|

https://ift.tt/xTtgYXZ

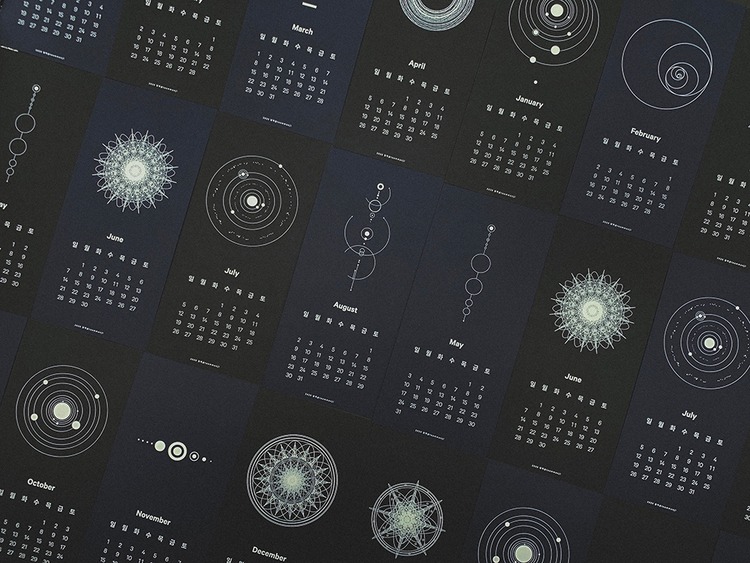

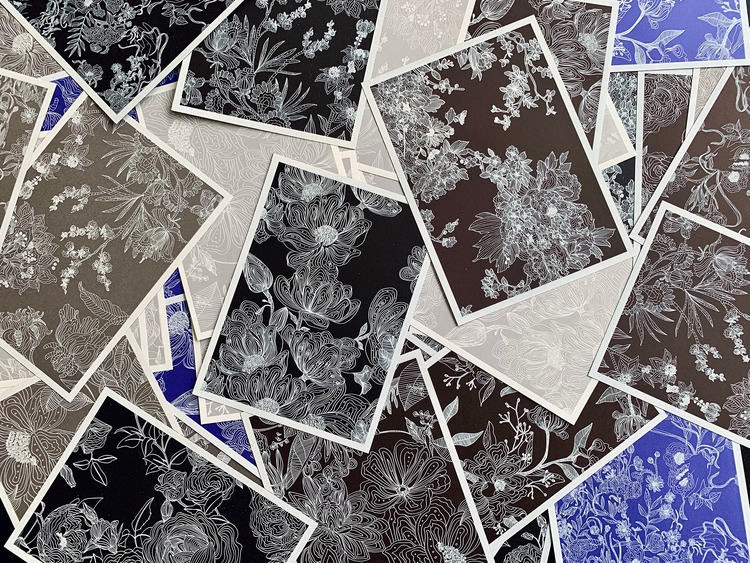

teammanji https://ift.tt/dO9Qw3b Teammanji, aka Michelle, is a visual designer and print enthusiast based in Hong Kong. During the day, Michelle works as UXUI designer tackling hands-on projects that involve product management and brand communications. At night, she works on line art, printed matters, or research on creative papers.

Printing via People of Print https://ift.tt/tvWLblE May 24, 2023 at 11:44AM

0 Comments

Postal Service Honors Capital One and CenterWell Pharmacy at National Postal Forum https://ift.tt/qZOyNcD CHARLOTTE, NC — USPS today recognized Capital One and CenterWell Pharmacy with the 2023 Partnership for Growth award on the final day of the National Postal Forum (NPF), the country’s premier mailing and shipping conference. The Partnership for Growth award is bestowed annually at NPF to recognize companies that have made significant contributions to the mailing and shipping industry with forward-thinking and innovative practices. Printing via USPS News https://ift.tt/IOlHfF0 May 24, 2023 at 11:13AM

https://ift.tt/kpSfx1l

Virgin Orbit Auctions Assets to Space 3D Printing Ventures https://ift.tt/OjRtHE9 If there were any indications that Virgin Orbit could be kept operating as a single entity after going bankrupt, they have been crushed. Following a comprehensive sale process and competitive auction, the company announced that it has decided to sell its assets to four winning bidders, including Rocket Lab (Nasdaq: RKLB), Vast, and Stratolaunch, and will cease operations. The final sale hearing is scheduled for today, with the transactions expected to close shortly thereafter. The following company statement highlights the impact that the firm’s rockets had on the new space race and the team that worked to drive its mission:

