|

https://ift.tt/2PD0xf4

3D Printing Webinar and Event Roundup: October 31, 2021 https://ift.tt/3jOWKaj Happy Halloween, and welcome to this week’s webinar and event roundup! We’ve got several multi-day events, both in-person and online, to tell you about, starting with ICAM 2021, and then plenty of webinars about topics ranging from cybersecurity and cardiac 3D reconstruction to software, 3D printing for animals, and more. Read on for all the details! ASTM’s ICAM 2021 The first event this week is a hybrid one: the International Conference on Additive Manufacturing (ICAM) 2021, hosted by ASTM International’s Additive Manufactured Center of Excellence (AMCoE) from November 1-5. The conference will be held in-person at the JW Marriot, Anaheim Resort in California, with the option to attend virtually as well, and whichever option you’re more comfortable with, you don’t want to miss it, as the event will include nearly 600 presentations covering 26 symposia, four certificate courses, and an Awards Ceremony for the Student Presentation Competition winners and recipients of the ASTM International Young Professional in AM Award and the Awards of Excellence. Keynote speakers include Tracy Frost with the Department of Defense, Tom Kurfess with Oak Ridge National Laboratory, Terry Wohlers from Wohlers Associates, and more. Plus, I will be attending this event in-person, and I’m excited to see everyone and check out some really interesting presentations.

You can register for ICAM here, and don’t forget to come say hello! Kornit Fashion Week Los Angeles + Industry 4.0 Event Also in California, just a little north in Los Angeles, Kornit Digital is holding its Fashion Week Los Angeles + Industry 4.0 Event, celebrating fashion technology innovation and sustainability. From Tuesday the 2nd through Friday the 5th, technology innovators, visionaries, fashion designers, influencers, celebrities, and major brands will gather to showcase and view digitally-created, environmentally-responsible designer collections. There will be 17 individual shows during the event, where designers like threeASFOUR will debut their latest collections produced with digital means, such as 3D printing, and reflecting diversity in all its forms. Attendees will learn tips for effective e-commerce to increase margins and revenue, strategies for shortening production cycles, quickly taking concepts from inspiration to repeatable, finished pieces, and more.

You can register for the free event here. DMC at Advanced Engineering Show The 12th edition of the Advanced Engineering Show, held from November 3-4, will welcome manufacturing innovators to Birmingham’s NEC for industry insight and networking. The event is the UK’s top annual gathering of OEMs and engineering supply chain professionals, and digital manufacturing production and engineering facility Digital Manufacturing Centre (DMC) will be there, attending as part of Silverstone Technology Cluster’s VIP Lounge and Innovation Zone.

You can register for the show here. ASME’s Digital Twin Summit Also from November 3-4, ASME will be holding its Digital Twin Summit, “Gateway to the Future of Manufacturing.” The online event welcomes operations managers, data scientists, engineers, manufacturers, and other industry leaders that want to identify, implement, and scale predictive, analytics-driven business operations by deploying digital twins that can help deliver ROI. Event features include daily keynotes, product presentations, exhibitor showcases, and more.

You can register for the event here. AM Solutions Continues Live Event Series On Wednesday the 3rd, AM Solutions will continue its interactive “Inside AM” live event series at 9 am EST. Featuring representatives from companies in different industrial sectors discussing their AM applications, experience, obstacles, and visions, the first guest was Christoph Hansen, the Director of Technology & Innovation at Sauber Engineering AG, followed by Andreas Knöchel, Head of Program Management Additive Manufacturing Lattice for Oechsler AG, and the third was Jan Hötter, GKN Additive‘s Global Operations Manager for Additive Manufacturing. The fourth guest was Sebastian Piegert, Technology Field Lead Additive Manufacturing for Siemens Energy, and this week, AM Solutions will welcome Jan Philippe Grage, Business Manager 3D Printing for Dunlee, a brand of the Philips Company group.

You can register for the livestream here. AM Coalition on Cybersecurity & the Supply Chain Also on the 3rd, at 3 pm EST, the Additive Manufacturing Coalition is holding its latest forum, called “‘Cyber’ Securing the Additive Manufacturing Supply Chain.” Several experts will discuss cyber threats to AM, the regulatory framework companies should follow to avoid these threats, and what technologies are coming to protect us from future threats. A member of Congress has been invited to speak, and other speakers include Landscape panelists Jennifer Tisdale, Principal at forum sponsor GRIMM, and Brian Finch, Partner at Pillsbury Law, in addition to AM panelists Jonathan Faia, Director of Quality/Cybersecurity at Laboratory Testing Inc., Dr. Vyas Sekar, CyLab Security and Privacy Institute at Carnegie Mellon University, and Dr. Howard Grimes, with the Cybersecurity Manufacturing Innovation Institute (CyManII) at the University of Texas at San Antonio.

