|

https://ift.tt/0WOZgVT

The ultimate guide to email surveys: benefits, types, and best practices https://ift.tt/eIwjpXc Are you looking for a cost-effective and convenient way to gather data from your audience? Look no further than email surveys! With their ability to reach a broad range of participants, high response rates, and easy data analysis, email surveys have become a popular choice among researchers, marketers and businesses. In this article, we will explore the benefits and types of email surveys, strategies for increasing response rates and analyzing the results, and help you understand how to make the most out of this powerful tool to gather data. Table Of Contents Advantages of email surveysIn today’s quick-paced digital world, email surveys have grown in popularity as a means of data collection. They are appealing for organizations of all sizes because they provide a number of advantages over conventional survey methodologies. If you are wondering if you should use email surveys, consider the following benefits. Cost effectiveOne of the main benefits of email surveys is the fact that they hardly cost anything. There are a variety of free and low cost solutions available for creating your survey and sending it out to your audience is completely free.

ConvenientThe convenience that email surveys provide to respondents is another advantage. Instead of being required to be present at a given time or location to participate in a survey, respondents can complete the questionnaire whenever it is convenient for them. This generally results in more accurate results. EngagingComparing email surveys to other survey methodologies, they frequently have high response rates. This is in part because of how convenient they are and how many people they can reach. Email surveys increase the likelihood of reaching a representative sample because they may be distributed to a large number of potential participants in a short amount of time. Easy to interpretData analysis for email surveys is simple. It is possible to construct surveys so that data is automatically gathered and stored in a database, making it simple to evaluate and interpret the results. When compared to manual data entry and analysis, this can save a lot of time and effort.

Difference between audience and individual surveysSo far we’ve used the word survey as a blanket term for a method of collecting information from your audience. We can, however, differentiate between Audience Survey and Individual Survey based on the intent of our research. Audience surveysAudience surveys are email surveys designed to learn more about your audience’s needs and wants. By conducting audience surveys, you can gain valuable insights into what your customers want and need, which can be used to improve your products and services. The data collected can be used to identify areas for improvement, as well as to develop new products and services that better meet the needs of your target audience. Audience surveys can include questions like “What do you like in our products?” or “How do you think we could improve?”.

Individual surveysIndividual surveys are for learning more about individual users. This type of survey can be used to gather information about user demographics, preferences, and other important metrics, creating an individual profile of the respondent. The data collected can be used to segment users into different groups, and to target specific groups with personalized offers and communication. Individual surveys can include questions like “When is your birthday?”, “Where do you live?” or “What kind of resources are you interested in?”. Sometimes, there is overlap between these two categories. Asking your users to rate their satisfaction with your business helps you identify your individual promoters and detractors, while also giving you a general outlook on your business.

Email survey examplesIn the following, we are going to show you a few examples for email surveys and how they can be used in your business. Post-purchase surveyPost-purchase email surveys are a useful tool for companies trying to get customer feedback. Customers typically receive these surveys after making a purchase, and they can offer insightful information on the customer’s experience with the product or service. One of the major benefits of a post-purchase email survey is that it lets you get valuable feedback from your customers while their experience is still fresh. This can give you insightful information about what they liked and disliked about their purchases, as well as help identify areas where you need to improve.

Net Promoter Score (NPS) surveyNPS is a widely used customer satisfaction metric that measures how likely a customer is to recommend a product or service to others. NPS surveys typically ask customers a single question: “On a scale of 0-10, how likely are you to recommend our product/service to a friend or colleague?” The responses are then grouped into three categories: promoters (9-10), passives (7-8), and detractors (0-6). The NPS is calculated by subtracting the percentage of detractors from the percentage of promoters.

Research email surveyTo use email surveys for research, first, create a list of questions that will be asked in the survey. These questions should be specific, clear, and relevant to the research topic. Next, design the survey using a survey software or through a google form. Make sure that the survey is easy to understand and navigate, with clear instructions and a logical flow. After the survey is distributed, you can track responses and analyze the data collected. The data can be used to draw conclusions and make recommendations based on the research findings.

Survey embedded in newsletterIf you regularly send out a newsletter to your customers, you can enhance it further with relevant surveys. You can ask your recipients how useful or relevant the newsletter is to them or suggest different topics to include in your next newsletter. In the short survey example below, the email service provider tracks the clicks of the user and assigns a tag to them, indicating their preferences. This data can be used later to send relevant offers and more personalized email communications.

Email survey for lead enrichmentEmail surveys can be a powerful tool for lead enrichment, as they allow you to gather valuable information about your potential customers. By sending out a survey to a list of leads, you can learn more about their needs, interests, and pain points, which can help you tailor your sales and marketing efforts to better meet those needs. These surveys can also help you identify leads who are in the early stages of the buying process and nurture them until they are ready to purchase.

Email survey quizSending quizzes to users is a great way to engage them and encourage interaction with your brand or product. Quizzes can be used to entertain, educate, or collect valuable information about your users. You can use quizzes to send tailored offers to them. You can also share the results of the quiz with the users, and even allow them to share their results on social media.

Best practices for creating email surveysCreating an effective email survey requires careful planning and attention to detail. By following best practices, you can increase the response rate and ensure that your survey is both effective and efficient. Design clear and concise questionsQuestions should be easy to understand and should not be overly complex or technical. It is important to avoid using jargon or technical terms that may be unfamiliar to participants. Keep things short and sweetDon’t ask unnecessary questions or questions you already know the answer to. The fewer fields are in the survey, the higher your completion rate will be. If you can’t avoid asking many questions, include a progress bar and try to use drop-down or multiple choice selections instead of free-form text answers wherever possible. Pick the right timeTo ensure that people participate in your survey, it is important to choose the right timing for the invitation. The best time to send a survey can vary depending on the type of survey and the goals of the research. For example, surveys that measure customer satisfaction (CSAT) and customer effort (CES) are typically most effective when sent immediately after customers have interacted with your business. On the other hand, surveys like the Net Promoter Score survey may be sent via email up to a month after a customer has completed a purchase.

Use an appropriate survey structureSurveys should be well-organized and easy to navigate. This can be achieved by using a logical flow of questions, consistent formatting, and clear instructions. By incorporating skip logic, participants can skip irrelevant questions and answer only the questions that are relevant to them. Incorporate personalization and brandingPersonalization can increase the response rate by making the survey email feel more relevant and targeted to the participant. Branding the survey page with your logo or colors can also increase the response rate by making the survey appear more professional and trustworthy. Offer something in returnWhen you ask your customers to participate in a survey, you’re asking them to spend their time and effort, so that you could gain valuable insights. It’s only fair to offer something in return. If you’re conducting a particularly in-depth survey, gift cards are great to show that you value the time of the respondents. Don’t want to go this route? Then consider discounts, samples, gifts, upgrades, or even exclusive content.

