|

Penn State Creates a Breakthrough 3D Printing Technology for the NASA Housing Challenge http://bit.ly/2IaLIJ6 In 2017, just a few months before his death, theoretical physicist Stephen Hawking said humanity only has about 100 years to escape Earth. Even though we have seen the signs alerting us that life on this planet is ailing, with plastic conquering the oceans, thousands of animal species becoming extinct and a shortage of water that affects every continent, the conversion towards a fully sustainable lifestyle that could revert the feeble state of our home is just not happening. So, many are actually paying attention and heeding Hawkins advice, trying to look for other “celestial bodies”, to conquer. One of the first to announce they were looking for volunteers to travel to the red planet was Mars One back in 2013, with over 200,000 people from 140 countries applying for a one-way ticket to join a human settlement on Mars by 2023. Millions of dollars later, Mars One went bankrupt showing us all how challenging developing the technology for Mars would be. Happily, they are not the only ones, four years ago, NASA outlined a plan to land humans on the surface of Mars by 2030, and world-renowned investor Elon Musk already has a timeline for colonizing Mars. The race is on to develop the technology, space shuttles, and medicine that will take the first settlers. One key challenge is housing of course, which is why NASA hosted the 3D printing habitat challenge, a four-part massive event that began in 2015 and created a competition among citizen inventors to use readily available and recyclable materials to print habitats useful for Mars colonization. Additionally, these discoveries in science and technology can also be adapted to improve life on Earth. During the final phase, runner up team Pennsylvania State University of University Park, was awarded $200,000 for their work. The interdisciplinary team of students and faculty from the Colleges of Arts and Architecture, Engineering, Agricultural Sciences, and the Materials Research Institute, have worked arduously during the last few years on this challenge and in the process, they engineered a breakthrough that moves forward 3D printing construction research and pushes the team closer to the goal of creating sustainable housing on Earth. VIDEO The four-phase competition requires entrants to develop advanced 3D printing technology, including the mechanical elements of the printer and a cement mixture using indigenous materials, to produce a structurally sound habitat that can be 3D printed by NASA’s space explorers on Mars. During the final phase, which took place on the first week of May, and after 30 hours of 3D printing, with nearly 200 spectators gathered at Caterpillar Edwards Demonstration and Learning Center in Peoria, two teams competed side by side, PennStateDen@Mars (the only university team in the competition) and AI SpaceFactory, culminating with the final print of each team’s structure. And although the Penn State team didn’t win phase-three of the competition, they returned to University Park having developed 3D printed home construction technology that could impact construction or help rebuild areas ravaged by natural disasters.

NASA’s encounter has generated many experiments, challenges and innovative results, helping 3D technology advance into uncharted territory, and Mars or any other planet humans intend to inhabit in the future will be a difficult endeavour. Mars is a rocky planet with volcanoes, canyons, limited access to water and a very thin atmosphere made of carbon dioxide, nitrogen, and argon. It’s similar to Earth in some ways, but you might need to suit up before wandering around the terrain, let alone try to build your own home. According to NASA it’s a tough place to live, but thanks to the knowledge and understanding gained through these competitions, we might get a little bit closer to conducting live printing experiments on site. Associate professor of architecture and fellow team leader, Shadi Nazarian, also believes that the technology could be life-changing for many people:

The Penn State team, led by Duarte and Nazarian, was originally selected to take part of the competition from an initial entry pool of 77 teams. PennStateDen@Mars was one of only five teams who qualified to participate in the Centennial Challenge. In both phases of the contest, the participants had to 3D print structural habitat pieces in no more than four days, that were evaluated and then crush-tested on site, using some of Caterpillar’s most overwhelming construction machines. During the event, the team faced the challenge of creating robots to build the habitat. The team was very successful, finishing in second place in phase two and second and third place in construction levels one and two of phase three of the competition, generating nearly $300,000 in prize money. The PennStateDen@Mars entry to the competition was based on previous research aimed at developing functionally graded materials and verifying the possibility of designing and constructing seamless buildings, which can have a significant impact on architectural language and building processes. They further developed additive-manufacturing technology to 3D print habitats using a specially formulated concrete made from materials that can be found on Mars. But Penn State being selected for this challenge has also a lot to do with their experience and innovation in 3D printing. They have many 3D printing labs on campus, like the Maker Commons, which houses a large-scale printing installation of 32 desktop 3D printers as well as the Invention Studio; university researchers delved into 4D Printing with Wood Composites for architectural applications, while a Penn State startup, Trimatis LLC, hopes to help the planet with recycled filament and the university also created VenturePointe, a new startup incubator for urban campus Penn State Shenango, complete with 3D printers. Both Nazarian and Duarte have been doing research with materials and 3D printing in the past, resulting in the development of innovative and graded material interfaces, which would enable the design of seamless shelters and impermeable bonds between glass and geopolymer concrete to protect individuals and the climate inside the habitat.

