|

https://ift.tt/nu0Ht4h

3D Printing Financials: Markforged’s Supply Chain Issues Wind Down FX20 Production https://ift.tt/WNKqhuQ Supply chain disruptions continue to torment the manufacturing industry. In additive manufacturing, the challenging operating environment is harming production continuity. For Markforged (NYSE: MKFG), in particular, these production hurdles slowed its ramp to volume production, and as a result, the company was unable to meet its revenue target for the quarter. Despite a challenging macro environment, Markforged CEO Shai Terem said the company delivered another solid quarter as demand for The Digital Forge continues to grow globally. As a result, revenue increased by 5%, to $25.2 million, in the third quarter of 2022 from $24 million year-over-year. Specifically, revenue in the Asia-Pacific (APAC) region grew 82% during the three months that ended September 30, 2022, compared to the same period in 2021, led by solid demand for mature products and accelerated demand for the brand’s continuous composite 3D printer line, the FX20.  The FX20 3D printer by Markforged The FX20 3D printer by Markforged

During a conference call with investors, Terem and Chief Financial Officer (CFO) Mark Schwartz said that solving supply chain problems today would ensure production continuity of its machines, like the FX20. However, Schwartz pointed out that despite best efforts, Markforged could not secure electrical and mechanical components to complete the production of FX20 units and meet the growing demand. The FX20 is the largest and most precise continuous fiber machine Markforged has ever produced, opening up high-temp materials. As the company’s newest production-grade printer, the FX20’s demand continues to exceed internal expectations as manufacturers seek solutions to make their own supply chains more resilient and flexible. Management said that despite being unable to meet the platform’s demand and the cost of the FX20 production exceeding estimates, Markforged exited the quarter with one of the largest pipelines in the company’s history.

Is profitability on track?The company took certain measures to address its long-term profitability growth. For example, strong cost controls allowed Markforged to see sequential operating leverage and deliver on its earnings per share (EPS) target in the third quarter. Even more so, the company reorganized its go-to-market team and reprioritized initiatives with the potential for the greatest impact on profitable growth. These cost controls resulted in a strong balance sheet that Markforged anticipates will keep it on the path to profitability in 2024. However, profitability for the period missed its mark, as the firm posted a net loss of $23 million, or 12 cents per share, for the quarter, a decline from last year’s quarterly net profit of $21.7 million, or 13 cents per share. As a percentage of revenue, Schwartz indicated that net loss improved compared to the second quarter of 2022. However, he also pointed out that the current cost of producing an FX 20 versus the target at steady state production negatively impacted Markforged’s gross profit by $1.1 million in the third quarter, or over four gross margin percentage points.

Growing market opportunityAs for the third quarter operating expenditure, Markforged reported $35 million, and it had roughly $182 million in cash/cash equivalents and no debt as of September 2022, which executives said is “on plan and well positioned to execute on our long term goals.”  Markforged helps companies through its Digital Forge. Image courtesy of Markforged. Markforged helps companies through its Digital Forge. Image courtesy of Markforged.

Looking ahead, Markforged expects revenue for the fourth quarter to be between $28 million and $32 million, which, at the midpoint, would result in 2022 full-year revenue near the lower end of the range the company provided previously. For the full year, executives anticipated in the third quarter earnings conference call on November 9, 2022, that revenue would be between $99 million and $103 million. Overall, despite near-term macro headwinds, Terem assured analysts and investors that the long-term fundamentals remain unchanged. He highlighted that strong cost controls drove sequential operating leverage in Q3 and anticipated staying on track to profitability during the second half of 2024. Even more so, he suggested that the acquisition of metal binder jetting technology maker Digital Metal, which closed in the third quarter, would help expand Markforged’s addressable market into the mass production of end-use metal parts. This addressable market expansion couldn’t come at a better time, especially with demand building in automotive, luxury goods, medical, and metal injection molding (MIM) applications. The post 3D Printing Financials: Markforged’s Supply Chain Issues Wind Down FX20 Production appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/N7m8BLP November 29, 2022 at 10:12AM

0 Comments

https://ift.tt/vqresF5

MIT 3D Printing Experiment Rides SpaceX’s Dragon to the ISS https://ift.tt/KJfxHv2 SpaceX successfully launched its Falcon 9 rocket Saturday, November 26, 2022, ferrying new science investigations, supplies, and equipment for the crew at the International Space Station (ISS). Against the backdrop of the Artemis 1 launch, the new payloads traveling aboard SpaceX’s 26th commercial resupply mission (CRS) include an MIT Media Lab project that could help advance large-scale AM construction in space.  SpaceX’s Falcon 9 rocket, with the Dragon spacecraft atop, soars into the sky from NASA’s Kennedy Space Center. Image courtesy of NASA. SpaceX’s Falcon 9 rocket, with the Dragon spacecraft atop, soars into the sky from NASA’s Kennedy Space Center. Image courtesy of NASA.

