|

https://ift.tt/3AZ6ANE

VELO3D Goes Public: We Speak to CEO Benny Buller https://ift.tt/39UZ3TX VELO3D (NYSE: VLD) went public today with the company listing on the New York Stock Exchange (NYSE) under the ticker symbol “VLD”. The company merged with JAWS Spitfire Acquisition Corporation and now has $274 million to play with to expand. We interviewed VELO3D CEO Benny Buller to find out more. At fist glance, Benny didn’t seem particularly ecstatic about this major milestone. He was, it turned out, laser-focused on next steps.

VELO3D Founder and CEO Benny Buller. Image courtesy of VELO3D. “The only thing I’m thinking of right now is how we finish the quarter, how we grow next quarter, how we complete the products we are working on. If the question is: is the glass half empty or half full, I can only see the empty glass. I’m entirely focused on that. I’m a bit of a party pooper really. I did have moments of joy when I saw that we had $300 million in the bank, but I’m more about moving the company forward. ”

VELO3D Sapphire 3D printing factory. Image courtesy of VELO3D. The firm now has substantial funds to address his concerns and drive the firm forward. Buller explained his plans for how it would be used.

Buller suggested that Germany, specifically Bavaria, was a real center for 3D printing due in large part to the high quality of local industry, which is particularly relevant to VELO3D. For that reason, the company will establish its European headquarters and tech center in Augsburg as the base for a massive European expansion, with the German market expected to be important to the company. Similarly, Singapore will act as VELO3D’s foothold for growth in Asia. The company is currently seeking qualified employees to fill sales, technical sales, application engineering, service engineering and marketing roles across its locations. However, anchoring its growth, according to Buller is making part costs as low as possible for VELO3D clients.

VELO3D will be introducing universal material quality specifications for any and all of its systems. These criteria will be applied to all of the firm’s material suppliers. These calibrated specifications are meant to provide customers information about what they can expect from a material. “This will let customers get started faster and let them focus on cost and productivity. We really anticipate that, [over the next few years], this will let us drive costs down and scale up production,” Benny said.

VELO3D builds support free metal AM parts. Image courtesy of VELO3D. VELO3D is unique in that it has a very tight focus on a few applications, where it aims to sell many machines to key customers. Specifically, this means areas where flow, whether it be fluids and/or heat, are managed, according to Buller. Think thermodynamic engines, rocket engines, manifolds, pumps, heat exchangers, and fuel tanks valves. In turn, the industries of highest interest are aviation, space, and power generation. Interestingly, what VELO3D is not looking at are structural parts.

In the “3D Printed Metals: A Patent Landscape Analysis 2019“ report from SmarTech Analysis, the market research firm suggested very clearly that, based on its analysis of the metal 3D printing patent landscape, VELO3D was a good company, if not the company, to watch in this area. The public listing of the firm suggests that SmarTech may have been right on the money with its projection. I think that the focus on so very limited verticals and applications is almost the most interesting thing about VELO3D. It’s a brilliant way to approach the market and focus on the most valuable long-term prospects that could be converted into many sales per client. Once you convince them and dial in the application, they can use several machines per customer. The first machine will take a while, but the second wave will be very quick, which should accelerate VELO3D’s sales relative to other players in the market. I love flow as an application and think that VELO3D has the best go-to-market. It also avoids the long lines of companies chasing the same deals in automotive and medical, which I think is very smart. VELO3D’s going public will definitely bring more competitiveness to our industry and that will really be good for us all in the end. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com September 30, 2021 at 03:00PM

0 Comments

Day of the Dead Comes Alive with New Forever Stamps https://ift.tt/3ilrQG4 EL PASO, TX — The U.S. Postal Service commemorates the Day of the Dead, an increasingly popular holiday in the United States, with the release of four new Forever stamps. A dedication ceremony for the stamps was held today at the El Paso Museum of Art. Printing via USPS News https://ift.tt/2hH9aDC September 30, 2021 at 12:05PM Postal Service Maintains Service Performance Improvements Ahead of Peak Season https://ift.tt/3F95mBE WASHINGTON, DC — The U.S. Postal Service reported updated fiscal fourth quarter service delivery performance that showed maintained improvements versus the third quarter ended June 30 for all First-Class, Marketing and Periodical mail categories. Printing via USPS News https://ift.tt/2hH9aDC September 30, 2021 at 10:40AM

