|

2023 Stamp Dedication Updates https://ift.tt/cwnJs6d The Postal Service has updated the first-day-of-issue dates and dedication ceremony locations for the following stamps in its 2023 program: Printing via USPS News https://ift.tt/r90fsVI November 30, 2022 at 09:17AM

0 Comments

http://img.youtube.com/vi/-q_IIYdYWJQ/0.jpg

3D Printing News Unpeeled: NASA, ICON, MIT and Purdue https://ift.tt/JKNLXr1 Purdue University makes a wet mixing technology that can make strain and temperature sensors out of Direct Write and FDM 3D printed parts. This could enable new functionality in 3D printed components. NASA awards $57 million to ICON to make moon habitats. And an MIT experiment on board ISS will look to extrude resins into forms that can not be made on earth. The post 3D Printing News Unpeeled: NASA, ICON, MIT and Purdue appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/4U9vJgE November 30, 2022 at 08:51AM

https://ift.tt/yWVMTYE

3D Printing Financials: Desktop Metal Fails to Meet Expectations https://ift.tt/16Yqui8 Making sense of the markets this earnings season was not easy. Plagued with inflationary pressures, layoffs, and supply chain uncertainties, additive manufacturing companies are trying to make their operations recession-proof. For 3D printing tech company Desktop Metal (NYSE: DM), financial results for the third quarter that ended September 30, 2022, were mixed, with revenue increases year-over-year, net losses, and higher operating expenses. Desktop Metal published its Q3 earnings report on November 9, 2022, posting revenue of $47.1 million, up 85% from the third quarter of 2021 revenue of $25.4 million. Significantly impacted by customers delaying purchase decisions amid macroeconomic uncertainty, this period saw a quarterly revenue decrease compared to Q2, which had seen close to $58 million in sales. The 3D printer manufacturer also posted a loss of $60.8 million, or 19 cents per share, a 9.1% improvement from last year’s third-quarter loss of $67 million, or 26 cents per share.  Desktop Metal CEO Ric Fulop. Image courtesy of Desktop Metal. Desktop Metal CEO Ric Fulop. Image courtesy of Desktop Metal.

Despite meaningful progress in Desktop Metal’s long-term growth strategy, Founder and CEO Ric Fulop said third-quarter results did not meet management expectations. According to the executive, the lower-than-expected sales volume towards the end of the quarter (typically when the 3D printing company sees a sharp acceleration in volume) was a significant contributor, which also weighed on gross margins. In addition, as macroeconomic headwinds accelerated during the quarter, some customers delayed purchase decisions. However, this divergence in the expected trend was not uniform across all business lines, explained Fulop to analysts during a conference call following the earnings release. For example, the company saw good resilience in its dental and healthcare platforms, offset by softness across other areas. This is not the first time a recessionary cycle has impacted growth in the additive market, explained Fulop.

Metal parts 3D printed with Desktop Metal’s technology. Image courtesy of Desktop Metal. Metal parts 3D printed with Desktop Metal’s technology. Image courtesy of Desktop Metal.

Confident that the demand for 3D printing will continue past the challenges of the current economic headwinds, Fulop pointed out that in the meantime, Desktop Metal had already taken swift actions to course correct to reduce the expense structure, well beyond what was outlined in June 2022, when the company announced a strategic integration and cost optimization initiative. The CEO revealed that those actions have already achieved $40 million of annualized cost savings. However, as of the closing of the third quarter, it has become clear to management that it needs to intensify further the expense reduction effort in light of the current ongoing environment, which will drive necessary gross margin improvements in the fourth quarter and coming years.

Promising new partnershipsAs part of an ongoing strategic expansion initiative, Desktop Metal announced a collaboration with Align Technology to accelerate the adoption of digital dentistry in the $30 billion annual dental parts market. Align’s market-leading iTero intraoral scanners will be offered as a seamless managed service to dentists in a subscription model with recurring revenue, enabling a gateway for a connected suite of digital dentistry solutions with a workflow backed by Desktop Labs’ experienced network of dental laboratories and premium Desktop Health 3D printers and materials. Additionally, it announced a multi-faceted partnership with Siemens to accelerate the adoption of AM 2.0 with large manufacturers for scalable production applications. As well as an extended partnership with Henkel to qualify additional industrial photopolymer resins on Desktop’s Xtreme 8K, a large-volume resin 3D printer produced by Desktop Metal subsidiary EnvisionTEC.  Top-down DLP 3D printing on the Xtreme 8K 3D printer from ETEC. Image courtesy of Desktop Metal. Top-down DLP 3D printing on the Xtreme 8K 3D printer from ETEC. Image courtesy of Desktop Metal.

Weaker revenue outlookDesktop Metal made a slight downward revision to its revenue guidance for its full fiscal year. Revised company revenues are projected to be between $200 to $210 million for the full year 2022, lower than the prior outlook of roughly $260 million from August 8, 2022. However, the revised guidance still implies an improvement of between 78% to 87% from the 2021 figure. On that note, the fourth quarter 2022 revenue expectation is between $51 to $62 million, and adjusted EBITDA could be a loss of at least $20 million.