Packed inside BlackBox 2, a remotely commanded commercial Space Station platform developed by in-space service provider Nanoracks to allow for multiple experiments to occur simultaneously, the AM investigation called Extrusion blasted into space with several other experiments from the MIT Media Lab that were sponsored by the ISS National Lab.  An inside view of the MIT Space Exploration Initiative Extrusion payload, shown in preparation for flight prior to sample loading. This technology demonstration tests new methods for rapid extrusion and UV curing of liquid resin shapes in microgravity. Image courtesy of the MIT Space Exploration Initiative. An inside view of the MIT Space Exploration Initiative Extrusion payload, shown in preparation for flight prior to sample loading. This technology demonstration tests new methods for rapid extrusion and UV curing of liquid resin shapes in microgravity. Image courtesy of the MIT Space Exploration Initiative.

Through the new AM investigation, researchers will demonstrate the extrusion of liquid resin into custom forms in the microgravity environment to create geometries that cannot be made on Earth. The payload architecture itself is comprised of three pumps that inject photocurable resin into pre-made flexible forms while a camera captures footage of the process.

The silicone skins contain and shape the liquid extrusion process during the MIT Extrusion experiment in orbit. Image courtesy of Rapid Liquid Printing/MIT Media Lab. The silicone skins contain and shape the liquid extrusion process during the MIT Extrusion experiment in orbit. Image courtesy of Rapid Liquid Printing/MIT Media Lab.

An avid teacher of 3D printing at MIT, Ekblaw explains that in a microgravity environment, extrusions into free space that would typically sag can proceed unimpeded, allowing for the creation of structures that could not be produced in a gravity environment. On Earth, gravity deforms large objects, such as the beams used in large-scale construction. Traditional additive manufacturing processes, especially those that use liquid resin as the feedstock, are constrained by gravity. Instead, space’s weightlessness enables the fabrication of longer and thinner structures without this deformation. If successful, the Extrusion project could help lay the groundwork for additive manufacturing of more complex in-space structures, including space stations, solar power arrays, telescopes, and industrial equipment to support future space exploration.  An example of the silicone skins that will contain and shape the liquid extrusion process during the MIT Extrusion experiment in orbit. Image courtesy of Rapid Liquid Printing/MIT Media Lab. An example of the silicone skins that will contain and shape the liquid extrusion process during the MIT Extrusion experiment in orbit. Image courtesy of Rapid Liquid Printing/MIT Media Lab.

Furthermore, considering that launching large structures in one piece is not feasible since they must be built to withstand much greater forces on Earth and during launch than they experience in space, these pieces could be created in orbit using Extrusion technology and shipped back for use on Earth. Prior to being launched to the ISS, the team led by Ekblaw tested the Extrusion payload on a parabolic flight in May 2021. Once on board the ZeroG aircraft, the team successfully demonstrated that the technology tested new methods for rapid extrusion and UV curing of liquid resin shapes in microgravity. The early version of the hardware for Extrusion used two feedstocks, a small-gauge flexible wire and a photocurable resin. It extruded them both through a nozzle assembly which simultaneously bent the wire into a 3D shape and coated it with an even layer of the resin. According to the original project excerpt, just after the nozzle, an array of UV LED emitters were positioned to cure the resin, both hardening it and bonding it to the wire. Once the entire shape was created, a cutting mechanism cleaved the coated wire just after the nozzle exit to allow for the creation of another shape.  Team members (from right to left) Che-Wei Wang, Aiden Padilla, Sean Auffinger, Martin Nisser, and Ariel Ekblaw pose with the experiment installed on the Zero-G aircraft. Image courtesy of Steve Boxall/ZERO-G. Team members (from right to left) Che-Wei Wang, Aiden Padilla, Sean Auffinger, Martin Nisser, and Ariel Ekblaw pose with the experiment installed on the Zero-G aircraft. Image courtesy of Steve Boxall/ZERO-G.

Cutting-edge 3D printing experiments, like this one from MIT researchers, are routinely sent to the ISS for testing. In the last month, another resupply spacecraft – this one operated by Northrop Grumman – returned Techshot’s highly publicized bioprinting platform, better known as the BioFabrication Facility, to the microgravity laboratory with new capabilities to further human tissue printing research. While last February, Cornell University tested software that enables 3D printing on the space station. On the ground, the space agency is also supporting a myriad of additive manufacturing and bioprinting projects that will contribute to the growing space ecosystem, such as the “replicator” 3D printer, which aims to produce cartilage in space. Also supporting a range of microgravity and lunar research projects across science, engineering, art, and design, MIT Media Lab’s Space Exploration Initiative is on a mission to “build out the technologies of our sci-fi space future while keeping our innovations and team as open and accessible as possible.” This idea of democratizing access to space exploration will allow new disciplines and technologies (like AM) to deliver more experiences in space. Through this initiative, MIT researchers are creating and deploying space innovations that envision a bold and culturally rich “new space age,” from astro-bacteria wearables and open-access CubeSat constellations to musical instruments for space voyages, floating space habitats, and advanced zero-gravity 3D printing. The post MIT 3D Printing Experiment Rides SpaceX’s Dragon to the ISS appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/N7m8BLP November 29, 2022 at 08:11AM

