Vikram II rocket, which is set to launch later this year. During its most recent test-firing, the 3D printed Dhawan II achieved a peak thrust of 3.kN and lasted for over 200 seconds

Boeing Approves Burloak to Inspect AM Aluminum Alloy ComponentsIn 2021, Burloak Technologies Inc., a division of Samuel, Son & Co., Limited, was approved to 3D print aluminum AlSi10Mg components to the Boeing BAC5673 specification. Now, it’s announced that Boeing has approved it to use X-Ray Computed Tomography (CT) to inspect 3D printed aluminum alloy components to its BSS7046 specification. This qualification is specific to Boeing, but Burloak has included CT in its ISO17025 scope, which makes it commercially available to any industry. Boeing completed a “rigorous evaluation” of Burloak’s CT system, which features a 180kV nanofocus tube and a 300kV microfocus, and the qualification process included an examination of the operators’ technical proficiency, in addition to associated documentation and laboratory processes. Now that it’s received the qualification, Burloak Technologies can continue to expand the scope of its CT capabilities to go past aluminum alloys and include titanium alloys.

3DQue Launches Automated Ordering Solution for 3D Print Farms3DQue Systems Inc., which is on a mission to free 3D printer operators from the repetitive and mundane tasks involved with running a 3D print farm, has announced its latest automated solution: Direct2Print, which eliminates manual order management and tracking to offer overwhelmed print farms some much needed relief. As soon as a customer places an order at an online store, the details are imported into Direct2Print, and the proper G-code files are automatically added to the print queue. Each print in that order is matched with the next available printer that meets all its requirements, like material type, bed size, and filament color. With the AutoFarm3D/Direct2Print integration, operators are provided with all the necessary information through 24/7 remote monitoring, AI failure detection, and automatic part removal. Finally, the operator is notified once the order is complete, and all they have to do is mark it completed once everything has been shipped to the customer.

You can join the Direct2Print waitlist here. AML3D Signs Reseller Agreement with Phillips CorporationAML3D, OEM of the ARCEMY industrial metal 3D printing systems, has signed a value-added reseller (VAR) agreement with Phillips Corporation to scale up its sales capability and access to the U.S. Federal Government and defense sector. The company’s U.S. sales team will work with the federal sales division of Phillips, a top service provider and manufacturing reseller partner to the government, to co-sell its ARCEMY printers into all defense branches in order to speed up the development of a U.S. ARCEMY sales pipeline. The VAR agreement, which is non-exclusive in sectors outside the government, will run for 18 months, but is renewable after this first term, and while AML3D won’t pay a distribution fee, Phillips will get a margin based on the difference between the end customer sale price and the wholesale price of the ARCEMY. This agreement will bring both companies into an exclusive resale agreement for the U.S. Federal Government sector.

Solukon Creates Perfect-Fit Post-Processing System for SLM SolutionsSLM Solutions launched its 12-laser NXG XII 600 3D printer at Formnext Connect in 2020, and it’s used to print large, heavy metal parts, which puts a lot of demand on industrial depowdering systems. Solukon‘s SFM-AT1000-S, also launched in 2020, has a reinforced body and higher torque, which allows it to easily and safely depowder large parts that weigh up to 800 kg. Now, the two companies have collaborated to optimize the SFM-AT1000-S system, giving it features specific to the NXG XII 600. The depowdering system is based on Solukon’s standard but unique SPR Smart Powder Recuperation Technology, and also features its Digital-Factory-Tool for process monitoring and data recording and SPR-Pathfinder® software. But to perfectly fit the system to the NXG XII 600, Solukon added a short swivel arm to reach the best center of gravity balance position. Another new optimization is a pneumatic front-top-loading feature, which makes it easier to load, handle, and unload parts. SLM Solutions now has the optimized SFM-AT1000-S in its facility, and Solukon is launching this special version at RAPID + TCT in Chicago this week; see it for yourself at Booth #1820.

Colorado Teen’s Manifesto Included 3D Printed Gun Instructions

William Whitworth, who identifies as a female named Lilly, is accused of planning school shootings in Colorado. (School photo is a screengrab from CBS Colorado; the mugshot is from the District Attorney’s Office in the 18th Judicial District in Colorado) According to Colorado authorities, 19-year-old Lilly Whitworth, accused of planning shootings at churches and schools, had a manifesto with several lists, including potential targets and instructions on how to 3D print a gun. The Elbert County Sheriff’s Office responded to a disturbance call by Whitworth’s sister, who told deputies that she had anger issues and threatened to shoot up a school. Whitworth, who is now facing attempted murder and other charges, allegedly told police that she had been planning the shooting for a couple of months, and that she had begun a manifesto. Deputies found a dry-erase board with what appeared to be a labeled floor plan of a school, as well as notebooks with more floor plans, a list of what appeared to be potential targets, and a drawing of a clock to use as a detonation device. After Whitworth was booked into the Elbert County Jail, police found a leather-bound book with more locations and and names, information about constructing improvised explosive devices, and a list of firearms and how to 3D print them. Last summer, we found that 3D printed gun arrests had tripled in less than two years. The Biden Administration has beencracking down on ghost guns due to an increasing threat of mass shootings and potential for crimes committed with 3D printed firearms, and this certainly isn’t the first time we’ve heard about suspected shooters investigating the use of 3D printing to make weapons. But, while 3D printed weapons do bring up some big security and legal issues, many believe it is unlikely that 3D printed guns pose a major risk. The post 3D Printing News Briefs, April 29, 2023: Rocket Engine, Post-Processing for NXG XII 600, & More appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/HLBR6QT April 29, 2023 at 08:45AM