Choose the right survey softwareThere are many email survey software options available, and it’s essential to choose one that is easy to use and has the features needed for the specific research objectives. The software should also be able to handle the data analysis, so it’s important to choose one that is compatible with your data analysis needs. Test and pilot the surveyBefore sending the survey to the participants, it’s important to test the survey with a small group of people to identify and fix any issues. This will ensure that the survey is working properly and that the data collected is accurate. Conducting email surveys with GetResponseIn this segment, we are going to show you three different ways of sending out email surveys with GetResponse and enriching customer data with the survey responses.

Editor’s note

In November 2022, the Survey feature of GetResponse was discontinued. however, you can still create surveys with third party tools, integrating them with GetResponse. Google Forms is a powerful tool that allows users to create surveys and gather data quickly and easily. The platform is user-friendly and offers a wide range of customization options, making it a popular choice among researchers, marketers, and business owners. Google Forms also offers a range of customization options, including the ability to add a cover page, change the theme, and add images and videos. Once your survey is complete, you can distribute it by sharing the link in email.

f you want to enrich your subscriber information with the survey answers, you will need to include an email address form in your field. Once your campaign has run its course, you can export your results to a spreadsheet. Log in to your GetResponse account, then navigate to Contacts, and select Custom fields. Here, you can create new custom fields for the survey answers. Let’s assume that in your survey you asked your subscribers about their favorite football team. Now, you can create a new custom field labeled favourite_team. When that’s done, it’s time to import the survey results and update your customer information with their answers. Click on Add contacts, select file upload, then select the “Only update existing” option under the ‘What should we do with contact information?’ question.

In the next step, match the survey answers with their corresponding custom fields. Import your list and wait for the import to finish. Don’t forget to check if the newly added custom values are visible on your subscribers’ profiles. Jotform ($0-$99/month)JotForm is an online form builder that allows users to create, publish, and manage forms for various purposes such as surveys, questionnaires, and contact forms. It offers a drag-and-drop interface and a wide variety of customizable templates and widgets, making it easy for users to create professional-looking forms without any coding knowledge. Jotform integrates with GetResponse and the integration process is simple and straightforward. First, in the Form Builder, click on the Settings tab. Then, go to the Integrations panel. Search for GetResponse and click on it. Next, enter your GetResponse API Key, and click the Authenticate button. After that, choose a list and match your form fields.

GetResponse loads all the fields from your GetResponse forms. If you want to map another field, click on the Add New Field button. It’s important to note that the field mapping will only work if their subscribers provide their email addresses in your survey.

Survicate is another great email survey software. They offer a variety of customizable templates, and with their GetResponse integration, they automatically capture respondents’ details from GetResponse contact lists. This means that if you are sending your Survicate survey with GetResponse, your subscribers don’t have to provide their contact information in the survey, instead, Survicate will match the submitted surveys with your subscribers. For this to work, you need to create a Survicate account and design a survey. After that, select the Configure menu option and select GetResponse from the dropdown menu. Publish your survey and distribute it in email to your subscribers; Survicate will take care of the rest.

Another great feature of Survicate is their embedded email survey solution. This means that you can embed surveys into your GetResponse emails without coding skills. If you want to automatically enrich your subscriber data with the survey responses, you can use a multi-step Zapier automation. After designing the survey, click on the Connect menu option and select Zapier from the list. Then, follow the integration steps. Head over to Zapier and create a Zap that updates a contact when they answer a question in your survey.

Now, it’s time to update the user. Under “Choose Account” > User, select the email address from the first step of your zap. Here, you can pick the fields to update upon your survey submission, add a tag to your user or update your existing fields with the survey response. If you don’t want to update some fields, simply leave them empty.

In conclusionConducting an email survey can be a valuable tool for gathering customer feedback and understanding their needs. By following the guidelines outlined in this article, such as crafting clear and concise questions, keeping the survey short and to the point, and providing incentives for participation, you can ensure that your email survey is effective in collecting valuable data. Additionally, by analyzing the results and using them to inform your business decisions, you can improve customer satisfaction and drive growth for your company. How do you use surveys in your business? Let us know in the comments! And if you learned something new from this article, sign up for our newsletter to be the first to receive our educational resources. No fluff, only quality content. Printing via GetResponse Blog https://ift.tt/OoSwcZd January 31, 2023 at 02:43PM

0 Comments

https://ift.tt/gyLvHSK

Rail Giant Alstom Turns to Nexa3D’s NXE 400Pro to 3D Print Replacement Footrests https://ift.tt/FM47wn1 Trains are vital to transportation all over the world, but as they get older, it becomes increasingly difficult to keep them in service. Finding replacement parts is often a key factor, and this usually boils down to the components being discontinued for various reasons. Without a way to install high-quality replacement parts railways risk delaying the transportation of people and goods, and ultimately their bottom line. Alstom, one of the largest railway companies in the world, faced this first hand when outdated footrests threatened to sideline many of its fleets. The company needed a way to fix its trains quickly, and do so in a cost effective manner. Alstom’s solution? 3D printing. The business sought Lorenzo Gasparoni, its 3D printing and 3D scanning product leader in Italy, to establish additive manufacturing (AM) practices to help keep its aging trains operational while reducing the time needed to service the carriages.

An Alstom AGV Train. (Source: Nexa3D) Alstom is no stranger to 3D printing and had previously partnered with BASF Replique and Stratasys to use AM to solve sourcing issues in the past. This time, however, it wanted to stay internal to its manufacturing and service center in Sesto San Giovanni, Italy, and needed Lorenzo Gasparoni for the job. The two have been in working together since 2019, but, in mid-2022, a new project arose: the use of 3D printing to produce hundreds of footrests to replace older counterparts. Lorenzo got to work and iterated through many materials and printing methods to narrow down the best option for this task. While his team did explore selective laser sintering, the company ultimately landed on vat photopolymerization and even examined materials from Carbon, EnvisiontEC, and 3D Systems. In the end, Alstom chose Nexa3D and the NXE 400Pro because of its open platform, large build volumes, fast printing speeds, and monocomponent resins.

An Alstom employee designing the 3D printed footrests. (Source: Nexa3D)

With the NXE 400Pro, Lorenzo saves €150 per part and can produce 30 footrests in 10 hours with Henkel Loctite’s xABS3843 resin. The resin is comparable to the original footrest material— Lexan— and the new 3D printed footrests require no post-processing before installation. So far, 100 replacement footrests have been installed into Alstom’s rail cars, and, with this new system, more can be printed on demand as needed.