https://ift.tt/4A7algP

ICON Scores $57M from NASA for Moon 3D Printing https://ift.tt/ZFIderV It’s been quite the year for additive construction developer ICON. The Austin-based tech company’s seamless integration of advanced construction technologies into homebuilding spearheads faster and more accurate construction of complex or bespoke structures. Since ICON arrived in the 3D printing scene with the first permitted 3D printed home in the US during the SXSW event in March 2018, this engineering trend has evolved. Not only has ICON partnered with the Texas Military Department to build the largest 3D printed barracks in the country or teamed up with homebuilding giant Lennar to build a 100-home community in Texas, but it has even worked with NASA to design and construct a reusable landing pad that could be 3D printed with materials found on the Moon. This last collaboration may have resonated a lot lately, especially with the first Artemis launch bringing humanity one step closer to returning to the Moon. On the heels of this milestone, ICON has just announced a new contract that will target the first construction on another planetary body. ICON revealed on November 2022 it had won a Small Business Innovation Research (SBIR) Phase III contract worth $57.2 million to research and develop a lunar surface additive construction system. The new contract builds upon previous NASA and Department of Defense (DoD) funding for ICON’s Project Olympus, a multi-purpose construction system for off-world developments expected to leverage in-situ resources as building materials to further the efforts of NASA and commercial organizations to establish a sustained lunar presence.

Under the coveted third phase SBIR program, ICON, in partnership with NASA, will continue to pioneer methods and technologies to solve some of the most vexing construction challenges facing our species, from affordable housing to living on other planets. The company said that NASA’s award is a vote of confidence in a young, growing company and its mission to revolutionize the construction industry both on and off Earth. In support of NASA’s Artemis program, ICON plans to bring its advanced hardware and software into space via a lunar gravity simulation flight. The construction startup also intends to work with lunar regolith samples brought back from Apollo missions and various regolith simulants to determine their mechanical behavior in simulated lunar gravity. These findings will yield results that inform future lunar construction approaches for the broader space community, including critical infrastructures like landing pads, blast shields, and roads. This upcoming technology will help to establish the critical infrastructure necessary for a sustainable lunar economy, including, eventually, longer-term lunar habitation. According to Ballard, the final deliverable of this contract will be humanity’s first construction on another world. NASA has signaled that, through the Artemis program, the Moon will be the first off-Earth site for sustainable surface exploration, which is why building a sustainable presence on the Moon requires more than rockets. Scientists have been exploring what it would take to live off-Earth for a long time, and conclusively, living on the Moon will not be easy. Before the first crew survives in one of the most hazardous spaces known to humankind, many challenges must be solved on Earth. While Apollo astronauts inhabited the Moon for only a few days, the highly anticipated crewed Artemis missions will last longer, which could severely affect human health. Not only will crews have to face the toxic moondust, but also radiation, low gravity, and a colder and longer lunar night than on Earth. Robust infrastructure will need to be built on the Moon to provide better thermal, radiation, and micrometeorite protection. For that to happen, ICON’s development plans follow a “live off the land” approach by prioritizing using native materials found on site called regolith. Discussing some critical issues about ICON’s upcoming technology, NASA Space Technology Mission Directorate’s Director of Technology Maturation, Niki Werkheiser, believes that “to explore other worlds, we need innovative new technologies adapted to those environments and our exploration needs.” Furthermore, she believes that pushing this development forward with NASA’s commercial partners will create the capabilities needed for future missions. From landing pads to habitats, humans will require collective efforts to survive off-Earth. With companies like ICON on board and ready to support the space agency’s plans for exploring the Moon, Mars, and beyond, delivering the technologies that will build entire ecosystems in space feels more real than ever. Although today, NASA is heavily encouraging new ideas and innovations for space, ICON has proved itself already, having received a subcontract to deliver the world’s first and only simulated Mars surface 3D-printed habitat and helping create a lunar landing pad that has been tested on Earth. With so much going on at ICON, it is inevitable to imagine that this startup will continue to mature off-Earth applications for potential sustainable lunar missions and develop technology with shared agency benefits for Earth and space. The post ICON Scores $57M from NASA for Moon 3D Printing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/F8Phdaw November 29, 2022 at 07:25AM