The post 3D Printing Financials: Desktop Metal Fails to Meet Expectations appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/4U9vJgE November 30, 2022 at 08:51AM

https://ift.tt/ZbmoVk1

A First-Timer’s “Definitive” Guide to Surviving Formnext https://ift.tt/jqJr8yK Believe it or not, this year was my very first time attending the additive manufacturing (AM) industry powerhouse event known as formnext, which has been held in Germany for eight years now. In 2021, there were 606 exhibitors, and this year there were 802, with nearly 51,150 square meters of exhibition space booked at Messe Frankfurt, and over 29,500 attendees from 96 nations. There were numerous world premieres of materials, software, and hardware, as well as plenty of partnership announcements. It was busy, exhausting and amazing. To help future first-timers, and just to give you an idea of life on the floor, I’ve put together a “definitive” guide to Europe’s largest AM trade show, with definitive in quotes because I am only one person with my own opinions, and others may disagree. Plus, I am coming at this from a journalist’s perspective, so exhibitors and other visitors may need to keep different details in mind when attending.  Photos taken from the top of the Photocentric booth. Photos taken from the top of the Photocentric booth.

Arrive a day early.formnext was held from Tuesday to Friday, and my original travel plan was to arrive in Frankfurt early Monday afternoon, so I’d have time to check in to my hotel and unpack at my leisure, walk the route to and from the event, and maybe walk around the city a little to help with jet lag. Then I would attend the Monday evening Wohler’s Report LIVE, and get to bed early so I’d be well-rested for opening day.  Sunrise at the Frankfurt Airport Sunrise at the Frankfurt Airport

This is not what ended up happening, unfortunately. My flight from Ohio to Chicago was first delayed, and then cancelled, and so I wasn’t able to fly out Sunday evening as I’d originally planned. Luckily, I was able to rebook and fly out Monday morning, but I didn’t land in Frankfurt until 7:30 am on Tuesday. I took a taxi from the airport to the hotel, checked in, unpacked, showered, scarfed down a protein bar, and was out the door again by 9:30 am. While I was sad to have missed my leisurely day of unpacking, walking, and resting, because I’d originally planned to arrive a day early, the only thing I ended up missing on the actual first day was HP’s booth opening party. Ah, the mimosas that could have been. Pack less clothes and more snacks.Did you catch my mention of a protein bar? I was very glad I ended up bringing several with me, as well as some hearty snacks. These are good for long days at the airport, late nights when there are no hotel vending machines or the restaurants are closed, breakfast on the go, and a quick pick-me-up on the show floor when you think you just can’t walk another step without sustenance. As for the amount of clothing I brought, I wish I had taken out the dress I packed and about two shirts and left them at home. I had assumed there would be time to go back to my hotel room at the end of a day on the floor and change out of my sweaty clothes before heading out to dinners/happy hours/parties, and that everyone else at these events would be doing the same. I quickly learned this was not the case. Most people just stayed in their sweaty clothes for the evening events…or maybe they weren’t sweaty? I tend to be a very fast walker, so maybe I was worse than everyone else? Regardless, people aren’t there to be fashion plates, so it’s fine if you go to evening events in what you were wearing during the day. Bring euros.This was a tip I received from more than one person before I left for Germany, mainly because most of the taxis don’t take credit cards, and I was very glad I listened to this advice. On the way to dinner Tuesday night, I split with a cab with a few other ladies and we forgot to ask the driver about this. When we arrived at our final destination, and he learned we didn’t have cash, he swore in frustration. I had thought I left my euros in the safe in my hotel room, and would be going back to get them before dinner (see previous paragraph), but when I dug through my laptop bag just to check, I realized that Morning Sarah had been very smart and brought some cash. Crisis averted! Wear comfortable shoes.Again, this was one piece of advice that I heard from multiple people ahead of time: wear comfortable shoes. Typically when I go to a trade show, I wear my trusty black ballet flats with Ortholite foam inserts. But from everything I was hearing, sturdier shoes would be required, and so I ditched the flats in favor of my Skechers, with new inserts. This was a Very Good Decision.  You can peep my cushy pink Skechers in the reflection of Inkbit’s Vista 3D printer. You can peep my cushy pink Skechers in the reflection of Inkbit’s Vista 3D printer.