A 3D printed footrest installed on an Alstom train. (Source Nexa3D) Alstom highlights what 3D printing can bring to the table for railway manufacturing, and continues the trend of railways partnering with companies like Siemens, DiManEx, and Wabtec to incorporate additive manufacturing into its production process. This trend is on pace to grow as 3D printing matures, and if Alstom can continue to produce excellent parts at low quantities and low prices, then it could become the most affordable way to maintain older trains. The post Rail Giant Alstom Turns to Nexa3D’s NXE 400Pro to 3D Print Replacement Footrests appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/WMhqstX January 31, 2023 at 11:44AM

https://ift.tt/RFPIU7b

3D Printing Archipelago: Islands of In-company 3D Printing Bureaus https://ift.tt/VaJEPeS In essence, I believe that the 3D printing industry is turning into Indonesia. Rather than have a market that is ostensibly globalized or local in nature, the sector will have very segmented markets, each in competing within themselves. If you look at the first article in this series, you can see that the theory is that we have gone through four stages of growth. a local stage with local firms operating locally; a ¨globalized¨ stage, where a few companies act globally and regionally; a continental stage, whereby regional, national, and technology-specific power bases predominate; and, finally, an archipelago 3D printing industry, which we are now transitioning into. In other words, we are shifting not to a single, global market, but rather very specific sets of materials, services, market conditions, verticals, and offerings. I think that this has deep implications for the sector’s mutual competitiveness and the direction each business should be taking. Overall, I believe that, in order to properly understand market dynamics, competitiveness, and where the segment should play, we should not consider the additive manufacturing (AM) segment as one true 3D printing industry. We are not one world. We are an archipelago of islands. Split One: Commoditization in Powder Bed FusionOne example of this is in powder bed fusion (PBF), where I believe that we shall see a split in the market between, on the one hand, the most powerful and capable systems for defense, aerospace, new space, and other high-end markets and, on the other hand, a commoditization of quotidian systems at each quality level. It will be possible to buy any number of metal PBF systems at similar price points that could be used for jewelry and other products of similar quality levels. This idea is laid out in more detail in this article. Such a trend will mean that market for metal PBF will, in fact, become a commodity market that competes on different quality level on one island, while on another island, a different market will be vying to make the newest combustion chamber components at unheard of sizes. If you’re looking for a $300,000 quad-laser machine with a build volume of 250 mm by 250 mm by 330 mm, you’re unlikely to also shop on the same island as a $5 million system with 12 lasers. Split Two: High Service vs High AutonomyHigh ServiceIf you imagine running the prototyping or 3D printing department for a large corporate, like Hyundai New Horizons Studio or D.Ford, what would your needs be? What keeps you up at night? Uptime, ease-of-use, and high degrees of service are your worries. For that one deadline, you absolutely need that part to be there. So, you would demand or enjoy excess capacity in your supplier network for prototype and limited production items. You would like your in-house machines to be easy to operate. Ideally, you’d have an iron clad service agreement or be able to get machines replaced quickly. Consumables costs don’t really matter to you. You know you’re getting ripped off on materials, but that isn’t important because the component cost is nothing when compared to delays before the executive suite or in multi-million dollar projects. You wouldn’t mind a closed architecture or many restrictions on what materials you can use, as long as the machine works. The software or experience could be completely proprietary or stand alone. Part handling and labor cost are okay, as long as key personnel don’t suffer interruptions or they have to fix machines. That wouldn’t work. To me, a corporate 3D printing department would evolve into a high-service customer. You wouldn’t mind paying a monthly service fee if everything just worked. You wouldn’t care about understanding the machine. You want to click to print. You wouldn’t want to learn about designing for 3D printing, ideally, the real world parts would be spit out automagically, looking identical to the ones you’d use in molding or other processes. High AutonomyMeanwhile, imagine that you’re Bosch, ZF, Sony, or Ford that has to perform short-run production, mass-customization or actual mass production with 3D printers. You’d care a lot about consumables costs. If two equal printers perform about the same, but the materials for one are much higher, then you’d go for the one that has the lowest total cost of ownership (TCO) at adequate yield. If one had an open architecture that wouldn’t lock you in, you’d opt for that so that it provides you with redundancy. You’d want software to work with enterprise resource planning (ERP) and lots of other software you operate. You’d want your machines to work autonomously. You’d balk at high service prices and would want to service your own machines by yourself as much as possible. Ideally, you wouldn’t need anyone to come tell you anything. You’d like a lot of training initially, but then to never have to call the original equipment manufacturer (OEM) again. You’d love to have a deep understanding of design for 3D printing in order to optimize the parts you’d be printing. You’d be very interested in quality assurance, automation, and lowering part cost. The Now is Not Indicative of the FutureIn the recent past, a Formlabs printer, Ultimaker S5, HP multi jet fusion system, or EOS P110 would be the ideal machine for both the High Service and High Autonomy customers. However, going forward, the needs of these parties will diverge. At the same time, lower cost entrants will be good enough for a lot of lower cost manufacturing. Also finishing processes, part handling solutions, and software will make up more of the cost and cost reduction picture. As machines become more specific, on one side, we will see a further divergence between high service customers who want a lot of uptime, a lot of help, and don’t mind costs. On the other side, will be high autonomy customers who prefer a thorough understanding of (and access to) their machines, software, materials, and processes in order to produce at low-cost, high-yield objects at the right quality level. In some cases, the same machine or software would make sense for both but we would expect specifically designed solutions for one market segment to significantly outperform depending on the prevailing metric for that segment. So, a material extrusion manufacturer would ideally want a large Prusa i3 with all of the electronics in the bottom and easy part ejection with a 20kg spool that is completely customizable for them. Of course, there will still be commonalities between these two markets. For example, same day replacement of machines will be an exciting prospect for both the cash strapped manufacturer and the design center of a major corporate. ConclusionTherefore, some possibilities to offer singular products to the whole market will be tantalizing. But, as a general rule, we’d expect a balkanization of the systems, materials, markets, machines and service offerings, as everything more perfectly conforms to the very specific values of very specific markets. We will not be one market, but an archipelago. Images by: Lau Svensson, Dmitry Teslya, Егор Журавлёв, The post 3D Printing Archipelago: Islands of In-company 3D Printing Bureaus appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/WMhqstX January 31, 2023 at 11:44AM

https://ift.tt/A1rgvqc

C3Nano Launches “First” Low-Temperature Conductive Ink for Electronics 3D Printing https://ift.tt/prtKkae C3Nano, a Silicon Valley-based additive manufacturing (AM) materials company that specializes in conductive inks, announced the release of SuperGrid: a material that is pitched as “the first low-temperature curing,” flexible conductive ink for AM applications. As with conductive inks generally, SuperGrid is designed for use in electronics printing. SuperGrid is a follow-up to C3Nano’s Activegrid LT conductive inks, which the company announced in Q4 of 2022. SuperGrid builds on the low-temperature curing advantage of the Activegrid series by dropping the curing temperature even further, to 25°C (about 77°F), while also improving flexibility. The latter consideration has become increasingly important in the AM materials market, the more that companies across the sector turn their focus towards printed electronics.