TurmoilOn April 4, 2023, Virgin Orbit filed for Chapter 11 bankruptcy and is currently undergoing a sale. This shocking announcement followed the company’s previous statement about reducing its workforce due to an inability to raise sufficient out-of-court capital to continue operating its business at the current run rate. Adding to its list of woes, the bankruptcy comes on the heels of the mission failure of LauncherOne, Virgin Orbit’s rocket designed to fly small satellites into orbit. Upon announcing the filing for Chapter 11 bankruptcy, CEO Dan Hart emphasized the team’s achievement in developing and implementing a groundbreaking approach to satellite launches. LauncherOne was designed for air launch from a modified Boeing 747 jet known as Cosmic Girl and introduced numerous advantages compared to conventional rocket launches. These advantages include fuel savings, flexibility in site selection, and the ability to bypass weather-related delays.

A NewtonThree thrust chamber is built in Virgin Orbit’s hybrid additive, subtractive manufacturing machine. Image courtesy of Virgin Orbit/Greg Robinson. A NewtonThree thrust chamber is built in Virgin Orbit’s hybrid additive, subtractive manufacturing machine. Image courtesy of Virgin Orbit/Greg Robinson.

Unfortunate turnTo maximize the value of its assets during the bankruptcy process, Virgin Orbit secured $31.6 million in new money debtor-in-possession financing from Virgin Investments Limited. This financing was obtained to support the ongoing sale process. Recent court filings reveal that Rocket Lab has acquired Virgin Orbit’s primary production facility in Long Beach, California, for $16.1 million. The acquisition includes various assets, such as 3D printers and a specialty tank welding machine. Virgin Orbit had equipped its Long Beach facility with advanced manufacturing capabilities, including a laser metal deposition Lasertec 4300 3D printer by DMG Mori. This state-of-the-art printer utilizes fused metal powder to add and subtract material, enabling the production of rocket parts, including components for the LauncherOne system. Rocket Lab intends to leverage these resources to expedite the manufacturing of rocket parts, including rocket engine components.

Rocket Lab plans to leverage Virgin Orbit’s Long Beach facilities and crucial manufacturing infrastructure to expedite the production of its Neutron rocket. The successful bid encompasses the lease for Virgin Orbit’s expansive 144,000-square-foot headquarters and manufacturing complex located at 4022 E. Conant St. in Long Beach, along with all associated production assets, machinery, and equipment. The combination of these assets with Rocket Lab’s existing production, manufacturing, and testing capabilities is expected to enhance the Neutron rocket’s production significantly. It’s important to note that Rocket Lab clarified that it would not integrate Virgin Orbit’s launch system into its existing launch services, indicating a separation between the two companies offerings.

Stratolaunch submitted a $17 million “stalking horse” bid for the Boeing 747 and related equipment. This comes as no surprise since the business has already developed a massive aircraft, the Stratolaunch Carrier, which has the largest wingspan of any aircraft ever built and aims to air-launch space transportation. In another bid, rocket engine and spacecraft startup Launcher, which was acquired by developer Vast last February, bought the lease on a testing site in California’s Mojave Desert with machinery, equipment, and inventory there for $2.7 million.  Stratolaunch’s mobile launch platform to deploy high-speed vehicles into the hypersonic environment. Image courtesy of Stratolaunch via Twitter. Stratolaunch’s mobile launch platform to deploy high-speed vehicles into the hypersonic environment. Image courtesy of Stratolaunch via Twitter.

