|

https://ift.tt/37c3w44

3D Printing Webinar and Virtual Event Roundup: January 31, 2021 https://ift.tt/39yDJEw This week is a little less busy in terms of 3D printing-related webinars and virtual events: just two on Tuesday, three on Thursday, and one available to watch on-demand. Read on for all of the pertinent details! Hands-On Virtual Mimics Enlight Mitral Workshop If you missed last month’s Materialise webinar about medical 3D planning for TMVR (Transcatheter Mitral Valve Replacement), fear not—the online workshop, “Mimics Enlight Mitral Workshop,” returns this Tuesday, February 2nd, at 11 am EST. During the hands-on webinar, four trainers will discuss how to plan for TMVR using the software interface and image segmentation system, and attendees will learn the value of 3D planning for TMVR, how to create an accurate virtual 3D model, how to plan efficiently and assess risk by leveraging automation and consistent measurements, and more. After the workshop, attendees will receive a three-week evaluation license so they can keep learning about 3D planning.

You can register for the workshop here. AM Coalition: Congressional Policy Panel Last week, the Additive Manufacturing Coalition, a national membership organization that works to connect members with the federal government and help them navigate legislative and public funding challenges, held a live Zoom forum about what the AM industry can expect from the 117th Congress. Congresswoman Haley Stevens (MI-11) discussed the upcoming session of Congress, and this week the AM Coalition is holding a second live Zoom forum about the subject at 3 pm EST on the 2nd. “A View From Washington: Congressional Policy and Budget” will consist of a panel discussion regarding the 117th Congress and the Biden administration. The panelists include North Carolina State University’s Director of Federal Affairs Matt Peterson; the Senior Advisor for The Roosevelt Group, Matthew Hermann; and Ryan Keating, the Deputy Chief of Staff for Congressman Tim Ryan (OH-13). You can RSVP for the event here, and if you have questions you’d like to be included in the Zoom forum, you can email them to the AM Coalition. TriMech Discusses DELMIAWORKS Stratasys and SOLIDWORKS reseller TriMech is getting its slate of webinars started this month with one on Thursday, February 4th, at 10 am EST called “Get to Know DELMIAWORKS.” TriMech Elite Application Engineer Stephen Petrock will explain how the software can connect all of your business systems into one, show real-time production monitoring and scheduling, demonstrate quality management of your manufacturing process, show how you can link your business operations, and more.

You can register for the webinar here. HP Hosts Virtual Tour At 1 pm EST on the 4th, HP will be hosting a virtual tour of its 3D Printing Demo Center. Attendees will get to see HP’s entire end-to-end 3D printing process, all the way from file preparation to post-processing the completed parts during the virtual tour, which means they’ll have a chance the see HP Jet Fusion 5200 3D printer live and in action.

You can register for the virtual tour here. Transitioning from AutoCAD to DraftSight? The last webinar on Thursday, February 4th will be hosted by AutoCAD expert and Technology Evangelist Lynn Allen, titled “Can DraftSight REALLY replace AutoCAD?” and beginning at 2 pm EST. From the perspective of an AutoCAD user, Allen and the DraftSight team will explore the 2D and 3D CAD solution, and discuss APIs, constraints, file compatibility, product and licensing options, and more.

You can register for the webinar here. GE Healthcare Using Simulation for Product Optimization The final webinar in this week’s roundup is an on-demand option about GE Healthcare‘s use of simulation during the pandemic, hosted by Dassault Systèmes and titled “Learn How GE Healthcare Uses FEA/CFD to Optimize Products During COVID-19.” We all know by now that COVID-19 has brought about a lot of challenging situations for engineers, including the team at the GE Healthcare Anesthesia and Respiratory Care (ARC) Group; perhaps even more so, as the Group’s duties are directly tied to the frontlines of healthcare. For product development during the pandemic, the engineering team relies a lot on integrated simulation tools.

You can check out this on-demand webinar for yourself here. Do you have news to share about any future webinars or virtual events? Please let us know! Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 31, 2021 at 07:08AM

0 Comments

https://ift.tt/2YqaRrE

3D Printing News Briefs, January 30, 2021: Azul 3D, TCT 3Sixty, 3DP4ME, DyeMansion, & cytena https://ift.tt/3oxZYyz We’re starting with a little business news in today’s 3D Printing News Briefs, as Azul 3D welcomes a new member to its advisory board and yet another industry event has been postponed due to health and safety concerns. Moving on, 3DP4M has been established as a charity by the Jordanian government. ProGlove has achieved serial production runs of a new product in collaboration with DyeMansion and FORMRISE, and cytena has officially launched its single-cell dispensing system. Azul 3D Welcomes Zhenan Bao to Advisory Board 3D printing company Azul 3D, which develops printers based on High Area Rapid Printing (HARP) technology, announced that Zhenan Bao, an entrepreneur and world-renowned expert in stretchable electronics, has joined its advisory board. A professor of chemical engineering at Stanford University, Bao works to develop flexible, stretchable devices that can interface with skin and could be used in the robotics field, as well as for prosthetics. She is also chairperson of the university’s chemical and engineering department, as well as a co-founder and member of the Board of Directors for Silicon Valley tech startups C3 Nano and PyrAmes. Last year, Azul 3D added two important members to its board of directors, raised $12.5 million in a seed financing round, and formed an exclusive development collaboration with DuPont Electronics & Imaging, and it seems like 2021 will be just as busy.