https://ift.tt/sMGOhar

7 ways to make money with your email list in 2023 https://ift.tt/dAhzI1x I’m sure you’ve heard the expression – “money is in the list.” And it’s true. Email marketing has a tremendous ROI, and we’ve got multiple case studies that prove it. What’s also true is that there isn’t just one way to make money with email marketing. There are many. And I’m about to share them with you. Whether you’re an affiliate marketer, coach, or an all-around marketer, you’ll want to stick around. As these seven tactics are about to turn your email marketing program into a growing revenue source. Table Of Contents How to make money with email list: 7 actionable waysBefore going over the ways you can make money with email, I want to make a disclaimer. Even though email marketing boasts an impressive ROI of 3,800%, it is a long-term game. Building an engaged email audience takes time and effort, and that’s only a part of the equation. So if you ever hear someone making promises that you’ll generate an extra $5k in income from email just after 30 days of work, simply ignore them. With that out of the way, let me take you through the key ways of making money with email marketing. 1. Use affiliate marketing and promote other people’s products or servicesOne of the first associations people make about making money online comes down to joining a lucrative affiliate program. The dynamics are pretty straightforward — you select a brand that has a program for affiliates, sign up for it, and start promoting its product or services to your email subscribers. For every purchase that comes from your affiliate link, you receive a commission.

Let’s say you’re a personal finance blogger and online coach. The most fundamental way for you to capitalize on your position as a financial expert is to tap into the affiliate products offered by FinTech software such as eToro, Binance, or Robinhood:

Another option in this niche is to partner with banks offering an enticing commission for offering their products. There are plenty of them out there — for example, American Express pays up to $200 per sale.

How does affiliate marketing work?Before we get into the technical side of this marketing channel, let’s say it out loud — the key to success is to promote products or services that meet both fundamental requirements:

Speaking of the second aspect — Michał Szafrański, one of the most famous Polish financial bloggers, got on the media’s front pages when he earned 70,000 PLN (currently over $16K) on one blog article which was connected to one bank’s affiliate program! Super crazy! And it wouldn’t be possible if it wasn’t for his personal brand and huge credibility. That said, let’s look at the technical part:

Affiliate products are a proven way to generate income, and if you handle it well, it can be super easy (injecting an affiliate link in your email content) and profitable. For instance, GetResponse’s affiliate program offers 33 percent recurring commission — what a great way to secure a passive income! ? Learn more with our affiliate marketing for beginners guide. 2. Include sponsored content or advertising in your emailsAnother way to make money with email marketing is to introduce sponsored content and advertising into your email campaigns. Those commercial tactics are an excellent fit for email marketers that have been on the scene for a while and managed to grow their mailing lists to a number of at least 2,500 subscribers. Naturally, the bigger and more engaged your email list is, the better. Only this way you will become an attractive asset for potential advertisers. There’s another reason why hundreds of folks on your email list won’t be enough, but thousands will make a difference. And it’s called CPM (Cost per thousand impressions) — a unit that will help you and your advertiser to set the prices for a banner displayed in your newsletters. How about solo ads?A solo ad works like this — advertisers go to email list owners and purchase a placement in their email. Simply put, a brand buys a dedicated email and taps into the existing email audience of that owner. Even though solo ads don’t have the best reputation from the advertiser’s point of view, it can be a different story when you run a thriving online business and have the capability of providing solo ads service to advertisers. To make it work, make sure that:

Check out this detailed guide about solo ads and think if that’s a good idea for your online business. Monetize your newsletter with sponsored contentBrands are on the lookout for getting the word out about their products through channels other than paid social media ads and Google Display Network. That’s why, once your newsletters become a powerful medium, several brands that will find your audience has an overlap with their buyer persona will be open for a partnership with you.

There are three main ways of sponsoring your newsletter:

Once you decide which format you will implement, it’s time to think about your pricing. You can set up a flat fee, like $500, for an ad placement. Or, you can opt for a CPM (CPM = Cost of an ad in email send / Number of email subscribers) x 1,000) model. From there, it’s time to reach out to potential buyers with your sponsored weekly newsletter offer or sign up for marketplaces like Paved, Swapstack, Whosponsorsstuff, or Sponsorgap. The other option is to pitch your email recipients with your sponsored offer if you know that decision-makers already subscribe to you (which you can check in an email marketing platform like GetResponse). Here’s how Erin Balsa from Haus of Bold does it:

3. Create a tripwire offerOK, another method to generate more money through email marketing is tripwire offers. And while the name of that technique is not the most fortunate in the world, it’s pretty standard among email marketers out there. Implementing a tripwire means offering your new subscribers a low-priced product or service. The entry threshold is set low (as the tripwire), increasing the chances of getting more people to purchase. “OK, it costs only $5, no biggie” — and they’re in! OK, it doesn’t have to be that cheap. Let’s say you’re an online life coach, and you’re offering a bargain deal of $30 for the first online strategy session. As long as you deliver quality after closing that sale, you open an avenue to pitch your more expensive services. In practice, it can mean creating a landing page with a curated offer and sending an upsell email after finalizing the first deal.