https://ift.tt/3CZdGSJ

How Additive Manufacturing is Quietly Revolutionizing the Defense Industry https://ift.tt/3oq0kuL (3DPrint.com PRO is available only to subscribers) During the inaugural AM Investment Strategies summit, which was held virtually this September, I was fortunate enough to speak on a panel of industry leaders about trends in additive manufacturing and how they may be shaping (or shaped by) public and private investment. During the discussion, a natural running theme emerged as a universal truth in the current state and the future of additive manufacturing (AM) – a deeper focus on solutions, and therefore applications, has emerged the last two years in the industry in an effort to further adoption. This trend is being empowered by the decade-long efforts to continue developing the hardware platforms in the industry to be viable digital tools for processing more and more advanced materials, and also by efforts to connect workflows through software tools and reduce the need for process-specific expertise just to manufacture parts. With the new playbook for AM’s development squarely set on developing real-world applications that bring value and can stand on their own from an economic or return-on-investment standpoint, today I want to shed some light on an area where this trend is taking off in earnest—but where almost nobody seems to realize. This area could be referred to as the ‘defense’ industry, but to be more specific, it is in the market for military ground equipment and small arms accessories and parts, as well as their civilian market equivalents. Already a subscriber?You are set to receive premium content directly to your inbox twice a month. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com September 30, 2021 at 08:36AM

https://ift.tt/3kUOYwH

3D Printed Pork to Enter Chinese Market via CellX https://ift.tt/3CZp7Km One of the biggest difficulties presented by industrial agriculture involves the contradictions between the constantly growing scale of production on the one hand, and on the other, the capacity that existing infrastructure has for storing and distributing the food produced. Analyses vary concerning the exact amount of food that industrial agricultural systems waste, but a fairly good estimate is around one third. A much higher percentage of fruits and vegetables sent to market are wasted, when compared to meat; but then you also have to consider the quantity of inputs devoted to producing animal meat. Of course, industrial meat production is severely damaging to the environment in many other ways, especially related to the pollution caused by animal waste. Meat’s carbon footprint, combined with the long-term future shortages anticipated because of growing global demand, have caused such a stir that for awhile it seems like all we were hearing about were new versions of meat. Perhaps more so than any other major facet of 3D printing, this sector of the field epitomizes the industry’s rapid trajectory from quirky newsmaker to venture capital darling: for instance, earlier this year, Israel-based company Redefine Meat raised another $29 million in its latest round of funding, which it used for international expansion; the company expects to hit U.S. stores in 2022. It was only a matter of time, then, before we saw a Chinese 3D printing meat startup: certainly not the last, but apparently the first, of these, is Shanghai’s CellX, which just received another $4.3 million in investments. CellX is using the money for more R&D into its own particular niche it hopes to establish in the alternative meat game, 3D printed pork that combines tissue engineering and 3D printing to make a cultured meat version of pork. Like other cultured meat products, We will explore CellX’s manufacturing process in more depth as we learn more. What it seems to consist of is the harvesting of cells from live animals – in this case, CellX uses China’s native black pig – which are then seeded into scaffolding molds. After the molds are incubated, the resulting tissue is 3D printed, resulting in a slab with a look, feel, and taste approximating that of raw meat fresh from the slaughterhouse, minus the slaughtering. CellX is also planning on working on a fish product, giving us a scaffolding-based competitor to the extrusion-based Vish to look forward to. But the company’s pork product is what I think will really make its mark. For one, while it’s true that pork production is certainly less damaging to the environment in the ways described above than beef and probably less damaging to the environment than chicken, it’s also true that this is a bit like saying hybrid cars are less damaging to the atmosphere than conventional-engine vehicles. They’re less damaging now, but who knows how true that will be if/once everyone starts driving hybrid cars, at which point you will have also reinforced a culture of driving in a way you might not have had hybrid cars not existed, etc. The point is that whatever the case may be now, don’t expect it to be that way, necessarily, much longer. All you have to do is imagine pork production increasing in response to beef and chicken production decreasing to envision how there’s no meat that, in the long term, won’t be subject to a paradoxical mix of overproduction and shortages. Another thing, however, simply has to do with the fact that pork is bacon, and people will give up lots of other things- lots of other meats, even! – before they’ll give up bacon. Veggie “fakin bacon” has been one of the most plausible alternative meats before the phrase “alternative meat” even really existed, so it’s easy to imagine this crossing over into the realm of bioprinted meat. And finally, even more simply, it’s hard to imagine an easier shape to mass-produce with 3D printing than the beloved strip, so if CellX can get the flavors right, cornering the market on 3D printed pork could end up meaning cornering the market in general. China may not have much of a domestic market yet for alternative meat, but if the current era has one major theme to it, it’s that shortages hit anywhere at any time, so being China’s first domestically-produced cultured meat company also gives the company another huge edge. And in general, wherever you are on the planet, whatever anyone says they won’t try when things are plentiful, you can bet they’ll start rethinking things when someone says they were just at the store and they were all out of bacon. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com September 30, 2021 at 08:06AM