TCT 3Sixty Postponed Again Rapid News Group already had to reschedule TCT 3Sixty once, and now it’s had to do it again, announcing that the new dates for the UK’s flagship event for 3D printing intelligence are now September 28-30, 2021, instead of in June 2021. This will allow the community to (hopefully) plan ahead, and give the worldwide COVID-19 vaccine programs the proper amount of time to have the maximum effect so that all attendees will be safe and secure. The event will still feature live stream feeds that offer interactive, 360° insights, as well as an extensive conference program delivered on multiple stages, a community platform, networking events, and interactive features as well. TCT 3Sixty will be held in Hall 3 of the National Exhibition Centre (NEC) in Birmingham, alongside the Interplas plastics show and Med-Tech Innovation Expo, two other industrial events put on by Rapid News Group.

3DP4ME Continued Growth in 2020 California not-for-profit organization 3DP4ME, which operates in the Middle East, was formed to help people in developing areas get better access to hearing aids by using 3D printing to make them. According to 3DP4ME, only 1 out of 50 people in the developing world who need a hearing aid actually have one, and its mission is to use 3D printing and facilitate access for those who need it. In an email sent to 3DPrint.com, we learned that the organization has continued to grow over the last year, starting with official approval from the Jordanian government as a charity this summer after six years. With its official registration in hand, 3DP4ME signed a lease on a new office space last month, and is also working to set up its hearing express pilot, with a long-term goal of providing 12,000 3D printed hearing aids to those in need; thanks to a donation from Ultimaker BV and its sales partner Raidy, 3DP4ME will soon receive a new Ultimaker S5 Pro 3D printer on which to begin R&D efforts.

ProGlove Using DyeMansion & FORMRISE Technologies Startup ProGlove, which manufactures wearable barcode scanners used by companies like Audi, Bosch, and Lufthansa Technik, collaborated with AM service provider FORMRISE and post-processing firm DyeMansion to achieve serial production runs for its new MARK Display product. ProGlove originally used FDM 3D printing to make prototypes of the MARK Display, which presents information like storage and product numbers to the user while scanning occurs, but eventually switched to selective laser sintering (SLS) technology. While the startup appreciated the design freedom and reduced number of components it had with 3D printing the barcode scanner’s casing, there were issues with finishing and part coloring, which DyeMansion has helped it solve through the use of its Print-to-Product workflow. ProGlove says the post-processing takes just three hours, and is now using the process to 3D print and finish barcode scanners at volumes up to 10,000 pieces.

cytena Launches UP.SIGHT Single-Cell Dispenser Swedish bioprinting manufacturer CELLINK and its subsidiary cytena GmbH have officially launched their rapid, all-in-one imager and single-cell dispenser, UP.SIGHT. The system, which offers a double assurance of clonality and no need for image stitching, is said to increase the efficiency in cell line development workflows, thanks to cytena’s patented, rapid single-cell dispensing technology and high-quality imaging system. According to CELLINK, biologics are used to develop eight out of the top ten best-selling drugs in the world, and developing cell lines is a major part of that. The UP.SIGHT system is certified to help laboratories triumph over their cell line development issues and work faster and smarter, as it can ensure precise cell isolation and monoclonality.

Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 30, 2021 at 07:08AM U.S. Postal Service Board of Governors to Meet Feb. 9 https://ift.tt/3bxIa3X Jan. 29, 2021 U.S. Postal Service Board of Governors to Meet Feb. 9Meeting to be conducted by live audio webcast WASHINGTON, DC — The U.S. Postal Service Board of Governors will meet in open session on Feb. 9, 2021, at 9:00 a.m. ET. The Board is expected to discuss the following items:

The public is welcome to listen to a live audio webcast of the meeting (no in-person attendance) at http://about.usps.com/who/leadership/board-governors/briefings/welcome.htm. Three hours after the conclusion of the open session meeting, a recorded audio file will be available for listening. In compliance with Section 508 of the Rehabilitation Act, the audio webcast will be open-captioned. The Postal Service receives no tax dollars for operating expenses and relies on the sale of postage, products and services to fund its operations. ### Printing via USPS News https://ift.tt/2hH9aDC January 29, 2021 at 12:04PM

https://ift.tt/3cjMBQc

Australian Scientists 3D Print “Bone” with Living Cells at Room Temp https://ift.tt/3iWFgr0 A novel, fast-setting ceramic-based bioink could allow surgeons in the future to 3D print bone with living cells to repair damaged bone tissue. Scientists from the University of New South Wales (UNSW) in Sydney, Australia, used a LulzBot Mini desktop 3D printer and customized bioink to fabricate complex bone-like structures at room temperature without the need for harsh processing conditions that require invasive chemicals, radiation, or postprocessing steps. The new biofabrication strategy can create bone mimicking constructs for bone tissue regeneration. Eventually, the process could generate custom bone microenvironments for disease modeling, multicellular delivery, in vivo bone repair, and even allow integration with sensitive biomolecules and drugs for controlled release. Inspired by the bone process where living organisms produce minerals, the scientists developed a new technique, dubbed ceramic omnidirectional bioprinting in cell-suspensions (COBICS), enabling them to print bone-mimicking constructs that harden in minutes when placed in water. In a paper published in the journal Advanced Functional Materials, the authors describe how they developed a special calcium phosphate bioink in a microgel matrix with living cells. The study demonstrated that mineralized constructs could be deposited within a high density of stem cells, directing the cellular organization, and inducing osteogenesis in vitro. While the idea of 3D printing bone-mimicking structures is not new, this is the first time such material can be created at room temperature – complete with living cells – and without harsh chemicals or radiation. Senior study author Iman Roohani, a researcher at UNSW’s School of Chemistry and leader of the Biomaterials Design and Tissue Engineering Lab at UNSW, explained that this is a unique technology to produce structures that closely mimic bone tissue. “It could be used in clinical applications where there is a large demand for in situ repair of bone defects such as those caused by trauma, cancer, or where a big chunk of tissue is resected,” he specified.