C3Nano anticipates that SuperGrid will have its biggest impact in the markets for semiconductor packaging and shielding for radio frequency (RF) components. In addition, owing to its transparency, flexibility, and relatively lower cost compared to other conductive inks, the company also expects that SuperGrid will attract interest from producers of the ever-expanding quantity of end-use goods that require screens. Conductive inks exemplify one of the macro supply trends that, in general, best accounts for the recent acceleration of interest and progress in 3D printed electronics: the disappearance of boundaries between consumer electronics and all other manufacturing sectors. For instance, this same dynamic can be gleaned in the investment by Lockheed Martin Ventures in AM materials supplier Fortify, at the end of 2022. Even in the heaviest industrial sectors like aerospace manufacturing, the demand for small-scale, flexible electronics is becoming the nucleus for supply chain management strategy. Thus, the ability to fast-cure conductive inks at room temperature is a selling point perfectly matched for the use of the materials on a greater scale. Moreover, growth in the demand for conductive inks should only accelerate further, as the entire global industrial landscape continues to transition towards an energy security footing. The potential to use printed electronics in a wide range of sensors and control panels should be indispensable to the electrification of the power grid. Even more excitingly, the possibility for mass 3D printing of solar cells with conductive inks could lead be integral to the next generation of solar power. Images courtesy of C3Nano The post C3Nano Launches “First” Low-Temperature Conductive Ink for Electronics 3D Printing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/WMhqstX January 31, 2023 at 11:44AM

https://ift.tt/qD05fUt

AME-3D Taps AMFG Automation Software to Strengthen 3D Printing & Vacuum Casting https://ift.tt/uvbKoCN According to SmarTech Analysis in its “Opportunities in Additive Manufacturing Software Markets 2023” report, this market is expected to grow faster than previous projections showed, as it’s “evolving at a pace now consistent with the printer segment of the last two years.” The top trend behind the growth is connecting main elements of the AM software workflow into end-to-end platforms. London-based startup AMFG develops manufacturing execution systems (MES) and workflow automation software to help additive manufacturing companies streamline and manage their production workflows. Now the company has announced a new partnership with fellow UK company AME-3D in order to shore up both its AM and vacuum casting production. AME-3D has been a top product development, design, and prototyping business for over two decades, and will use AMFG’s MES and workflow automation software in order to reinforce its main production operations. AME-3D offers several 3D printing services, including SLS and SLA technologies for low volume production and rapid prototyping, and recently purchased three additional 3D printers. Besides additive, the company also has expertise in RIM and vacuum casting for production. By implementing AMFG’s solutions, it will be able to further scale up production on a more secure foundation.

AME-3D’s SLS 3D printing AME-3D’s SLS 3D printing

AME-3D works with a variety of clients, from large enterprises down to small startups, and works to adapt the services it offers to each client’s use-case. Over the last two years, the company has received some sizable financial investments, which allowed it to begin a period of development and plan for expansion. As a way to grow and scale its manufacturing processes, AME-3D determined that MES and workflow software would be a logical investment. The company was looking to increase efficiency by decreasing manual input to make its quotation speed faster, thus enabling employees to speed up their quotation throughput and manage higher RFQ volumes. Looking for software that coordinated with its own goals for improved operation, AME-3D found AMFG.

AMFG’s order management software AMFG’s order management software

Using AMFG’s quotation automation feature in its software, AME-3D reported decreased labor time, as well as more control over the quality of its order quotations. In addition, AME-3D’s customers enjoyed the use of AMFG’s digital catalog functionality, which gave them the freedom to order from a list of preconfigured CAD files. This not only lowered the need for client input, but also made for a much simpler purchasing journey. Now that the partnership between the two is official, AME-3D has been working with AMFG on software implementation, so that it can accelerate its continuing growth. The two collaborated on an intensive process of studying AME-3D’s business framework, so that AMFG’s software can be configured to increase the benefits and fit AME-3D’s needs; the company has already noticed some operational improvements. In addition to SLS and SLA 3D printing, AME-3D has also incorporated its vacuum casting capability into its solution from AMFG in order to scale this manufacturing method smoothly as well. If you want to talk more about software in the 3D printing sector, join us at Additive Manufacturing Strategies, taking place in New York City from February 7-9, 2023. Register for your ticket to attend here. The post AME-3D Taps AMFG Automation Software to Strengthen 3D Printing & Vacuum Casting appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/WMhqstX January 31, 2023 at 11:44AM

https://ift.tt/1Iq8XFv

Special Presentation: Future investment in AM – AMS Speaker Spotlight https://ift.tt/G6U3Llp Where is the investment side of the market heading in 2023? Rising interest rates, inflation, geopolitical uncertainty – these indicators do not look promising for emerging companies that need to raise capital, sell their products to cash-strapped companies or explore an exit. However, despite economic turbulences and the current monetary policy tightening, we remain optimistic as a VC in additive manufacturing (AM). Here are our thoughts on why there are plenty of opportunities for AM startups. As the AM market continues to grow, there is no going back from adopting AM as a means of creating end-use applications. Whereas it is true that publicly-traded AM companies have not performed up to expectations fed by big promises, the fact that funding was largely unaffected in 2022 is significant and therefore a very good sign. Investors remained bullish about opportunities in the private 3D printing space. VC investments grew from $1.8 billion in 2021 to an all-time high of $2.1 billion in 2022. The average annual growth rate for startup investments has been 62% since 2013. The recent decline in valuations will spark the appetite of 3D printing incumbents for new acquisitions to drive their inorganic growth as they keep looking to deliver on their promises. The macroeconomic turmoil of the past few quarters can lead to fantastic M&A opportunities as well as good opportunities for VC firms with large amounts of dry powder left to allocate. Funds are available to provide further support to the most innovative AM startups that are solving major problems in legacy manufacturing. We firmly believe that startups with a working business model, a strong leadership team and a compelling offering will still raise capital, even though valuations will be different than what have seen in previous years. What the new “story” will be remains to be seen, but widespread valuations readjustments are to be expected. The value of an emerging company has so far been expressed by a multiple of its sales. Given the shift away from the “growth at all costs” attitude in the startup landscape, we expect that valuations will increasingly be geared towards profitability. VC firms will become highly selective, looking for deals that generate cash rather than consume it. Companies that raised money pre-crisis at sky-high valuations will face difficulties in finding additional funding. In contrast, we anticipate that it might be “easier” for newly-established companies to raise capital. The most encouraging sign is that more than half of our deal flow last year was based on startups in the business of developing applications. This is a promising indicator since these startups are the justification for our industry’s existence. Whether heat exchangers, components of electric motors, antennas or membranes for filtration needs, the trend in 3D printing is clear: AM is being adopted by more and more industrial verticals. This shift has been visible on AM Ventures’ tech radar for about two years now: most of the identified startups are application-based. We are convinced that industrial 3D printing is one of the beneficiaries amid the economic downturn and political tectonic shifts. There is a lot of pressure on companies to digitize their processes, tools and supply chains. Manufacturing cannot go digital without the help of AM technologies. We are convinced that there are many startups out there that are going to push AM to the next level: to evolve from a stabilized technology that does one thing right once, to ensuring that it does exactly this many million times and with every single new system built over generations of machines. This should provide promising funding opportunities in 2023. Arno Held, Managing Partner at AM Ventures, will be participating at the Additive Manufacturing Strategies 2023 Business and Networking Summit, which takes place in New York City February 7 – 9, 2023. Arno will be participating in the Special Presentation: Future Investment in AM, taking place on February 9. AM Ventures is sponsoring the Networking Reception: Bavarian Beer & Pretzels on February 7. Register for AMS 2023 here. The post Special Presentation: Future investment in AM – AMS Speaker Spotlight appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/WMhqstX January 31, 2023 at 11:44AM