4. Sell your own product or serviceOK, affiliate marketing and advertising can help you earn money. In some cases, those results can be impressive. But, regardless of how high the affiliate commission is, it’s still a percentage. If you’re lucky, you get 20, 30, or 40% of conversions or sales. By selling your own products or services, you can make money on a scale that will drive your online business forward substantially. You own it — the 100% goes into your pocket without sharing that with a sponsorship marketplace or a merchant. How can you pull this off? At your serviceLet’s start with offering a service. If you’re a consultant, an online coach, or a freelance marketer, you can market your services to your email subscribers. Your email list is your potential customers. As long as you provide them value for free through your email marketing program, at some stage, they will naturally go down the sales funnel and be more prone to try your offer. Create your own productAnother one is a digital product. It can be a paid ebook or a package of coaching sessions. The rule of thumb would be the same as with your services. Your product needs to solve pains and generate gains for your target audience. It has to be relevant to them! We’re in the middle of an AI revolution. And for you, as a content creator, it’s a massive opportunity because, with ChatGPT4, you can now develop applications, Chrome extensions, mobile games, and other digital products without an army of software developers and designers! And how to know if your audience will be ready to purchase your product? Use newsletters and autoresponders to survey your subscribers and get their opinion first. The best way to market any product is to learn what your buyers need.

5. Create a paid newsletterThis part might be tricky. Especially if you have just started growing your email list. You can say: “I’m struggling to have people opt into my email list for free, so how am I supposed to get them to pay me for it?” And you’re absolutely right. It’s a real challenge at the early growth stage. It will take some time, but by providing high-end value to your readers, you will reach the moment to:

Before you go full-scale, try to test the waters first. Voice of customer data is essential here. Email marketing gives you a natural opportunity to gather feedback from your email subscribers. Ask them:

Looking for inspiration? There are several thriving paid newsletters out there, each of them dedicated to a specific niche:

6. Create a paid courseEarlier, I mentioned crafting a digital product to make money with email marketing. Creating a paid online course is one of the most popular and profitable digital products used by solopreneurs. Sharing tips and tricks and leading thoughts through a free or paid newsletter is one thing. Teaching your subscribers interested in your expertise, new skills, and workflows is another. To create a paid course, you’ll need to get back to the drawing board and list your audience’s pain points. From then, make a step-by-step process to overcome those challenges. Once you have the idea for your online course, you need to:

How to sell an online courseDo you enjoy creating educational courses and want to turn your knowledge into a profitable business? Follow these simple steps and start selling your first online course today! Sell your online course with a conversion funnelOver the past few years, the booming popularity of e-learning platforms like Udemy or Coursera has translated into proven ways to make money online for thousands of coaches and trainers. But the entire process of managing a digital course can scare many people away. The good news is — that there is a way to manage it from top to bottom through GetResponse’s conversion funnel.

How can you customize your funnelBut the best part of conversion funnels for teaching and training online is that you can build that architecture of actions and stages the way you want! Examples? Of course! Check this video where Ian Cleary, Founder of Razor Social, breaks down the process of building their funnel for selling an online course. Their approach was a bit different:

Another interesting case comes from Alex Terrier. This jazz musician was widely successful in selling his online music course with the conversion funnel. Only during the first 30 days of his campaign he managed to land:

His secret sauce? Offering free and high-quality content to hook aspiring musicians. 7. Run paid webinarsAnd there comes our last email monetization method — running webinars. Conducting online events can serve multiple purposes. For instance, free webinars are a perfect way to generate leads and nurture existing email subscribers with additional helpful content. Webinar tools such as polls and surveys, chat, and Q&A enable you to interact with your audience and know them better. This knowledge can help you refine your messaging when you are all set to create content — for a blog post or an ebook. But paid webinars are a different story. It’s not about capturing leads. Running webinars with an entry fee means selling advanced knowledge and insights to people who want to upgrade their skill sets or learn something super valuable that is not available for free elsewhere. How much money can you make with paid online conferences and training sessions? Here are some examples from the State of Online Events 2022:

Impressed? No wonder! Let’s sneak a peek at how to run paid webinars! How to run a paid webinarFollow this step-by-step workflow:

Pro tip: You can orchestrate everything in GetResponse – your webinar, an email campaign, and paid ads on Facebook or Instagram. Start making money with email marketing!Even without a big marketing team or a dedicated email specialist, email marketing has a wide array of options to make money — from promoting affiliate products, through running a paid newsletter, to implementing advertising in your emails. Another strategy is to pitch your services to your subscribers and sell products, such as ebooks, templates, workflows, training sessions, online courses, and paid webinars. The critical point is consistently delivering high-quality and value for your target audience. Once you look after this part, you can experiment with different ways to make money. And finally, to start implementing your revenue-generating program, you need a solid email service provider! And GetResponse is the one that will help you keep everything under one roof! Try all the features for free for the next 30 days. Printing via GetResponse Blog https://ift.tt/nO2kVrJ April 28, 2023 at 10:46AM

https://ift.tt/9QhEIrn

Biden’s Plan for National Semiconductor Technology Center is a Treasure Trove of 3D Printing Opportunities https://ift.tt/Y7Mc39J Whether the Biden administration’s CHIPS Act will truly succeed at transforming American manufacturing is a question that can only be answered years from now. Nevertheless, it is already clear that this is exactly what the set of policies aims to accomplish. This is most strikingly spelled out in “A Vision and Strategy for the National Semiconductor Technology Center”, the latest addition to the constantly growing library of government documents on CHIPS. Just as striking, if one reads between the lines, is the virtually limitless potential that the CHIPS era will open up for the additive manufacturing (AM) sector, in particular. Despite all the excitement surrounding tax breaks, funding grants, and other subsidies, the National Semiconductor Technology Center (NSTC) is clearly the cornerstone of the CHIPS Act. The idea of the NSTC itself isn’t so revolutionary. As the NSTC blueprint points out, other similar institutions already exist around the world, with the Taiwan Semiconductor Research Institute (TSRI) being probably the most notable.