VIDEO Team members focused their efforts in developing a novel concrete formulation, advancing 3D printing processes, and designing the overall 3D printing system necessary to print large structures. According to Penn State, the production of the geopolymer binder used in the formulation of the concrete designed by the team does not emit carbon dioxide into the atmosphere, unlike the production of the most common types of cement. Last year, assistant professor of civil engineering at Penn State, Alexandra Radlinska, along with NASA launched an experiment, the Microgravity Investigation of Cement Solidification – Multi-use Variable-gravity Platform (MICS-MVP), to examine cement samples aboard the International Space Station, which could have significant benefits for humans living on Earth and, eventually, the moon and Mars. Processing the samples provided with the fundamental baseline and insight regarding cement solidification in extraterrestrial bodies such as Mars. The 3D Printed Habitat Challenge will resume next year and PennStateDen@Mars team is ready to advance the additive construction technology needed to create sustainable housing. In the meantime, they are looking to showcase their breakthrough in 3D printing for housing on campus, where a 3D printed tiny house could be constructed, which, according to the university, will be a fully sustainable building and offer a glimpse into the future of home construction. Additive Manufacturing is being used widely to develop sustainable housing options. With countries like Singapore busy at work 3D printing public housing, as well as INNOPrint 3D, a French 3D printer that (unrealistically) claims it can print emergency housing in 30 minutes, looking to print homes for the first settlers to colonize Mars seems like the right direction for the technology. Many innovators, companies and governments are passionate about life on other planets, and Mars has qualities that experts consider similar to Earth, with challenges picking up the pace of 3D printing technologies used in construction, it might not be long before 3D printers are being shipped to Mars for some of the first construction experiences in outer space. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com May 31, 2019 at 10:48AM

0 Comments

U.S. Postal Service Honors Artist Ellsworth Kelly with Stamps http://bit.ly/2HO2Rt2 SPENCERTOWN, NY — Ellsworth Kelly forged a distinctive style of abstraction over his seven decades as an artist and today he was commemorated with 10 U.S. Postal Service stamps highlighting his work. Printing via USPS News http://bit.ly/2hH9aDC May 31, 2019 at 10:40AM

http://bit.ly/2Wy7yzf

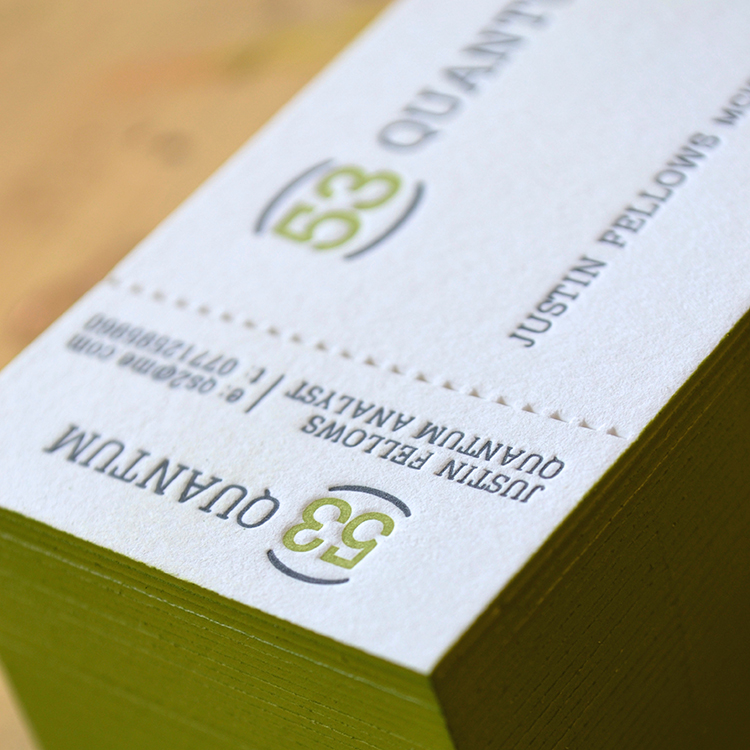

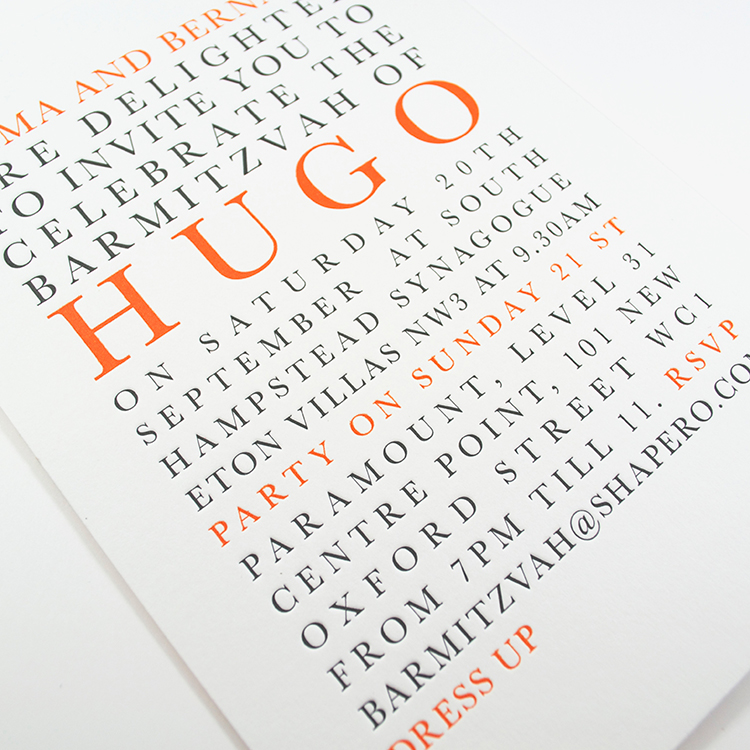

Letterpress Design http://bit.ly/2Kp0sqD Letterpress Design was set up as a commercial enterprise in 2008 by Lisa Paice. Lisa originally studied for a BSc in Typography at Exeter School of Art and Design in 1996, where her love of letterpress took hold. Whilst at university Lisa met her future husband, Ross Jones, who now works with her creating beautiful things for clients all over the world.