I’ve also never seen so many 3D printed shoes (midsoles, rather) in my life, which was really awesome. Perhaps that will be an investment I make before the next trade show? Have a plan…but leave room for wandering.Before I go to a trade show, I always make a detailed spreadsheet of my scheduled interviews and press conferences, any presentations I want to see, and any companies I want to visit with whom I don’t already have a formal interview scheduled. Because this was my first time at formnext, I didn’t want to cram too much into my schedule, and so I purposefully left myself plenty of time to wander the four halls of the trade show and see what there was to see. Leaving this time open was the best thing I could have done for myself. It allowed me to get a handle on where I would be going in the future, figure out where the restaurants and coffee shops were located, and just take everything in without running around like a crazy person…at least the entire time. Find the maps.Did you see where I just said that wandering helped me figure out where I was going? This was somewhat true, but the large maps at each entrance to the four halls and out in the common areas also helped. In addition to an overview of the area, I could also run through the companies in that particular hall alphabetically, and find out exactly where on the floor they were located. I got into trouble with my last interview on the first day — I was absolutely positive that the company for which I was looking was in one of the four corners of my current hall, but I just could not find it. I was flummoxed, because I’d walked past it several times that day already, and I wasted about ten minutes walking up and down the aisles searching for the booth. I finally visited one of the maps and realized that I needed Hall 12.1, not Hall 12.0. I mostly blame this on sleep deprivation. Don’t forget an adapter or charger.Speaking of blaming things on lack of sleep, I forgot my adapter. And I don’t mean I left it at home, I mean I set it out on the desk in my hotel room that first morning and then completely forgot to toss it in my laptop bag. I had my charger with me, but no way to adapt it to European plugs at formnext. By mid-afternoon, my cell phone battery was dangerously low, and I really didn’t want to lose 30 minutes of precious time on the floor to walk 15 minutes to my hotel room and back to get it. I even headed to the quiet trade show oasis of the press center, and while they had plenty of snacks, beverages, and plugs for the journalists onsite, they did not have a spare adapter. My last idea, and the one that ended up being my saving grace, was finding an American company at the show that might have the correct adapter. I’d like to extend my sincerest gratitude to the team at 6K for letting me use their adapter to charge my phone at their booth and temporarily use their counter as a workspace, and also for providing me with a much-needed cup of afternoon coffee. While I remembered both my charger and adapter on the second day, I’d also like to thank XJet for letting me recharge my devices at their booth that afternoon. I’ve lost count of who all to thank for keeping me caffeinated and hydrated. Go the after-hours events.My final tip is to enjoy yourself at the various happy hours and dinners and parties. At the end of the day on Wednesday, I found myself at the Velo3D booth, sipping a glass of red wine paired most elegantly with a Stratasys-branded pack of gummy bears I’d snagged earlier, before walking across the aisle for another glass and a delicious piece of cake at XJet’s booth. Then I headed to one of the onsite restaurants for the Women in 3D Printing happy hour, and after that, outside to a taxi, which deposited me at a nearby club for AMT’s hopping PostPro Fest.  AMT PostPro Fest swag AMT PostPro Fest swag

Not only are these events a great chance to network with a lot of people in a more casual setting (so long as the music isn’t too loud), but they’re also a fun way to unwind after a long day walking the floor at formnext. Take a look at some more of my pictures from formnext 2022 below:

The post A First-Timer’s “Definitive” Guide to Surviving Formnext appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/4U9vJgE November 30, 2022 at 08:51AM

https://ift.tt/hIQKXOR

SmarTech Analysis: Global Metal 3D Printed Parts Market to Reach $75B by 2031 https://ift.tt/8lB6p09 The global metal additively manufactured (AM) parts market is forecasted to experience growth in the coming years. According to research conducted by leading provider of market data and consulting services to the 3D printing industry, SmarTech Analysis, metal AM technologies are now expected to produce more than $75 billion in components annually by 2031 as a result of a renewed emphasis on adopting and developing metal AM technologies and strong investments. SmarTech’s findings have been published in its latest report, “Metal Parts Produced 2022: Global Market Data & Forecast,” which tracks volumes of additive manufactured parts produced today across numerous key industries, including parts made by various AM service providers as well as private original equipment manufacturers (OEMs) and suppliers in each market, split among the currently identified and expected future leading use cases for various metal AM technologies. This report marks the third iteration in a flagship series and is a companion to SmarTech’s “Polymer Parts Produced” data product, combining singular and comprehensive AM parts market coverage. Providing valuable insights and shedding light upon the market dynamics of metal AM parts production, this data-only report offers a detailed data file with historical and projected production volumes and resulting market value of AM metal parts spanning prototypes, tools and tooling, and end-use production parts across eight significant industries and dozens of part categorizations, from aircraft and helicopter engine components in aerospace to nuclear reactor components in the energy sector. Furthermore, the data reflect actual market activity through the second quarter of 2022 as well as proprietary projections over the coming decade. SmarTech’s annual report services provide ongoing market metrics based on long-term data and industry analysis dating back to 2017. The resulting database being announced today follows two previous iterations, including the first analysis of metal additive manufactured parts produced, which was published in November 2019, and the 2021 edition of the landmark study, which accounted for the metal AM parts production market database and forecast in a post-Covid environment. Available as a one-time purchase to non-subscribers or through ongoing subscription advisory services, the latest report is fully customizable, allowing for purchasing individual data segments and subsets. Users of this product will have access to forecast projections and current-day estimates of the volumes and total market value of all metals-based parts produced via AM in a given industry, within various print technologies, material types, and, most importantly, part functionality and type. Stakeholders interested in evaluating different key use cases for specific types of AM technology, AM materials, or broader end-user markets will be able to utilize this database to help identify market strategies to guide product development and go-to-market in the ever-growing world of additive.  Metal AM production volumes chart for the SmarTech “Metal AM Parts Produced 2022.” Image courtesy of SmarTech. Metal AM production volumes chart for the SmarTech “Metal AM Parts Produced 2022.” Image courtesy of SmarTech.

Painting a promising picture of the volumes and total market value of all metals-based parts produced via additive manufacturing across numerous key industries, the study reconfirms the positive long-term outlook for leading metal AM technologies moving into significant manufacturing roles across a multitude of industries over the coming decade. Most notably, data from the report shows that the most exciting areas of metal AM are all related to the production of various end-use parts in terms of part volume growth. This confirms the adoption trend and industry focus on production applications from the past several years. Additionally, from the report, SmarTech Analysis concludes that both the aerospace and medical industries remain the most attractive sectors in terms of realizing value through additively produced parts versus traditional production technologies. Furthermore, the study shows that powder bed fusion (PBF) is currently considered to lead the metal AM parts market distinctly. However, looking forward, SmarTech Analysis anticipates that metal binder jetting (MBJ) offers promise as a leading parts printing process for displacing traditional manufacturing methods. For the full report, you can head to the SmarTech website to request an excerpt or purchase the entire “Metal Parts Produced 2022: Global Market Data and Forecast” report by SmarTech Analysis. For custom or subscription pricing, please contact [email protected]. The post SmarTech Analysis: Global Metal 3D Printed Parts Market to Reach $75B by 2031 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/4U9vJgE November 30, 2022 at 08:51AM