What is transformational about the NSTC is that it will be coming into existence at a time when there’s more eyes than ever on the semiconductor industry, on supply chain management, and on the reshoring of American manufacturing — the trifecta of issues that the $11 billion institution is being established to address. The NSTC is the nucleus around which all of the other changes to the US industrial base will be expected to coalesce. In the same way as the NSTC embodies the central organizing principle of the CHIPS Act, the central organizing principle of the NSTC is a comprehensive push for accelerating the nation’s rapid prototyping efforts. If this sounds like an overstatement, then you need to read the document, even if you just search the text for “prototyping” and read one or some of the 15 portions where that word appears.

The “lower[ing of] some of the existing barriers”, in this context, will likely mean subsidies for rapid prototyping equipment, i.e., 3D printers. And although the Commons and the NTSC are separate institutions, at the same time, they are also being designed to work together, as well as with all of the other elements making up what the blueprint curiously refers to as the “semiconductor community”. The document also emphasizes the need to create “a common language” for the semiconductor industry, so it can be assumed that fundamental features such as lowering the barriers of entry for rapid prototyping equipment will be consistent across all institutions making up the US semiconductor industry. Those also include all of the Manufacturing USA institutes devoted to semiconductor manufacturing, with the blueprint pointing out, too, that the CHIPS Act provides funds for the creation of three more Manufacturing USA institutes specifically devoted to semiconductor manufacturing. All of those institutes have AM as one of if not their main area of competency, so that is yet further evidence supporting the idea that the CHIPS Act is inherently just as much about how things are made, as it is about the goods being produced. This is not to mention the National Advanced Packaging Manufacturing Program (NAPMP), which would require another article to break down. In any case, regardless of politics, it’s hard to see how anyone in the 3D printing industry doesn’t want four more years of Joe Biden. The post Biden’s Plan for National Semiconductor Technology Center is a Treasure Trove of 3D Printing Opportunities appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/HLBR6QT April 28, 2023 at 09:29AM Average time to deliver across postal network steady at 2.5 days https://ift.tt/DU87oQX WASHINGTON — The United States Postal Service reported new delivery performance metrics for the third week of the third quarter for fiscal year 2023 showing consistent or improved delivery performance across all mail categories. Printing via USPS News https://ift.tt/XtyMG2v April 28, 2023 at 08:58AM

https://ift.tt/Zphy83B

Concrete Dreams: Construction 3D Printing for Disaster Relief https://ift.tt/FDUovNz Whereas, in general, the additive construction hype is focused on houses, I’m much more focused on 3D printing money. I think that locally 3D printing mass-customized infrastructure at a factory and then trucking the parts to building locations is the most logical, profitable, and impactful opportunity out there. For the developing world, it would mean that the single most important infrastructure elements that can be 3D printed would be made to spec regionally, as per the most pressing needs. So, stakeholders wouldn’t put in a whole sewage system centrally, but print out septic tanks and cisterns where the need is the highest, resulting in the highest impact. Such an approach also lends itself well to disaster relief. The U.S. military is already looking at this, just starting a $3.5 million project to look at swarm based 3D printing of concrete structures at disaster sites. The US Army project at the University of Arkansas will look at using collaborative robots to print vertical structures, such as culverts and Jersey barriers. The team will explore local soils and other materials to see how they can be incorporated into 3D printing concrete mixes, along with qualifying parts and materials. As we’ve said previously, construction 3D printing could get an even bigger boost from US self reliance and infrastructure spending. Why Perform Construction 3D Printing for Disaster Relief? The completed concrete slab with half of the 3D printed foam elements removed. Image courtesy of ETH Zürich. The completed concrete slab with half of the 3D printed foam elements removed. Image courtesy of ETH Zürich.

NGOs and governments helping out in a disaster often don’t really know what to bring. They also often bring the wrong things. It is pretty difficult to obtain all of the interlocking components of a construction project together just after an earthquake or war. Research has indicated that, generally for disaster relief, 3D printing could be the ideal tool for a builder’s knapsack. Additionally, disaster situations are almost always constantly evolving with needs changing over time, sometimes very suddenly. Timely production of the right things is something that 3D printing really excels at. Additive manufacturing (AM) can also iterate quickly, so if a better design is needed, it’s possible to make that part faster than with other processes. Often in disaster areas, it is expensive and difficult to protect, feed, and provide for aid workers. So, each additional worker is a burden on the system that makes the system less efficient. An aid agency, like an army, marches on its stomach. 3D printing for construction could be efficient in make timely structures of the right design by using comparatively few people. In some cases, a lot of the iteration and design capability could be outsourced to others who are more conveniently located overseas. That would also let a group to make the right thing at the right time. It is in at this difficult moment to make the right thing that is the key thing at this difficult place. Product Help FitSo, yes, it is possible to build structures to house people in, but we’ve seen that refugees can survive in tents for many years. This is not optimal or kind, but it is cost effective. Tents are light, they’re easy to transport, and they’re inexpensive. However, imagine you need a safe building to store food aid, like a silo or other structure to keep grain in sheltered from water and animals. Or you urgently need a septic tank set up to keep cholera from spreading through a village. Those are more difficult goals to achieve. Think of a few villages that have been completely cut off by land slides. AM could be used to make simple pedestrian bridges exactly to size in a week. Exposed rock in danger of causing landslides, build a wall that would stop them or change the slope through concrete elements. A sea wall has been washed away by the storm, quickly rebuild it before there are more floods. These are all cases where 3D printing could really play a role. Timely and CorrectThe main thing here is that, with relatively few people on site, it’s possible to mass customize designs that are optimal for solving a given problem. Sure, one could build cookie cutter structures to house all of the refugees. But, in that case, other methods may be more cost-effective, or simply more cost-effective for the time being. With AM, there is a unique ability to make precisely the right structure with the right shape, design, and properties to adequately solve a problem in a timely manner. The technology can be used to print footbridges on Monday, wells on Tuesday, and road structures on Wednesday. That is where AM can play an outsized role in disaster relief. The post Concrete Dreams: Construction 3D Printing for Disaster Relief appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/CJbsc3B April 28, 2023 at 08:18AM