Deciding to throw caution to the wind Letterpress Design was born in 2008. Surviving the recession at the time, they have gone from strength to strength with the acquisition five years ago of Lyme Bay Press – suppliers of all things letterpress to the letterpress print community.

“For now, the pressroom smells of rubber based ink, the coffee has been made and the sun is coming up over Wootton Creek, letterpress feels like this every day.” You can learn more about becoming an official People of Print member here.

Printing via People of Print http://bit.ly/2DhgcW7 May 31, 2019 at 10:26AM Interview with Justin Finesilver of the 3D Printing Store http://bit.ly/2Z2PLOy

Justin Finesilver is the owner of the 3D Printing Store in Denver, Colorado. They are a 3D printing service bureau that helps various organizations and individuals with their 3D printing needs in Denver. From the consumer toy, to even the highly private aerospace solution, the 3D Printing Store has your needs covered. Justin helps to manage the day to day retail aspect of the store, as well as the social media marketing of the organization. Give us some background when it comes to education and life experiences that have gotten you to this point?

What was the first thing you 3D Printed?

What are your thoughts on the maker movement?

A contest entry in the store’s Additive For Coloradans competition. What are the coolest products you’ve seen in Colorado?

What industry you think could benefit the most?

VIDEO What are your thoughts on the industry in five years?

Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com May 31, 2019 at 09:57AM Topology Optimization in a World of Fields and Implicit Geometry http://bit.ly/2Mjydft Topology optimization is an important tool within the “generative design” toolbox that can be used as a component of a larger engineering and product design workflow. Let’s explore how topology optimization exists, in fact thrives, within a framework that utilizes field data, implicit geometry, and block architecture. Topology Optimization and Generative Design Let’s start by clarifying some terms often seen in the industry, most notably “generative design” and how it is viewed with respect to topology optimization. A brief internet search of the two terms yields mixed results and in general it seems fair to use them interchangeably. However, after converging on more precise definitions, it becomes clear that some people do just want traditional topology optimization, while others are envisioning a more “generative” technique. Topology optimization has been known for decades and is becoming more practical thanks in part to advances in computational technology and additive manufacturing. The approach is typically formulated as a conventional optimization problem, where an algorithm is used to minimize some chosen objective function subject to several constraints. For example, minimizing the weight of a structural bracket subject to constraints including stress, deflection, or overhang angles in the case of additive manufacturing. Topology optimization problems that are quite complex can be formulated, where they involve multi-objective, multiphysics applications with millions or even billions of design variables2. Whatever the scale and complexity, the optimization process is conceptually operating in a continuous design space and converging on a global optimum while satisfying the known constraints. What is Generative Design? Generative design is the larger computational process and workflow built by an engineer for their specific product and application, of which topology optimization is simply one function that can be called upon. What in part makes a design platform “generative” is the way its connected workflows can be used to explore the design space, perhaps cycling through different materials, manufacturing processes, functional requirements, or even the most basic assumptions built into the process by the engineer. Whether this happens using simple parameter sweeps or more advanced design-of-experiments, for each iteration the process has generated a new design. We could stop there, but an observation worth noting is that these fully connected processes essentially generate data, and that is the key ingredient to even more advanced algorithms that are now emerging. The Details of Topology Optimization Considering topology optimization as a “function call” and a subset of generative design, let’s explore some topology optimization possibilities within an advanced software platform. The examples in this discussion were generated using the Solid Isotropic Material with Penalization (SIMP) method implemented within nTop Platform for a basic compliance minimization problem. For each element in the design space, the optimizer will attempt to find a density value that minimizes compliance (i.e., maximizes stiffness) while satisfying a simple volume constraint. The simple structural bracket example shown in Figure 1 highlights a few key concepts of the optimization process and results. First, a discretized domain is provided as the design space, materials are defined, and boundary conditions are applied much like any other finite-element model setup. In this example a volume fraction of 30% was applied, meaning the volume of the optimal design must be less than or equal to 30% of the original.

Figure 1: Structural bracket design space and raw topology optimization result. Interpolation of Data Fields Interpreting the results of density-based topology optimization is where most software applications begin to divert from each other. Interpolation schemes, such as SIMP, are used to convert the element densities into continuous design variables better suited for optimization algorithms. The result is the element densities can range from 0 (no material) to 1 (solid material) but also vary in between. This is shown in Figure 1 where the red regions correspond to the highest density and then the values gradually decrease towards zero density (elements not shown), with intermediate results blending between the two. While a rough representation of the optimal material distribution starts to appear, one implication of these interpolations schemes is that there is no definitive boundary in the result and the user is usually left to pick a threshold value between 0 and 1. At this point, most software will extract an isosurface at the selected threshold value to form a rough approximation of a boundary which can be used as inspiration for final geometry reconstruction. Before we get to geometry construction, note that the most basic result of the density-based optimization process is a spatially varying set of scalar values, a density “field.” Figure 2 shows a planar section cut through the original design space which has been filled with an isotruss lattice structure. Here, the density field from the topology optimization is used to directly drive the thickness of the lattice, resulting in thicker lattices in the regions of higher density. This example demonstrates the fundamental idea that topology optimization results, as fields, are naturally represented in this kind of platform and can be used like any other in the software. While this is a very simple demonstration with an isotropic material model, it is the key technique underlying some soon-to-come physics-based cellular material design capabilities.