You can RSVP for the Zoom forum here. 3DQue’s CR-10 Livestream In technology startup 3DQue‘s latest livestream, Mateo and Steven will discuss “How to Slice for Mass Production on CR-10.” At 7:30 pm EST on Wednesday, November 3rd, 3DQue will show off its Quinly “virtual operator,” and how it can be used for more efficient slicing with the Creality CR-10. Attendees will also learn some helpful tips about slicing large parts.

You can set your notifications for Wednesday’s livestream here. Nano-Micro-Lithography Symposium Moving on to Thursday, November 4th, BICO company Nanoscribe, a 3D laser lithography innovator, will present the third Nano-Micro-Lithography (NML) Symposium, hosted on gather.town and co-hosted by Raith Nanofabrication, Heidelberg Instruments, GenISys, and microresist technology. The symposium focuses on direct write, optical, ion, and electron beam lithography, welcoming customers, users, and technical experts to learn more about the latest products and technologies for NMLS, and will also feature a new dedicated job fair, student project pitch, presentations, and online networking opportunities. The first session will start 2:40 am EST, with the undergraduate student project pitch taking place at 7 am EST; the second and final session will begin at 8 am EST.

You can register for the symposium here. Materialise Mimics & Cardiac 3D Reconstruction At 9 am EST on the 4th, Materialise will hold a Mimics Innovation Course on “Cardiac 3D Reconstruction: Making the Complex Simple in Conjunction with King’s College London.” Cardiac surgery experts from King’s College London, University of Bristol and Imperial College London, East Midlands Heart Centre, Sheffield 3D imaging Lab, and Guys & St Thomas’s Hospital Trust will present their cases, and Materialise Application Engineers will show optimized workflows so that attendees can learn how to most efficiently prepare for complex cases. Attendees will hear about the latest 3D technology advancements for surgical planning, participate in a live Q&A, learn about segmentation challenges and how to overcome them, see how to get the most out of the Mimics Innovation Suite for even the toughest adult and pediatric cases, and more.

You can register for the webinar here. Sivó’s Hybrid Manufacturing Workflow powered by ESPRIT and Meltio Recently, laser metal deposition manufacturer Meltio added ESPRIT TNG hybrid manufacturing CAM software to its technology ecosystem, which will make its Direct Energy Deposition (DED) technology accessible to any machine shop through a single interface. This collaboration will streamline both additive and subtractive manufacturing workflows for Meltio Engine CNC Integration system users in a hybrid workflow. To learn more about how operations can advance through this hybrid solution, Meltio and Hexagon will jointly present a webinar at 10 am EST on November 4th about the hybrid manufacturing process that combines its own technology with ESPRIT’s CAM system. Spanish industrial machine shop Sivó will discuss how its hybrid manufacturing applications are powered by ESPRIT TNG and Meltio.

You can register for the webinar here. Stratasys GrabCAD AM Platform Launch Also at 10 am EST on the 4th, Stratasys is holding a virtual launch event, “Experience Stratasys: Software,” to unveil the “super-charged” GrabCAD Additive Manufacturing platform. When combined with Stratasys 3D printers, this new software should offer supply chain flexibility, majorly reduced production costs, SKU reduction through part consolidation and geometric freedom, and more—all helping users change how they manufacture production parts. The changes to GrabCAD should enable better connectivity and production at scale.

You can register for the live launch event here. AM Post-Printing 2021 Survey Results PostProcess Technologies will present the results of its third annual Additive Manufacturing Post-Printing 2021 survey during a brief webinar at 12 pm EST, and discuss what’s on the horizon for post-printing processes. Attendees will hear what respondents had to say during the industry’s only in-depth look into the end-user perspective of 3D post-processing, as well as hear some expert insights and enjoy a time for Q&A with post-printing experts.

You can register for the webinar here. 3D Printing for Animals with 3DHEALS Finally, at 2 pm EST on Thursday the 4th, 3DHEALS will discuss “3D Printing for Animals” with a group of international speakers who use 3D printing and other innovative technologies to take care of our furry family members and other animals. Sponsored by HP, the speakers for this webinar are Matteo Zanfabro, Doctor of Veterinary Medicine and R&D member for PlayCast and PlayVet; veterinarian Dr. Johnny Uday, a 3D biomodeler and researcher and owner of AXIS 3D Medical Printing; Mateusz Pawlik, co-founder of CABIOMEDE and CEO of Pets Analytics; and Alexander Tholl, Co-Founder of DiveDesign.