https://ift.tt/puSn9a1

BLT Breaks Ground on 163,200-Sq-Meter Metal 3D Printing Plant https://ift.tt/G1I9VeY Xi’an Bright Laser Technologies Co., Ltd (BLT) is among an established crop of Chinese manufacturers of metal laser powder bed fusion (PBF) machines that are expanding both domestically and internationally. BLT in particular has been growing at an astounding rate, recording a 66 percent increase of revenues from 2021 to $140 million in 2022. As the firm undergoes tremendous expansion, BLT has now broken ground on a new 163,200-square-meter construction site that will allow it to manufacture metal 3D printing powders and custom metal parts. Growth of a Metal 3D Printing GiantEstablished in 2011, BLT was among the earliest Chinese manufacturers of metal PBF machines. Publicly listed on the SSE STAR Market since 2019, it boasts over 1,100 employees. In addition to manufacturing machines, it also produces titanium and Inconel powders with over 10 production lines as well as a 3D printing service bureau. Having installed its 200th metal LPBF machine for its own 3D printing service in 2021, BLT became possibly the largest provider of metal AM services by machine units.

The BLT S1000 3D printer. By 2022, it had delivered thousands of metal 3D printers to over 20 countries and regions globally. That year, it also launched its BLT-S1000, a large-format machine with a build volume of 1200 x 600 x 1500 mm and eight to 12 500W lasers, enabling speeds of 300 cm³/h. This brings the total number of metal 3D printers offered by the company to 10. BLT claims a market value of about $2.53 billion, which would make it more valuable than any other publicly traded AM firm. BLT’s 2023 ExpansionIn 2023, it is expected to grow even more with a variety of initiatives already in the works. For instance, as the Chinese Association for Science and Technology aims to execute over 60 space launches and deploy more than 200 spacecraft throughout the year, BLT will be benefitting from the country’s burgeoning new space economy.

Lattice-structure-of-the-hydrazine-bottle-adapter-3D-printed-by-BLT Just one part the company has developed for new space is a load-bearing satellite adaptor that links the fuel storage container to the main satellite structure. Produced on the BLT-S600, the aluminum part features an external skin, internal latticework, and lightweight frame to reduce the overall weight by more than 60 percent compared to forging and casting. These developments have driven BLT to break ground on its Phase IV AM and powder production factories in the High Tech Zone of Xi’an, China. Dedicated to production lines for metal 3D printing powder and customized, the site represents a total construction area of approximately 163,200 square meters.

Phases II and II already represent about 100,000 square meters one management building, a high-level R&D center, and six AM factories, signifying what the company describes as “the largest intelligent metal additive manufacturing factories in China.” Phase III, now under construction, takes up 190,000 square meters and is focused on design for AM, big data, intelligent equipment, unmanned factory automation and other areas.

A BLT metal 3D printing factory. Because the company already collaborates with some of the largest names in manufacturing—including Airbus, Audi, AECC, COMAC, and HUAWEI—we can expect this growth to continue to ramp up. The question is whether or not the other firms, including GE and Nikon, can keep up. To learn more about this quick-growing company, BLT will be making its first U.S. appearance at RAPD + TCT next week. Under the name Xi’An Bright Laser Technologies Co. Ltd., the company will be at booth 1827. Images courtesy of BLT. The post BLT Breaks Ground on 163,200-Sq-Meter Metal 3D Printing Plant appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/CJbsc3B April 28, 2023 at 08:18AM Blue Origin and Aerojet Rocketdyne 3D Printing to Push NASAs Space Exploration with 3D Printing4/28/2023

https://ift.tt/mbFRAua

Blue Origin and Aerojet Rocketdyne 3D Printing to Push NASA’s Space Exploration with 3D Printing https://ift.tt/n7gyMPK Blue Origin and Aerojet Rocketdyne will expand their partnerships with NASA, with the aerospace giants aiming to carry out two additive manufacturing (AM) projects to advance the future of propulsion capabilities for the agency’s Moon to Mars campaign. NASA selected 16 proposals from 12 companies, including two from Aerojet Rocketdyne and two from Blue Origin, through its Announcement of Collaboration Opportunity (ACO). Since ACOs are not funded by NASA and are rather cooperative agreements, the agency will provide access to its unique facilities and technical expertise, allowing more direct support for the development of promising technologies without the transfer of funds.