Examples of computer-generated 3D models (top) and corresponding 3D printed bone-like structures (bottom) through COBICS technique. Image courtesy of University of New South Wales (UNSW). The breakthrough technology was co-developed by Roohani and Associate Professor at UNSW’s School of Chemistry, Kristopher Kilian. He described the process as a significant advance on current state-of-the-art technology. Until now, making a piece of bone-like material to repair a patient’s bone tissue involves first going into a laboratory to fabricate the structures using high-temperature furnaces and toxic chemicals, emphasized the study co-author. The resulting dry material is then brought into a clinical setting or a laboratory, where it is profusely washed before living cells are added to it. Bone defects resulting from injury or disease usually need surgical procedures. Conventional treatment options include shortening the bone, using a metal external frame to help create new bone and bone grafts. Bone defect repair is one of the most common regenerative procedures, with more than two million bone grafts performed worldwide annually. However, these proven procedures are associated with variable clinical outcomes of postsurgical morbidity, especially at the donor site, and increased surgical costs. The field of regenerative medicine could hold immense potential to overcome these limitations by repairing bone with live 3D printed tissue. Although still a nascent sector, relevant advances in the past years have improved cell understanding, bioink development, and bioprinting processes to guide the technology into the future. Quote request Are you looking to buy a 3D printer or 3D scanner? We're here to help. Get free expert advice and quotes from trusted suppliers in your area. Powered by Aniwaa According to Kilian, no technologies can directly extrude the bioink into an area with cells, like a cavity in a patient’s bone. He suggested that surgeons could “go directly into the bone with this technique,” where there are cells, blood vessels, and fat, and “print a bone-like structure that already contains living cells.” The study originated after co-authors Thomas Molley, and Stephanie Nemec attended a Regenerative Biomaterials & Therapeutics Group workshop at Carnegie Mellon University (CMU) led by Professor of Biomedical Engineering and inventor of the FRESH technique, Adam Feinberg. The researchers ended up taking home printers from CMU in Pennsylvania. Kilian pondered on a Twitter post: “We were stabilizing microgels for cell culture, which begged the question: Can microgel baths support ceramic filaments?.” The team got to work, demonstrating they could print complex bone-mimetic architectures. This allowed the printed ceramic to be harvested like FRESH or integrated with a suspension of chemically crosslinked microgels and live cells, went on Kilian. The authors claim that when the ink is combined with a collagenous substance containing living cells, it enables in-situ fabrication of bone-like tissues. This process may be suitable for bone tissue engineering applications, disease modeling, drug screening, and in-situ reconstruction or replacement of bone and osteochondral defects directly in the clinic, using patients’ cells in real-time.

Researcher and study Co-author Sara Romanazzo prepares to use a LulzBot Mini to 3D print a piece of bone using the COBICS technique. Image courtesy of University of New South Wales (UNSW).

The new bone 3D printing process could open up a whole new way of treating and repairing bone tissue, so the study has already caught the attention of interested surgeons and medical technology manufacturers. Kilian hopes that one day, a patient needing a bone graft can walk into a clinic where their bone’s anatomical structure is imaged, translated to a 3D printer, and directly printed into the cavity with his or her cells. Next up, the duo will be performing in vivo tests in animal models to see if the living cells in the bone-like constructs continue to grow after being implanted in existing bone tissue and invite dentists, orthopedic surgeons, bone scientists, and research institutes to explore the potential of their COBICS technique to create synthetic bone matrices in situ. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 29, 2021 at 09:02AM

https://ift.tt/2YnjgvY

Burloak First in Industry to Meet Boeing Specification for 3D Printing Aluminum https://ift.tt/3ciJgAV Burloak Technologies Inc. has become the first company to achieve Boeing’s BAC 5673 specification for the 3D printing of aluminum AlSi10Mg components. This marks a substantial gain for the service bureau, as it continues to grow in the additive manufacturing (AM) space.