https://ift.tt/p1KGnsC

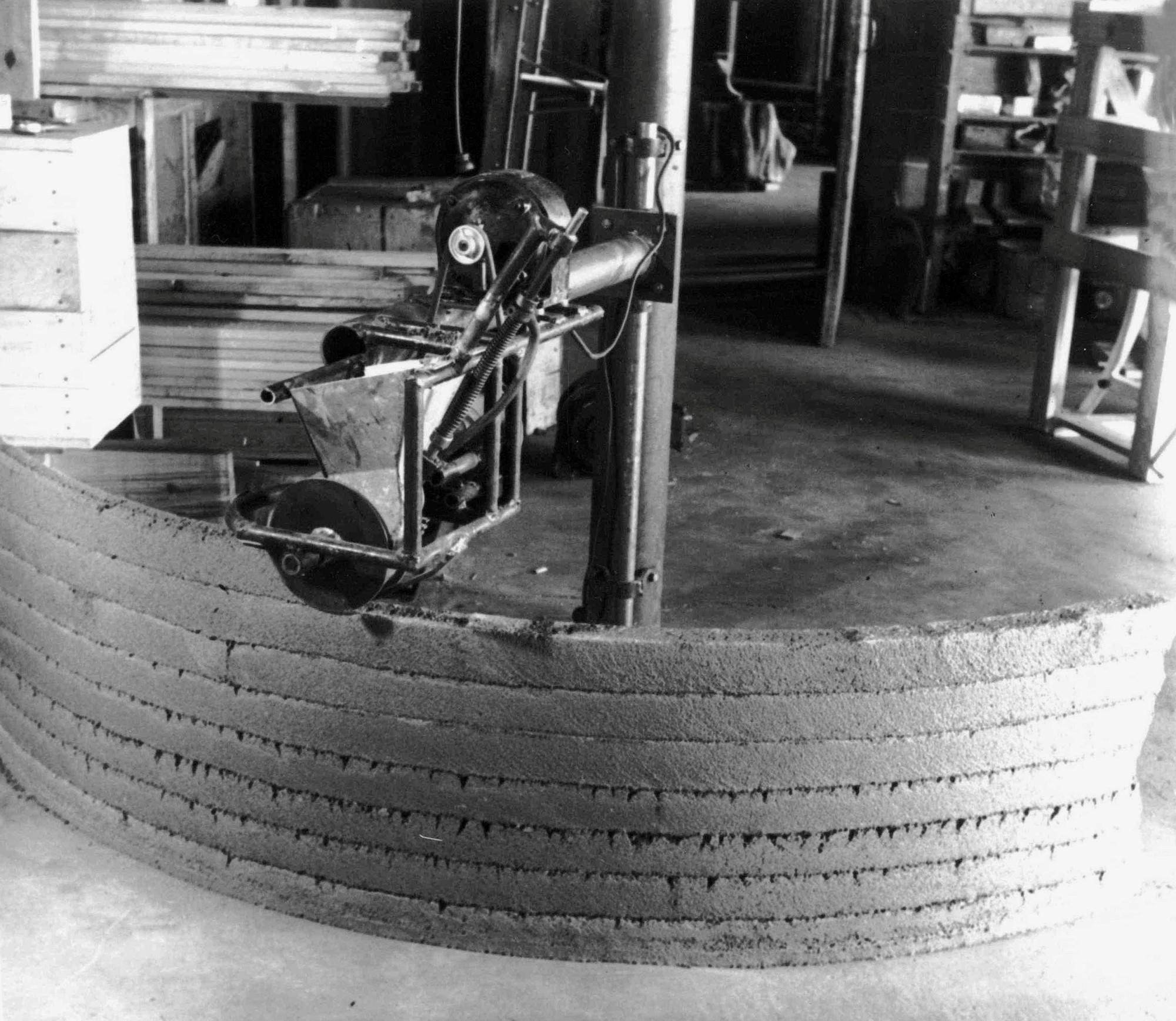

3D Printed Houses Are Much, Much Older Than You Think https://ift.tt/DYCbQA5 Particularly in the last several years, 3D printed houses have become increasingly prevalent, but the technology may be much older than you might have thought. The seeds for the concept actually date back to William E. Urschel’s “Wall Building Machine” in 1941. Although the machine was not completely automated, the progenitor resembles bears a striking resemblance to many construction 3D printing systems we know today. Now, if you have heard of the Urschel name, you are probably in the food manufacturing industry or from Indiana. The company has been located in the state since its founding in the early 1900s, when William E. Urschel started selling his gooseberry stemmer machine to local farmers. The firm eventually expanded to other food processing equipment and is still known for the technology today. However, in the 1940s, priorities changed briefly when the company was instructed to halt food processing operations to focus entirely on WWII efforts. Generating the necessary supplies meant everyone was expected to do their part. For Urschel and his company, that not only meant manufacturing shell loadings and assembly equipment, but also exploring new inventions that could help the U.S. military on the battle front. One such inventions was the Wall Building Machine.