https://ift.tt/NEFgb8W

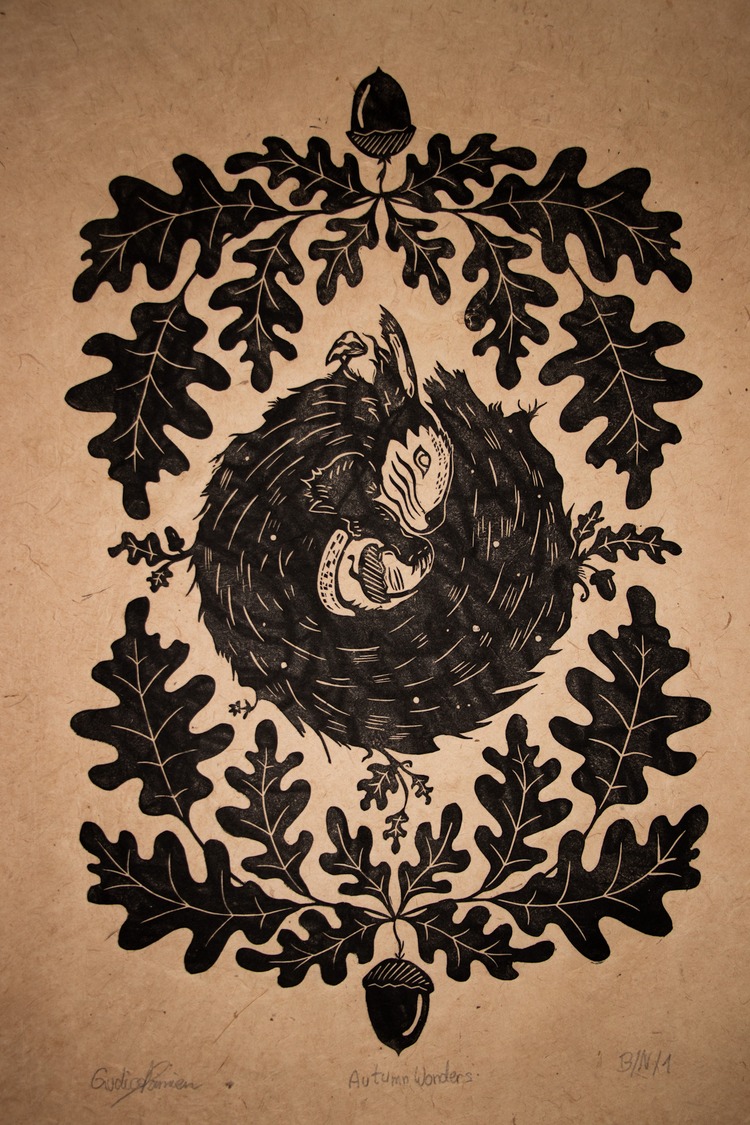

Damien Giudice | Autumn Wonders https://ift.tt/aQgifqc Autumn Wonders is the latest lino print release from Luxembourg-based printmaker and graphic designer Damien Giudice. The 50×40 artwork features a creature in the middle of two oak branches. Damien tells us; “Of course it is a squirrel, but others think they recognise a rabbit. What it is is still up to the viewer”.

Autumn Wonders was printed using a hand press onto natural paper to compliment the design. Thus, except for the pre-drawing, Damien works completely analogue.

Printing via People of Print https://ift.tt/FhYryEJ November 29, 2022 at 06:39AM

http://img.youtube.com/vi/aQbvfNwZBU8/0.jpg

3D Printing News Unpeeled: Warhammer, AVIC and Pearson Lloyd https://ift.tt/sibGD4R Today we look deeper in to Warhammer 40K and other table top games. Why is 3D printing being used for these games and why has it not spread? How come people haven’t created their own fantasy worlds with 3D printing? China’s AVIC brags about using 3D printing extensively in fighter aircraft. Person Lloyd and Bene make design objects using Material Extrusion with desktop 3D printers. The post 3D Printing News Unpeeled: Warhammer, AVIC and Pearson Lloyd appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/F8Phdaw November 28, 2022 at 10:01AM

https://ift.tt/8HRVKl5

Fire at Icon’s House 3D Printing HQ Highlights Need for Decentralized Supply Chains https://ift.tt/lb52odm Early in the morning on Black Friday, a fire started in the St. Elmo warehouse district in South, Austin, Texas. Those buildings were in a mixed-use, 200,000 square foot area of the district called The Yard, which serves as home to a wide range of different businesses: including the headquarters to additive construction (AC) startup, ICON. Although there were no reported injuries, the Austin Fire Department (AFD) has said that at least two buildings so far are “a total loss.” AFD is still investigating the cause of the fire.

Despite the severity of the blaze, representatives from the company anticipate that the incident will have little effect on ICON’s operations, which include the building of Wolf Ranch, a planned community of 100 homes that will be completed largely with AC techniques. In a tweet referencing the fire, posted later in the day on Friday (November 25), ICON’s co-founder and CEO, Jason Ballard, wrote, “Grateful no one was hurt. Thankfully the printer fleet is out in the field doing good work and teams were at home for the holiday.”