NASA’s Volatiles Investigating Polar Exploration Rover, or VIPER, conducts mobility testing at NASA Glenn’s Simulated Lunar Operation Laboratory. Image courtesy of Bridget Caswell/NASA NASA’s Volatiles Investigating Polar Exploration Rover, or VIPER, conducts mobility testing at NASA Glenn’s Simulated Lunar Operation Laboratory. Image courtesy of Bridget Caswell/NASA

Aside from Aerojet Rocketdyne and Blue Origin, NASA also enlisted Boeing, Canopy Aerospace, Lockheed Martin, Maxar, Phase Four, Psionic, Roccor (a Redwire company), Stratolaunch, Sierra Space, and Venturi Astrolab. These companies plan to demonstrate a wide range of space innovations, including a new lunar rover tire design, a robotically assembled power system, and an electrically actuated device to join in-space propellant transfer lines. Engine techAerojet Rocketdyne and NASA’s Marshall Space Flight Center in Huntsville, Alabama, will work on a fully additively manufactured liquid oxygen-liquid hydrogen (LOX-LH2) engine demonstration over the next two years. The company is one of the leading manufacturers of LOX-LH2 engines, with a long history of providing propulsion systems for a variety of space missions, including the Apollo program and the Space Shuttle. Its RS-25 engines, which use a combination of LOX and LH2 as propellants, will power the core stage of NASA’s super heavy-lift Space Launch System (SLS) rocket during the historic Artemis III mission that will return humans to the surface of the Moon for the first time in more than 50 years. Designed to handle some of the most extreme temperatures as they move massive amounts of propellants to generate enough energy for the rocket to escape Earth’s gravity, the existing RS-25 engines already havenumerous 3D printed parts. These collaborate towards reducing the engine’s overall production costs by nearly 35% while maintaining performance, reliability, and safety. Four have already been used to power the first Artemis lunar mission on November 2022.  RS-25 engines attached to the core stage for NASA’s Space Launch System (SLS) rocket for the agency’s Artemis missions. Image courtesy of NASA/Eric Bordelon RS-25 engines attached to the core stage for NASA’s Space Launch System (SLS) rocket for the agency’s Artemis missions. Image courtesy of NASA/Eric Bordelon

Actively using 3D printing technology for a variety of components, Aerojet has been able to produce heat exchangers for LOX-LH2 engines. Thanks to its 3D printing technique, the aerospace firm can produce these parts as single, monolithic components, which are stronger and more durable than traditional designs. In addition to heat exchangers, Aerojet Rocketdyne is also using AM to make the injectors that deliver the propellants to the combustion chamber and turbopump components, such as impellers and vanes, which can improve pump efficiency and reduce manufacturing costs. In an interview with 3DPrint.com, the company has stated that it sees significant potential for 3D printing to transform the aerospace industry. Given how much Aerojet already uses 3D printing in its manufacturing process, having a fully additively manufactured large-scale rocket engine that uses cryogenic propellants like LOX and LH2 seems like the next logical step. Breaking new groundAs for Blue Origin, it will team up with NASA’s Marshall and Langley Research Center in Hampton, Virginia, to tackle Friction Stir Additive Manufacturing (FSAM), a 3D printing technology particularly useful for processing high-strength and high-temperature materials, such as aluminum alloys and titanium, which are difficult to weld through conventional methods. FSAM also enables the production of large and complex parts with minimal waste, making it an attractive option for aerospace and other high-performance applications. Both companies are actively using 3D printing technology in their manufacturing processes, clearly seeing it as a valuable tool for improving efficiency, reducing costs, and accelerating innovation in the space industry. Blue Origin has developed its own powder bed fusion technology, which it uses to produce rocket engine components and other parts for its New Shepard and New Glenn rockets. The two-decade-old space firm has stated that the use of 3D printing has enabled it to produce parts with greater efficiency and precision. Similarly, Aerojet has stated that the use of 3D printing has enabled it to reduce the weight of its engines while maintaining performance and reliability and has also allowed for more rapid prototyping and iteration of new designs.  NASA Marshall advances 3D printed rocket engine nozzle technology. Image courtesy of NASA/MSFC/David Olive NASA Marshall advances 3D printed rocket engine nozzle technology. Image courtesy of NASA/MSFC/David Olive

NASA is certainly looking to develop technologies under the ACOs that can support the Artemis program, a long-term human space exploration initiative that aims to land the first woman and the next man on the Moon by 2025. The Moon landing is clearly NASA’s highest-priority mission at the time. However, these technologies also have additional applications. Organizations interested in developing space technology with NASA can explore opportunities online here. The post Blue Origin and Aerojet Rocketdyne 3D Printing to Push NASA’s Space Exploration with 3D Printing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/CJbsc3B April 28, 2023 at 08:18AM

https://ift.tt/Oh2cL3y

Katya Slobodskaia | False Floor https://ift.tt/tDA6k5F False Floor is a fine art / photography research project that explores the limits of artificial intelligence, raises questions about the relationship between technology and nature, and explores the psychological and emotional impact of artificial images that blur the boundaries between the real and the fake. Using machine learning algorithms, Katya Slobodskaia created a series of deadpan photographs that mimic the look and feel of analogue film, complete with flaws and imperfections that would normally be attributed to human error or technical glitches. By using imperfect and unpolished photography, the photographs emphasise the human element in the creation of these images, while simultaneously highlighting the uncanny nature of the AI-generated scenery. The deliberate subversion of expectations challenges the viewer to confront the unsettling nature of the uncanny valley and to consider the implications of the intersection of nature and technology. The curious thing about these images is that they were not taken by a camera or edited by a human hand, but rather constructed by a neural network trained on a vast dataset of real-world photographs.