“The Wall Building Machine” by William E. Urschel Originally intended to quickly build bomb and other shelters for war, William E. Urschel’s Wall Building Machine is one of the oldest forms of semiautomated layer by layer concrete construction. It was patented on October 20th 1941, and relied on a radial print arm to rotate in a circle to deposit cement. This is not dissimilar to the architecture of Apis Cor’s 3D printing system.

“The Wall Building Machine” Building a Tractor Shed The machine also incorporated spinning disks to the side of the print head to smooth the extruded concrete and featured a tongue and groove fitting to increase adhesion between layers. Rebar could also be laid with the concrete to give the cement added support to withstand strong winds and shockwaves from bombings. Interestingly enough, even the doors and windows were made using techniques similar to those used today. Overall, Urschel’s structures resembled a modern 3D printed house, and if you were to put them side by side, then you could see how one inspired the other.

Close up of the print head of the “Wall Building Machine”

“The Wall Building Machine” building a door to a bomb shelter. Unfortunately for Urschel, this machine was well ahead of it’s time, and did not receive the same attention that 3D printed houses get today. The technology grew cold after the war and wouldn’t resurface for another 50 years when concrete 3D printing began its renaissance. To think this history was almost lost if Jarett Gross had not posted his original video discussing the topic. The post 3D Printed Houses Are Much, Much Older Than You Think appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/4U9vJgE November 30, 2022 at 08:51AM

https://ift.tt/sGVuZk2

Top 2023 Calendars https://ift.tt/D6exj92 Get organised in the new year and add some statement art to your walls with our low down of the best 2023 calendars. From vibrant illustrations, to lunar calendars, and celebrations of typography, you’re sure to find something you love below: Lou Rowland Ring Riso Calendar Big Mitten Linocuts RISOTTO Drucken 3000 Fuzzy Phunk World of Type Superkolor Crispin Finn Known As Studio Colophon Foundry Abby Sumner Kapitza OMG Kitty LEMONNI

Printing via People of Print https://ift.tt/nxSBC4l November 30, 2022 at 07:16AM

https://ift.tt/eamESUo

Desktop Metal: AM 2.0 Highlights from the Formnext Show Floor https://ift.tt/bc1eUBJ Formnext, the leading international platform for Additive Manufacturing and industrial 3D Printing, returned in full swing to the halls of the Frankfurt convention center in Germany this November. With challenging economic forecasts headlining the news around the world, manufacturers from a variety of industries came eager to discover agile production solutions to help their businesses survive and thrive in through forecasted challenges – and Desktop Metal’s portfolio of innovations took center stage. With over 350 parts presented in the Desktop Metal booth, Additive Manufacturing 2.0 solutions for metal, polymer, sand, and wood were on display showcasing the possibilities of 3D printing. Interest in metal 3D printing remained strong as many sectors look for processes to help reduce lead times, costs, and waste. With the most experienced team of metal binder jetting and sintering experts in the world, Team DM presented the broadest range of scalable printing systems and material capabilities. The entry-level Studio System was running at the show, highlighting the ease of use and office-safe nature of bound metal deposition 3D printing. The two-step process makes getting started with metal 3D printing without loose powder as easy as print and sinter.

As the company grows, it was clear to attendees that Desktop Metal offers solutions for industrial production in materials beyond metal. Announced just before the opening of the expo, the Shop System Forust edition is also the world’s first high-speed 3D printer for upcycled wood parts. Based on metal printing platform, the Shop System Forust Edition is modified to safely process unfinished sawdust byproduct from the wood milling industry. By unlocking the power of 3D printing of wood, architects, designers, and manufacturers can produce luxurious custom pieces with a variety of printed grains that combine design and functionality for home décor and lighting, consumer products, architectural design, and automotive applications. As the company grows, it was clear to attendees that Desktop Metal offers solutions for industrial production in materials beyond metal. Announced just before the opening of the expo, the Shop System Forust edition is also the world’s first high-speed 3D printer for upcycled wood parts. Based on metal printing platform, the Shop System Forust Edition is modified to safely process unfinished sawdust byproduct from the wood milling industry. By unlocking the power of 3D printing of wood, architects, designers, and manufacturers can produce luxurious custom pieces with a variety of printed grains that combine design and functionality for home décor and lighting, consumer products, architectural design, and automotive applications.

The impressive display from Desktop Metal’s portfolio made it clear the company is now more than just metal. The cohesive theme presented by all Team DM brands and technologies throughout the week was offering production-capable technologies that deliver the combination of speed, tolerance, surface finish, and material properties to compete with conventional manufacturing methods. The tooling-less solutions presented by Desktop Metal helped spur ideas to help manufacturers drive down the cost and increase innovation to move into the next era of digital production. Download more information on the complete Desktop Metal portfolio in this brochure. The post Desktop Metal: AM 2.0 Highlights from the Formnext Show Floor appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/N7m8BLP November 30, 2022 at 07:06AM

https://ift.tt/WnSKCEN

Desktop Metal Receives $9M 3D Printer Order from German Car Maker https://ift.tt/T6SiDKh Original equipment manufacturer (OEM) Desktop Metal (NYSE: DM) announced that the company has received a $9 million order from a “large German car manufacturer.” Although it is not clear which platform was purchased in particular, DM noted in a press release that the order was for a metal binder jetting system. According to DM, this is the second platform ordered by the same German company in less than a year, which brings the purchases by said unnamed car manufacturer to a total of $16.9 million during that timeframe. This latest sale was for a platform that will be used in the production of powertrain components for the commercial auto market.