You can register for the webinar here. Do you have news to share about any future webinars or virtual and live events? Please let us know! Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 31, 2021 at 07:45AM

0 Comments

https://ift.tt/3GBxGO0

3D Printing News Briefs, October 30, 2021: Research, Turbine Repair, & More https://ift.tt/3bw7FRH Today’s 3D Printing News Briefs is a little bit of everything, starting with a research paper on 3D printing tungsten carbide surfaces with extreme wear resistivity. Moving on, a runner partnered with CRP Technology to 3D print customized athletic track shoes, and Optomec delivered a $1 million metal 3D printer for use in turbine repair. Finally, Sinterit published a case study showing how its Lisa PRO was used to help a company called Nabson produce small run parts and prototypes with better accuracy. 3D Printing Tungsten Carbide-Coated Steel Surfaces

Images of a printed WC/Co specimen: top view (top left) and side view (bottom left). The right panel depicts the cross-section where the three zones of growth can be identified. A team of researchers from Aalen University in Germany published a paper, “Additive Manufacturing of Tungsten Carbide Surfaces with Extreme Wear Resistivity,” which is focused on their additive manufacturing process to produce wear-resistive tungsten carbide (WC) coatings. Laser powder bed fusion (LPBF) technology creates solid metal components by selectively exposing successive powder layers to a laser beam, but the high energy input from a laser on a very small area, paired with rapid cooling, can cause high temperature gradients, which then lead to residual stress and major deformations; that’s why LPBF technology uses support structures during printing and heat treatment post-print, the latter of which helps meet the demands of wear resistance. When processing conventional sintered materials, like WC, using LPBF, local under-carbonization can take place, and most coating processes, like vacuum deposition and electroplating, take a long time and only achieve small thicknesses of less than 10 microns. That’s why the Aalen team wanted to come up with a better solution, which is detailed in their study.

3D Printed Carbon Fiber Spike Shoes Venetian middle-distance runner Miro Buroni created a customized athletic track shoe, also called a spike shoe, called the Pleko, and worked with Italian sportswear and footwear manufacturing Diadora and CRP Technology to 3D print the midsole, outsole, pins, and ribbing of the shoe—in a single unit—in order to enhance the shoe’s performance. Diadora took a 3D scan of an athlete’s foot, and then performed a biomechanical analysis of running and footing, while CRP Technology offered its Windform SP carbon fiber-filled composite material and PBF process to build the shoe’s supporting structure. The material offers strong mechanical properties, like flexibility and resistance to deformation, which are very important for track shoes.

Optomec Delivers Metal AM Systems for Turbine Production Repair Moving on, Optomec has announced the delivery of a $1 million multifunctional metal 3D printer to one of its long-standing customers—a top supplier in the worldwide aviation engine Maintenance Repair and Overhaul (MRO) market, which already has more than five other Optomec metal AM systems it’s using to repair a range of aircraft engine turbine components, in addition to industrial gas turbines. Optomec’s proprietary process uses adaptive software, advanced machine vision, automation, and on-the-fly laser power adjustment to repair and add metal to worn engine components, which restores them to their original geometric specifications. The company’s printers use Directed Energy Deposition (DED) technology, and the machine that was just delivered combines two turbine repair operations that are normally performed manually, which will improve the consistency and quality of the flight-critical procedures and lower the cost of engine overhauls.

Sinterit & Nabson Case Study Finally, NABSON Inc., which manufactures products for the power, transportation, communication, and defense industries, purchased a dual extruder FDM 3D printer two years ago to speed up new product R&D and develop one of its product lines. The endeavor was successful, and NABSON decided to expand its AM capability with the addition of an SLS 3D printer that could more accurately produce prototypes and small run parts; after plenty of market research, the company chose Sinterit’s LISA PRO. As the case study details, NABSON was asked to install a series of thermal switches in one product line, which would shut down power to the aircraft if the connector overheated, and the switches had to be encased in epoxy for their protection. The LISA Pro was used to create an epoxy-filled housing unit for the switches, and because NABSON manufactured the part in-house, the company estimates it saved nearly 50% of the cost per sleeve, and also had the option to modify the design as much as necessary. Additionally, the unit’s thinnest wall measurement at the corners was 0.6 mm, so NABSON definitely got the accuracy it was looking for.

Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 30, 2021 at 07:33AM

https://ift.tt/3ms2Dfs

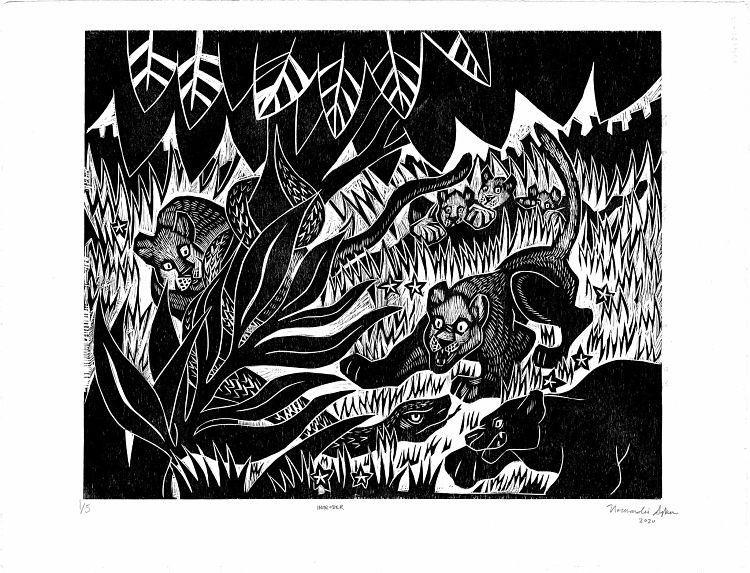

Normandie Syken https://ift.tt/3w0qaHI Normandie Syken is an illustrator and printmaker from Queens, New York. She studied Art at the Frank Sinatra School of Arts and earned her BFA in illustration from the School of Visual Arts. Normandie’s artist’s books, prints, and paintings are in collections such as the British Library, the New York Historical Society, and the Beinecke Library at Yale University.