The project is currently being prepared to be turned into an exhibition. Printing via People of Print https://ift.tt/ETAhfmC April 28, 2023 at 07:53AM

https://ift.tt/XAuxfBs

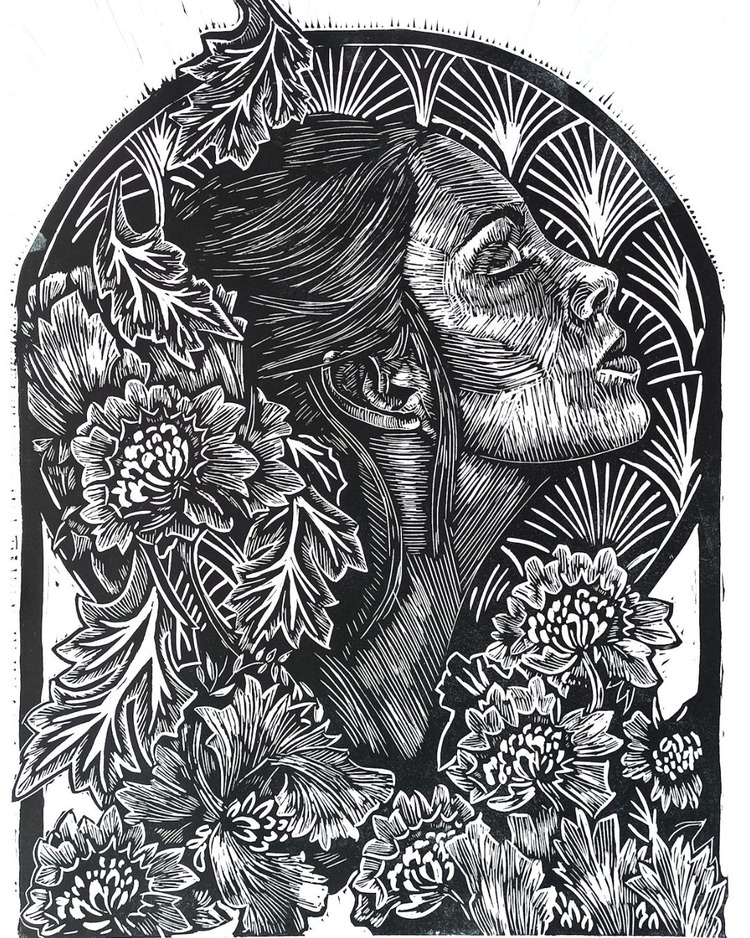

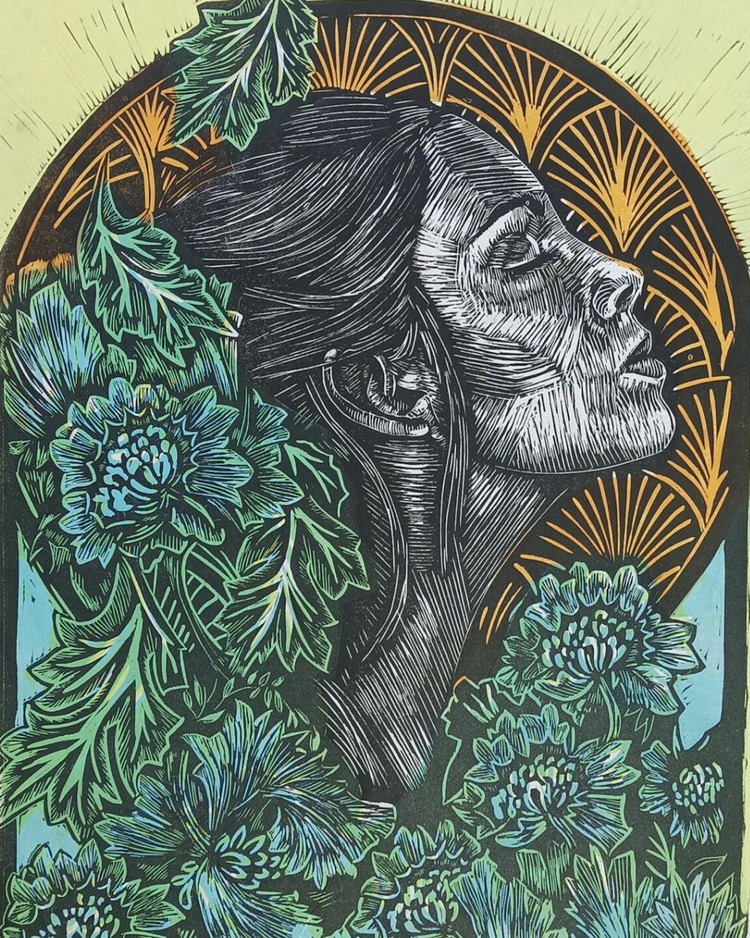

Clare Morgan | Transient Series https://ift.tt/oBp8Eji Clare Morgan has been printmaking for over 20 years. She first started to explore print while studying Fine Art at university, and has been obsessed ever since. Having experimented with many processes, Clare’s recent love is linocut printmaking; “I adore the energy in the carved marks and the strength of lines that can be created”. Her practice explores the transient nature of the seasons. Created at the start of 2023, her series, Transient, features portraits of women adorned with floral elements and incorporates symbolism through circles and arches. Clare tells us; “I love the decorative motifs of the art nouveau style and the arts and crafts movement, and this has been becoming a more noticeable feature of my work. I hope to draw upon traditional elements while adding a touch of modernity to the artwork.”