It is not news that, against the backdrop of a generally dismal 2022 for American equity markets, OEMs in the AM sector have had an especially difficult year. Unsurprisingly, companies such as DM, which went public not long before markets saw their peaks in 2021, have endured the most challenging operating conditions. In a recent interview with 3DPrint.com’s editor-in-chief, Michael Molitch-Hou, Fulop acknowledged the macro difficulties that all companies have faced this year. Echoing financial analysts’ increasingly pessimistic consensus about the trajectory of the global economy, Fulop cautioned that the unforgiving fiscal environment is likely to continue into 2023. On the other hand, I’ve noted before that, for the AM sector, there is a silver lining to take away from a rough 2022: any company that survives it will have proven its tenacity and adaptability to investors. As for DM, the European auto market could turn out to be one of the best sectors for an AM hardware firm to have exposure to. Put simply, no one knows what will happen next year. In this sense, at least for some companies, there is perhaps just as much reason to think that the bleakness of 2022 is a sign that a bottom is being reached, as there is to think that it forebodes a far worse financial climate in the near-term. Images courtesy of Desktop Metal The post Desktop Metal Receives $9M 3D Printer Order from German Car Maker appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/N7m8BLP November 29, 2022 at 10:12AM

http://img.youtube.com/vi/iCy553gB2KY/0.jpg

3D Printing News Unpeeled: 3D Printing MEMS, Desktop Metal gets a $9 Million Order https://ift.tt/yGix8jI Props for the movie Black Panther Wakanda Forever have been 3D printed, Desktop Metal reports that it has received a $9 million order from an unnamed European automaker. Research looks into making MEMS components using 3D Printing. The post 3D Printing News Unpeeled: 3D Printing MEMS, Desktop Metal gets a $9 Million Order appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/N7m8BLP November 29, 2022 at 10:12AM |

Categories

All

Archives

April 2023

|

Designed in collaboration with Designer

Designed in collaboration with Designer  This awesome calendar is a collective project between 12 illustrators on the theme ‘Ring’. Featuring 12 illustrations printed in teal and orange, the calendar was designed and printed in Berlin. Jazz up your walls with a new illustration each month!

This awesome calendar is a collective project between 12 illustrators on the theme ‘Ring’. Featuring 12 illustrations printed in teal and orange, the calendar was designed and printed in Berlin. Jazz up your walls with a new illustration each month! Obsessed by all things astrological? Then this 2023 Zodiac planner by Big Mitten Linocuts is for you! The full-year calendar features Zodiac constellation blockprint art, wall size at 12×18 inches, printed on recycled paper that is manufactured by a hydropowered plant.

Obsessed by all things astrological? Then this 2023 Zodiac planner by Big Mitten Linocuts is for you! The full-year calendar features Zodiac constellation blockprint art, wall size at 12×18 inches, printed on recycled paper that is manufactured by a hydropowered plant. Plan your year in style with RISOTTO’s 2023 wall calendar! This risograph calendar has lots of space to scribble those all important dates. This year even features Italian Vocabulary References to practice your days of the week, months and seasons! Also featured is the latest lunar movements to keep you in the loop, and each page is filled with fluorescent gradients, bringing your weekends to life!

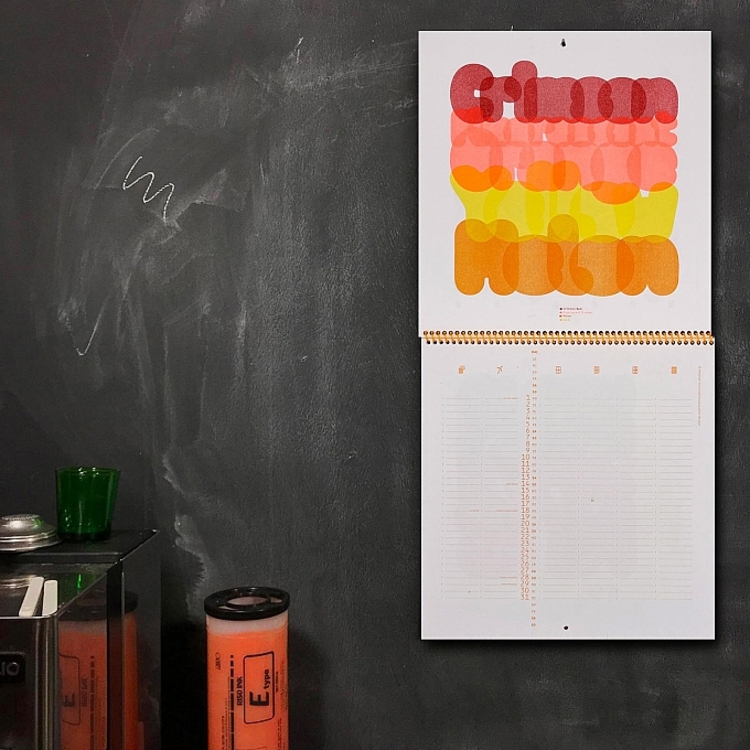

Plan your year in style with RISOTTO’s 2023 wall calendar! This risograph calendar has lots of space to scribble those all important dates. This year even features Italian Vocabulary References to practice your days of the week, months and seasons! Also featured is the latest lunar movements to keep you in the loop, and each page is filled with fluorescent gradients, bringing your weekends to life! Featuring an incredible 43 colours, this Riso printed calendar from Drucken 3000 provides all the space you’ll need to get yours and your families 2023 plans in order. Designed by

Featuring an incredible 43 colours, this Riso printed calendar from Drucken 3000 provides all the space you’ll need to get yours and your families 2023 plans in order. Designed by  This hand-carved block printed calendar by Fuzzy Phunk helps you keep track of the lunar cycle for 2023. Frame as a beautiful piece of wall art! The calendar comes editioned and signed.