www.normandiesyken.com Printing via People of Print https://ift.tt/2DhgcW7 October 29, 2021 at 11:15AM Holiday peak season preparations continue across the USPS network https://ift.tt/2XVguS0 WASHINGTON, DC — The U.S. Postal Service reported service delivery performance scores for the first three weeks of the fiscal first quarter started in October showing continued positive gains across all First-Class, Marketing and Periodical mail categories. Printing via USPS News https://ift.tt/2hH9aDC October 29, 2021 at 10:15AM Board of Governors to meet Nov. 10 https://ift.tt/3mqy6ig WASHINGTON, DC — The U.S. Postal Service Board of Governors will meet Nov. 10, 2021, in open session at Postal Service headquarters, 475 L’Enfant Plaza, SW, Washington, DC. Printing via USPS News https://ift.tt/2hH9aDC October 29, 2021 at 08:14AM

https://ift.tt/3GvO7vb

3D Printing Financials: Materialise Shares Up After Q3 Earnings Top Estimates https://ift.tt/3vTV6Jz In an evolving, dynamic world shifting towards powerful digital tools and innovative ecosystems, 3D printing companies are regaining momentum and performing better financially. That seems to be the case for 3D printing software and service provider Materialise (NASDAQ: MTLS). The Belgium-based business reported better-than-expected revenue and net profit for its third quarter of the year, driven by solid operational performances and strong double-digit growth from all three segments: software, medical, and manufacturing. Furthermore, it revealed several aspects of an ongoing project with Lift Aircraft, a Texas-based vertical takeoff and landing (eVTOL) aircraft manufacturer. Revenue for the three months ending September 30, 2021, was €52.2 million ($61 million), up 28% year-over-year from €40.8 million ($47.7 million) in the third quarter of last year. Materialise also reported a consolidated net profit of €8.7 million ($10 million), or 15 Euro cents per share—a whopping change against the previous year’s third-quarter loss of €282 ($330), or 1 Euro cent per share. With revenue from its manufacturing segment hiking 61.2% in just a year to €22.8 million ($26.6 million), Materialise’s Executive Chairman Peter Leys expects consolidated revenues for the entire year to be near the higher end of his €197 million to €200 million range estimate from previous months. Additionally, the company saw increases of 10.4% and 10.2% year-on-year from the software and medical segments, respectively. Particularly in the medical sector, Materialise recorded a 15% increase in medical software sales, which accounted for 31% of the entire segment’s revenue. During the earnings call, Leys said this “is not pent-up demand” but a continued solid growth that this medical subsegment has been showing over the last four to eight quarters. After such a strong earnings season, Materialise shares opened up around 6% on October 28, following the release of the quarter’s earnings report. By 10:30 AM, the stock had peaked at $25.62 before easing back a bit and closing at $25.14. According to expert analysts at Simply Wall Street, Materialise stock underperformed in the US market, which returned 33.4% over the past year. However, with profits and earnings gaining momentum, experts forecast earnings will grow 52.45% per year. As investors continue to bet on the 3D printing industry, we can expect the sector to pick up business, especially now that the US and European economies are reopening. Throughout the Covid-19 pandemic, Materialise continued to invest in its workforce, existing software platforms, such as Magics and Mimics, 3D printing manufacturing activities, and growth initiatives, which is already paying off in the short term, Leys explained during the company’s earnings call. Overall, the strong revenue growth and improved gross margin were triggered by increased in-sourcing and continuous productivity improvements, and disciplined spending, in particular with respect to overhead.

A great example of this forward motion is a project with Lift Aircraft, the startup behind Hexa, an eVTOL single-passenger wingless multicopter for short-distance travel. According to the management team, Materialise is designing and producing 89 different 3D printed end parts for the aircraft, such as the Y brackets, a structural component made with titanium. Now in serial production, the topology-optimized part was flying just six weeks after Lift Aircraft made the request to Materialise. Moreover, the part weighs 150 grams, a major weight reduction compared to traditionally manufactured Y brackets that weigh 250 grams. In a plane estimated at under 115 kilograms, this 40% weight reduction is critical. The optimization also reduced costs by decreasing the build time and eliminating support structures, thus enabling Lift Aircraft to reach its target pricing. This story is another proof point that AM can make entirely “new types of value creation” and possible business concepts, highlighted Vancraen during the call. Even though these types of applications take time to develop, he considers them truly meaningful, especially if they will be sustainable in the future. Finally, Leys said the company intends to gradually increase its operational expenses to boost growth initiatives, but expects these accelerated efforts to impact the 2022 results much more than this year. Therefore, for 2021, management is increasing its adjusted EBITDA guidance by €3 million ($3.5 million) to up to €28 million ($32.7 million). Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 29, 2021 at 08:03AM