ICON’s signature technology is the Vulcan concrete printer, which is optimized for use with the company’s Lavacrete cementitious material. ICON has been one of the main beneficiaries of the growing interest in the AC market segment over the last several years, with the company most notably collaborating with the US military on multiple projects. The success of that collaboration has resulted in ICON’s attracting significant financing from investors, such as homebuilding giant Lennar, which is also an ICON partner on the Wolf Ranch development. While the fire was no doubt tragic for the businesses involved, it is certainly fortunate that no one was injured. Moreover, for ICON, specifically, the outcome could potentially even be positive for the startup’s reputation. As the update tweeted by ICON’s CEO reflects, the decentralized nature of distributed manufacturing (and construction) operations inherently lends itself to resilience. This is a particularly dramatic example of that, but the same thing that will allow ICON to withstand an unforeseen calamity like a fire, underscores the potential for companies to decentralize their business activities to defend against far more routine supply chain disruptions.

Additionally, to narrow the focus down to the AC space, the incident may have added a point to the pros column for on-site deployment of concrete printers, compared to prefabrication at a central site. The profit advantage of prefabricated homes is frequently touted as one of the strongest arguments in favor of using AC to address shortages in housing markets. At least in this case, however, ICON was clearly better off not having a warehouse full of prefabricated housing components. And, given that the technology is meant precisely to hedge against the risk of both man-made and natural disasters — like fires — this may reframe the narrative concerning the relative strengths/weaknesses of on-site construction and prefabrication. Regardless of the short-term profit motive, the trajectory of construction printing as both a technology and an industry may be best-served by making decentralization a strategic priority. Images courtesy of ICON The post Fire at Icon’s House 3D Printing HQ Highlights Need for Decentralized Supply Chains appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/F8Phdaw November 28, 2022 at 10:01AM

https://about.usps.com/newsroom/global/images/releases/holly-with-boxes.png

USPS Operation Santa Now Open for Letter Adoption https://ift.tt/x5hIRN0 WASHINGTON — Are you in a position to give a child or family some extra magic this season? If so, you can now adopt a letter written to Santa at USPSOperationSanta.com. Printing via USPS News https://ift.tt/ISwUEoC November 28, 2022 at 09:04AM

https://about.usps.com/newsroom/global/images/releases/holly-with-boxes.png

La Operación Santa de USPS ya está en marcha para el envío de cartas https://ift.tt/AaYZvou WASHINGTON — ¿Tiene la posibilidad de darle a un niño o a una familia un poco de magia extra esta temporada? De ser así, ahora puede adoptar una carta escrita a Santa en USPSOperationSanta.com. Printing via USPS News https://ift.tt/ISwUEoC November 28, 2022 at 09:04AM

https://www.youtube.com/embed/gLqgClozs_0

AMS Spotlight: Slurry Metal 3D Printing with MetShape https://ift.tt/GcQfLCB AM Ventures is the Networking Sponsor for the Bavarian Beer & Pretzels Networking Reception at the Additive Manufacturing Strategies, business summit February 7-9, 2023. In order to more deeply understand the investment landscape in 3D printing, we will be taking a deeper look at some of its startups. We’ll start with the portfolio of dedicated 3D printing venture capital firm AM Ventures, which has invested in Conflux, Dye Mansion, Headmade Materials and many other specialized firms. Most recently, AM Ventures raised a new fund worth €100 million specifically for 3D printing startups. Among AM Ventures’ portfolio companies is precision metal part service provider MetShape. We spoke to MetShape CEO Dr. Andreas Baum, as well as AM Ventures Senior Associate Alois Hotter, to learn how the company uses a unique metal 3D printing technology to produce small, smooth components at a low cost. Slurry Metal 3D Printing and MetShape’s BeginningsMetShape’s history is closely intertwined with that of another AM Venture portfolio firm, Lithoz. Lithoz’s ceramics digital light processing (DLP) was invented at TU Wien in 2006. In 2015, the University of Applied Science Pforzheim worked with Lithoz on porting its technology to metals as a research project dedicated to recycling magnets. Lithoz adapted its technique for metals while the university focused on the tricky debinding and sintering steps necessary for creating dense metal parts. The magnet recycling never panned out but the group did develop a process called lithography-based metal manufacturing (LMM) for the production of high-precision metal components with very smooth surfaces.  Image courtesy of MetShape. Image courtesy of MetShape.