Burloak offers design, engineer, CNC, 3D printing services and more. While Burloak was established in 2005 in Ontario, it was acquired by an even older company in 2017. Established in 1855 as a hardware and metals import/export business in Toronto, Samuel, Son & Co. is now the largest family-owned metals processor and distributor in North America. With the acquisition of Burloak, Samuel expanded its status in metal production with AM with the goal of delivering 3D printing solutions globally. With a new 40,000-square-foot 3D printing facility and a wide range of AM capabilities, Burloak and Samuel are certainly moving up in the industry. Most recently, Burloak began working on 3D printing parts for satellites. Burloak became one of the founding members of the GE Additive Manufacturing Partner Network alongside Carpenter Technology Corporation. Samuel, meanwhile, partnered with announced in 2017, a strategic alliance with Carpenter for end-to-end 3D printing supply chain solutions. Among its unique offerings, Burloak offers topology optimization, finite element analysis moldflow, and AM build simulation, poising it for such advanced applications as the type that giant manufacturers like Boeing are likely after.

Now that it has achieved the BAC 5673 specification, Burloak Technologies is working with Boeing to see it put to use, which means 3D printing components for Boeing aircraft. What the exact form of that will take is yet to be determined. Boeing has been hit extremely hard by the economic downturn that resulted from the COVID-19 pandemic. It posted a whopping $11.9 billion in losses for 2020 and laid off a total of 30,000 workers last year. Directing attention to its innovative 3D printing partnerships may, then, do the aerospace giant some PR good—especially given the memories of failed jet engines in everyone’s minds. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 29, 2021 at 08:31AM

https://ift.tt/3iYFjTa

Michigan Rep. Haley Stevens Discusses Directs Congressional Efforts to 3D Printing Jobs https://ift.tt/36nzbyQ The Additive Manufacturing Coalition hosted a live forum with Congresswoman Haley Stevens to discuss what the industry can expect from the 117th Congress, which convened for the first time in Washington D.C. on January 3, 2021. The Michigan Democratic Representative is currently focusing on a recovery scheme for the manufacturing industry and looking forward to champion initiatives that will help the 3D printing sector succeed—particularly as it pertains to the overwhelming demand for human capital and advanced technologies.

During the forum, Stevens said she believed additive manufacturing (AM) would be a high priority for this new Congress. The support for manufacturers will be tied into the next stage of the country’s growth trajectory. Furthermore, House members, particularly from the Great Lakes region and aerospace-intensive manufacturing states like Texas and Oklahoma, will be very interested in the AM community. “I think there will be a House and Senate engagement as it pertains to unlocking R&D capabilities,” explained Stevens.

Congresswoman Haley Stevens during the first day of her second term in office. Image courtesy of Haley Stevens via Facebook. In November 2020, the Detroit native was reelected in Michigan’s 11th congressional district, a suburban community with a rich manufacturing sector. During her first term, Stevens was assigned to the House Committee on Education and Labor and the House Committee on Science, Space, and Technology, where she also served as Chairwoman of the Research & Technology Subcommittee (a role she hopes to retain during her second term in office). Stevens was billed as supporting manufacturing on these committees, standing up for workers’ rights, and seeking to increase investment in critical research and development. Working on U.S. manufacturing policy is being framed as one of the congresswoman’s top priorities. During the hour-long live event, it was clear that advanced manufacturing initiatives hit home for Stevens, who previously worked on the Obama administration’s advanced manufacturing and economic growth initiatives to create advanced manufacturing job opportunities located around southeastern Michigan. Even more so, one-third of Michigan’s manufacturing jobs are concentrated in counties inside or adjacent to the 11th District, so any legislative project to help revitalize advanced manufacturing innovation would likely be celebrated. In her district, Stevens has a program called Manufacturing Mondays. She visits small companies, suppliers, makers, and training centers to see what companies are working on and the challenges they are facing. After visiting over 80 businesses and spending hours on shop floors with 3D printers, Stevens understands why local burgeoning sectors – like automotive, aerospace, and defense – are tied to the technology.

Rep. Haley Stevens visiting KCS Advanced Machining Services in Livonia, Michigan to learn about their aerospace work on a new generation of NASA spacesuits. Image courtesy of Haley Stevens via Facebook.

The priorities of the new Congress will be tied to the evolution of the COVID-19 pandemic, with negotiations for another economic relief package, which could include more resources to detect new strains of the virus and more funding for manufacturing and distributing the vaccines. According to Stevens, there is recognition of some interesting labor dynamics, including a fair number of people out of work and a recession skills gap, which needs to be addressed. But as the COVID-19 recovery phase moves along, the representative indicated that efforts from the AM sector – which gained so much prominence during the first months of the pandemic – will remain a congressional topic of discussion.

General Motors workers in Michigan produce face shields with 3D printing in response to the COVID-19 pandemic. Image courtesy of Jeffrey Sauger for General Motors. During the pandemic, manufacturers across the country stepped up to meet the industrial needs of essential workers, doctors, and nurses to keep them safe. Moreover, Stevens emphasized how Michigan’s manufacturing workforce showcased its capabilities by producing essential and potentially lifesaving equipment. Over 600 Michigan companies joined the fight against COVID-19, with automotive suppliers like Ford and GM producing tens of thousands of ventilators, distilleries making hand sanitizers, and other companies generating millions of masks and gowns. The efforts have paid off. In June, Michigan was one of three states “on track to contain COVID-19.” Now, Stevens thinks it’s time to encourage existing and future members of the workforce to pursue manufacturing as a career. Excited to see Joe Biden’s campaign pledge seem to become a reality after the President signed the Buy American executive order less than a week after Inauguration Day, Congresswoman Stevens said she plans to partner with the administration on this initiative. Expected to force the federal government to buy more goods produced in the U.S. to revive domestic manufacturing, Buy American utilizes the government’s purchasing power to unleash and continue to unlock the procurement of “buying from American manufacturers,” increasing the domestic content requirement, moving to an inner agency approach to address the accountability and the use of waivers for domestic preference laws. As a nod to the AM industry, Stevens said she knows “many of you are waiting to get on that preferred vendor list.” The legislator could become an important ally to the 3D printing industry during her next two years in office. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 29, 2021 at 08:02AM