Figure 2: Original design space shelled and filled with a lattice structure using the density field of the topology optimization (shown transparent) to drive thickness. While the usual goal of topology optimization is to ultimately find some optimal shape, the raw result is typically some inspirational representation and not a definitive geometry ready for verification or manufacturing. It’s at this point an engineer must usually intervene to manually reconstruct a geometric shape—which can be a major bottleneck in the workflow. While there do exist some powerful tools to do this manually, the lack of an automated and traceable process will likely not keep pace with the rapid and iterative nature of modern engineering workflows. Geometry Reconstruction The geometry reconstruction problem is addressed by leveraging implicit-modeling technology. With only a few inputs, an implicit geometric representation can be derived straight from a topology optimization result. The results of the simple structural bracket example are shown in Figure 3.

Figure 3: Automated smoothing process (middle) is immediately usable for additional modeling operations (right). Until recently, manual reconstruction of geometry after topology optimization has generally been viewed as a major impediment but, using implicit technology, a smooth geometry is generated in seconds and can immediately be used in downstream modeling, simulation, and manufacturing functions. This smoothing capability provides an integrated, continuous, and automated topology-optimization pipeline. An Evolving Landscape Whether you’re new to topology optimization or an experienced veteran, you’ve most likely noticed that the technology is moving at a rapid pace. Start-ups have been built around the technology and larger simulation providers are showing renewed interest. My company is actively engaged with a number of research institutions studying the topic and is amazed by the number of novel techniques being developed. While such continuous change may pose a challenge, in contrast, block architecture provides an extensible and robust API that can evolve with improving technology. Much like blocks can represent geometry functions, they are also used to construct optimization problems within an extensible framework, allowing engineers to configure the software for the key aspects of their product and workflow.

Figure 4. Automated smoothing (left), subsequent FE analysis (middle), and contour slices for manufacturing (right). As previously stated, a common goal of topology optimization is to find an optimal shape that is nearly ready for verification and manufacturing. Rather, the raw result from this method is best viewed as an inspirational representation, or one of many acceptable solutions. Either way, there are still data interpretation and geometry construction challenges not easily addressed through conventional techniques. However, when data is represented as a density field, this can drive geometric parameters, including lattice thickness, in a robust way. In addition, geometry reconstruction is no longer a bottleneck because of implicit-modeling technology. These two characteristics in particular allow for a more flexible, automated way to utilizing topology optimization as a viable solution for product design. Trevor Laughlin is the Director, Product Management of nTopology Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com May 31, 2019 at 08:06AM

http://bit.ly/2QDYwvd

How to Design Facebook Ads in GetResponse http://bit.ly/2MgalZV Want to generate more sales revenue with your landing pages and marketing funnels? Then look no further – read this post and start driving more quality traffic to your site with Facebook ad campaigns. Not sure if it’s the right thing for your business or maybe you’re worried that it’ll be difficult? Don’t be! In about 15 minutes, you’ll be ready to launch your first Facebook ad campaign through GetResponse. Yes, you read it correctly. Once you connect your Facebook Page to your GetResponse account, you won’t even need to switch between different dashboards to reach your audience on social media. It’s all been built into your GetResponse account. But other than providing you with a step by step guide on how to do this, I’m also sharing some best practices and tips on how to run your social media ad campaigns effectively. This way, your Facebook ad campaigns won’t strain your marketing budget, and you’ll feel more confident about managing your customer acquisition costs. So let’s get started, shall we?

Step 0. Accessing the Facebook Ads in your GetResponse accountTo access the Facebook Ads creator in your GetResponse account, all you have to do is click on the Menu icon on the left side of the navigational bar and then select Facebook Ads.

When you click on it for the first time, you’ll be taken directly to the Facebook Ads creator screen where you can adjust all the components of your ad. It’ll look like this:

Let’s move on to the next step and start setting up your campaign.

Step 1. Giving your campaign a nameThe first thing you should do when creating a new ad campaign is to give it a good name. Although it will only be visible in your account dashboard (your audience won’t see it), it’s important to choose an appropriate name that’ll help you quickly identify the following elements:

If you name it well, you’ll be able to understand and filter your reports more efficiently. Here some examples of ad campaign names we would use if we wanted to promote our Chocolate Monster shop to specific audiences in Poland and the US:

Step 2. Selecting the ad placementNow, you’ll have to select where your ad will be presented. To do that, select your Facebook Page or connect a new one if you haven’t done it before.