This hand-carved block printed calendar by Fuzzy Phunk helps you keep track of the lunar cycle for 2023. Frame as a beautiful piece of wall art! The calendar comes editioned and signed. Inspired by the legendary Dutch graphic designer Wim Crouwel, World of Type’s 2023 Wim Calendar is printed on 297x420mm sheets of high quality, 170gsm paper, with pure black pages. The sheets are detachable, designed to be removed with each passing month. The perfect addition to any type-fanatic’s office!

Inspired by the legendary Dutch graphic designer Wim Crouwel, World of Type’s 2023 Wim Calendar is printed on 297x420mm sheets of high quality, 170gsm paper, with pure black pages. The sheets are detachable, designed to be removed with each passing month. The perfect addition to any type-fanatic’s office! Impulsive, playful and optimistic, Superkolor’s Risograph wall calendar is entering its seventh round in 2023. Each month is printed in four bright Riso colours on selected sustainable design paper. Designed in collaboration with Benedikt Demmer (Blast Wave), this calendar is guaranteed to bring colour to your daily life.

Impulsive, playful and optimistic, Superkolor’s Risograph wall calendar is entering its seventh round in 2023. Each month is printed in four bright Riso colours on selected sustainable design paper. Designed in collaboration with Benedikt Demmer (Blast Wave), this calendar is guaranteed to bring colour to your daily life. The Crispin Finn 2023 Year Planner lets you see your year at a glance – the design is practical, useful, easy on the eye, and in a classic landscape format. An ideal calendar for the whole family and the super organised. 2 colour printed on 135gsm Revive 100% recycled paper.

The Crispin Finn 2023 Year Planner lets you see your year at a glance – the design is practical, useful, easy on the eye, and in a classic landscape format. An ideal calendar for the whole family and the super organised. 2 colour printed on 135gsm Revive 100% recycled paper. Printed in 2 beautiful Riso colours – purple and orange, this 2023 wall calendar by Known As Studio features 12 unique prints. Freshen up your walls with some fun artwork each month, whilst also planning the days ahead.

Printed in 2 beautiful Riso colours – purple and orange, this 2023 wall calendar by Known As Studio features 12 unique prints. Freshen up your walls with some fun artwork each month, whilst also planning the days ahead. Make a statement with Colophon Foundry’s 2023 Typographic Calendar. Silkscreened in gloss white on heavyweight black paper, with a nod to calendars by Vignelli, Tovaglia and Mari, the calendar uses a simplistic system to display each month as a numeral with corresponding dates and days. Three punched holes allow the calendar to conveniently be hung on a wall. The calendar utilises modified versions of their typeface Coign in cuts 19 and 47.

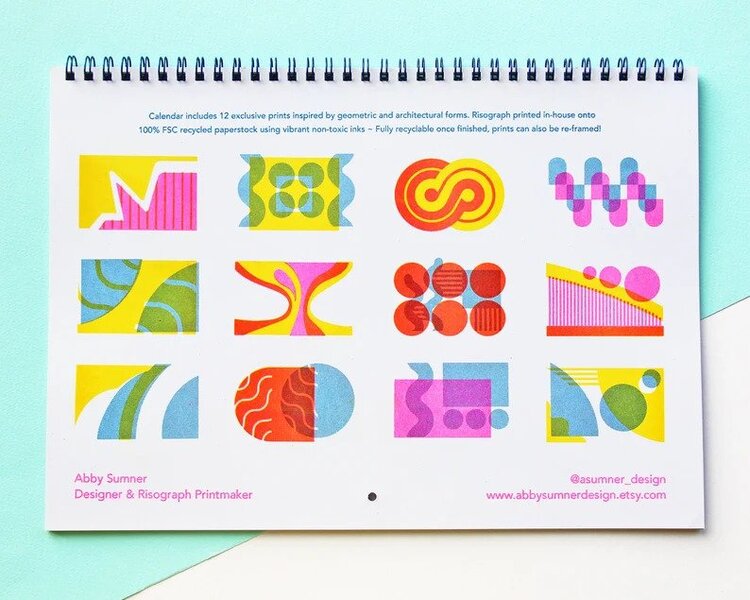

Make a statement with Colophon Foundry’s 2023 Typographic Calendar. Silkscreened in gloss white on heavyweight black paper, with a nod to calendars by Vignelli, Tovaglia and Mari, the calendar uses a simplistic system to display each month as a numeral with corresponding dates and days. Three punched holes allow the calendar to conveniently be hung on a wall. The calendar utilises modified versions of their typeface Coign in cuts 19 and 47. This A3 wall calendar by Abby Sumner is bound to bring colour to the whole of 2023! The limited edition calendar features 12 exclusive colourful geometric and abstract prints inspired by architectural forms, pattern, and geometry. Perfect as a treat for yourself or as a gift for Christmas that will last all year long!