According to filings with the federal bankruptcy court, Virgin Orbit claims the combined total proceeds were determined by a rigorous and competitive auction that maximizes the estate’s value and minimizes the remaining duration of the company’s restructuring. Virgin Orbit, primarily owned by Richard Branson’s Virgin Group, has traded on the Nasdaq exchange under the ticker symbol VORBQ since 2021. However, due to the Chapter 11 process, Nasdaq announced it was launching delisting proceedings, insisting that the company was “not compliant” with listing rules since it still hadn’t filed its annual results for 2022. As a result, Nasdaq informed the company that its stock would be suspended on April 13, 2023, and even though Virgin Orbit said it intended to appeal Nasdaq’s decision to delist, it will not impact the upcoming suspension. As a result of the delisting, Virgin Orbit’s shares fell 22% in premarket trading at 13 cents and continued plunging days after. The post Virgin Orbit Auctions Assets to Space 3D Printing Ventures appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/p0iUc9q May 24, 2023 at 09:00AM 3D Printing News Unpeeled: Marine Gearboxes 3D Printed Motors and $1.7 Million in Seed Funding5/24/2023

http://img.youtube.com/vi/mCb8SyxQK48/0.jpg

3D Printing News Unpeeled: Marine Gearboxes, 3D Printed Motors and $1.7 Million in Seed Funding https://ift.tt/8KIophM UK based Equipmake, just released their Ampere-220 e-axle system. The system which is meant for high performance electric cars was similar to one released on the Ariel HIPERCAR. It has peak power of 220kW, a maximum motor speed of 30,000rpm and weighs just shy of 20kg with a power density of 11kW per kg. 3D Printing has been used to consolidate parts, reduce weight and get better thermal management. Voxel has raised $1.7 million in seed funding from CincyTech to start its Cincinnati software solution for meta material & gradient component design optimization and iteration. This is a great idea but will they be able to find enough customers to fund further expansion? TheXXL3DDruck project run by the Laser Zentrum Hannover has looked at Wire Arc Additive Manufacturing (WAAM) The post 3D Printing News Unpeeled: Marine Gearboxes, 3D Printed Motors and $1.7 Million in Seed Funding appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/p0iUc9q May 24, 2023 at 09:00AM

https://ift.tt/nIoDB4u

Zeda Opens 3D Printing Facility in Cincinnati to Serve Regulated Industries https://ift.tt/4tNgQp3 Today, California-based Zeda, Inc. announced that it has officially opened the doors to its new 75,000-square-foot advanced manufacturing facility in Cincinnati, Ohio. The company, which rebranded to Zeda from PrinterPrezz and Vertex Manufacturing in March, specializes in nanotechnology and advanced 3D manufacturing solutions for the aerospace and defense, medical, and space. This new digital foundry will offer nano-coating, 3D printing, machining, and other manufacturing technologies to its customers in these highly regulated industries. AM leader Greg Morris, the CTO of Zeda, will lead the new facility, and is building a quality team that can support the company’s expansion. The new space has grown significantly from the company’s existing 16,000-square-foot space, and offers plenty of room for future growth and additional capabilities to meet increased demand for Zeda’s advanced manufacturing services. I toured the facility when it was still under construction, and at the time, Morris told me that when PrinterPrezz acquired his Vertex Manufacturing company back in 2021, the purpose was “to continue to do what we do with aerospace and the DoD, and energy, and other industries, but also a significant medical focus and making the actual cervical spinal implants and instrumentation.”  Greg Morris, CTO of Zeda and Rush LaSelle, CEO of AddUp welcome the placement of the first FormUp350 system at Zeda’s new 75,000-square-foot advanced manufacturing facility in Cincinnati, OH. Greg Morris, CTO of Zeda and Rush LaSelle, CEO of AddUp welcome the placement of the first FormUp350 system at Zeda’s new 75,000-square-foot advanced manufacturing facility in Cincinnati, OH.

Right after the rebranding was revealed, Zeda announced that it had closed a $52 million Series B funding round, which brought its total capital raised to $68 million. The company invested $20 million of that into the facility, and all of the high-tech, capital equipment needed for both large- and small-format metal 3D printing, along with secondary manufacturing processes like CNC machining. Due to its focus on regulated industries, the new facility will be AS9100 & ISO 13485 certified, and features advanced manufacturing technology, automation, and data collection capabilities.  Steve Rengers, Senior Vice President of Zeda Steve Rengers, Senior Vice President of Zeda

With all of this technology, the Cincinnati facility will support lights-out manufacturing, in addition to, as Zeda put it, “the vertical integration of medical cleaning, passivation, and pack automation.” In addition, the new digital foundry, which Zeda CEO Shri Shetty told me in March took more time to design than build because “a facility like this does not exist,” will also be able to support advanced manufacturing technologies, prototyping, and process development.