Once you’ve selected the page, it’s time to pick whether you’d like your ad to be presented on the News Feed of your Facebook Page or the Facebook Audience Network. If you’re unsure what Facebook Audience Network is, here’s how they describe it in their Ads Help Center:

Before you choose any of these methods, ask yourself this question: Who am I targeting? Are these people on one of those platforms? And if they are, how likely is it that I’ll interest them with my content? In some cases, you’ll be better off if you skip the Facebook Audience Network and only target those who are on Facebook. Other times, Facebook on its own won’t give you the level of exposure you’re looking for. Whatever you do, make sure to test your hypothesis using only a part of your budget. Once you’ve got the data, you can make a well-grounded decision and invest a bit more money in your ads knowing that they’ll drive you more leads.

Step 3. Pick your audienceIt’s time to select the people you want to target with your social media ad campaign. There are four main options you can choose from:

Here are short descriptions of all of these targeting options and how you can use them.

Existing contactsLet’s say you want to run a Facebook ad campaign to reach some of your email subscribers. For example, those who haven’t recently engaged with your email campaigns, so that you can reengage them, or those who have previously downloaded one of your ebooks because you’ve got a new product that they might be interested in. You can reach them by using the existing contacts targeting option, which lets you direct ads to one of your email lists or segments.

This is a powerful way to reach your audience on Facebook, but there are two key conditions that you should keep in mind: First of all, this option will work only if your email list or segment has at least 100 people in it. Otherwise, the group’s too small to create an audience on Facebook. Second, you should understand that people don’t always use the same email address to access Facebook and sign up for products or services like the ones you’re offering. That’s why the size of your target audience on Facebook may be smaller than what’s stored in your email list. Usually, Facebook is able to match 60-70% of the contacts from your list. This is especially the case if you’re targeting people who have given you a work email address. The chances are that they’ve registered to Facebook using their private mailbox, which would affect the size of the audience for your ad. So how can you use your existing contacts to run an effective Facebook ad? Here are some quick ideas.

Three ideas for using this targeting option:

Lookalike audienceHow about targeting people who aren’t on your email list yet, but share the same characteristics as your email subscribers? Enter: lookalike audience. Imagine that you’ve identified your most loyal customers or the highest-spenders. Or some other segment that has a huge potential for your business. Lookalike audience lets you search for and target people who are similar to them. To do that, you need to select an email list or segment. If your selected group has at least 500 people, Facebook will use it to look for people who share similar traits. Additionally, you can narrow down the search to target only a specific subset of your audience by providing other characteristics – like location, gender, age, or interest. For example: In this case, all you have to do is select the list or segment that includes the entrepreneurs that should be used for comparison and add California, United States, as the additional characteristic. Although this may not always be relevant, you can also choose your email list to be included in your Facebook ad target group.

Here’s a scenario where this solution could be useful: You’re promoting a new online course on Advanced SEO tactics. A good bet might be to promote it to those who’ve previously registered for your SEO tactics 101 course and those who are similar to them. With lookalike audience, you can target both groups at the same time. As you can see, this is one powerful option that lets you expand your audience and reach very promising leads.

Here are some other ways you could use lookalike audience in your ad campaigns.

Three ideas for using this targeting option:

Custom audienceNow let’s pick a different situation. You don’t have an existing audience to base your search on, but you have a good idea of whom you want to reach. By providing characteristics such as the location, gender, age, and interests, you can reach your target audience with your Facebook ads. The question is: how far should you go with providing these characteristics? You’ll have to answer this one for yourself, but keep in mind that the smaller and more specific audience you choose, the more expensive it’ll be to be reach them. Plus, sometimes it’s better to be a bit more flexible and target a slightly larger audience. You can never be 100% sure that someone’s not willing to use your services.

Three ideas for using this targeting option:

People liking the PageHow about including people that like your Facebook Page into the equation? This option is similar to the lookalike audience but instead of providing an email list or segment, you use those who already like your page on Facebook. You can use this option to:

Here’s one example of when you could use this option: Let’s say you’re just starting to build an email list, but you’ve already got an engaged community of brand followers on Facebook. They like your posts, participate in discussions, and often ask about your future projects. With the People liking the Page option you can start building your email list by targeting them and others that share similar characteristics. It’s a quick and efficient way of reaching you target audience. And not just any audience, but those who have already shown interest in your offer.

Three ideas of how you could use this targeting option:

Step 4. Set the budgetAlmost there! Now it’s time to set your ad budget. In other words, how much in total you want to spend and for how long your campaign should run. The daily spend can be anywhere between $5 and $100. So, let’s say you want to run an ad for a week. In this case, your minimum total budget will be $35 (7 days x $5). The maximum, on the other hand, would be $700 (7 days x $100). You might be wondering: Why am I not able to also set an exact amount (other than the minimum or maximum amounts), that’ll be spent every day over a specific period of time? The reason for this is that we let Facebook adjust your budget to help you generate a higher ROI. In case they notice that your audience is very active, they’ll spend a higher portion of your budget to deliver the best possible results. The opposite will happen if they see a slowdown in your target audience’s engagement. Thanks to this, you’ll be able to spend your marketing budget more efficiently

Step 5. Add your contentFinally, it’s time to add content to your Facebook ads. The words and images your target audience will see when they browse Facebook or other apps in the case of Facebook Audience Network. Your ad will consist of the following elements. You can customize all of them so that they’ll meet your preferences:

This may look like a lot of elements, but the good news is that not all of them are obligatory. You may choose to skip the optional ones, but before you do that, think twice whether it’s the right thing to do. Below’s a blank Facebook ad image that highlights all of the above sections and fields you can provide when creating your ad.