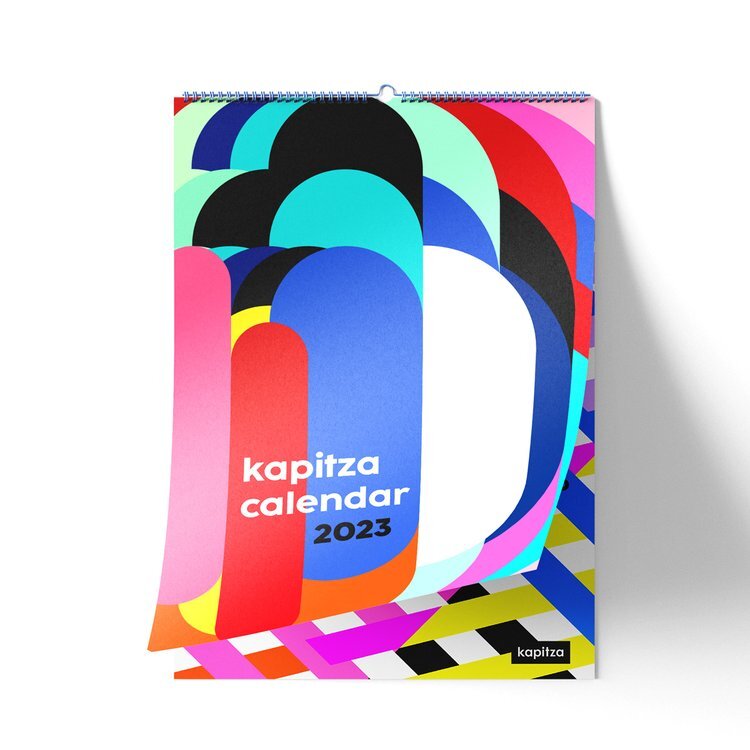

This A3 wall calendar by Abby Sumner is bound to bring colour to the whole of 2023! The limited edition calendar features 12 exclusive colourful geometric and abstract prints inspired by architectural forms, pattern, and geometry. Perfect as a treat for yourself or as a gift for Christmas that will last all year long! We love this extra large A3 wall calendar Kapitza which features twelve colourful geometric artworks. Colour, fun and happiness for every day in 2023! A joy-bringing gift for both friends and family!

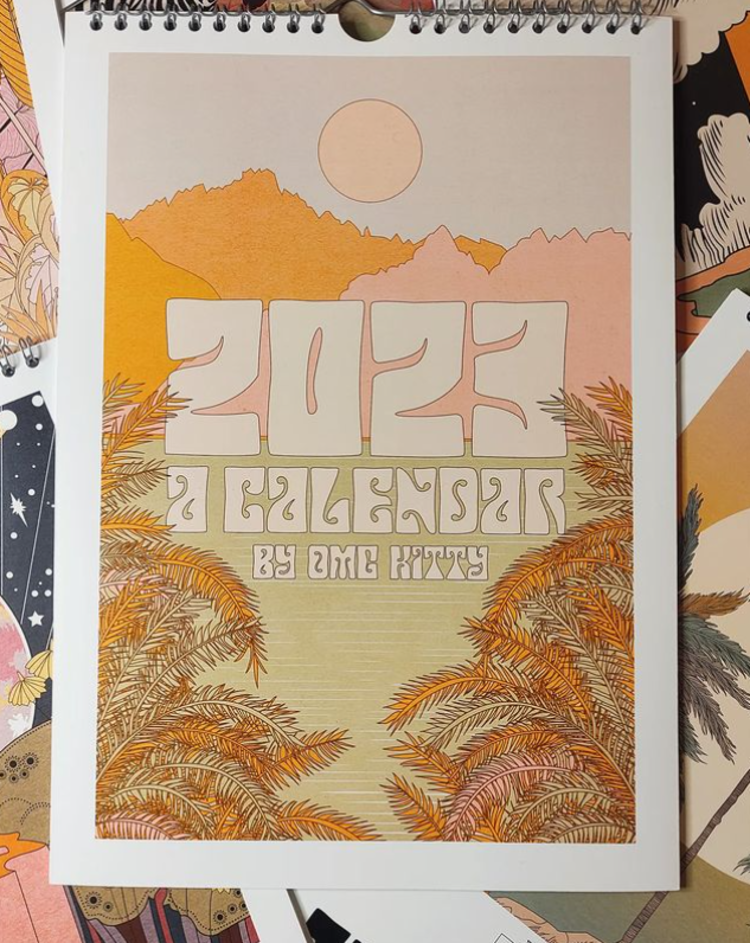

We love this extra large A3 wall calendar Kapitza which features twelve colourful geometric artworks. Colour, fun and happiness for every day in 2023! A joy-bringing gift for both friends and family! OMG Kitty’s A4 sized 2023 calendar features twelve of their most popular illustrations. Alongside a stunning image, each page also features a monthly date grid for writing down appointments and plans. Great pressie for any illustration-lover!

OMG Kitty’s A4 sized 2023 calendar features twelve of their most popular illustrations. Alongside a stunning image, each page also features a monthly date grid for writing down appointments and plans. Great pressie for any illustration-lover! Simple yet fun Risograph calendar from LEMONNI. Featuring funky shapes and dates at a glance, this calendar is perfect for seeing what lies ahead. Comes with a matching gold/neon twine for easy hanging!

Simple yet fun Risograph calendar from LEMONNI. Featuring funky shapes and dates at a glance, this calendar is perfect for seeing what lies ahead. Comes with a matching gold/neon twine for easy hanging!

RSS Feed

RSS Feed