https://ift.tt/3osvQVu

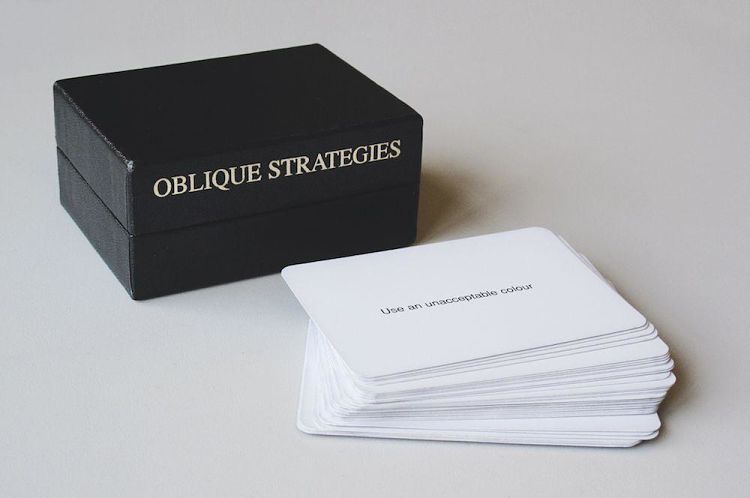

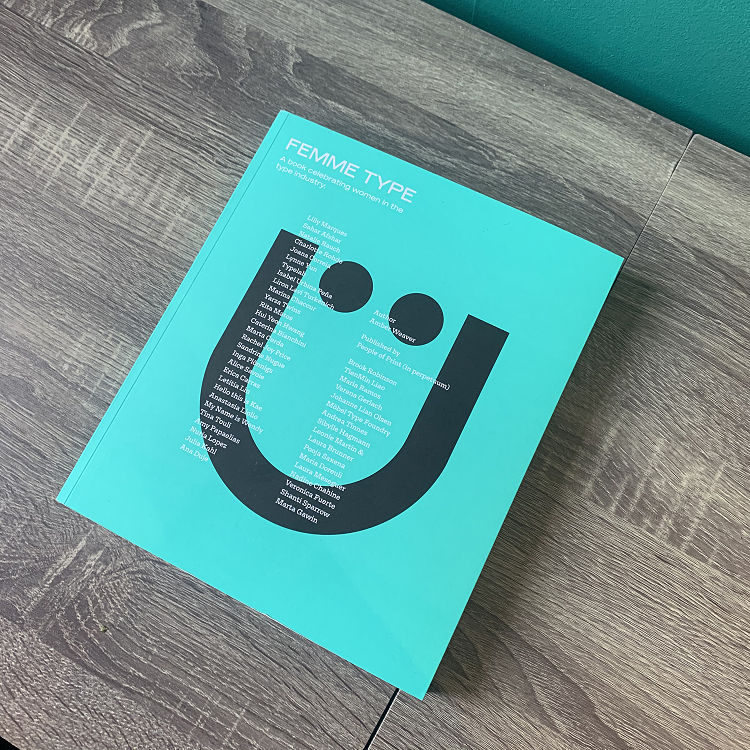

Print-related Celebration Days to Look Forward to in 2021 https://ift.tt/3cgUvtE With the uncertainty, fear and occasionally terminal-seeming boredom of ongoing lockdowns seemingly not packing in any time soon, we could all do with a few things to look forward to. In lieu of things like physical contact with friends, family and pubs, we’ve put together a list of national days to celebrate for print lovers and design nuts. Who cares if many of them are likely created by brands with the not-so-subtle aim of selling more stuff? We all need reasons to be vaguely cheerful, and we all definitely need as many markers as possible to try and work out what day of the week/month it is at the moment. Each of these days sounds pretty ridiculous, but honestly, h o n e s t l y they all exist, at least according to National Day Calendar and Days of the Year. 23 January, National Handwriting Day Inspo: Oli Frape, lettering artist 7 February, National Send a Card to a Friend Day Inspo: BananaPost ’89 artistamps by Maril Artist Anna Banana, 1989 2 March, National Old Stuff Day What does that really mean? Try switching up your creative process. “This is the day to do things differently,” apparently. “Take a moment to recognise the things that you do each day. Is there a better, more efficient way?…Evaluate how you fold laundry. Perhaps there’s an improved way of cleaning windows.” Sounds like an absolute blast, doesn’t it. Fitter, happier, more productive. Inspo: Stanley Donwood’s sleeve design for OK Computer 4 April, National Hug A Newsperson Day (formerly National Hug a Newsman Day) Inspo: Richard Turley, Civilisation print design 30 May, National Creativity Day Really, sometimes it’s nice to tell people you’re into their work, and you’ll feel all the nicer for being so nice. Inspo: Brian Eno Oblique Strategy Cards 9 June, National Donald Duck Day Some DD facts for you: – Donald made his screen debut on 9 June 1934 in The Wise Little Hen. – He has appeared in more films than any other Disney character. – In 2002, Donald was named as one of the 50 greatest cartoon characters of all time by TV Guide – His middle name is Fauntleroy. The name means “child king” and is derived from Old French. – Mickey Mouse was introduced to audiences during Donald’s second appearance on screen in Orphan’s Benefit. Donald’s girlfriend, Daisy Duck, along with his nephews, Huey, Dewey, and Louie, were introduced shortly after that. National Donald Duck Day was first proclaimed by L.A. Mayor Tom Bradley in 1984 on Donald’s 50th birthday. Inspo: Daniel Johnston, Space Ducks 14 July, National Nude Day Inspo: Mike Perry, Get Nude Get Drawn 12 August, National Vinyl Record Day Couple that intrinsic link between art and music with the fact that generally, print lovers like stuff—tactile stuff—and National Vinyl Record Day is as much about images as it is about sound. Sure, you’ve more than likely never heard of this annual celebration, but it’s a nice excuse to pore over some gorgeous gatefolds if ever there was one. National Vinyl Record Day was started by Californian Gary Freiberg, who chose 12 August to commemorate the day Thomas Edison invented the phonograph in 1877. “Freiberg encourages everyone to remember fond memories and the good things in life, especially vinyl records,” apparently. Inspo: Barney Bubbles, Hawkwind 22 September, Business Women’s Day The first ever Business Women’s Day was celebrated in 1983, and is said to “celebrate the contribution