If you’d like to see what your ads would look like when they’re published, you can check them out with this Facebook Preview Tool. Keep in mind that there are certain requirements when it comes to what your ad content’s going to look like. For example:

We’ll talk about this a bit more later in the last section on Facebook ad campaigns best practices.

Step 6. Submit the adNow that you’ve set you ad it’s time to hit the submit the ad button. Once that’s done, GetResponse sends the information to Facebook so they can have a look if everything’s been set correctly. Having said this, there might be some situations where Facebook will reject your ad and you’ll have to edit it before you can resubmit it. There are, in fact, about 100 reasons why an ad could get rejected. Here’s an official list provided by Facebook, in case you’re interested. Just to give you an overview of what these could be, I’ve summarized the ones that are quite common:

We’ll talk about the most important ones once again later, in the last section of this post.

Step 7. Managing your adsOnce you’ve submitted your ad, you can monitor its status in the Manage Ads section of your account. There, you’ll see the full details for all the ads you’ve created. This includes the thumbnail of one of the visuals you provided, the campaign name, the text introducing your ad, ad status, ad duration, budget, reach, and the number of clicks the ad generated.

In the Manage Ads section, you’ll also be able to edit, duplicate, delete, and of course – create new ads. When it comes to the ad status, there are few types of statuses you’re likely going to see. These are:

The most important piece of information is that you’ll only be charged if your ad gets approved by Facebook.

How to create effective Facebook ads: best practicesTo finish off this article, I’ve decided to provide you with a list of tips and best practices that’ll help you generate more bang for the buck with your Facebook ads. That of course requires that your ads get approved by Facebook first, hence some of the tips that you’re about to read are directly related to match their ad requirements.

Minimize the amount of text in your imagesFacebook found that ads that contain less than 20% text perform better. That’s why they want their advertisers to meet this criteria when submitting their ads through Facebook. To find out if your ad’s going to meet these requirements, you can use their Text Overlay tool that’ll evaluate your images. Note that there are some exemptions to these rules (e.g. if your ad shows a book cover or an album cover). That’s why it’s worth reading up more on these requirements directly on Facebook. There, you’ll also find some useful ad examples with different amounts of text and explanation on how that element could affect their reach. Make your ads personalWe see thousands of ads every day of the year. And we ignore most of them, too. If you want your ads to stand out, you need to make them personal. Rather than using stock photos, try using your own photos as often as you can. Show your products in action. Make them feel natural, not like they’ve just been rendered out. But that doesn’t mean they shouldn’t be high resolution! Match the colors and fonts in your ads with the ones that’ll be used on your landing page. Maintain the scent. Thanks to this, your audience will feel that they’re in the right place and the ad hasn’t mistakenly directed them to some random site. Not sure what’s going to work well for you? You can start by gaining inspiration by exploring the Facebook Ad Library and searching for other companies in your niche. Keep it simpleLike in all areas of marketing, in Facebook advertising, simplicity pays off, too. Effective ad campaigns are not only personal, but also tend to be simple. The reason for this is also simple, we only have a couple of seconds (if not less) to capture someone’s attention and explain what it is that we can do for them. So think twice before you submit a complex image or text that’s hard to comprehend. Although some studies in the past have shown that people focus and understand more when the things they’re reading are hard to read, it might not be the most optimal experience for Facebook. After all, many of your users will be accessing this social network to relax and socialize, not to strain their brain wires. Understand that Facebook advertising is a bit differentIf you’re new to Facebook advertising then you might not know this, but advertising on social media is a bit different from anything else. Unlike on Google or Bing, people are spending time on Facebook to socialize and entertain themselves. Sure, they do also learn about the latest news and events from it, but they’re not usually actively looking for that type of information. Having said this, your Facebook ads should be a bit different from what you’d usually use in Google or Bing. Your ads have to be eye-catching, interesting, and engaging. But, they can’t be distracting. Think about this when designing your ads and you’ll see that their performance will be positive, too. Match the ads with your funnel stages As you may have read in our guide to marketing funnels, a typical audience goes through several funnel stages before they actually convert. Typically, marketers refer to the top (awareness), middle (consideration), and bottom (conversion) of the funnel. Each part of the funnel aims to achieve a different goal and you need to keep that in mind when you’re designing your Facebook ads. If you’re running ads that are meant to fuel your marketing funnel at the top, i.e., drive traffic to your landing page, then your ad content should focus on generating awareness. Naturally, if you’d be interested in retargeting those who’ve gone through your funnel, but haven’t converted yet, your ads should focus on the conversion. To learn more about this, check out this article which provides further explanation on how to write ads for different business objectives.

Test different approachesThere’s not one single best way to reach your audience. That’s why rather than betting big that your ad is going to convert like crazy, prepare several versions (including images, copy, and targeting option) to find the approach that works best for you. Only when you know the potential outcomes, you should increase your budget.

Ready to take action?Although this article turned out to be a bit lengthy, you’ll see that creating Facebook ads is not more complicated than sending out a newsletter to your email subscribers. And if you want your marketing funnels to continually generate sales revenue, you should reach out to new audiences. As you saw, there are at least several ways you can do this using the Facebook ads integration with GetResponse.