https://ift.tt/34nh6js

3DPOD Episode 79: LEGO Additive Manufacturing Manager, Mandy Moshiri https://ift.tt/3F46oiy In this episode of the 3DPOD, we talk to Mandy Moshiri, Technology Manager at the LEGO Group. Far from the maddening crowds, the hype, and the promises of 3D printing,... The post 3DPOD Episode 79:... View the entire article via our website. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com September 30, 2021 at 07:36AM

https://ift.tt/3kUpOhA

Space Force Awards $88M to Rocket Lab, SpaceX, ULA and Blue Origin https://ift.tt/2Y5ML9i Commercial space companies are heralding a new phase in the space race as they lay down the groundwork for the future of space exploration. More than ever before, space agencies are turning to private startups and leading space ventures to create space technologies that will drive down launch costs, open up more opportunities thanks to a growing competitive landscape, and challenge a 60-year-old space status quo. As part of this trend, the U.S. Armed Forces space service branch known as Space Force has awarded Rocket Lab, United Launch Alliance (ULA), Blue Origin, and SpaceX $88 million to develop prototype projects through its new Space Systems Command (SSC), which is responsible for developing and acquiring lethal and resilient space capabilities for warfighters. The technology development projects are essential to maintaining space security and advancing space technology. More specifically, the SSC funds will go towards next-generation rocket engine testing, upper-stage resiliency enhancements, and orbital transfer and maneuver capabilities as part of the Space Force’s National Security Space Launch (NSSL) phase three strategy. In addition, the prototypes will accelerate the development of transformational space access capabilities and mobility and make them available for future launch vehicle procurement contracts, such as for trajectories beyond geosynchronous orbit. All four selected businesses are pioneering 3D printing to develop space applications, including rocket parts, tools, and support equipment used by astronauts. For example, Blue Origin and Rocket Lab have hundreds of 3D printed components in their rockets, and SpaceX has even created additively manufactured (AM) parts for its crewed Dragon capsule. As advanced technologies continue to prove their worth, we can expect the leading space firms will continue to leverage AM. The SSC’s Launch Enterprise in collaboration with the Space Development Corps’ Space Enterprise Consortium (SpEC), which was created in 2017 through the Air Force Space and Missile Systems Center to bridge the cultural gap between military buyers and commercial space startups, solicited proposals for these projects on May 11, 2021. Four months later, the SSC announced that the contracts were awarded to current national security launch providers SpaceX and ULA and newcomers Blue Origin and Rocket Lab. These last two companies are now expected to compete in 2024 for the next round of national security launch service contracts and are on track to become NSSL phase three launch providers starting as soon as 2025.  Rocket Lab founder Peter Beck stands with a Neutron fairing half. Image courtesy of Business Wire. Rocket Lab founder Peter Beck stands with a Neutron fairing half. Image courtesy of Business Wire.

Rocket system manufacturer Rocket Lab will receive $24.35 million to develop the Neutron launch vehicle’s upper stage to support national security and defense launch capabilities for scientific and experimental satellites for the largest and most critical national security payloads. Neutron is Rocket Lab’s medium-lift, eight-ton payload class launch vehicle for constellation deployment, cargo resupply, interplanetary missions, and even human spaceflight, expected to launch in 2024. Company founder and CEO Peter Beck said he is committed to building a next-generation rocket to transform space access for constellations and critical missions that will support the country’s national security.