In March, Morris told me that Zeda expected to get occupancy of the building in the next few months, with plans to start moving equipment in June. So the company is right on schedule. The post Zeda Opens 3D Printing Facility in Cincinnati to Serve Regulated Industries appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/p0iUc9q May 24, 2023 at 09:00AM

https://ift.tt/wfImUhJ

Dental 3D Market Grew to $4B in 2022 https://ift.tt/1GQhp6K SmarTech Analysis, a leading 3D printing market research firm and the sibling firm of 3DPrint.com, has released the latest iteration of one of its flagship reports, 3D Printing in Dentistry 2023: Market Study & Forecast. The SmarTech dental report is, according to the company, “the longest running dedicated research study for professionals in the dental industry” focused on AM. The firm is therfore uniquely positioned to analyze the market from a long-term perspective. This seventh edition of SmarTech’s report on the dental market for additive manufacturing (AM) includes data on some of the industry’s most closely watched companies, including mainstays Stratasys and 3D Systems, younger veterans such as Formlabs, and startups like Desktop Metal’s Desktop Health brand. Notably, the latest report found that in 2022, the revenue for dental 3D printing grew to $4 billion, representing nearly one-third of the overall 3D printing industry. By 2031, the market research firm expects it to reach $9.7 billion. Beyond just the hard numbers, the report’s analysis provides invaluable insight into the turning point the market currently finds itself at. In that vein, the fact that the report sheds light specifically on dental 3D printing in the post-COVID landscape means that readers might find this edition particularly useful. It is plausible to think that by 2030, the dental industry as a whole will look far more like the 3D printing market for dentistry in 2021-22, than it does like any pre-2020 version of dentistry.

The second point is true not only for the academics and technicians, but also, for those who are purely on the business side of things, especially business development managers and investment strategists. That is because dental is such a uniquely mature market for the 3D printing industry in terms of the present degree of commercialization of dental end-products. Just take LuxCreo’s directly 3D printed aligners and Stratasys’s directly 3D printed, full-color dentures for instance. Thus, perhaps more so than the data for any other 3D printing market, data on dental 3D printing is likely to have implications for mass produced commercial end products in all the other verticals. This is simply due to the fact that virtually anything in the dental market has a more established history of mass commercialization than all other applications, aside from hearing aids. And the hearing aid is one product, whereas dentistry is an entire industry. For anyone interested, then, in what the broad commercial mass prodcution of all forms of 3D printed products might look like by 2030, dental is still pretty much the only game in town. Images courtesy of SmarTech Analysis The post Dental 3D Market Grew to $4B in 2022 appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/p0iUc9q May 24, 2023 at 09:00AM 2023 Snapshot: Unraveling the Market Cap Rankings of 3D Printing Companies https://ift.tt/fFnaclg In the dynamic landscape of 3D printing, several companies stand out as industry leaders, reflecting their market capitalization and brand reputation. Our latest research findings into these firms’ financials offer insights into their historical and current market positions and growth potential. Despite facing numerous challenges, some companies have demonstrated resilience and strategic insight, navigating complex market conditions to maintain their positions within the industry. Our data provide valuable insights into each business’s market position and prominence, encompassing not only the top contenders but also those who have weathered bankruptcy or acquisition. The post 2023 Snapshot: Unraveling the Market Cap Rankings of 3D Printing Companies appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 24, 2023 at 07:16AM COBOD to 3D Print School in Ukraine https://ift.tt/EM2oS6K Construction 3D printing firm COBOD has announced its involvement in a project to 3D print a school in Lviv Ukraine. The single-story school will have a surface area of 370 m2. Aided by Team4UA and COBOD’s BOD2 printer, the project will be completed adjacent to school number 23 and serve refugees escaping Russian violence. 99% of the 3D printing material is locally sourced, while 90% of all the construction materials are to be local, as well. 2000 Ukrainian schools have been damaged and 277 have been destroyed by Russia, so far. Therefore, COBOD will have a lot of 3D printing to do yet if this project is successful. In the face of military conflict, the Danish firm is pressing ahead in a bid to make 3D printing a technology used in the rebuilding of Ukraine.