https://ift.tt/3mqkqDZ

US Army Robotically Delivers 3D Printed Tank Part in Project Convergence https://ift.tt/2XUQupR At the beginning of 2021, the Pentagon released a 20-page document with the characteristically bland name “Department of Defense Additive Manufacturing Strategy.” The gist of the document was the DoD’s announcement of the establishment of a whole host of groups dedicated specifically to working on specialized technical issues related to AM, which would be centrally coordinated by a new sub-agency—the Joint Defense Manufacturing Council (JDMC)— also announced in the report.

U.S. Army Staff Sgt. Johnathan Ellis working on a 3D printer in preparation for Project Convergence at Yuma Proving Ground, Ariz. (Image courtesy of DVIDS) This was followed up by a document released in June, titled “Use of Additive Manufacturing in the DoD.”

Both of these documents represent major steps in the Pentagon’s implementation of a major 2018 restructuring of how it carries out research, development, and acquisition in high-tech industries, including not only AM but also aerospace, artificial intelligence, and robotics. The release of a heavily-redacted US Navy audit came immediately after the June policy statement, in which the Pentagon drummed up fears of our nation’s vulnerability to infiltration of our military’s AM infrastructure—always an integral part of increasing the budget devoted to a given area. Now, as part of the military’s Project Convergence, which seems like part war games, part old-fashioned world expo, we’re seeing all the years of study, investment, and logistical restructuring come to fruition: in Yuma, Arizona, the Army has just tested its ability to 3D print a spare part for a tank, which was then delivered to the tank on the “battlefield” by a semi-autonomous robot. The Army refers to its AM operational support capacity as R-FAB, or Rapid Fabrication via Additive Manufacturing on the Battlefield.

This is, obviously, only the beginning. We may wonder if it’s something that should be happening, but the military essentially creates its own reality, and it started doing so on this front years ago. In the electoral political arena, the “debate” over military spending—it’s more like complaints from a few people here and there that we don’t throw as much money at other things as we do at the troops—is finally starting to heat up once again, but it would’ve been nice if this happened 20 trillion dollars ago. The truth is, a supply chain crisis is happening across the planet, no one seems to know what to do about it, and yet somehow the military has been fortuitously preparing for this exact situation for almost a decade. This is obviously pie-in-the-sky wishful thinking talking, but wouldn’t it have been nice if the US military had told someone? Of course, it did tell people; the military just has its own indirect, convoluted way of communicating, called the Defense Appropriations bill. Anyone who has been studying this even remotely closely has likely been noticing for years that increasing amounts of spending are being devoted to solving explicitly industrial problems rather than explicitly military ones. These “solutions,” as a part of the larger high-tech infrastructure, are now being highlighted by Project Convergence. When people complain about the military budget, though, they complain about the biggest-ticket items, rather than focusing on the nuances: the fact that an F-35 costs astronomically more than a 3D printer obscures the landscape. Again, it would be nice if public participation actually played a role in these decisions, but that ship seems to have sailed long ago. So what can people who care actually do? It’s hard to say practically, at this point, aside from (sigh) voting with your dollars, so that any societal shift toward 3D printing will at least result in some significant proportion of the industry being devoted to things like creating more sustainable, alternate supply chains relative to the amount spent on defense. But in the meantime, it would probably be helpful if people started focusing on the fact that the military works twenty years in advance, and interpreting the moves it makes seriously, so that hopefully a better-informed public can eventually exist. (Images courtesy of US Army unless otherwise noted) Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 29, 2021 at 07:33AM

https://ift.tt/3ErExYy

3D Printing Companies Divergent Technologies, Nexa3D, and More Join AMGTA https://ift.tt/2Zv07fq The Additive Manufacturer Green Trade Association (AMGTA) added six new 3D printing companies to the ranks as part of its ongoing efforts to promote sustainability in additive manufacturing. The additions bring the AMGTA’s membership total to 33. Among the new members, only vehicle manufacturer Divergent Technologies will be joining as a founding board member, and the rest of the companies will become participating members. Launched in November 2019, the AMGTA is dedicated to educating about the environmental benefits of AM, as well as promoting the technology as an alternative to traditional manufacturing. Open to any additive manufacturer or industry stakeholder that meets certain criteria relating to the sustainability of production or process, the non-commercial organization has been developing industry best practices, helping members grow their businesses, and promoting the adoption of 3D printing.