Rocket Lab is known for its almost entirely 3D printed rocket engine, the Rutherford, which relies on an electric motor rather than gas and features prop valves, injectors, pumps, and engine chambers that are all 3D printed with electron beam melting technology. Although this engine has powered the company’s small satellite Electron launch vehicle, Rocket Lab is now shifting focus to the development of Neutron, which also leverages 3D printing for part production.  Elon Musk at SpaceX getting ready to fire the Raptor rocket engine. Image courtesy of Elon Musk via Twitter. Elon Musk at SpaceX getting ready to fire the Raptor rocket engine. Image courtesy of Elon Musk via Twitter.

SpaceX will get $14.7 million for rapid throttling and restart testing of its Raptor rocket engine, designed for use on the Starship super-heavy rocket, set to carry both crew and cargo to Earth orbit, the Moon, and Mars. The funds will be used for liquid methane specification development and testing, and combustion stability analysis, and testing for its Raptor engine. Considered the future of the company’s missions, Raptor will carry spaceships off-Earth and is one of the first rocket engines to be powered by methane and designed to be reused one thousand times. Several major accomplishments in 3D printing for space applications make SpaceX the original pioneer in the commercial space segment. The powerhouse began using 3D printing technology on spaceflight hardware in 2014 and has even shown interest in buying 3D printing company Velo3D in 2021.  An Atlas V rolls to the launch pad at Cape Canaveral. Image courtesy of ULA. An Atlas V rolls to the launch pad at Cape Canaveral. Image courtesy of ULA.

As for ULA, the joint venture company born out of Boeing and Lockheed Martin will receive $24.35 million for uplink command and control of Centaur 5, the upper stage of its new Vulcan launch vehicle currently being developed to meet the needs of the NSSL program. The Vulcan Centaur rocket uses metal AM qualification and flight components provided by Oerlikon AM. Additionally, ULA has adopted 3D printing for the serial production of thermoplastic components and bespoke metal parts. Finally, Jeff Bezos’ space undertaking Blue Origin will also get $24.35 million in funds. The company will use it towards cryogenic fluid management (CFM) of its New Glenn rocket’s second stage. CFM technology is an integral part of exploration systems for Earth-to-orbit transportation, manned missions to the Moon and Mars, planetary exploration, and in-situ resource utilization.  Blue Origin rocket engine hot-fire testing. Image courtesy of Blue Origin. Blue Origin rocket engine hot-fire testing. Image courtesy of Blue Origin.

The Kent, Washington-based company has been leveraging additive technologies for years. Bezos was even spotted visiting the headquarters of space startup Relativity Space in early 2021, as reported by CNBC. Relativity Space founder Tim Ellis worked at Blue Origin before co-founding the company, which plans to build an entirely 3D printed rocket using patented wire-fed AM technology. Although neither Bezos nor Ellis commented on the visit, we hope that they will both escalate the use of AM in space applications. The prototype projects for orbital transfer and maneuver are anticipated for the award at the start of the fiscal year 2022 (FY22), pending congressional approval of the FY22 budget request. The SpEC believes the orbital transfer prototype projects will improve space access capability for national security launch systems. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com September 30, 2021 at 07:06AM