https://ift.tt/oUepFRA

Quality Control at Scale with In Situ Quality Assurance – AMS Speaker Spotlight https://ift.tt/LNTb3R0 The future of laser-based metal additive manufacturing is looking brighter than ever. The last few years have seen a substantial increase in production rates due to the increase in laser count, improved gas flow, and improved control systems. With the drive towards serial production and resulting increased speed and throughput, the compromise is often component quality. This makes quality control the last and most critical unresolved issue for the additive manufacturing industry. In situ monitoring offers an obvious solution to this problem. Melt pool monitoring is a particularly powerful tool that can ensure the quality and consistency of parts. By tracking the melt pool emission signatures, anomalies and faults can be detected. It is one of the few inspection technologies that can scale with production demand, making it an essential component of AM production at scale.  Fig 1. Example of melt pool imaging data from the AMiRIS NIR Imaging sensor. Fig 1. Example of melt pool imaging data from the AMiRIS NIR Imaging sensor.

In-situ monitoring can take many forms; keeping an eye on various parameters of the AM process, such as temperature, powder distribution, and consolidation properties. This information, coupled with intelligent analytics, can identify issues before they result in defects in the final product. Identifying faults in the process can help to reduce the number of defective parts produced and increase the overall operating efficiency of the manufacturing process. While in situ monitoring is an obvious solution to the quality assurance (QA) problem, what is non-obvious is the need to have a common form of QA across all production parts. Many machine vendors offer their proprietary monitoring solutions with varying capabilities depending on the approach and sensors used. Operators using L-PBF systems from different vendors will end up with non-compatible QA systems and with data that is not easily comparable. Curating non-comparable QA increases cost and in many cases is not acceptable for safety-critical parts. Additive Assurance has built the AMiRIS quality assurance suite to solve exactly this; provide uniform real-time quality assurance across all machines. The unique sensor package captures melt pool emissions from an off-axis vantage point at a very high resolution in the near-infrared (NIR) spectra. By utilising NIR wavelengths, the sensor has the unique capability of identifying melt pool anomalies through the process chamber window, without the need to modify the machine. Crucially, no machine requalification is required after installation. The sensor package feeds the captured melt pool data to a central server (cloud or on-premise) where a ML model has been trained to detect a range of process faults, including: lack of fusion, overmelting, spatter frequency, laser errors and more. Additive Assurance is working to enable the next generation of metal AM users, by reducing the entry barriers, making production quality simple, and reducing the workload on operators and quality managers. The AMiRIS cloud based platform has been, and continues to be, developed in collaboration with leading AM providers to do exactly this.  Fig 2. AMiRIS Sensor mounted to a Renishaw AM400 Fig 2. AMiRIS Sensor mounted to a Renishaw AM400

While process monitoring is a powerful tool for capturing faults and anomalies, it has previously been seen as a burden on operators to inspect and understand. Any effective QA system using in situ monitoring must have a high degree of automation in order for the technology to work at scale. Automation is a core philosophy behind the design of AMiRIS. Every part of the workflow has been automated, from initial calibration and detection of individual anomalies, to the final go/no-go part checks. For additive manufacturing operators at scale, in situ monitoring across a fleet of machines can provide a common form of quality control, which helps to ensure consistent AM quality and reduce the chances of defects, regardless of the machine brand/vendor. When automated, in situ process monitoring enables the production of quality assured parts at scale.  Fig 3. A screenshot of the AMiRIS platform for data visualisation Fig 3. A screenshot of the AMiRIS platform for data visualisation

In situ process monitoring is a powerful tool for solving the quality issues of AM, and has the flow on effects of reducing failures and increasing productivity. As the AM industry continues to evolve, in situ monitoring will become increasingly important for manufacturers at scale, providing a unified way to access, monitor and control the quality of the parts produced. Additive Assurance is participating at Additive Manufacturing Strategies, taking place in New York City from February 7-9, 2023. Marten Jurg, CEO and Co-Founder of Additive Assurance, will be taking part in Session 3, Panel 1: AM in the Auto Industry on February 8. Register for your ticket to attend here. The post Quality Control at Scale with In Situ Quality Assurance – AMS Speaker Spotlight appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/WMhqstX January 31, 2023 at 11:44AM

https://ift.tt/qEIi3ZS

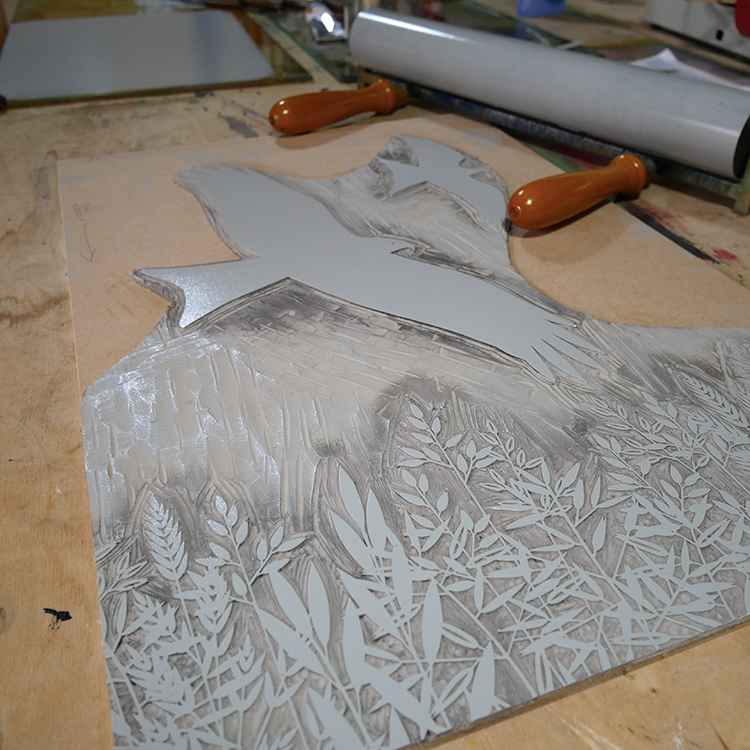

Ash Leaf Printmaking https://ift.tt/DAgQEr9 Ashley Hutchinson, the printmaker and designer behind Ash Leaf Printmaking, creates limited edition lino reduction prints as well as specialising in hand embossed paper. He studied illustration at Brighton University, where he focused on printmaking. Ashely continued with this specialism and now produces limited edition lino and wood cut prints with a twist; incorporating embossing into all of his designs, which gives them a unique look and feel. All of the prints are embossed by hand using his three etching presses. As a designer, Ashley is inspired by nature and the patterns within it, combining this with bold, graphic designs.