Joining the AMGTA as a new founding member, California company Divergent Technologies designs, prints, and assembles optimized and sustainable vehicle structures using a fully adaptive end-to-end production system. Its proprietary manufacturing platform, known as the Divergent Adaptive Production Systems (DAPS), is a complete software-hardware solution designed to replace traditional vehicle manufacturing. Given a set of digital requirements as input, the modular digital factory will automatically and computationally engineer, 3D print, and assemble any complex structure. In October 2021, Divergent doubled its car 3D printing capabilities after purchasing three more NXG XII 600 metal printers from SLM Solutions. Once they’re delivered in early 2022, Divergent will become the most prolific user of NXG XII 600 systems in the US. Divergent and SLM Solutions have had a joint development partnership since 2017, having also purchased seven SLM 500 systems, three SLM 280 systems, and one SLM 125 system. With so many printers available on-site, Divergent can build thousands of tons of vehicle parts, expected to be on the road within the next two years. Then, Divergent plans to scale its advanced facilities, designed using DAPS for sustainable production, starting with “fab-less” vehicle manufacturing. This second step will begin with the officially approved Czinger 21C hypercar, a two million dollar 3D printed car containing hundreds of generatively-designed AM components that promises an 8.1-second quarter mile.

Divergent Technologies founder and CEO Kevin Czinger with an additively manufactured component for the Czinger hypercar. Image courtesy of Divergent Technologies via LinkedIn. Divergent will serve alongside existing founding members ExOne, a pioneer and global leader in industrial 3D printing systems using binder jet 3D printing technology, now part of Desktop Metal; QC Laboratories, an advanced non-destructive testing laboratory focused on AM components; Sintavia, a designer and 3D printer of a new generation of flight and launch components; global polymer 3D printing leader Stratasys, and Taiyo Nippon Sanso Corporation, a supplier of stable industrial gases to a wide variety of industries. As founding members, these companies determine the strategic direction of the AMGTA, provide governance oversight, and consider future research projects that members may vote to commission. Moreover, now that Divergent has become a founding member, its CTO and vice president of AM and materials, Michael Kenworthy, will also serve on the AMGTA’s board of directors. Additionally, joining the AMGTA as participating members are five companies. From Germany, the Aachen Center for Additive Manufacturing (ACAM), located on the RWTH Aachen University campus, has the resources and facilities to develop know-how, processes, software, and systems engineering, as well as customized services covering all aspects of AM technologies. Another German company, Kurtz Ersa, has also joined the ranks. The technology corporation recently debuted on the metal 3D printing market with the Alpha 140 laser beam powder bed fusion machine, created in collaboration with Laser Melting Innovations, which is coincidentally an ACAM spin-off. Ultrafast polymer 3D printer manufacturer Nexa3D is the third company joining AMGTA this week. Founded by industry pioneer and X-Prize board member Avi Reichental, Nexa3D is on 3DPrint.com’s potential unicorn list, with a valuation that has already surpassed $100 million. In addition, the company’s innovative technologies and sustainable supply chain management make it an ideal partner for AMGTA. Also becoming part of the organization are Tekna Advanced Materials, a world-leading provider of high-purity metal powders for applications such as 3D printing in the aerospace, medical, and automotive sectors, and Trane Technologies, a global climate innovator bringing efficient and sustainable solutions to buildings, homes, and transportation through an environmentally responsible portfolio of products and services. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 29, 2021 at 07:03AM

https://ift.tt/3Gw4ojH

SprintRay Welcomes Usain Bolt, Launches 3D Printing Dental Resin & Post-Curing Unit https://ift.tt/3bt4FFH California 3D printing startup SprintRay Inc. is well-known for its DLP SLA 3D printers, as well as it’s Pro Desktop 3D printer for digital dentistry applications. The MedTech company just announced a multi-year dental-focused partnership with eight-time Olympic medalist Usain Bolt, the world’s fastest man, in order to make high-quality digital dental care more globally accessible, particularly in his home country of Jamaica. 35-year-old Bolt, the only Sprinter to win Olympic 100 meter and 200 meter titles at three consecutive Olympics (2008, 2012 and 2016), will now be a SprintRay Global Brand Ambassador for the next five years.

Together, Bolt and SprintRay are working with the Jamaica Dental Association to invest in an initiative called “Bolt Labs, powered by SprintRay,” which aims to offer accessibility in digital dentistry to Jamaican residents.

Both the Bolt Foundation and the SprintRay Foundation plan to launch the Bolt Labs, powered by the SprintRay initiative, and set up dental clinics, such as a mobile unit and 3D dental labs, to address the dental needs of children as well as adults, and also those people who live in more remote parts of Jamaica. At SprintRay’s inaugural 3D Next Summit last week in Miami, Florida, Bolt attended alongside doctors and industry leaders, and also participated as a keynote speaker, which I’m sure was an amazing presentation to see.