So, are you ready to give them a spin? Go ahead and create your first Facebook ad campaign through GetResponse. And if you have any questions, just let us know in the comments below

The post How to Design Facebook Ads in GetResponse appeared first on GetResponse Blog - Online Marketing Tips. Printing via GetResponse Blog – Online Marketing Tips http://bit.ly/2VUstfC May 31, 2019 at 06:35AM Generative Design Methods Combine 3D Printing & Organic Evolution http://bit.ly/2wvhGKE “Go take your lessons from nature, that’s where our future lies.” – Leonardo da Vinci

Jawad compares the natural world, where organisms grow in a pure manner, to that of the human environment where we create so much from artificial materials which are then put together in factories. Undeniably, manufacturing and mass production, along with the assembly press, have feathers in our caps for decades. Mass production promotes sameness among objects, along with subtractive technology as parts are made from cutting or chipping away at materials until a product is shaped. While this may have been a novel idea at first, today, our environment is saturated with chemicals and pollution, affecting both nature and man. Jawad proposes that while the natural and man-made worlds may be extreme opposites, they should still be viewed as ‘a paradox of unity and duality,’ with an emphasis on how they complement one another. The author also sees 3D printing as a catalyst for bringing together nature and design mechanisms, ‘fusing’ them to the advantage of both the natural world and humanity. The author is a fan of Neri Oxman, quoting her regarding the industrial revolution:

Like nature, design is always evolving—via human creativity, inspiration, and ambition. In generative design, Jawad explains that nature is imitated with a variety of different digital parameters. Many users may be familiar with software like Python or Grasshopper, which can be adjusted to the complexity level of organic forms, along with connecting in real time to create structures related to natural stimuli like the sun or moisture in the air.

Jawad highlights several art studios, ending with a glimpse into his own work:

As for his own work, Jawad states:

Works like ‘Desert Rose’ are made of beautiful crystals from Qatar, along with numerous other stunning pieces where Jawad employs his generative methodology in combining 3D printing and natural crystals to make items that are useful.

3D printing offers potential in a variety of different industry dynamics, with some users on the side of being able to mass manufacture more affordably and efficiently, while others are encouraged by the idea of being able to produce on-demand parts and customized products—bringing an end to large warehouses and stress on the environment overall. Find out more about growing generatively designed products here. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com. [Source / Images: ‘ Manufactured by Nature: Growing Generatively Designed Products’] Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com May 31, 2019 at 04:18AM China: Case for the Mass Customization of 3D Printed Martial Arts Shoes http://bit.ly/2WlBM9G In ‘Exploration and Analysis Based on Mass Customization Design and Production of Martial Arts Shoes,’ Wuhan University of Science and Technology researchers Peng Hong and Xia Xinqiao explore the dynamics not of mass production, but mass customization—putting the 3D printing spin on manufacturing, and a very interesting one at that as they go further to explain that while mass is usually associated with large amounts of items being made that all look exactly the same, and customization refers to unique and small productions (sometimes just one item), putting the two together could offer a novel ‘combination of two contradictory phenomena.’

In the US, 25 percent of customers shopping online seek customized shoes. The authors realize the potential for continued customization via 3D printing, and for this study, they explored martial arts shoes as an example, beginning with a look at Puma’s efforts. Puma has long been a proponent of allowing consumers to enjoy customizations, beginning with different colors and different shoelaces, but obviously that’s not too game changing. They went on in 2010 to create ‘Creative Factory,’ allowing customers to customize shoes at the storefront, choosing materials.

Along came Adidas though, with a huge emphasis on customization and the integration of 3D printing into their shoes—from 3D printed athletic shoes produced at scale and lace locks, to 4D shoes launched last year. In terms of the best product and usability, the research team recognizes that martial arts shoes must protect the ankles and skin of the wearer, while also being lightweight and flexible to accommodate the wide range of movement required in what can be a very high-performance sport. The authors discuss the challenges of mass customization as follows:

In overcoming current obstacles to manufacturing customized martial arts shoes, the researchers suggest use of a small foot scanner (by China’s Foot Technology Company) that could be installed in stores to measure feet and then upload data to a cloud database. The customized shoes would then be made in a factory.

Using Adidas’ model for Future Craft 4D sneakers, they realize the potential for better speed, affordability, and quality in product, pointing out that it only takes 20 minutes to make a pair of Future Craft shoes. And with the accompaniment of robotics, turnaround could be exponentially faster—and even more accurate.

What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com. [Source / Images: ‘ Exploration and Analysis Based on Mass Customization Design and Production of Martial Arts Shoes’] Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com May 31, 2019 at 03:18AM Shandong University Researchers Working on Optimal Parameters for 3D Printing PEEK http://bit.ly/2ENyG3o In their recently published paper, ’Experimental study on parameters of 3D printing process for PEEK materials,’ researchers from Shandong University of Technology conduct experiments regarding the use of PEEK 3D printing materials for creating artificial bone. While there have historically been many challenges in bone regeneration techniques, authors H. Liu, X. Cheng, X. H. Yang, G. M. Zheng, and Q. J. Guo realize the need for high performance, strong materials produced with efficiency and as little waste and impact on the environment as possible. During the course of their research, the authors realized that the optimum parameters for printing with PEEK materials in 3D printing are as follows:

While there are numerous ways to make bone, clearly refinements can be made in the process—with the use of special engineering plastic Polyetheretherketone (PEEK) showing the most promise overall due to its outstanding strength, stability, and best of all—biocompatibility.