that women make in the business world” and focus on ways to give women more equality. Inspo: Femme Type 28 October, Animation Day Inspo: Jan Švankmajer, Little Otik 30 November, National Personal Space Day Inspo: How Have You Been?, a film by Polly Nor & Andy Baker Studios Alternatively, you can celebrate… 10 November, Sesame Street Day Sesame Street day was initiated in New York in 2009 to celebrate the 40th anniversary of the show’s original broadcast. There’s absolutely no better day to watch Kermit the Frog’s turn as Talking Heads icon David Byrne. If only every day could be Sesame Street Day. 15 December, Cat Herders’ Day It’s nearly Christmas. Chase your invoices.

Printing via People of Print https://ift.tt/2DhgcW7 January 29, 2021 at 07:43AM

https://ift.tt/3au1sVR

Naval Group Uses WAAM to 3D Print First Propeller Installed on French Navy Ship https://ift.tt/3cn3Lwc While we often discuss the many rules and regulations involved with 3D printing for the aviation industry, make no mistake: things are just as exacting when it comes to 3D printing for maritime applications, as well. French Naval Group, which specializes in naval defense and marine renewable energy, was the first to 3D print a full-scale propeller blade demonstrator for military use, and has now announced the creation of a next-generation 3D printed propeller that will power the French Navy’s Tripartite minehunter FS Andromède (M643) ship. Naval Group, which designed the metal propeller, manufactured it using wire arc additive manufacturing (WAAM) technology, which has been utilized in the past to print other propellers.

Spanning 2.5 meters, the propeller weighs a whopping 1 metric ton, featuring five 220 kg 3D printed blades. WAAM, which is a better AM technique for large-scale applications, uses a robotic arm to melt metal wire that’s been heated up by an electric arc. The robots and other manufacturing tools for the work were supplied by the French subsidiary of the Yaskawa Group in Japan. As previously mentioned, there are pretty intense standards and requirements to be met with maritime 3D printing, such as corrosion, fatigue, and shock resistance, due to the difficult conditions ships constantly find themselves in. The Naval Group worked with Bureau Véritas to ensure that all of the certification, testing, and inspection requirements were met, so that the Fleet Support Services (FSS) and the French Defence Procurement Agency (DGA) would authorize a trial of the 3D printed blades on an actual Navy ship.

The 3D printed blades were successfully certified, and the propeller was transferred from the manufacturing site of Nantes-Indret to Brest this fall. The assembly was then sent to the submarine base, where it was mounted onto the intermediate propeller shaft of the French Navy ship Andromède in November. The ship is one of ten Tripartite mine hunters built in the 1980s for the French Navy, and eight of these, including the Andromède, won’t be retired for another ten years. So it’s imperative that the propeller and its 3D printed blades work properly. Successful sea trials of the tripartite minehunter ship with its new propeller occurred in December, so the Andromède can now get back to work, along with its 3D printed propeller. But Naval Group isn’t stopping there: it’s begun a new development phase with the purpose of revamping the design of other ships through the use of 3D printing, such as thrusters. The technology can offer increased part productivity, reduced weight, acoustic discretion, better thrust efficiency, and so much more.