Also referred to by myself as “slurry stereolithography (SLA)”, LMM is a process whereby a vat photopolymerization system prints a resin loaded with metal particles. The resulting green part is then debound and subsequently sintered. The resulting metal components are precise and, above all, quite smooth, including on internal features—a unique benefit. Once the item is dialed in, series can be made cost-effectively. In 2019, Lithoz spun out Incus3D to commercialize LMM systems, while MetShape was created as an LMM service provider, as well as an outsourcing partner for sintering and debinding for other processes. What Are the Advantages of LMM?During the vat polymerization step, DLP and SLA are typically used. This means that commercially available light engines, resins, and processing technologies can be incorporated into LMM. In the 4 cm3 to 0.1 cm3 range, LMM has particular advantages. Through the innovative LMM technology the spectrum of precise small and micro metal parts can finally be additively manufactured, which has not been possible before.  A 3D printed medical device component made by MetShape. Image courtesy of MetShape. A 3D printed medical device component made by MetShape. Image courtesy of MetShape.

In the future, we can expect advances in light engines, LED and other projection technologies as well as other machine configurations to accelerate LMM productivity and adoption. Furthermore, progress related to resins could lead to better productivity. Vat photopolymerization is relatively fast and low cost, as far as metal printing technologies are concerned. Handling costs could be reduced with automation going forward. Like many metal 3D printing technologies, the main hurdle is the sintering step. However, LMM may control for this better than other techniques. Powder bed fusion would be very troublesome and costly for small parts. Binder jet could make sense, but LMM is smoother and achieves greater detail. Some binder jet parts tend to collapse in the green state, as well. Automated post-processing procedures may achieve smooth surfaces, but in a more expensive manner.

Where LMM really shines is for very small items, or where smoothness is crucial. Slurry SLA processes also allow for the manufacturing of components with smooth internal cavities, holes, channels, and pin structures. For some internal geometries, the technology could be uniquely suited because residual resin can be rinsed from inside structures. This means that you do not have to tap or rely on processes such as abrasion flow machining to get smooth internal channels. For this reason, it could be the lowest-cost technology for making a complex component that is smaller than a cube with 2 cm on each edge. Think of heat exchangers, nozzles, and parts with cooling channels.  Image courtesy of MetShape. Image courtesy of MetShape.

This may seem like a limitation but it actually allows the company focus. The higher resolution also automatically ensures that if there is overlap the higher value part will mean that customers opt for LMM over binder jet. Furthermore, these kinds of small components are, by their very nature, often very high in value. The stronger green state could also help the firm deal with many more geometries than binder jetting. What’s more, green state collapse is not really predictable and could hinder productivity and the onboarding of customers. The Master of SinteringShrinkage is the bugbear of binder jet and all similar sinter-based technologies. Dr. Baum opined that, with LMM, “the shrinkage which occurs during the sintering process is very reproducible. Depending on the material, it is about 18%. Consequently, we add this proportion to the construction of the green part for our customers, providing a dimensionally precise finished part at the end of the whole production chain.” The ability to predict can be a real advantage in obtaining a first part quickly. Another advantage is that, during the print, no additional supports are required nor will their subsequent removal require additional costs. Smooth surfaces with up to Ra 2 μm roughness are achievable straight out of the printer, while 1 μm surfaces are doable with automated post-processing technologies, which are qualified by MetShape. AM Ventures Senior Associate Alois Hotter also highlighted the need to control the sintering process:

Dr Baum echoed AM Ventures regarding the unique advantage of the company’s core debinding and sintering knowledge. Especially with sintering, the team has made gains, allowing parts to be made without post processing.

Not only will this sintering expertise and control allow the firm to pick up business that others cannot, but it also will accelerate its sales cycles. MetShape can more quickly make and price a prototype and go into business with a customer, rather than incurring lag and costs to find out which clients are worthwhile. What Is the LMM Opportunity?

In the luxury and jewelry industry, MetShape has already made rings, charms, watch cases, and studs. There, quicker iterations and the ability to reduce waste will accelerate MetShape’s adoption even via some manual processes. Dr. Baum also envisions potential for individualized or custom pieces. In the medical field, Dr. Baum sees a large number of applications in medical production resources and tools as well as in surgical equipment and in the future also implants, where quality and patient-specific geometries are a good fit for MetShape. Thin walls along with low surface roughness could be key differentiators for the firm in that industry. He also disclosed that the company has already manufactured a wide range of medical devices such as surgical equipment and prototypes for implants. In small medical instruments, electronics, or small robotics components, LMM could be the cheapest technology, particularly if internal textures, channels, or structures are the driving force. There are billions of integrated circuits, complex assemblies, heat sinks, heat exchangers, electronics, luxury goods, and mechanical assemblies that could use LMM parts. Of these, many millions of SKUs could be 3D printed by LMM much more cost effectively than with other technologies.

MetShape is a service provider and scalable production partner for medical, aerospace, industrial, and electronics firms that do not want to operate the complex technology in-house, or want to start with buying parts before fully integrating the technology into their own value chain. .