https://ift.tt/3ijuMTF

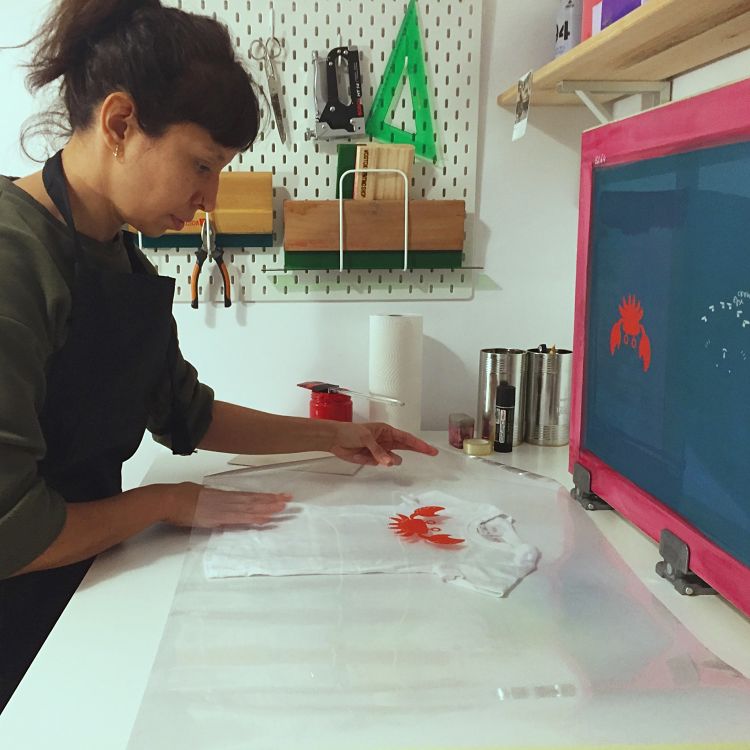

Pacifico Prints https://ift.tt/3uqdpoK Claudia Galindo, a Colombian graphic designer based in Barcelona, is the face behind Pacífico Prints. After many years spent working in design studios, Claudia began to feel more drawn towards illustration; “That’s why I decided to create Pacífico, a place where I could create my own things and not be always depending on what the client/brand has to say”. Pacifico is a space where Claudia can create, illustrate, and print.

As a graphic designer, Claudia has always been interested in working with physical materials, and not solely the computer. “This is what I like the most about the screen printing process: I get to work with my hands and get away from the screen which I have to be in front of 8 hours a day,” states the printmaker.

Printing via People of Print https://ift.tt/2DhgcW7 September 30, 2021 at 04:14AM

https://ift.tt/3kVPnPG

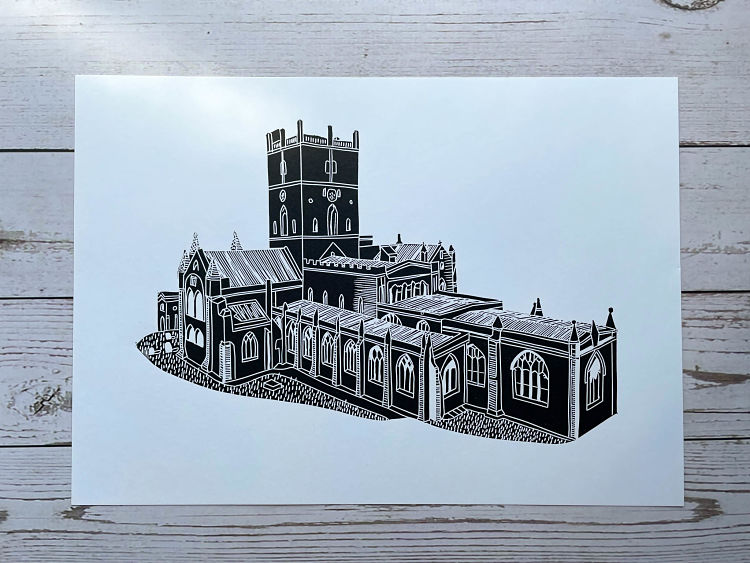

Georgina Kent https://ift.tt/3De11vB Georgina Kent is an illustrator and lino artist living a stones throw from the iconic Caerphilly castle in South Wales. Aside from a smattering of watercolours and digital illustrations, most of her work comes from carving lino. Georgina had her first taste of lino back in 1996 during her Intermediate GNVQ in Art & Design at Reading college. Then, 24 years later during the second lockdown of 2020, she revisited linocut printing and immediately fell in love with the medium.

In September of 2020, Georgina bought a linocut kit and carved her first piece of lino in many years. She comments; “I instantly knew this was what I wanted and needed to do with my life”. Two months later she opened her online store, and was soon lino printing full time.