www.ashleafprintmaking.co.uk Printing via People of Print https://ift.tt/3Ztezb9 January 31, 2023 at 06:22AM

https://ift.tt/0WOZgVT

The ultimate guide to email surveys: benefits, types, and best practices https://ift.tt/Z0qUgo9 Are you looking for a cost-effective and convenient way to gather data from your audience? Look no further than email surveys! With their ability to reach a broad range of participants, high response rates, and easy data analysis, email surveys have become a popular choice among researchers, marketers and businesses. In this article, we will explore the benefits and types of email surveys, strategies for increasing response rates and analyzing the results, and help you understand how to make the most out of this powerful tool to gather data. Table Of Contents Advantages of email surveysIn today’s quick-paced digital world, email surveys have grown in popularity as a means of data collection. They are appealing for organizations of all sizes because they provide a number of advantages over conventional survey methodologies. If you are wondering if you should use email surveys, consider the following benefits. Cost effectiveOne of the main benefits of email surveys is the fact that they hardly cost anything. There are a variety of free and low cost solutions available for creating your survey and sending it out to your audience is completely free.

ConvenientThe convenience that email surveys provide to respondents is another advantage. Instead of being required to be present at a given time or location to participate in a survey, respondents can complete the questionnaire whenever it is convenient for them. This generally results in more accurate results. EngagingComparing email surveys to other survey methodologies, they frequently have high response rates. This is in part because of how convenient they are and how many people they can reach. Email surveys increase the likelihood of reaching a representative sample because they may be distributed to a large number of potential participants in a short amount of time. Easy to interpretData analysis for email surveys is simple. It is possible to construct surveys so that data is automatically gathered and stored in a database, making it simple to evaluate and interpret the results. When compared to manual data entry and analysis, this can save a lot of time and effort.

Difference between audience and individual surveysSo far we’ve used the word survey as a blanket term for a method of collecting information from your audience. We can, however, differentiate between Audience Survey and Individual Survey based on the intent of our research. Audience surveysAudience surveys are email surveys designed to learn more about your audience’s needs and wants. By conducting audience surveys, you can gain valuable insights into what your customers want and need, which can be used to improve your products and services. The data collected can be used to identify areas for improvement, as well as to develop new products and services that better meet the needs of your target audience. Audience surveys can include questions like “What do you like in our products?” or “How do you think we could improve?”.

Individual surveysIndividual surveys are for learning more about individual users. This type of survey can be used to gather information about user demographics, preferences, and other important metrics, creating an individual profile of the respondent. The data collected can be used to segment users into different groups, and to target specific groups with personalized offers and communication. Individual surveys can include questions like “When is your birthday?”, “Where do you live?” or “What kind of resources are you interested in?”. Sometimes, there is overlap between these two categories. Asking your users to rate their satisfaction with your business helps you identify your individual promoters and detractors, while also giving you a general outlook on your business.

Email survey examplesIn the following, we are going to show you a few examples for email surveys and how they can be used in your business. Post-purchase surveyPost-purchase email surveys are a useful tool for companies trying to get customer feedback. Customers typically receive these surveys after making a purchase, and they can offer insightful information on the customer’s experience with the product or service. One of the major benefits of a post-purchase email survey is that it lets you get valuable feedback from your customers while their experience is still fresh. This can give you insightful information about what they liked and disliked about their purchases, as well as help identify areas where you need to improve.

Net Promoter Score (NPS) surveyNPS is a widely used customer satisfaction metric that measures how likely a customer is to recommend a product or service to others. NPS surveys typically ask customers a single question: “On a scale of 0-10, how likely are you to recommend our product/service to a friend or colleague?” The responses are then grouped into three categories: promoters (9-10), passives (7-8), and detractors (0-6). The NPS is calculated by subtracting the percentage of detractors from the percentage of promoters.

Research email surveyTo use email surveys for research, first, create a list of questions that will be asked in the survey. These questions should be specific, clear, and relevant to the research topic. Next, design the survey using a survey software or through a google form. Make sure that the survey is easy to understand and navigate, with clear instructions and a logical flow. After the survey is distributed, you can track responses and analyze the data collected. The data can be used to draw conclusions and make recommendations based on the research findings.

Survey embedded in newsletterIf you regularly send out a newsletter to your customers, you can enhance it further with relevant surveys. You can ask your recipients how useful or relevant the newsletter is to them or suggest different topics to include in your next newsletter. In the short survey example below, the email service provider tracks the clicks of the user and assigns a tag to them, indicating their preferences. This data can be used later to send relevant offers and more personalized email communications.

Email survey for lead enrichmentEmail surveys can be a powerful tool for lead enrichment, as they allow you to gather valuable information about your potential customers. By sending out a survey to a list of leads, you can learn more about their needs, interests, and pain points, which can help you tailor your sales and marketing efforts to better meet those needs. These surveys can also help you identify leads who are in the early stages of the buying process and nurture them until they are ready to purchase.

Email survey quizSending quizzes to users is a great way to engage them and encourage interaction with your brand or product. Quizzes can be used to entertain, educate, or collect valuable information about your users. You can use quizzes to send tailored offers to them. You can also share the results of the quiz with the users, and even allow them to share their results on social media.

Best practices for creating email surveysCreating an effective email survey requires careful planning and attention to detail. By following best practices, you can increase the response rate and ensure that your survey is both effective and efficient. Design clear and concise questionsQuestions should be easy to understand and should not be overly complex or technical. It is important to avoid using jargon or technical terms that may be unfamiliar to participants. Keep things short and sweetDon’t ask unnecessary questions or questions you already know the answer to. The fewer fields are in the survey, the higher your completion rate will be. If you can’t avoid asking many questions, include a progress bar and try to use drop-down or multiple choice selections instead of free-form text answers wherever possible. Pick the right timeTo ensure that people participate in your survey, it is important to choose the right timing for the invitation. The best time to send a survey can vary depending on the type of survey and the goals of the research. For example, surveys that measure customer satisfaction (CSAT) and customer effort (CES) are typically most effective when sent immediately after customers have interacted with your business. On the other hand, surveys like the Net Promoter Score survey may be sent via email up to a month after a customer has completed a purchase.