There are few businesses with deep experience in debinding, sintering, and additive manufacturing. MetShape has quite the opportunity in selling its debinding and sintering services and know-how to binder jet and bound metal firms. Should another technology come along that revolutionizes making green state parts, MetShape’s knowledge will still be valuable to it. Dr. Baum also pointed out that the firm is a partner to help customers from their first part all the way to manufacturing, precisely the area where 3D printing has struggled over the years. In helping companies industrialize, MetShape can help itself and the industry accelerate by being a force multiplier for manufacturing using 3D printing. What Is MetShape’s Starting Position?One particular strength of MetShape is the founding team’s close relationship with Incus, Lithoz, the University of Pforzheim, TU Wien, and AM Ventures. All of these firms’ futures are bound around a technology that few understand and fewer are investing in. The Langer family, who are early AM Ventures investors and the owners of EOS, also own a part of Scanlab. This optics provider powers many SLA and galvanometer scanning systems. There is comparatively little research and applications work going on in LMM. But, the work being done at Fraunhofer IFAM is going on in tandem with Incus and company. MetShape, therefore, finds itself at the eye of the storm with a little understood but highly cost-effective fabrication technology and a network of relatively local fellow travelers surrounding it. Beyond that network, there is currently little wider regard for or investment in this technology. This sounds exactly like the initial days of powder bed fusion for metals, where a small group of people who were very close to one another were developing a technology. Back in the late 90s and early 2000s, this collective consisted of some Fraunhofers, Electrolux Finland, and a handful of companies. One of those companies would later be sold to Renishaw (MTT), another to DMG Mori (Realizer), another (SLM Solutions) to Nikon, another to GE (Concept) and another remains today the largest firm in 3D printing, EOS. Billions in acquisitions and revenue came from a small technology cluster in Europe consisting of maybe two dozen people initially. It seems to me a lot like the Langer family is trying to do this again. Once more with feeling. To me this kind of thing makes MetShape’s starting position uniquely strong. Where Are the Exits?As a logical extension of business, MetShape would be a great acquisition target for a metal injection molding (MIM) firm. MIM in itself is about a $3 billion industry that is viable for high volume but with high startup costs. The area around MIM with other precision micromachining and manufacturing technologies of small parts is much larger as well. MetShape is more agile and can be used more iteratively in this space, which could lead to its customers winning over traditional machining here as well as just MIM across many volumes. In very competitive markets, MetShape could hasten time to market and reduce costs. Also, there is no need to shift designs, production technologies and specifications from low volume to high volume, which should help the firm penetrate competitive markets. Industry-specific manufacturing firms in medical or industrial would also be well placed to buy it. In some cases, firms in luxury or semiconductors could decide to acquire it to gain an advantage over competitors. Some firms, for example, excel in some fine finishing processes and has patents in 3D printing watch cases. MetShape could also scale and become profitable as an independent firm. Prototek or Protolabs, as well as similar firms, could perhaps acquire it in time. A sizable micro machining industry may also find this a company close to their field of work. Contract manufacturing firms, especially in medical, may be interested, too. All in all, we can see that in smooth, small parts with high precision, MetShape could be the scalable manufacturing partner for industrial, medical, aerospace, and luxury goods firms. I think that its unique positioning, knowledge, and go-to-market could be great advantages in conquering markets that others will find hard to penetrate. The post AMS Spotlight: Slurry Metal 3D Printing with MetShape appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/F8Phdaw November 28, 2022 at 08:16AM

https://ift.tt/q07xfpR

NASA Awards TROPICS CubeSat Mission to Rocket Lab https://ift.tt/VOSkYgG

Spacecraft manufacturer Rocket Lab (Nasdaq: RKLB) has more big plans for the company as it expands its US presence. Known for its almost entirely 3D-printed engines, the rocket company has been selected by NASA to launch a new mission that targets the formation and evolution of tropical cyclones, including hurricanes.

According to the contract, sometime after May 1, 2023, Rocket Lab will launch four CubeSats in two low Earth orbital planes for the TROPICS mission, which stands for Time-Resolved Observations of Precipitation Structure and Storm Intensity. These two dedicated Federal Aviation Administration (FAA) licensed missions will blast off aboard Electron rockets from Launch Complex 2 within the Mid-Atlantic Regional Spaceport at NASA Wallops Flight Facility in Virginia.