Its super-fast Brand Ambassador isn’t the only thing SprintRay introduced this month—the startup also launched its new ProCure 2, as the latest piece in what SprintRay calls “the world’s fastest dental 3D printing system.” The ProCure 2 is said to enable, for the first time, a one-hour chairside workflow in dental offices, as it can supposedly post-process most parts in less than five minutes, which is up to 15 times faster than the system that came before it. SprintRay says that its new ProCure 2 has 25 times the amount of power as its predecessor, and also offers easy-to-use pre-programmed cure profiles as well. In addition, the startup also launched SprintRay OnX, which it calls the first “fully radiopaque restorative 3D printed resin.” With a high condensed ceramic content and a good combination of translucency and opacity in order to replicate a person’s natural dentition, this new resin is said to be extremely aesthetic and easy to characterize. This year’s “Additive Manufacturing in Dentistry” report by SmarTech Analysis, which is the longest-running dedicated research study for dental industry professionals, explains how in early 2020, the dental industry suffered a majorly negative impact as government restrictions either discouraged and in some cases prohibited, non-emergency dental care. But the sixth edition of this study shows a quick recovery as restrictions began lifting in mid-2021, and SmarTech shows that dental 3D printing market revenues should return to growth in 2022. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 29, 2021 at 06:33AM

https://ift.tt/3vVkEpq

The 3D Printed Eternal Spare Part is a Quantum Leap in Supply Chain Management https://ift.tt/3EoFtN5 A new partnership has formed between one of Germany’s leading makers of gardening equipment and patio furniture, Siena Garden, and Replique, a division of BASF, based on a project to provide what the companies are whimsically referring to as the “Eternal Spare Part”.

The way it works is simple: parts are stored digitally on Replique’s platform, and produced on demand. Anyone placing an order with Siena Garden for the part(s) will automatically have the order manufactured and delivered by one of Replique’s in-network producers. Storing the parts digitally means that even if the particular piece of furniture you order gets discontinued, certain parts that comprise the furniture—especially those most likely to become lost or damaged with normal use—can still be replaced. No more buying an entire replacement chair all because you lost one of the scratch-proof caps, or broke an arm rest because you were “sitting wrong” as my parents used to chastise me for doing.

Stories about the supply chain and 3D printing have been multiplying since the very first days of the pandemic, and as the issues have increased, so too has the focus of leaders in the industry on precisely this advantage of 3D printing . In this respect, the greatest potential for upending the old/current way of doing business involves the steps towards creating networks of local hubs for on-demand production. So while this is a small step by a single company related to just one of its product lines, it’s likely that the model Siena Garden is applying here will be watched and replicated by plenty of other companies, sooner rather than later—especially given the involvement of BASF, by way of Replique. It starts with things like replacement parts, but you can easily imagine this spreading to the design model for patio furniture in general, not to mention other, more explicitly “essential” manufactures like cars. I see no reason why, if IKEA, for instance, insists on continuing to exist, it can’t at least eventually make all of its products on-demand, entirely using the eternal spare parts.

(Images courtesy of Incus Media) Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com October 28, 2021 at 12:15PM |

Categories

All

Archives

April 2023

|

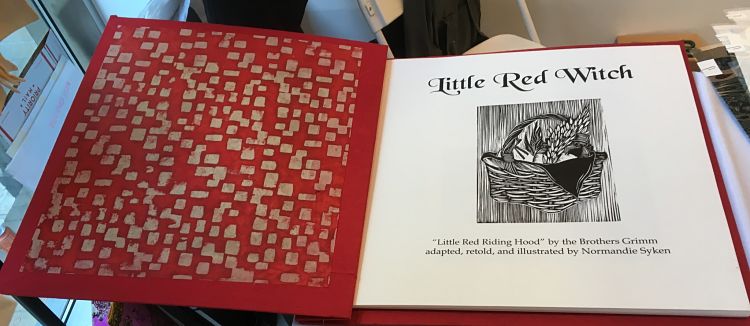

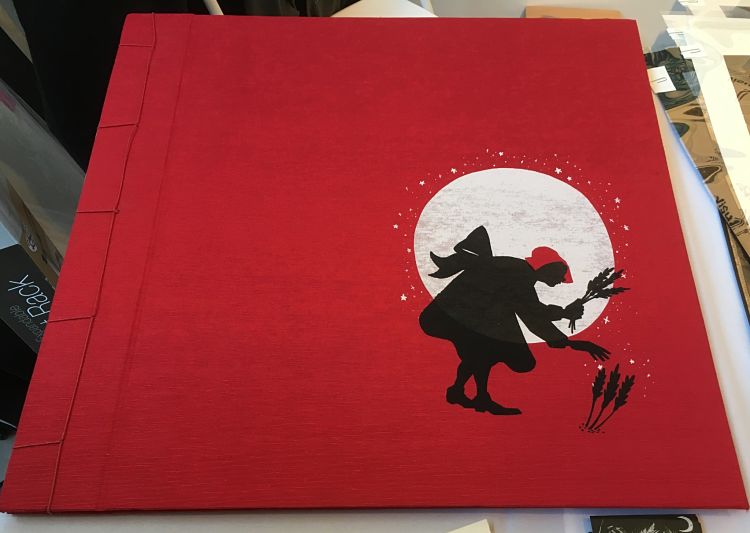

Looking to classics in children’s literature and early Disney concept art for inspiration, and drawing from both life and her imagination, Normandie creates whimsical illustrations for books and stories. One of her recent self-published picture books, Little Red Witch, is now part of The British Library’s collection. It is a large yet exquisitely detailed book that is a contemporary re-telling of the infamous Brothers Grimm tale. However, there is a twist: the story is set in Salem, Massachusetts during the 17th Century witch trials that saw 185 people accused of witchcraft in a one-year period, resulting in 59 trials and 19 executions. In Little Red Witch, Normandie carves her very own dark fairytale, reclaiming the negative connotations of witchcraft.