Printing via People of Print https://ift.tt/2DhgcW7 September 30, 2021 at 03:39AM

https://ift.tt/3A00XO0

Asia’s Largest Food Companies Drive Bioprinted Meat in Asia with Aleph Farms https://ift.tt/3ilIfdE The cultivated meat world seems to be trying to disrupt the $800 billion meat market by growing steaks directly from animal cells that are not genetically engineered or immortalized. One of the pioneering firms in this up-and-coming segment is the Israeli startup Aleph Farms. Better known for helping cosmonaut Oleg Skripochka successfully 3D bioprint meat on the International Space Station (ISS), Aleph created the world’s first slaughter-free steak made from cow cells in 2018 and developed a scalable manufacturing 3D tissue engineering platform, called BioFarm, to cultivate whole-muscle steaks. By reimagining the food system and trying to convince the average meat-eater that consuming animal steaks is not worth the environmental damage, Aleph wants to turn alternative meats into a global phenomenon. Today, the Leonardo Di Caprio-backed startup announced a new partnership with two of Asia’s largest food companies to accelerate its scale-up and go-to-market strategy while increasing the distribution of its cultivated meat in existing marketing channels across the Asia Pacific (APAC) region. Through the new deal with global protein leader Thai Union and food and lifestyle company CJ CheilJedang, Aleph will help drive the adoption of cultivated meat in Asia.  Aleph Farms’ leadership team from left to right: Technion Professor Shulamit Levenberg; Didier Toubia, Co-Founder and Chief Executive Officer; Dr. Neta Lavon, Chief Technology Officer. Image courtesy of Rami Shalosh/Aleph Farms. Aleph Farms’ leadership team from left to right: Technion Professor Shulamit Levenberg; Didier Toubia, Co-Founder and Chief Executive Officer; Dr. Neta Lavon, Chief Technology Officer. Image courtesy of Rami Shalosh/Aleph Farms.

Aleph’s Co-Founder and CEO, Didier Toubia, said the new partnership with two of Asia’s key players in the food market would help his company establish a new category of meat products. In turn, they could address the increasing consumption in the region, which is primarily fueled by the economic growth of the middle class. In fact, according to data from Meat & Livestock Australia (MLA), household income growth remains a significant growth factor driving increasing global meat consumption, which is projected to grow at an average rate of 1.2% annually over the next ten years. This growth means that beef consumption across Asia could increase by 2.7 million tonnes in the coming decade, considered the largest gain across any global domain. In a region that has historically consumed fish and other seafood, beef has become Southeast Asia’s second-fastest-growing meat category, with consumption expected to increase as much as 16% by 2022. Nonetheless, research from Thai Union and Aleph Farms reveals that 74% of Singaporeans and 97% of Thais are willing to try cultivated meat, fueled by several key motivators, like environmental benefits in Singapore and restaurant’s ability to trace the meat’s origins in Thailand. Quickly developing into one of the leading businesses in cultivated meat, Aleph has been targeting the APAC region for a while. The startup already announced a similar agreement with Mitsubishi in Japan in July 2021 to deliver its proven BioFarm platform for cultivating whole-muscle steaks. After developing several successful prototypes, the business is currently working with regulatory agencies to move ahead with its commercialization plans.  Cultivated meat. Image courtesy of Aleph Farms. Cultivated meat. Image courtesy of Aleph Farms.

Furthermore, to expand its product lines and technology platform ahead of an initial market launch in 2022, Aleph recently secured $105 million in a Series B funding round. The investment was led by L Catterton, the largest global consumer-focused private equity firm, and DisruptAD, the venture capital platform of the United Arab Emirates (UAE) ADQ sovereign wealth fund, and included the participation of Temasek, a global investment company headquartered in Singapore. The new funds will help expand its product lines and technology platform bringing the company closer to its vision of providing secure and unconditional access to high-quality nutrition to anyone.