Each CubeSat will host a high-performance radiometer scanning across the satellite track to provide temperature profiles, storm intensity, precipitation measurements, and cloud ice measurements. These data will help scientists better understand the processes affecting high-impact storms, ultimately leading to improved modeling and prediction. Even more so, one of the key objectives of the satellite constellation is to allow NASA to closely observe the 2023 Atlantic hurricane season, which begins on June 1. A rocky startThese four TROPICS satellites were initially slated to travel to LEO on a rocket from launch vehicle maker Astra. However, the first pair of CubeSats were destroyed on June 12, 2022, when the second stage of a Rocket 3.3 failed just before reaching orbit, leading to Astra’s decision to abandon the booster in favor of its larger Rocket 4. Following this failure, NASA announced last August it was seeking new launch vehicles to put the sats in orbit. Luckily, NASA had 12 other companies lined up to provide launch services through its Venture-Class Acquisition of Dedicated and Rideshare missions program. Competing against other powerhouses like ABL Space Systems, Relativity Space, Firefly, and Virgin Orbit, it is finally Rocket Lab that gets to deliver the last four TROPICS satellite to space.  An Electron rocket lifts off from the new Pad B at Launch Complex 1 in New Zealand. Image courtesy of Rocket Lab. An Electron rocket lifts off from the new Pad B at Launch Complex 1 in New Zealand. Image courtesy of Rocket Lab.

Although the contract award for the upcoming feat remains undisclosed, Astra was originally given a total value of $7.95 million for the TROPICS launch contract in February 2021. It is still unclear whether the modification to this existing launch services agreement will change the value of the contract. NASA’s new launcher designation is a huge vote of confidence move for Rocket Lab. The latest contract joins a growing list of upcoming Rocket Lab missions for NASA, including the launch services and spacecraft bus that will deliver the CAPSTONE satellite to the Moon, another subcontract to design two Photon spacecraft for a scientific mission destined for Mars, and the launch of the agency’s Advanced Composite Solar Sail System (ACS3) technology. Discussing details of the upcoming mission, Rocket Lab Founder and CEO Peter Beck said this year’s devastating effects of hurricanes and tropical storms proved how important improved climate data from space is to enable scientists and researchers to accurately predict storm strength and give people time to evacuate.

NASA selects Rocket Lab to launch the TROPICS mission. Image courtesy of Rocket Lab. NASA selects Rocket Lab to launch the TROPICS mission. Image courtesy of Rocket Lab.

The two dedicated TROPICS launches will take off aboard Rocket Lab’s Electron. The company has successfully leveraged 3D printing for part rocket part production. The Electron launch vehicle, in particular, is powered by Rocket Lab’s in-house designed and additively manufactured Rutherford engines. AM heritage for rocketsSince its first launch in 2017, Rocket Lab has released additional performance from Rocket Lab’s Rutherford engines boosting the Electron’s total payload lift capacity up to 300 kg/660 LBM. Rutherford is also the first oxygen/hydrocarbon engine to use additive manufacturing for all primary components, including the regeneratively cooled thrust chamber, injector pumps, and main propellant valves. Headquartered in Long Beach, California, Rocket Lab is a United States company that operates launch sites in Māhia, New Zealand, and Wallops Island. In addition, rocket Lab operates more than five acres of manufacturing facilities and test complexes. It employs advanced manufacturing techniques, including 3D printing, to enable the high-rate production of satellites and launch vehicles. Today, Rocket Lab is a $2.5 billion company publicly traded on Nasdaq. Although the company is waiting to achieve profitability once the work on its reusable Neutron rocket is complete, its revenue grew more than tenfold in the past year, and Beck’s firm delivered quarterly results that boasted record revenue. Company stock soared more than 20 percent in early November after reporting third-quarter revenue results in line with expectations. With this latest TROPICS constellation contract from NASA, Rocket Lab has a lot to look forward to in the next couple of months, including the launch of the first Electron rocket from the US in December. The post NASA Awards TROPICS CubeSat Mission to Rocket Lab appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/F8Phdaw November 28, 2022 at 08:16AM |

Categories

All

Archives

April 2023

|

The design started out as a drawing on a tablet which he then printed on lime paper. The whole thing was then transferred to the linoleum by hand with a pencil. Damien comments; “I love symmetry and cleanliness, it should not be too complicated. The only complicated part is the carving. What seems so simple takes hours to carve out so finely. Which is for me a very meditating part. Mistakes can happen, but they also happen in nature, so it doesn’t matter if one leaf looks slightly different from the other.”

The design started out as a drawing on a tablet which he then printed on lime paper. The whole thing was then transferred to the linoleum by hand with a pencil. Damien comments; “I love symmetry and cleanliness, it should not be too complicated. The only complicated part is the carving. What seems so simple takes hours to carve out so finely. Which is for me a very meditating part. Mistakes can happen, but they also happen in nature, so it doesn’t matter if one leaf looks slightly different from the other.” The printmaker concludes; “The togetherness of human and nature is especially important to me. We are currently living in an unpleasant time, but you should still keep your eyes open for the small wonders we still have left on our beautiful planet.”

The printmaker concludes; “The togetherness of human and nature is especially important to me. We are currently living in an unpleasant time, but you should still keep your eyes open for the small wonders we still have left on our beautiful planet.” RSS Feed

RSS Feed