Use an appropriate survey structureSurveys should be well-organized and easy to navigate. This can be achieved by using a logical flow of questions, consistent formatting, and clear instructions. By incorporating skip logic, participants can skip irrelevant questions and answer only the questions that are relevant to them. Incorporate personalization and brandingPersonalization can increase the response rate by making the survey email feel more relevant and targeted to the participant. Branding the survey page with your logo or colors can also increase the response rate by making the survey appear more professional and trustworthy. Offer something in returnWhen you ask your customers to participate in a survey, you’re asking them to spend their time and effort, so that you could gain valuable insights. It’s only fair to offer something in return. If you’re conducting a particularly in-depth survey, gift cards are great to show that you value the time of the respondents. Don’t want to go this route? Then consider discounts, samples, gifts, upgrades, or even exclusive content.

Choose the right survey softwareThere are many email survey software options available, and it’s essential to choose one that is easy to use and has the features needed for the specific research objectives. The software should also be able to handle the data analysis, so it’s important to choose one that is compatible with your data analysis needs. Test and pilot the surveyBefore sending the survey to the participants, it’s important to test the survey with a small group of people to identify and fix any issues. This will ensure that the survey is working properly and that the data collected is accurate. Conducting email surveys with GetResponseIn this segment, we are going to show you three different ways of sending out email surveys with GetResponse and enriching customer data with the survey responses.

Editor’s note

In November 2022, the Survey feature of GetResponse was discontinued. however, you can still create surveys with third party tools, integrating them with GetResponse. Google Forms is a powerful tool that allows users to create surveys and gather data quickly and easily. The platform is user-friendly and offers a wide range of customization options, making it a popular choice among researchers, marketers, and business owners. Google Forms also offers a range of customization options, including the ability to add a cover page, change the theme, and add images and videos. Once your survey is complete, you can distribute it by sharing the link in email.

f you want to enrich your subscriber information with the survey answers, you will need to include an email address form in your field. Once your campaign has run its course, you can export your results to a spreadsheet. Log in to your GetResponse account, then navigate to Contacts, and select Custom fields. Here, you can create new custom fields for the survey answers. Let’s assume that in your survey you asked your subscribers about their favorite football team. Now, you can create a new custom field labeled favourite_team. When that’s done, it’s time to import the survey results and update your customer information with their answers. Click on Add contacts, select file upload, then select the “Only update existing” option under the ‘What should we do with contact information?’ question.

In the next step, match the survey answers with their corresponding custom fields. Import your list and wait for the import to finish. Don’t forget to check if the newly added custom values are visible on your subscribers’ profiles. Jotform ($0-$99/month)JotForm is an online form builder that allows users to create, publish, and manage forms for various purposes such as surveys, questionnaires, and contact forms. It offers a drag-and-drop interface and a wide variety of customizable templates and widgets, making it easy for users to create professional-looking forms without any coding knowledge. Jotform integrates with GetResponse and the integration process is simple and straightforward. First, in the Form Builder, click on the Settings tab. Then, go to the Integrations panel. Search for GetResponse and click on it. Next, enter your GetResponse API Key, and click the Authenticate button. After that, choose a list and match your form fields.

GetResponse loads all the fields from your GetResponse forms. If you want to map another field, click on the Add New Field button. It’s important to note that the field mapping will only work if their subscribers provide their email addresses in your survey.

Survicate is another great email survey software. They offer a variety of customizable templates, and with their GetResponse integration, they automatically capture respondents’ details from GetResponse contact lists. This means that if you are sending your Survicate survey with GetResponse, your subscribers don’t have to provide their contact information in the survey, instead, Survicate will match the submitted surveys with your subscribers. For this to work, you need to create a Survicate account and design a survey. After that, select the Configure menu option and select GetResponse from the dropdown menu. Publish your survey and distribute it in email to your subscribers; Survicate will take care of the rest.

Another great feature of Survicate is their embedded email survey solution. This means that you can embed surveys into your GetResponse emails without coding skills. If you want to automatically enrich your subscriber data with the survey responses, you can use a multi-step Zapier automation. After designing the survey, click on the Connect menu option and select Zapier from the list. Then, follow the integration steps. Head over to Zapier and create a Zap that updates a contact when they answer a question in your survey.

Now, it’s time to update the user. Under “Choose Account” > User, select the email address from the first step of your zap. Here, you can pick the fields to update upon your survey submission, add a tag to your user or update your existing fields with the survey response. If you don’t want to update some fields, simply leave them empty.

In conclusionConducting an email survey can be a valuable tool for gathering customer feedback and understanding their needs. By following the guidelines outlined in this article, such as crafting clear and concise questions, keeping the survey short and to the point, and providing incentives for participation, you can ensure that your email survey is effective in collecting valuable data. Additionally, by analyzing the results and using them to inform your business decisions, you can improve customer satisfaction and drive growth for your company. How do you use surveys in your business? Let us know in the comments! And if you learned something new from this article, sign up for our newsletter to be the first to receive our educational resources. No fluff, only quality content. Printing via GetResponse Blog https://ift.tt/OoSwcZd January 31, 2023 at 06:16AM