France’s Naval Group announced it had 3D printed the world’s first propeller for use on an operational mine hunter of the French navy. (Sources: DefenseNews, Naval Group / Images courtesy of Naval Group unless otherwise noted) Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 29, 2021 at 07:32AM

https://ift.tt/2L5uane

Artisan’s Asylum Makerspace Relocates to Harvard’s Allston Campus https://ift.tt/3abo6Cc One of the largest makerspaces in the United States is building Boston’s most inclusive, vibrant hub for artistic expression, learning, manufacturing, and creative entrepreneurship. As part of a new long-term partnership with Harvard University, the local non-profit collaborative, Artisan’s Asylum, will move its facilities to the Lower Allston neighborhood in September 2021. Since its foundation in 2010, the member-supported fabrication hub has been continuously introducing 3D printing classes, events and promoting advanced technology’s use to its members, churning out startups, and nurturing talented entrepreneurs. After a decade of sharing skills and ideas, envisioning projects, and building a network of entrepreneurial ventures in Sommerville, Massachusetts, Artisan’s will settle in at Harvard space in Allston. The plan is to transform a warehouse at 55 Antwerp St. into a vibrant community center, reported The Harvard Gazette. Another project is planned at 176 Lincoln St., currently under development by Berkeley Investments. Both sites are part of Harvard University’s Allston campus, home to Harvard Business School, graduate student residences, and athletic facilities.

Harvard University’s plan for its Allston campus, across the Charles River. Image courtesy of The Plan for Harvard in Allston Executive Summary/Harvard University. Since 2006, just six years after purchasing the land from the Massachusetts Turnpike Authority (MTA), Harvard has been planning and building an expansion of its Allston campus, with completed projects that include the Harvard Innovation Labs, Life Lab, and ArtLab. The new partnership will allow Artisan’s to expand its space and continue to grow operations.

Artisan’s Asylum members working on a project at the Somerville, Massachusetts, location. Image courtesy of Artisan’s Asylum. “An inclusive refuge for makers and creatives,” that is Artisan’s promise. Everyday makers, hackers, engineers, artists, artisans, entrepreneurs, and creatives go to Artisan’s Sommerville facility to use the fabrication equipment, professional design and modeling software, educational and training opportunities, and shop, studio, and storage spaces. The Mission? Making creativity a way of life. Artisan’s inspires people to learn new skills, pass those skills to others, and encourage the growth of an inclusive creative community that is always searching for new members. Best of all, spaces like Artisan’s provide access to tools, education, and resources needed to make a living out of creative inspiration. The relocation plan from Sommerville to Allston’s 52,500 square feet space means Artisan’s is looking to invest $4.7 million in the design, build-out, and finishing of its new home. It will include the base build (mechanical, electrical, plumbing, and structural work), finishes to the space (shop walls, studios, and amenities), and operating costs associated with the move. However, thanks to early support from key partners, like Berkeley Investments, and individual donors, Artisan’s has already secured nearly $4 million and is only $715,000 away from its fundraising goal. At this rate, the new site’s base build will be complete by May 2021, and just two months later, the move can begin. Quote request Are you looking to buy a 3D printer or 3D scanner? We're here to help. Get free expert advice and quotes from trusted suppliers in your area. Powered by Aniwaa

Artisan’s Asylum instructors teach members to 3D Print on the hub’s entry-level printers Flashforge and Taz. Image courtesy of Artisan’s Asylum. Since its inception, Artisan’s Asylum has generated meaningful community impact in Somerville and throughout the Boston region by providing a home for restless makers. It is credited with attracting the Greentech incubator Greentown Labs to Somerville and contributing substantially to the local creative economy’s value, contributing more than $70 million in business activity. As the result of an original collaboration between robotics engineer Gui Cavalcanti and costume designer Jenn Martinez, the dynamic hub has successively helped launch 25 startups responsible for creating over 150 jobs during the last ten years. Artisan’s saw the birth of the world’s first 3D pen, the 3Doodler; GeoOrbital, the self-powered electric wheel, and MegaBots, a startup that recreates giant robots from science fiction. Overall, members have already raised $4 million on Kickstarter campaigns for various small businesses. Artisan’s Digital Fabrication and Design Lab currently have 3D printers from MarkForged, FlashForge, and Ultimaker. Members can also attend 3D printing classes, such as Rebecca Knepple’s “Tool Training: 3D Printers” or the more advanced “3D print Optimization” course. However, the new, larger shared workshop will offer up to 120 studios for creativity, making, and entrepreneurship of all kinds; a multipurpose community space, more classroom areas, and much more. Since the launch of the “maker” movement in 2005, these spaces have benefitted local economies by helping the skill base grow and encouraging hands-on learning. Hubs like Artisan’s create unique opportunities to enlighten minds, so we can expect this new expansion to attract more participants to the space. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com January 29, 2021 at 07:02AM

https://ift.tt/3t5QPAQ

Seán Jospeh Brennan: Uselessness https://ift.tt/3iWIAm1 Seán Joseph Brennan is a screen printer living and working in Dublin, Ireland. After having to return to Ireland from Australia due to the Covid pandemic, he is currently working as a screen printer in his day job in a car parts manufacturer, as well as producing screen prints of his own artworks from his home studio.