A lot of 3D printing companies made really brave press releases, but may not have done much to support Ukraine. In a truly inspiring move, COBOD has shipped its people and equipment to the nation to really make a difference. For an industry that makes so much and can make so much more, additive manufacturing (AM) are remarkably absent in Ukraine. The industry could do so much more to help amputees and repair energy infrastructure, as well as hospitals and schools. By shipping 3D printers and expertise to the country, the sector could really help the country survive and thrive amid the conflict. If this project does not appeal to your ethics or heart, then do please think of your bottom line. Ukraine will be rebuilt and many tools will be used for this process. Ukraine will need to once again find its footing and purpose after a harrowing experience that will have left deep scars. It could yet see many resources be diverted by graft, try to rebuild what it had, or use this opportunity and tragedy to rebuild a new state and society on a more unified, optimistic and technologically advanced footing. A much-chastised meddling stated on its doorstep, Ukraine knows that it will need to be watchful and prepared for future interference and perhaps more war from Russia. In 202, Zelensky already stated that he wanted Ukraine to become a ¨big Israel.¨ If those statements are more than sentiment, Ukraine will become a technocratic, technology-led nation with a lot of military production and prowess. Israel’s foresight in developing indigenous technologies, such as drones and other weapons, along with a startup mentality and deep research and development has let it thrive. If Ukraine takes a similar course, then 3D printing will play a big part in rebuilding the state. Independence, short supply chains, quick innovation, iteration, unique shapes, and cutting-edge performance will all lead the country to invest in additive. Therefore, COBOD is not only showcasing excellent heart, ethics, and bravery but also foresight. The post COBOD to 3D Print School in Ukraine appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 24, 2023 at 07:16AM

http://img.youtube.com/vi/qR74pnOQF5w/0.jpg

3D Printing Unpeeled: Thing Memberships, Formwork and Deutsche Bahn https://ift.tt/cIUgzJY Both Thangs and Prusa Research owned Printables announced memberships for exclusive models to support their platforms and creators. This could greatly encourage new open source creations, or it could reduce the diversity and uniqueness of 3D Printed free designs. Barberio Colella Architetti, Angelo Figliola, and Zheng Hui Chen worked on the Flowin´ footbridge meant to cross the Fuxi river in China. The bridge is to have 3D printed reusable formwork. With many small bridges slated for replacement this is a workflow that I really believe in. Deutsche Bahn has been pioneering 3D printing for maintenance and repair for years now. The company now has announced that it has over a 1000 models in its digital warehouse and has made over 100,000 spare parts.

The post 3D Printing Unpeeled: Thing Memberships, Formwork and Deutsche Bahn appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 23, 2023 at 08:40AM

https://ift.tt/XbUvDhE

Finite Space & nano3Dprint Forge New Frontier in Space Manufacturing https://ift.tt/wQ3nftx California-based electronics printing company nano3Dprint announced a partnership with Finite Space, an ambitious German startup with a vision to utilize on-site resources for the production of vehicles, construction machinery, and everyday equipment required by Moon and Mars crews. This collaborative venture aims to push the boundaries of extraterrestrial sustainability to new heights. By leveraging nano3Dprint’s cutting-edge technology and expertise in electronics printing, in collaboration with Finite Space’s goal of establishing a self-sufficient lunar economy, the partnership aims to revolutionize practices in outer space. In the initial phase of the project, nano3Dprint’s multi-material A2200 electronics printer will be utilized along with locally sourced materials from the moon, including metals, silicon, and recycled plastics. These resources will be employed to manufacture a three-foot-long lunar rover for exploration purposes. Moreover, the duo has plans to progressively produce additional rover components and tools throughout the project.  Rendering of 3D printed lunar rover for moon-based exploration. Images courtesy of Finite Space. Rendering of 3D printed lunar rover for moon-based exploration. Images courtesy of Finite Space.

Tobias Patzer, Finite Space’s Design Lead, mentioned that the decision to collaborate with nano3Dprint was influenced by NASA‘s research highlighting the advancements achieved with their printers. The flexibility of material choice and quality provided by the A2200 is a key capability that caught their attention. For instance, the demo design includes a cargo bay and tool slot that can be integrated with a plow, drill, or robotic manipulator. Patzer claims that additional capabilities will be added as the project evolves. By using conductive inks with a fused deposition modeling (FDM) extruder, the A2200 can 3D print electronic objects as a continuous part, reducing the need for assembly. This technology enables the fabrication of complex parts and tools using multiple materials (such as PCB circuits, interconnects, and wiring harnesses) with the added benefit of printing electronics and circuitry directly into the components. Such capabilities mark a significant breakthrough for space exploration and colonization, as it facilitates the on-site production of essential tools and parts, ultimately contributing to the development of a self-sustainable lunar economy.  A2200 3D printer. Image courtesy of nano3Dprint. A2200 3D printer. Image courtesy of nano3Dprint.