Asia is leading the global food industry in supporting and adopting cell-cultured meats, stated the company. Moreover, Singapore has become the first country to approve cultivated meat and offer it on a restaurant menu. In December 2020, lab-grown chicken made by California-based startup Eat Just made its historic debut at restaurant 1880 in Singapore after its food agency approved its commercialization. During the inaugural event, Chef Colin Buchan, who previously worked as head chef at Jason Atherton’s Pollen and with renowned British chef and restaurateur Gordon Ramsay, served the cultivated chicken as part of a trio of sample dishes priced roughly at $23. CJ CheilJedang Chief Technology Officer of Food R&D, Sze Cotte Tan, said: “We are at the forefront of a trend in Asia food industry as Asian consumers show increasing interest in alternative proteins, and we have the opportunity to lead consumption patterns toward a more sustainable, resilient future that benefits all of Asia and the world.” Similarly, Thai Union President and CEO Thiraphong Chansiri stated the company is closely tracking changing consumer demands and finding new, sustainable ways to meet increased global protein demands to respond to the growing population of the world.  Aleph Farms and Mitsubishi Bring Cultivated Meat to Japan. Image courtesy of Aleph Farms. Aleph Farms and Mitsubishi Bring Cultivated Meat to Japan. Image courtesy of Aleph Farms.

Expected to be commercially available in months, Aleph relies on a bioengineering platform developed with the Technion – Israel Institute of Technology to create its whole-muscle steak. The technology developed is a great leap forward in producing a cell-grown steak that mimics the traditional texture, structure, flavor, and shape of beef muscle tissue steak, claim the company. But without the need for devoting vast tracts of land, water, feed, and other resources to raise cattle for meat, or use of antibiotics, helping the startup garner strategic partners from the food industry needed to build a sustainable ecosystem for cultured meat. Unlike 3D printing technology, Aleph’s bioprinting platform makes actual living cells that are then incubated to grow, differentiate, and interact to acquire the texture and qualities of a real steak. A proprietary system, similar to the vascularization that occurs naturally in tissues, enables the perfusion of nutrients across the thicker tissue and grants the steak a similar shape and structure to its native form as found in livestock before and during cooking. The innovative proposal has attracted several high-profile backers, like environmental activist and Academy Award-winning actor DiCaprio, who joined the Aleph Farms family as an investor and a member of its Sustainability Board. Other alternative meat companies using 3D printing and bioprinting are also promising great breakthroughs in the sector. Still, up until now, it seems Aleph is one of the contenders to produce and commercialize the first cultured meat to millions of people worldwide. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com September 29, 2021 at 05:30PM |

Categories

All

Archives

April 2023

|

Claudia fell in love with screen printing many years ago when she partook in a screen printining workshop. However, afterwards she lacked the time and the materials to do it on her own. During the Covid pandemic, after losing her job she decided to invest her time in things that she could enjoy doing. Thus, she rediscovered screen printing. Claudia says; “I started to illustrate different things that reminded me of something, someone or a moment, and decided to print t-shirts”. She soon realised that she enjoyed creating prints on textiles, and that this was the direction that she would love to continue to grow, creating not only illustrations, but also patterns to create full textiles.

Claudia fell in love with screen printing many years ago when she partook in a screen printining workshop. However, afterwards she lacked the time and the materials to do it on her own. During the Covid pandemic, after losing her job she decided to invest her time in things that she could enjoy doing. Thus, she rediscovered screen printing. Claudia says; “I started to illustrate different things that reminded me of something, someone or a moment, and decided to print t-shirts”. She soon realised that she enjoyed creating prints on textiles, and that this was the direction that she would love to continue to grow, creating not only illustrations, but also patterns to create full textiles.

Her process starts by illustrating something that she has in mind onto paper. Claudia comments “I’m not very good at illustrating, or I’m not really confident about it, so it takes me some time to decide on something that I like”. Afterwards, she moves to the computer to create the layers and wrap up the design, and then, her favourite part, she goes to her workshop and starts printing.

Her process starts by illustrating something that she has in mind onto paper. Claudia comments “I’m not very good at illustrating, or I’m not really confident about it, so it takes me some time to decide on something that I like”. Afterwards, she moves to the computer to create the layers and wrap up the design, and then, her favourite part, she goes to her workshop and starts printing.

There are many illustrators and designers that inspire Claudia’s work, but the majority of inspiration comes from nature and music. Alongside her passion for colourful things, everyday things that happen to her are also reflected in her prints; be that places she has visited, people she has met, or her Colombian heritage.

There are many illustrators and designers that inspire Claudia’s work, but the majority of inspiration comes from nature and music. Alongside her passion for colourful things, everyday things that happen to her are also reflected in her prints; be that places she has visited, people she has met, or her Colombian heritage.