Transient includes some of her biggest pieces to date. Printed on 40cm x 50cm paper, Clare put them through an etching press rather than hand printing with a barren as she usually would. The thinner papers she normally uses would crease with this method, but the masa worked very well without getting too thick. The paper is also bright white which makes the colours pop. “I love working with Japanese papers where I can, as I like the strength in something that appears fragile,” comments Clare.

“I hope to create beautiful and thought-provoking artworks that showcase the importance of finding and embracing one’s place in the natural world and going with the ebb and flow of nature rather than fighting against it,” concludes the printmaker. www.curiousinkyme.com Printing via People of Print https://ift.tt/ETAhfmC April 28, 2023 at 07:34AM |

Categories

All

Archives

April 2023

|

The concept of the False Floor of the Uncanny Valley refers to the idea that there is a point where an artificial entity or image appears to be nearly indistinguishable from a real one, leading to a sense of comfort and familiarity (MacDorman, 2006). As AI technology advances, it becomes increasingly difficult to distinguish between real and simulated experiences. This is particularly true in the realm of visual media, where computer-generated images can look indistinguishable from photographs. However, there is often a subtle yet noticeable difference between the two, which creates an uncanny feeling in the viewer.

The concept of the False Floor of the Uncanny Valley refers to the idea that there is a point where an artificial entity or image appears to be nearly indistinguishable from a real one, leading to a sense of comfort and familiarity (MacDorman, 2006). As AI technology advances, it becomes increasingly difficult to distinguish between real and simulated experiences. This is particularly true in the realm of visual media, where computer-generated images can look indistinguishable from photographs. However, there is often a subtle yet noticeable difference between the two, which creates an uncanny feeling in the viewer.

In this project, Katya use AI photography to explore the False Floor of the Uncanny Valley, creating images that are both beautiful and unsettling. The hyper-realistic nondramatic depictions of nature challenge our perceptions of reality and question the role of technology in shaping our understanding of the world. By simulating the look of film photography and using imperfect and unpolished shots, she aims to create a nostalgic and dreamlike atmosphere, while also exposing the limitations of AI and the underlying human biases that shape its output.

In this project, Katya use AI photography to explore the False Floor of the Uncanny Valley, creating images that are both beautiful and unsettling. The hyper-realistic nondramatic depictions of nature challenge our perceptions of reality and question the role of technology in shaping our understanding of the world. By simulating the look of film photography and using imperfect and unpolished shots, she aims to create a nostalgic and dreamlike atmosphere, while also exposing the limitations of AI and the underlying human biases that shape its output.

False Floor is an invitation to reflect on the relationship between humans and machines, and the implications of AI technology for the future of art and visual culture. Through the lens of AI photography, Katya hopes to spark a conversation about the boundaries of creativity and the meaning of authenticity in an age of digital reproduction.

False Floor is an invitation to reflect on the relationship between humans and machines, and the implications of AI technology for the future of art and visual culture. Through the lens of AI photography, Katya hopes to spark a conversation about the boundaries of creativity and the meaning of authenticity in an age of digital reproduction.

The printmaker works with Linocut; using 2 blocks she creates a 1-layer monochrome version that is graphic in nature, and a colour version. Clare uses a jigsaw method of cutting up the second piece of lino to be able to use contrasting colours, as well as a reduction technique on the leaves and flowers to get a range of colours in the intricate areas.

The printmaker works with Linocut; using 2 blocks she creates a 1-layer monochrome version that is graphic in nature, and a colour version. Clare uses a jigsaw method of cutting up the second piece of lino to be able to use contrasting colours, as well as a reduction technique on the leaves and flowers to get a range of colours in the intricate areas.

“The way the portraits blend into the environment around them symbolizes the need to be one with nature and embrace its constant changes. The use of seasonal elements in the paintings, such as blooming flowers and falling leaves, emphasizes the transient nature of life and the world we live in.”

“The way the portraits blend into the environment around them symbolizes the need to be one with nature and embrace its constant changes. The use of seasonal elements in the paintings, such as blooming flowers and falling leaves, emphasizes the transient nature of life and the world we live in.”

Another key feature of Clare’s Transient series is the use of arches and circles. Archways are significant in these pieces because they represent a crossing over; a gateway to a new stage of life. They are associated with the passing of time, representing an individual’s progress through life. Clare implements archways as a framing device to enclose the portraits and create a sense of unity and balance. Circles have also featured in many of her pieces over the years. Representing completion and unity, they emphasise the importance of finding one’s place in the world.

Another key feature of Clare’s Transient series is the use of arches and circles. Archways are significant in these pieces because they represent a crossing over; a gateway to a new stage of life. They are associated with the passing of time, representing an individual’s progress through life. Clare implements archways as a framing device to enclose the portraits and create a sense of unity and balance. Circles have also featured in many of her pieces over the years. Representing completion and unity, they emphasise the importance of finding one’s place in the world. Clare seeks to create artwork that brings us to the present moment, thus, when printing, she chooses a colour that is often associated with growth, harmony, and renewal, reflecting the natural world and inspiring feelings of tranquillity, balance, and vitality.

Clare seeks to create artwork that brings us to the present moment, thus, when printing, she chooses a colour that is often associated with growth, harmony, and renewal, reflecting the natural world and inspiring feelings of tranquillity, balance, and vitality. RSS Feed

RSS Feed