Compact in size and similar to a microwave oven, the A2200 can be transported to space and rapidly produce tools and parts on demand. By deploying a space-based printer, both the frequency of resupply missions and the quantity of supplies astronauts need to carry can be significantly reduced. Ramsey Stevens, CEO of nano3Dprint, expressed enthusiasm, emphasizing the importance of space for daily life and the various applications it supports, such as GPS, weather forecasting, and satellite imagery. He anticipates that Finite Space’s utilization of the new rover will further advance space exploration. Finite Space’s in-space manufactured (ISM) modular rover will play a crucial role in supporting extraterrestrial bases. By utilizing in-situ resource utilization (ISRU) and on-site additive manufacturing, the startup aims to minimize the costly delivery of spare parts. Having 3D printing systems in space allows for the production and installation of spare parts on-site, eliminating the need for redundancy and enabling Finite Space to equip its rovers with heavier loads.  Rendering of 3D printed lunar rovers for moon-based exploration. Images courtesy of Finite Space. Rendering of 3D printed lunar rovers for moon-based exploration. Images courtesy of Finite Space.

This strategic alliance between nano3Dprint and Finite Space holds tremendous promise, paving the way for innovative solutions that enhance the efficiency, durability, and environmental friendliness of technologies deployed beyond Earth’s atmosphere. Although the project is still quite ambitious, especially since there is no specific timeline on when additive manufacturing will be deployed to the moon, they aspire to make significant contributions to the future of space exploration and the establishment of sustainable practices in the cosmos. The post Finite Space & nano3Dprint Forge New Frontier in Space Manufacturing appeared first on 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing. Printing via 3DPrint.com | The Voice of 3D Printing / Additive Manufacturing https://ift.tt/jgTHpcx May 23, 2023 at 08:40AM |

Categories

All

Archives

April 2023

|

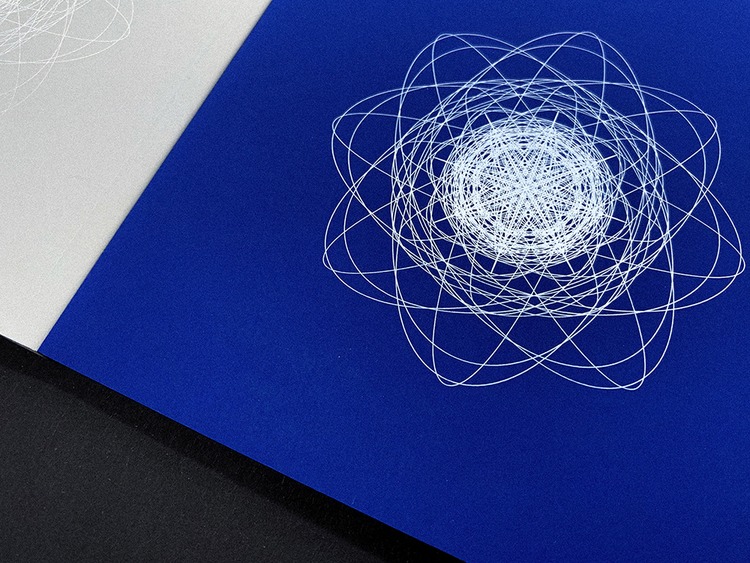

As a visual designer, Michelle creates stunning visuals to attract consumers’ eyes. She parcticularly enjoys the execution stage where she can play with a variety of materials, finishing, and printing methods. “Believing that in the modern digital world, the best thing about the job is it has given me the resources to work things in the classic way – creating tangible designs that speak to people’s soul,” says the designer.

As a visual designer, Michelle creates stunning visuals to attract consumers’ eyes. She parcticularly enjoys the execution stage where she can play with a variety of materials, finishing, and printing methods. “Believing that in the modern digital world, the best thing about the job is it has given me the resources to work things in the classic way – creating tangible designs that speak to people’s soul,” says the designer.