Looking to classics in children’s literature and early Disney concept art for inspiration, and drawing from both life and her imagination, Normandie creates whimsical illustrations for books and stories. One of her recent self-published picture books, Little Red Witch, is now part of The British Library’s collection. It is a large yet exquisitely detailed book that is a contemporary re-telling of the infamous Brothers Grimm tale. However, there is a twist: the story is set in Salem, Massachusetts during the 17th Century witch trials that saw 185 people accused of witchcraft in a one-year period, resulting in 59 trials and 19 executions. In Little Red Witch, Normandie carves her very own dark fairytale, reclaiming the negative connotations of witchcraft.

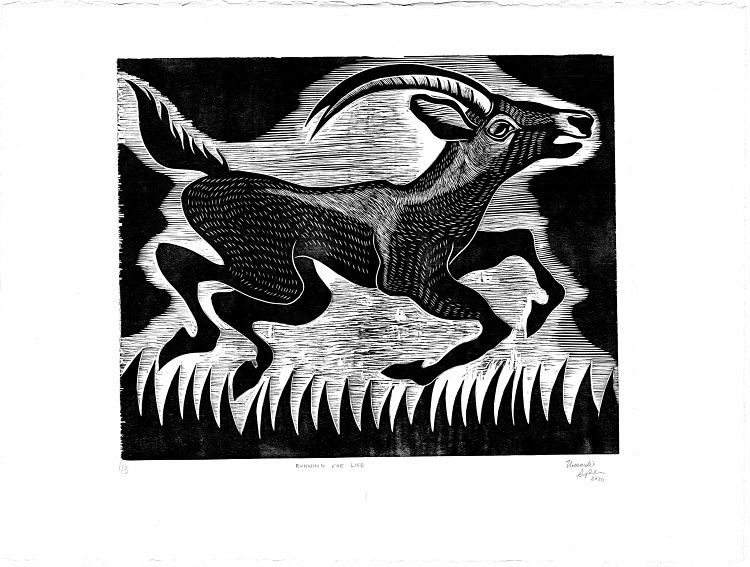

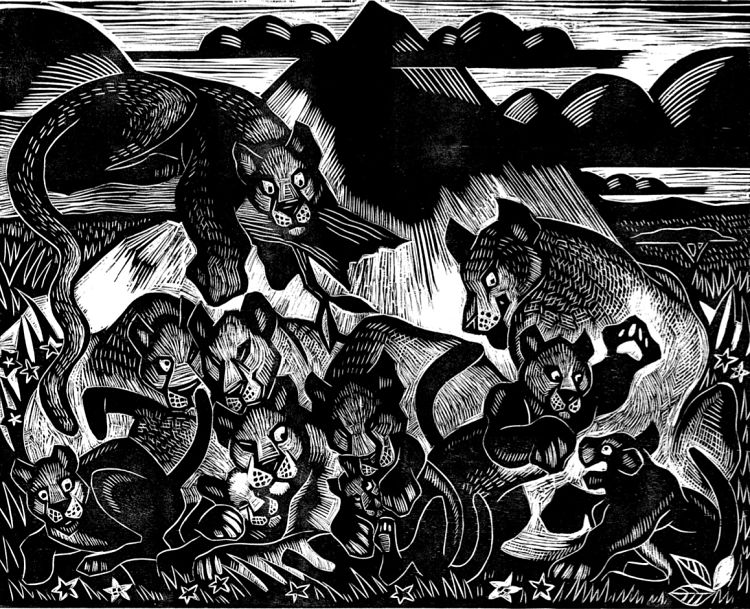

Normandie mostly creates using block printing or watercolour with pen. However, she has recently been developing a series of woodcuts based on her own story. All of the prints in the collection are 12×16 or 16×20 and printed on White Rives BFK Paper. These prints will then go on to become part of a limited edition artist’s book.

Normandie mostly creates using block printing or watercolour with pen. However, she has recently been developing a series of woodcuts based on her own story. All of the prints in the collection are 12×16 or 16×20 and printed on White Rives BFK Paper. These prints will then go on to become part of a limited edition artist’s book.

Going forward, Normandie hopes to have her books professionally published, take part in some exciting exhibitions, and continue selling her work.

Going forward, Normandie hopes to have her books professionally published, take part in some exciting exhibitions, and continue selling her work.

RSS Feed

RSS Feed