This summer, Claudia launched a collaborative project with her friend, Tierra de Peludos (a dog photography project). Claudia designed a printed a limited edition of bandannas for dogs, which were then photographed by her friend. “It was really hard because it was the first time working with such a big screen, but we are really happy with the result,” says Claudia. There are 3 colours (neon pink, neon orange and neon green) and 3 different sizes (S, M, L) available.

This summer, Claudia launched a collaborative project with her friend, Tierra de Peludos (a dog photography project). Claudia designed a printed a limited edition of bandannas for dogs, which were then photographed by her friend. “It was really hard because it was the first time working with such a big screen, but we are really happy with the result,” says Claudia. There are 3 colours (neon pink, neon orange and neon green) and 3 different sizes (S, M, L) available.

Claudia hopes to continue to grow Pacifico Prints, and leave her job at a graphic design studio to work on screen printing full time. She is looking forward to creating patterned textiles for clothing and home decor in the future, as well as bringing her illustrations to life through the process of animation.

Claudia hopes to continue to grow Pacifico Prints, and leave her job at a graphic design studio to work on screen printing full time. She is looking forward to creating patterned textiles for clothing and home decor in the future, as well as bringing her illustrations to life through the process of animation. “It’s funny, the course at Reading college was unremarkable,” says the printmaker. Future courses taught her so much more, but this little bit of exposure to lino is what has now born a career for her. After her year at Reading college, Georgina moved to West Wales to study at Pembrokeshire college, Here, she discovered her love of still lives, form, and illustration. She then went on to attend the University of Wales Institute Cardiff (now called Cardiff Met) to study Graphic Communication. After leaving half way through her final year, Georgina spent the next 20 years working for insurance companies and found creative outlets wherever she could in her work. But it was at the end of 2020 that Georgina took the plunge and followed her dreams to be a full time artist.

“It’s funny, the course at Reading college was unremarkable,” says the printmaker. Future courses taught her so much more, but this little bit of exposure to lino is what has now born a career for her. After her year at Reading college, Georgina moved to West Wales to study at Pembrokeshire college, Here, she discovered her love of still lives, form, and illustration. She then went on to attend the University of Wales Institute Cardiff (now called Cardiff Met) to study Graphic Communication. After leaving half way through her final year, Georgina spent the next 20 years working for insurance companies and found creative outlets wherever she could in her work. But it was at the end of 2020 that Georgina took the plunge and followed her dreams to be a full time artist.

Georgina states; “My career as a lino artist is still very early on and the learning curve is steep. Traditional lino is definitely a tricky medium to master getting a good print from, and while it’s delightful to carve, I am finding a preference for vinyl lino.” Pfeil carving tools are her go-to, along with ho-sho, awagami editioning, and 190gsm Kent papers. All of her prints are currently produced on a small A4 table top printing press.

Georgina states; “My career as a lino artist is still very early on and the learning curve is steep. Traditional lino is definitely a tricky medium to master getting a good print from, and while it’s delightful to carve, I am finding a preference for vinyl lino.” Pfeil carving tools are her go-to, along with ho-sho, awagami editioning, and 190gsm Kent papers. All of her prints are currently produced on a small A4 table top printing press. Recently, she has started dabbling in merchandise too, designing her first range of washi tapes, as well as printing some of her own greetings cards. Looking to the future, Georgina hopes to “keep growing, keep creating beautiful art and prints, to feel fulfilled in work, and to continue to find inspiration and be inspired”. Dreaming further, she aims to move out of her home studio into a bigger space with a larger etching press and drying racks. Some of Georgina’s work is due to appear on TV next year, and her work is continually available in different shops across South Wales.

Recently, she has started dabbling in merchandise too, designing her first range of washi tapes, as well as printing some of her own greetings cards. Looking to the future, Georgina hopes to “keep growing, keep creating beautiful art and prints, to feel fulfilled in work, and to continue to find inspiration and be inspired”. Dreaming further, she aims to move out of her home studio into a bigger space with a larger etching press and drying racks. Some of Georgina’s work is due to appear on TV next year, and her work is continually available in different shops across South Wales. RSS Feed

RSS Feed