In this study, the authors 3D printed a variety of different cubes for experimentation, each with a length of 34 mm, a width of 12 mm, and a height of 3 mm.

The researchers completed 17 runs, as outlined in Table 2: For the verification experiment, the researchers used the aforementioned best parameters, resulting in success when compared with the control model. The authors stated that in comparison influence of each output response in comparison to the factors in their research was critical as interactions between said factors was so influential regarding the outcome.

3D printing and bioprinting for the regeneration of bone have become a serious focus for researchers around the world, eager not only to make scientific strides, but also to help eliminate pain and suffering for patients with conditions related to bone loss. From continued success using titanium to the use of nanofibers, to magnesium alloys, researchers continue to make impressive progress in the field of medicine. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com. [Source / Images: ’ Experimental study on parameters of 3D printing process for PEEK materials’] Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://3dprint.com May 31, 2019 at 02:06AM Forever stamps commemorating the first moon landing on sale July 19 http://bit.ly/2KdxvgX The U.S. Postal Service is celebrating the 50th anniversary of Apollo 11 and man’s first steps on the Moon with two Forever stamps. Printing via USPS News http://bit.ly/2hH9aDC May 30, 2019 at 02:05PM |

Categories

All

Archives

April 2023

|

Lisa later went on to study for an MSc in Interactive multimedia, graduating in 2001 from Westminster University. However, the smell of ink was still too strong and she continued to print; starting with a table top Adana 6×4, before progressing on to an Arab Crown Folio.

Lisa later went on to study for an MSc in Interactive multimedia, graduating in 2001 from Westminster University. However, the smell of ink was still too strong and she continued to print; starting with a table top Adana 6×4, before progressing on to an Arab Crown Folio. “Growing Letterpress Design hasn’t always been plain sailing with some dead ends along the way. Were we to become purely a wedding stationery press, where we started, or was there more to be had and more to learn from this wonderful craft? There was a lot more to be had.”

“Growing Letterpress Design hasn’t always been plain sailing with some dead ends along the way. Were we to become purely a wedding stationery press, where we started, or was there more to be had and more to learn from this wonderful craft? There was a lot more to be had.”

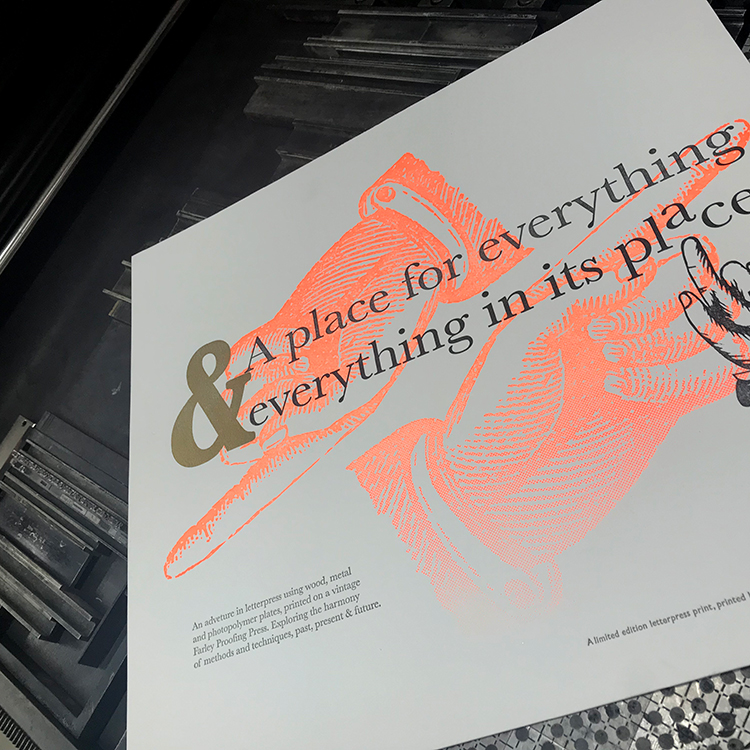

Struggling to fit many of the presses, type and plate-making equipment in the pressroom, the duo decided to move to the very beautiful Isle of Wight. They currently boast three Heidelberg platens with the capability to print up to A3 letterpress and A4 foil. They also like keep things old school with a selection of Adanas, Jardine, the impressive Chandler & Price and Farley SP25CWl with a huge 22x32in print area. Being able to produce something tactile and beautiful with letterpress using methods from the past, present and future is their aim.

Struggling to fit many of the presses, type and plate-making equipment in the pressroom, the duo decided to move to the very beautiful Isle of Wight. They currently boast three Heidelberg platens with the capability to print up to A3 letterpress and A4 foil. They also like keep things old school with a selection of Adanas, Jardine, the impressive Chandler & Price and Farley SP25CWl with a huge 22x32in print area. Being able to produce something tactile and beautiful with letterpress using methods from the past, present and future is their aim.

They are about to embark on a new range of workshops, for the beginner to the more advanced printer from their base on the Isle of Wight. These workshops will provide participants with the opportunity to learn a wonderful age old craft within a stunning scenic landscape.

They are about to embark on a new range of workshops, for the beginner to the more advanced printer from their base on the Isle of Wight. These workshops will provide participants with the opportunity to learn a wonderful age old craft within a stunning scenic landscape.

RSS Feed

RSS Feed