In her day job, Michelle implements a clear set of steps to execute her creative process, however this comes the opposite way around when she is working on prints and illustrations. She will first start with doodling all kinds of thing that inspires her; boutiques she visits, street side flowers she saw, or a florist that gives her ideas for a little floral bouquet.

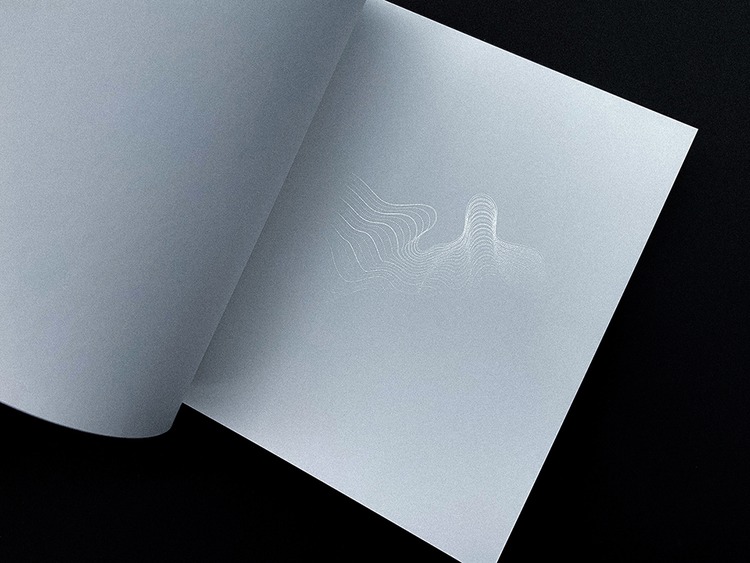

In her day job, Michelle implements a clear set of steps to execute her creative process, however this comes the opposite way around when she is working on prints and illustrations. She will first start with doodling all kinds of thing that inspires her; boutiques she visits, street side flowers she saw, or a florist that gives her ideas for a little floral bouquet. Besides line drawing and patterns, she is highly passionate about flower illustration and printing production. Michelle loves to explore different print execution with various type of creative paper; “this helps me to find the solution that can depict the design in the best form, and also maximise the beauty of line art”.

Besides line drawing and patterns, she is highly passionate about flower illustration and printing production. Michelle loves to explore different print execution with various type of creative paper; “this helps me to find the solution that can depict the design in the best form, and also maximise the beauty of line art”.

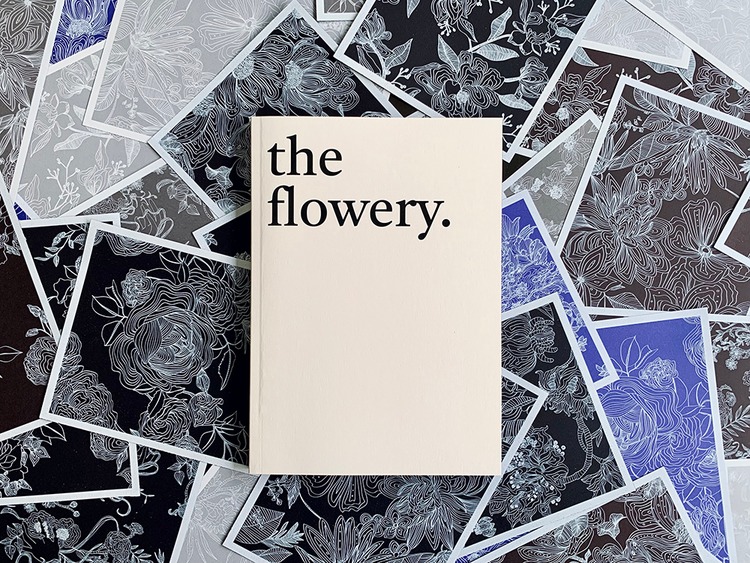

Her recent project, The Flowery, showcased a range of botanical illustrations with the combination of Anatalis Pop’Set, and specialty dry inks from Iridesse production press, which also aimed to demonstrate the fine line detailing of the graphics.

Her recent project, The Flowery, showcased a range of botanical illustrations with the combination of Anatalis Pop’Set, and specialty dry inks from Iridesse production press, which also aimed to demonstrate the fine line detailing of the graphics.

RSS Feed

RSS Feed