https://ift.tt/Z6NeQ8f

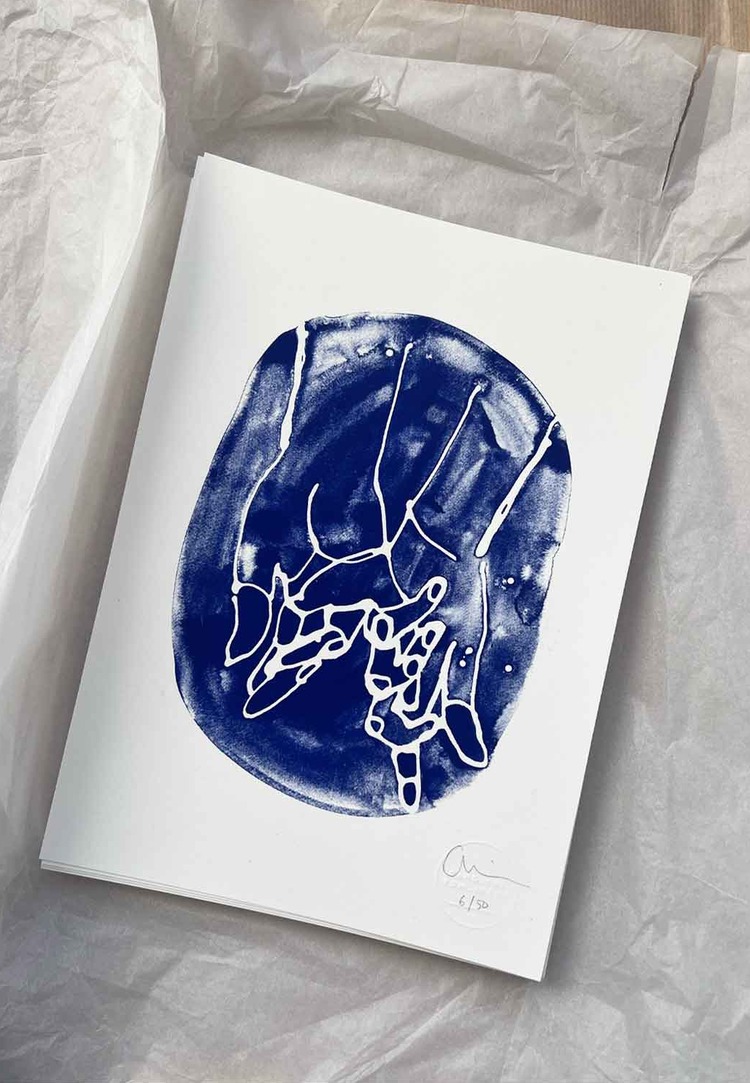

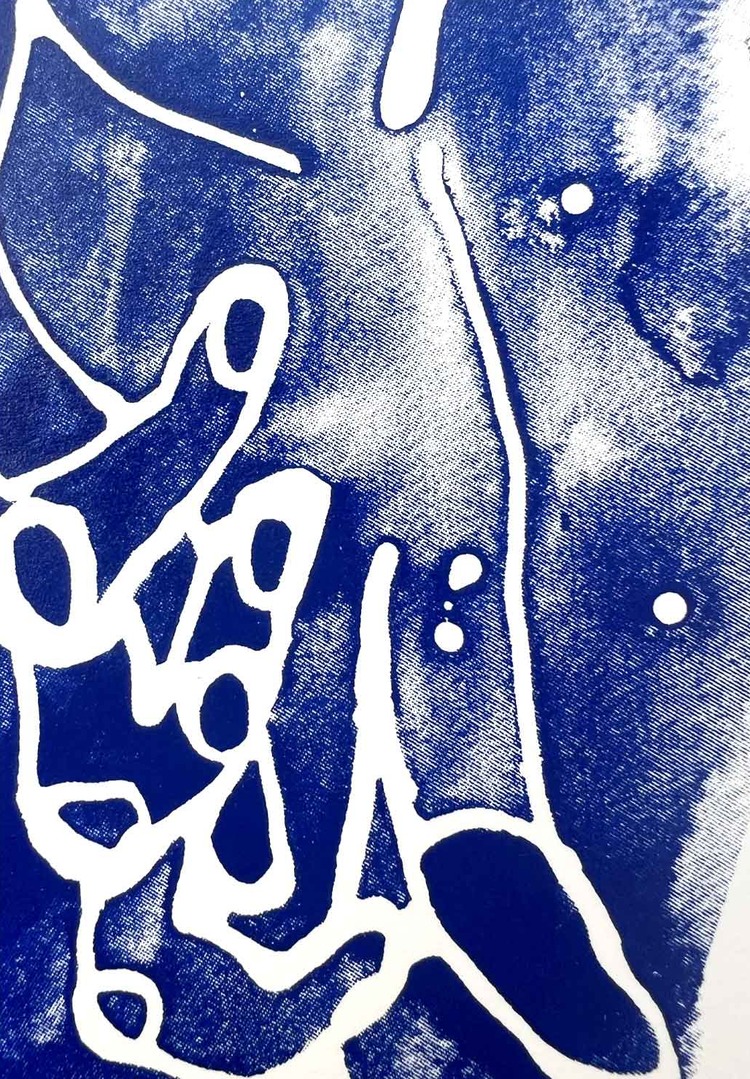

Caroline Tomlinson | Together https://ift.tt/04wvHSX The latest release from London-base illustrator and artist, Caroline Tomlinson, is Together; an edition of 50, single colour A4 silkscreens in celebration of love. After years of travel to seek out inspiration and adventures, the sense of belonging has become Caroline’s new inspiration. Rather than looking to new destinations for answers, the standing still and pausing actually revealed what is truly important in life, and what she had been longing for and hoping to find on her travels.

www.carolinetomlinson.com Printing via People of Print https://ift.tt/3Ztezb9 January 31, 2023 at 05:13AM |

Categories

All

Archives

April 2023

|

For the last fifteen years he has been a supplier in the greetings cards industry, operating under the company name Linoking Cards. These bright, contemporary designs are individually hand embossed and printed on recycled paper and papers from sustainable sources. In the past Ashley has supplied to the likes of RHS, Eden Project, National Trust, and V&A.

For the last fifteen years he has been a supplier in the greetings cards industry, operating under the company name Linoking Cards. These bright, contemporary designs are individually hand embossed and printed on recycled paper and papers from sustainable sources. In the past Ashley has supplied to the likes of RHS, Eden Project, National Trust, and V&A.

In 2016, he renamed the company to coincide with the building of his new studio. Built under an ash tree in the heart of Sussex, he designed and built the studio himself which has helped suit the exacting needs of his work. Ashley now spends most of his time printing, making letterpress prints, screen printed tea towels, as well as hand embossed paper products, such as greeting cards and calendars.

In 2016, he renamed the company to coincide with the building of his new studio. Built under an ash tree in the heart of Sussex, he designed and built the studio himself which has helped suit the exacting needs of his work. Ashley now spends most of his time printing, making letterpress prints, screen printed tea towels, as well as hand embossed paper products, such as greeting cards and calendars. His latest piece, Red Kites Over the South Downs, is a six colour reduction lino print finished with hand embossing.

His latest piece, Red Kites Over the South Downs, is a six colour reduction lino print finished with hand embossing.

“Pieces of life coming together. People coming together. The true sense of finding your very own place in a world. It is a human need, an instinct which we all crave. To belong. To somewhere or someone. And the stories gathered along the way, everything it took to reach that destination have become a focus of my latest work.”

“Pieces of life coming together. People coming together. The true sense of finding your very own place in a world. It is a human need, an instinct which we all crave. To belong. To somewhere or someone. And the stories gathered along the way, everything it took to reach that destination have become a focus of my latest work.”

Alongside this concept Caroline has also continually been exploring and experimenting with new mark making processes, print techniques, and motifs to develop a visual language. This want to capture the thoughts, places, and emotions that lead her to where she belongs today has kickstarted a new phase within her practice.

Alongside this concept Caroline has also continually been exploring and experimenting with new mark making processes, print techniques, and motifs to develop a visual language. This want to capture the thoughts, places, and emotions that lead her to where she belongs today has kickstarted a new phase within her practice. RSS Feed

RSS Feed