Printing via People of Print https://ift.tt/2DhgcW7 January 29, 2021 at 03:49AM |

Categories

All

Archives

April 2023

|

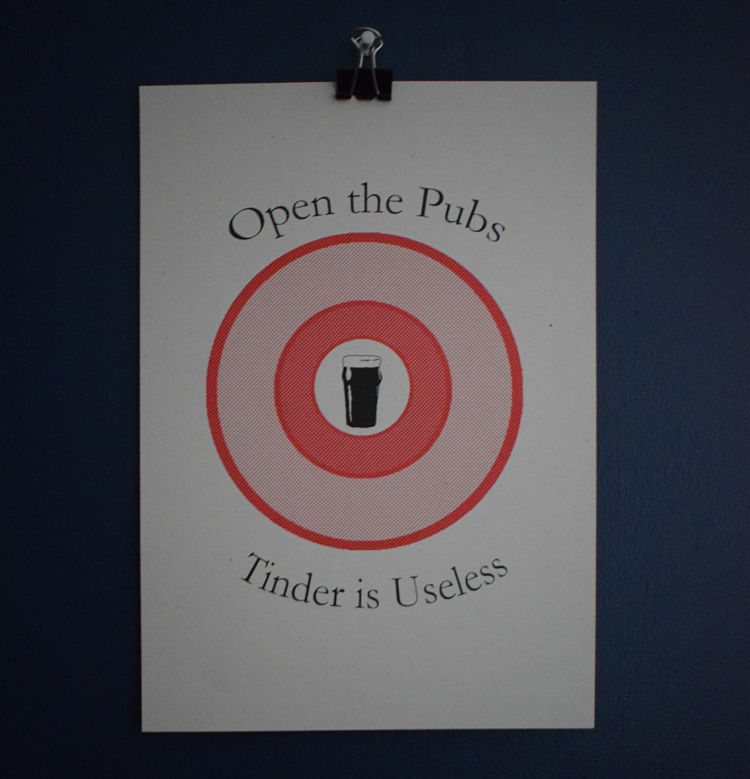

His most recent works revolve around creating a more upbeat mood during this difficult time. The Useless Geansaí and The Useless Risograph are products Seán created during lockdown to lighten the mood a little. A sweatshirt and Risograph print depicting the slogan “Open the Pubs… Tinder is Useless” pokes fun at the situation of being locked in and trying to connect or date online. Seán has partnered up with Irish artist and illustrator Luke Fallon to create an online shop called

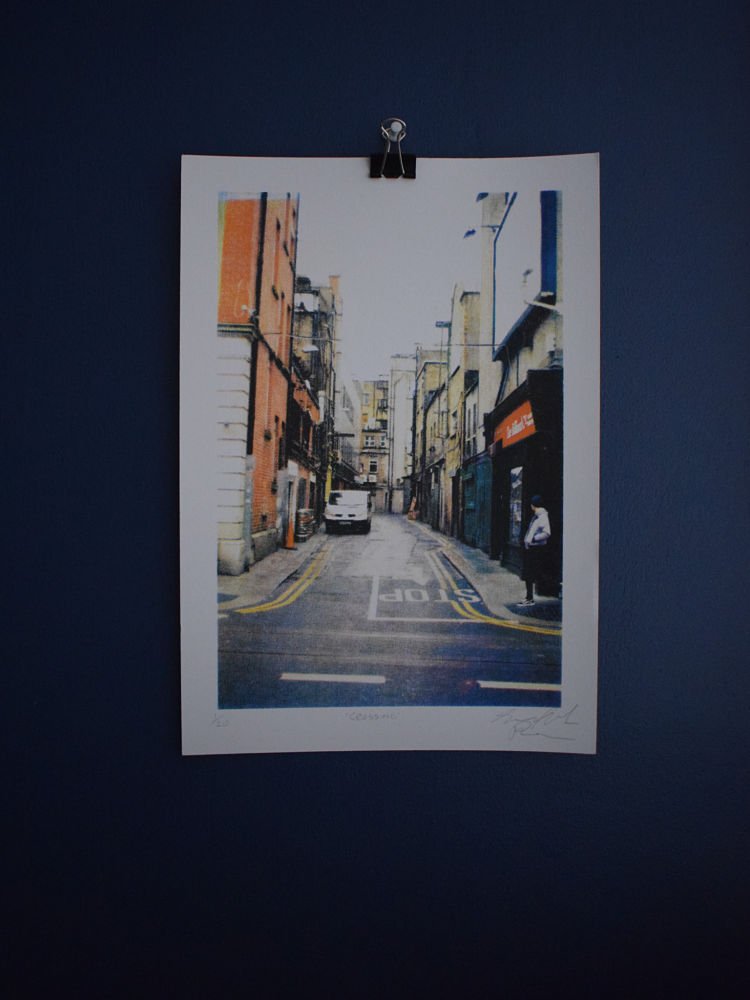

His most recent works revolve around creating a more upbeat mood during this difficult time. The Useless Geansaí and The Useless Risograph are products Seán created during lockdown to lighten the mood a little. A sweatshirt and Risograph print depicting the slogan “Open the Pubs… Tinder is Useless” pokes fun at the situation of being locked in and trying to connect or date online. Seán has partnered up with Irish artist and illustrator Luke Fallon to create an online shop called  Seán has also turned his attention to screen printing his photographic work using the CMYK method. By dividing the image on Photoshop into cyan, magenta, yellow, and black, and converting it to halftone, Seán is able to screen print detailed photographic images at home. His photographs explore Dublin city and the life that revolves around it.

Seán has also turned his attention to screen printing his photographic work using the CMYK method. By dividing the image on Photoshop into cyan, magenta, yellow, and black, and converting it to halftone, Seán is able to screen print detailed photographic images at home. His photographs explore Dublin city and the life that revolves around it.

RSS Feed

RSS Feed